Documentos de Académico

Documentos de Profesional

Documentos de Cultura

A Generalized Equation For Diffusion in Liquids

Cargado por

JosemarPereiradaSilvaDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

A Generalized Equation For Diffusion in Liquids

Cargado por

JosemarPereiradaSilvaCopyright:

Formatos disponibles

A Generalized Equation for Diffusion in Liquids

RAMALINGAM SITARAMAN, S. H. IBRAHIM, and N. R. KULOOR

Department of Chemical Engineering, Indian Institute of Science, Bangalore 12, India

The association parameter in the diffusion equation due to Wilke and Chang has

been interpreted in determinable properties, thus permitting easily the calculation

of the same for unknown systems. The proposed equation also holds good for water

as solute in organic solvents. The over-all percentage error remains the same as

that of the original equation.

THE IMPORTANCE of diffusion coefficients in mass

transfer operations have been well recognized. However,

The highly associated molecules may have high viscosities

and hence the size and structure of the molecules are

an exact theoretical equation for the evaluation of diffusion different. Instead of arriving a t this parameter in an arbi-

coefficients is still not available since the kinetic theory trary manner we feel it would be better to reach the goal

of liquids is incompletely developed. The theories of through some readily determinable physical property which

Einstein (1) Eyring ( 7 ) , and Hirschfelder, Curtiss, and has direct relation to association and the consequent in-

Bird (8) are definitely helpful in understanding the ternal pressure.

mechanism of diffusion, but by their use it is not possible

to predict diffusivity with confidence. Hence, empirical

PROPOSED CORRELATION

correlations are relied on for the prediction of diffusivity

in cases where experimental data are not available. As the heat required to vaporize a substance consists of

A wide variety of correlations are available for this energy absorbed in overcoming the intermolecular forces of

purpose. For the diffusion in dilute solutions, the cor- attraction in the liquid and work performed by the vapors

relations of Othmer and Thakar ( 1 3 ) , Arnold ( 2 ) , Scheibel in expanding against the external pressure, we believe the

( 1 5 ) ,Wilke and Chang (16), and Ibrahim and Kuloor (9) latent heat of vaporization of the solute and the solvent

seem to be useful. Every correlation has its own drawbacks. should be an effective property to assess association. T o

As first pointed out by Olander (12), the one drawback check this assumption, we have taken the correlation of

of all the correlations is the inapplicability of these equa- Wilke and Chang and eliminated X and introduced the

tions when water is a solute in different organic solvents. latent heat factor. T o arrive a t the best equation, we must

Whereas all the correlations hold good for the diffusion of modify the exponent V , of Wilke and Chang from 0.6 to

organic solutes into water they do not hold good when 0.5. The final equation thus obtained is

water diffuses into organic solvents. Olander (12) postulates

that this may be due to the polymerization of water mole-

cules. Apart from this, all correlations deviate in cases

where association of either solute or solvent molecules takes

place, when the internal pressure becomes higher due to From this equation, the diffusion coefficient was calculated

association, when the polymerization of solute molecules for nearly 120 systems. All the calculated values of diffusion

occurs, or the solvation of solute molecules takes place. coefficient ( D T )are comparable with values (Dw) of Wilke

Hence a correction factor has to be introduced for all these and Chang. The complete analysis is given in Table I and

cases. I t was considered desirable to have a single equation Figure 1. I n cases like aniline in ethanol, benzoic acid in

of universal application with no extra correction factor. toulene, and acetic acid in carbon tetrachloride, there seem

The earlier correlation due to Ibrahim and Kuloor (9) is to be some arithmetical errors in the reported values ( O W )

simple in application but requires different equations for of Wilke and Chang. We have recalculated these and given

different solvents. We have critically examined all the the values in the Table I, and the recalculated values

available correlations to arrive a t a generalized equation. agree with DT.

As a first attempt, we have chosen the following equation

of Wilke and Chang ( I t ? ) , for further analysis

This correlates most of the experimental values within an

average deviation of =k 13%. But the trouble comes when

one must find the association parameter ( X ) for unknown

systems. The association parameter was introduced in the

above equation to define the effective molecular weight

of the solvent with respect to the diffusion process. Apart

from the difficulty of getting this parameter for an unknown

system, the value of 1.0 for organic unassociated solvents

and 2.6 for water may probably lead to errors in the dif-

fusion values as pointed out by Garner and Marchant (6).

According to them, for alcohols diffusing into water, the

parameter of 2.6 is approximately correct but requires

gradual reduction to about 2.35 for glycerol or Cs alcohols *IO

diffusing into water. This shows that the abnormality may

be due to the lack of understanding of intermolecular forces

in liquids. Figure 1. Graph for generalized diffusion coefficient

198 JOURNAL OF CHEMICAL AND ENGINEERING DATA

Table I. Diffusion Coefficients in Various Solvents

Dev. Dev.

from from

Temp., Exptl., Exptl.,

Solute Solvent c. u.

DE DT c/c D W /C

n-Propyl alcohol Benzene 15 1.60 1.41 12 1.92 20

Ethyl ether Benzene 15 2.21 1.50 32 2.24 1

chloroform Benzene 15 2.11 1.85 12 1.90 10

Chlorobenzene Benzene 15 1.42 1.48 4 1.57 11

Bromobenzene Benzene 15 1.86 1.59 15 1.54 11

Nitrobenzene Benzene 15 1.84 1.41 23 1.50 19

Ethylene bromide Benzene 15 1.97 1.84 7 1.72 13

Isoamyl alcohol Benzene 15 1.48 1.26 15 1.47 1

Phenol Benzene 15 1.27 1.42 12 1.37 8

Bromobenzene Benzene 7.3 1.41 1.39 1 1.29 9

Carbon tetrachloride Benzene 25 2.00 1.89 6 2.02 1

Bromine Benzene 12 2.00 2.40 20 2.36 18

Iodine Benzene 20 1.95 2.39 23 2.28 17

Formic Acid Benzene 6.2 1.991 1.715 14 1.480 26

Formic Acid Benzene 13.9 2.306 2.00 13 1.76 24

Benzene Benzene 15 1.885 1.53 19 1.795 5

Aniline Methyl alcohol 15 1.49 1.425 4 1.61 8

Allyl alcohol Methyl alcohol 15 1.80 1.46 19 2.04 13

Carbon tetrachloride Methyl alcohol 15 1.70 1.72 1 1.69 1

Chloroform Methyl alcohol 15 2.07 1.80 13 1.90 9

Ethyl bromide Methyl alcohol 15 2.40 1.99 17 2.02 16

Ethylene bromide Methyl alcohol 15 1.95 1.82 7 1.72 12

Furfural Methyl alcohol 15 1.70 1.455 14 1.75 3

Isoamyl alcohol Methyl alcohol 15 1.34 1.24 7 1.43 7

Phenol Methyl alcohol 15 1.40 1.39 1 1.62 15

Acetone Methyl alcohol 18.8 2.22 1.70 23 2.12 4

Nitromethane Methyl alcohol 16 2.23 1.735 21 2.27 3

Ethyl acetate Methyl alcohol 17.8 1.72 1.46 15 1.73 0

Nitrobenzene Methyl alcohol 16.8 1.48 1.44 3 1.47 0

Ethyl benzoate Methyl alcohol 16 1.28 1.19 7 1.085 15

Methyl alcohol Methyl alcohol 25 2.27 2.24 1 3.84 70

Acetone Water 20 1.16 1.01 13 1.115 4

Acetic acid Water 12.5 0.91 0.91 0 0.99 9

Acetic acid Water 20 1.19 1.12 6 1.15 3

Aniline Water 20 0.92 0.913 0 0.875 1

+ 0.04

Allyl alcohol Water 15 0.90 0.823 9 0.97 8

Glycerol Water 10 0.63 0.654 4 0.70 11

Isoamyl alcohol Water 15 0.69 0.70 2 0.70 2

Isobutyl alcohol Water 20 0.84 0.833 0 0.90 0

hO.10

Diethylamine Water 20 0.97 0.90 7 0.867 11

Ethyl acetate Water 20 1.00 0.89 4 0.895 4

=k 0.07

Furfural Water 20 1.04 0.94 2 0.96 0

=k 0.08

Ethyl alcohol Water 15 1.oo 0.845 16 1.11 11

Methyl alcohol Water 15 1.28 0.985 34 1.38 8

n-Propyl alcohol Water 15 0.87 0.785 12 0.91 5

n-Butyl alcohol Water 15 0.77 0.725 6 0.79 3

Nitrogen Water 22 2.02 2.07 3 1.97 3

Bromine Water 12 0.90 0.695 22 1.08 20

Iodine Water 25 1.25 1.56 25 1.24 1

Carbon dioxide Water 18 1.71 1.51 12 1.68 2

Hydrogen Water 25 3.36 3.54 5 3.25 3

Nitrous oxide Water 16 1.54 1.38 10 1.60 4

Oxygen Water 25 2.60 2.40 8 2.29 12

Chlorine Water 12 1.40 1.67 16 1.14 21

Hydrogen Chloride Water 20 2.64 1.73 34 2.12 20

Hydrogen iodide Water 20 1.51 2.08 38 1.59 5

Ethyl benzoate Etliylacetate 20 1.85 1.86 0 2.01 9

Nitrobenzene Ethyl acetate 20 2.25 2.34 4 2.48 10

Acetone Ethyl acetate 20 3.18 2.64 16 3.41 6

k0.04

Acetic acid Ethyl acetate 20 2.18 2.94 29 3.62 60

Nitrobenzene Ethyl benzoate 20 0.73 0.58 21 0.66 10

Acetone Ethyl benzoate 17 0.83 0.605 27 0.815 2

Ethyl acetate Ethyl benzoate 15.7 0.68 0.516 24 0.63 7

Nitromethane Ethyl benzoate 14.9 0.73 0.623 15 0.881 21

Ethyl benzoate Nitrobenzene 20 0.60 0.497 17 0.51 15

Acetone Nitrobenzene 17.8 0.79 0.69 13 0.87 10

Ethyl acetate Nitrobenzene 16.8 0.64 0.595 7 0.684 7

Nitromethane Nitrobenzene 18.6 0.81 0.765 6 1.02 26

VOL. 8 , No. 2, APRIL 1963 199

Table I. Diffusion Coefficients i n Various Solvents (Continued)

Dev. Dev.

from from

Temp., Exptl., Exptl.,

Solute Solvent OC. DE Ref. DT % Dw Ref. %

Isoamyl alcohol Ethyl alcohol 20 0.78 0.77 1 0.85 9

Aniline Ethyl alcohol 18.5 2.7 0.804 70 0.75 70

Bromoform Ethyl alcohol 20 0.97 0.865 11 0.96 0

Bromonaphthalene Ethyl alcohol 20 0.76 0.68 11 0.72 5

Pyridine Ethyl alcohol 20 1.12 0.91 19 1.00 12

Ethyl alcohol Ethyl alcohol 25 1.05 1.04 1 1.445 38

Iodine Ethyl alcohol 40 1.772 1.96 11 1.72 3

Acetone Isobutyl alcohol 20 0.74 0.354 50 0.36 48

10.05

Acetic acid Isobutyl alcohol 20 0.34 0.396 4 0.382 0

1 0.04

Diethylamine Isobutyl alcohol 20 0.34 0.32 0 0.28 0

i0.06

Nitrobenzene Acetone 20 2.94 2.71 8 2.83 3

Formic acid Acetone 25 3.768 4.07 8 3.59 5

Ethyl benzoate Acetone 20 2.47 2.15 13 2.29 7

Cinnamic acid Acetone 25 2.41 2.27 6 2.51 4

Acetic acid Acetone 25 3.309 3.630 10 2.850 14

Benzoic acid Acetone 25 2.622 2.44 7 1.89 28

Acetic acid Toluene 25 2.265 2.38 5 2.00 12

Benzoic acid Toluene 25 1.493 1.62 9 2.06 38

Benzoic acid Toluene 20 1.74 1.535 12 1.87 7

m-Bromotoluene Toluene 7.4 1.52 1.7 12 1.48 3

Carbon tetrachloride To1uene 25 2.19 2.26 3 2.22 1

Cinnamic acid Toluene 25 1.18 1.51 22 1.14 3

Formic acid Toluene 25 2.646 2.70 2 2.54 4

Methyl iodide Toluene 7.4 2.23 2.66 19 2.40 8

Diethylamine Toluene 20 2.36 1.79 13 2.06 0

f0.30

Acetone Toluene 20 2.93 1.99 31 2.66 5

j=0.03

Acetone Butyl Acetat% 20 2.66 1.63 37 2.42 7

i0.06

Acetic acid Butyl acetate 20 1.64 1.93 13 2.56 50

~t0.07

Acetone Carbon tetrachloride 20 1.86 1.49 15 2.11 13

i0.10

Acetic acid Carbon tetrachloride 25 1.49 1.64 10 2.43 63

Formic acid Carbon tetrachloride 25 1.888 1.86 1 2.01 6

Iodine Carbon tetrachloride 25 1.50 2.06 37 2.3 53

Carbon tetrachloride Carbon tetrachloride 25 1.41 1.545 10 1.74 23

Bromobenzene Ethylbenzene 7.3 1.44 1.52 6 1.55 8

Bromobenzene Mesitylene 7.3 1.31 1.49 14 1.54 18

Bromobenzene m -Xylene 7.3 1.52 1.66 9 1.69 11

Bromobenzene n-Hexane 7.3 2.6 2.82 8 3.02 16

Iodine Heptane 25 3.42 4.15 21 4.60 35

Iodine Cyclohexane 15 1.54 1.49 3 1.19 23

?'-Propyl alcohol n-Propyl alcohol 25 0.646 0.806 25 0.885 37

Water Acetone 25 4.56 4.1 10 8.7 91

Water Furfural 20 0.9 1.08 8 2.14 114

10.1

Water Ethylene chlorohydrin 21.5 0.46 0.515 12 1.20 160

Water Aniline 20 0.7 0.41 32 0.83 19

1 0.1

Water Isobutyl alcohol 20 0.36 0.45 15 0.81 107

1 0.03

Water Ethyl alcohol 18 1.1 1.17 6 2.58 125

Water Ethyl acetate 20 3.2 3.33 0 1.52 124

f0.15

Calculated by the authors using Equation 1.

CONCLUSION hold good, we believe that the equation proposed here

should have wider applicability. However, the interaction

The proposed equation holds good even for systems in of solute-solvent is not taken into account in either of

which water is a solute in different organic solvents whereas these correlations. This has certain obvious disadvantages.

the Wilke and Chang equation does not hold good for them. For example, in the system Methyl alcohol-benzene ( 3 ) ,

By explaining the association, arriving a t the association even a slight change in concentration causes considerable

parameter in a rational way, and obtaining an equation decrease in diffusion coefficient. I n such cases, if the corre-

which has general applicability for systems in which water lations are used, they will tend to give wrong values.

is solute where the Wilke and Chang correlation does not Perhaps this sort of abnormal behavior exists in systems

200 JOURNAL OF CHEMICAL AND ENGINEERING DATA

with iodine or bromine as solutes. Therefore, one must be DE = experimental diffusion coefficient

cautious in using these correlations meant for infinite di- DW = diffusion coefficientcalculated by Equation 1

lution and be assured that such abnormal behavior as found

in methyl alcohol-benzene is not present in the system for LITERATURE CITED

which diffusion coefficient is required. We would also like

to point out that we have taken viscosity of solvent which (1) Einstein, Albert, Ann. Phys. 17, 549 (1905).

is easily available, whereas Wilke and Chang have used (2) Arnold, J.H., Ind. Eng. Chem. 22,1091 (1930).

viscosity of solution in their equation. (3) Caldwell, C.S., Babb, A.L., J. Phys. Chem. 59, 1113 (1955).

T h e average percentage error remains within 13% for (4) Chemical Engineers Handbook, J.H. Perry, ed., McGraw

the proposed equation which is the same for Wilke and Hill, New York, 1950.

Chang equation. I n the latter case, the diffsuion values (5) Dummer, E., 2. Anorg. Allgem. Chem. 109, 31, (1919).

(6) Garner, F.H., Marchant, P.J.M., Trans. Znst. Chem. Engrs.

for water as solute were not included in calculating the (London), 39,397 (1961).

average because the Wilke and Chang equation does not (7) Glasstone, S., Laidler, K.T., Eyring, H., The Theory of

hold good. Rate Processes, McGraw Hill, New York, 1941.

(8) Hirschfelder, O., Curtiss, C.F., Bird, R.B., Molecular

Theory of Gases and Liquids, Wiley, New York, 1954.

NOMENCLATURE (9) Ibrahim, S.H., Kuloor, N.R., Brit. Che. Eng. 5, 795, (1960);

D = diffusion coefficient, sq. cm./sec. 6, 781,862, (1961); 7, 106, (1962).

n = viscosity of solvent in Equation 2 and viscosity of solution (10) Johnson, P.A., Babb, A.L., Chem. Reu. 56,387, (1956).

in Equation 1, cp. (11) Lewis, J.B., J A p p l . Chem. (London) 5, 228, (1955).

v, = molecular volume, cc./gram mole (12)

(13)

Olander, D.R., A.Z.Ch.E.J. 7, 175, (1961).

O t h e r , D.F., Thakar, M.S., Ind. Eng. Chem. 45, 589 (1953).

M, = molecular weight of solvent

x = association parameter (14) Reid, R.C., Sherwood, T.K., Properties of Gases and

L, = latent heat of vaporization of solvent, at normal boiling Liquids, McGraw-Hill, New York, 1958.

point, cal./gram (15) Scheibel, E.G., Ind. Eng. Chem. 46, 2007, (1954).

L = latent heat of vaporization of solute, at normal boiling (16) Wilke,C.R.,ChangPin, A.I.Ch.E.J. 1, 264, (1955).

point, cal./gram

DT = diffusion coefficient calculated by Equation 2 RECEIVED

for review April 13, 1962. Accepted November 19, 1962.

Specific Heat Measurements of Complex Saturated Hydrocarbons

B. J. G U D Z I N O W I C Z , R. H. CAMPBELL a n d J. S. A D A M S

M o n s a n t o Research C o r p o r a t i o n , Everett, Massachusetts

Specific heats of complex saturated hydrocarbons were measured from 100 to 400F.

Major hydrocarbon groups investigated were cyclohexanes, bicyclohexyls, tercyclo-

hexyls, decalins, and hydrindans. A differential heating method employing twin

thermal cells was used. The cells were charged with 25 ml. of test fluid and 25

ml. reference fluid (diphenyl ether), respectively, and suspended in air in identical

bronze cylinders. These cylinders were, in turn, welded in place to the circular

metallic cover of a silicone fluid bath regulated to i ~ O . 0 2 F .from 80 to 420F.

The samples were stirred magnetically and the rate of heating of each was followed

using Chromel-Alumel thermocouples connected to a precision potentiometer. Calori-

metric cell constants were previously obtained with fluids of known specific heats.

The over-all accuracy of the method at two temperatures, 104 and 212F., was

determined by measuring fluids of known specific heats. Density and viscosity data

obtained by standard techniques are included for each fluid.

RECENTLY, greater emphasis has been placed on the

physical properties of complex saturated hydrocarbons as

This article summarized experimentally determined

specific heat results for many new complex saturated

potential fuels for supersonic aircraft and advanced missile hydrocarbons.

power plants. I n addition tca density-temperature, viscosity-

temperature, and vapor pressure-temperature relationships, EXPERIMENTAL

and heat of combustion, boiling range, freezing point, and

thermal stability data, the heat transfer properties of these A differential heating method was chosen for determining

organics have been examined more closely in the past the specific heats of hydrocarbon fuels over a wide tempera-

several years. It is increasingly evident that heat capacity ture range. I n recent years, more emphasis has been placed

and thermal conductivity information a t higher tempera- on differential heating techniques. For evaluating the

tures is of paramount importance in fully evaluating the specific heat of hydrocarbon fuels over the desired 100

potential of any hydrocarbon as a fuel in high performance to 400 F. temperature range, a small-sample calorimeter

aircraft and missile vehicles. using twin tubes was selected. T h e apparatus constructed

for this fuels program is very similar to that described in

Present address, Monsanto Chemical Co., Nitro, W. Va. the literature by Porter et. al. (71, Spear ( 8 ) , and Thompson

VOL. 8, No. 2, APRIL 1963 201

También podría gustarte

- Compound Forming Extractants, Solvating Solvents and Inert Solvents: Iupac Chemical Data SeriesDe EverandCompound Forming Extractants, Solvating Solvents and Inert Solvents: Iupac Chemical Data SeriesAún no hay calificaciones

- ChE302 Exp03normalDocumento13 páginasChE302 Exp03normalMdSiShovonAún no hay calificaciones

- See FigDocumento5 páginasSee FigEdgar John PagulayanAún no hay calificaciones

- Process Engineering and Design: A Solvent-Resid Phase Diagram For Tracking Resid ConversionDocumento7 páginasProcess Engineering and Design: A Solvent-Resid Phase Diagram For Tracking Resid ConversionVinodh KumarAún no hay calificaciones

- Valori Tipici Coefficiente Di DiffusioneDocumento1 páginaValori Tipici Coefficiente Di Diffusioneziojoe2Aún no hay calificaciones

- CH 2Documento63 páginasCH 2Arbanah Muhammad82% (11)

- Boone 2002Documento2 páginasBoone 2002Stephanie AvilaAún no hay calificaciones

- What Is %LEL / %UEL / Lower and Upper Explosive Limits For Flammable Gases and VaporsDocumento8 páginasWhat Is %LEL / %UEL / Lower and Upper Explosive Limits For Flammable Gases and VaporsSherwin Delfin CincoAún no hay calificaciones

- Solvatochromic and Fluorescence Spectroscopic Studies On Polarity of Ionic Liquid and Ionic Liquid-Based Binary SystemsDocumento13 páginasSolvatochromic and Fluorescence Spectroscopic Studies On Polarity of Ionic Liquid and Ionic Liquid-Based Binary SystemsElcasihumano ZAún no hay calificaciones

- Aset - K As - D - N Su Ve Solvent S - Stemler - Arasinda Da - Ilim Katsayilari (#218831) - 191388Documento5 páginasAset - K As - D - N Su Ve Solvent S - Stemler - Arasinda Da - Ilim Katsayilari (#218831) - 191388fandel zalukhuAún no hay calificaciones

- مدلسازی تعادل بخار -مایعDocumento25 páginasمدلسازی تعادل بخار -مایعVahid EskandarinejadAún no hay calificaciones

- Xii Chemistry RTC QN BankDocumento64 páginasXii Chemistry RTC QN BankAdityanshu BeheraAún no hay calificaciones

- Table 2: Refractive Index For The Varying Mol Percentage of Methanol Ethanol Mol % Refractive Index Volume of Ethanol (ML)Documento5 páginasTable 2: Refractive Index For The Varying Mol Percentage of Methanol Ethanol Mol % Refractive Index Volume of Ethanol (ML)brittanyAún no hay calificaciones

- Vinyl Emulsion Polymerization: AcetateDocumento7 páginasVinyl Emulsion Polymerization: AcetateAnyiSakuraAún no hay calificaciones

- Vapor Liquid Equilibrium Ethanol WaterDocumento13 páginasVapor Liquid Equilibrium Ethanol Waterhao GamesAún no hay calificaciones

- Physical Chemistry 2 Laboratory Experiment No. 2 - Steam DistillationDocumento10 páginasPhysical Chemistry 2 Laboratory Experiment No. 2 - Steam DistillationAmiel Clark CabotajeAún no hay calificaciones

- PDFDocumento4 páginasPDFaminbm.pt24Aún no hay calificaciones

- Chapter 5 Solutions: Warm-Ups P5.1Documento101 páginasChapter 5 Solutions: Warm-Ups P5.1Lupita Avalos CordovaAún no hay calificaciones

- Correlation of Vapor-Liquid Equilibria Using Wilson Equation With Parameters Estimated From Solubility Parameters and Molar VolumesDocumento11 páginasCorrelation of Vapor-Liquid Equilibria Using Wilson Equation With Parameters Estimated From Solubility Parameters and Molar VolumesLuciano GonçalvesAún no hay calificaciones

- Manikyamba1990 PDFDocumento13 páginasManikyamba1990 PDFViviana TorresAún no hay calificaciones

- Vis Absoption Spectra of Dispersed DyesDocumento7 páginasVis Absoption Spectra of Dispersed DyesDr. Sujit K. ShahAún no hay calificaciones

- Lab ReportDocumento8 páginasLab ReportNurin BatrisyiaAún no hay calificaciones

- Lab ReportDocumento8 páginasLab ReportNurin BatrisyiaAún no hay calificaciones

- Results and DiscussionDocumento4 páginasResults and DiscussionEdgar John Pagulayan100% (1)

- Dilution of Flammable Polar Solvents by Water For Safe DisposalDocumento12 páginasDilution of Flammable Polar Solvents by Water For Safe Disposal1940LaSalleAún no hay calificaciones

- Difusividad de Liquidos - PerryDocumento3 páginasDifusividad de Liquidos - PerryGladys Ventura FloreAún no hay calificaciones

- Gravelle, Panayiotou - 1980 - Iv PDFDocumento4 páginasGravelle, Panayiotou - 1980 - Iv PDFPriscila TorresAún no hay calificaciones

- Refractometric Determination of Ethanol Concentration: Research NoteDocumento3 páginasRefractometric Determination of Ethanol Concentration: Research NoteMihir Kr MechAún no hay calificaciones

- Dissolved Hydrocarbons in WaterDocumento4 páginasDissolved Hydrocarbons in Waterengineer's documentAún no hay calificaciones

- Polar Protic Vs Polar Aprotic Vs Nonpolar: About Solvents in Organic ChemistryDocumento11 páginasPolar Protic Vs Polar Aprotic Vs Nonpolar: About Solvents in Organic ChemistrySiddarth PalletiAún no hay calificaciones

- What Is LEL UEL PIDDocumento11 páginasWhat Is LEL UEL PIDHafed HafedAún no hay calificaciones

- Wang 2015Documento6 páginasWang 2015Luthfi Ma'arifAún no hay calificaciones

- LEC 03.04 Boiling Point Diagram of A Binary Mixture: Related ConceptsDocumento4 páginasLEC 03.04 Boiling Point Diagram of A Binary Mixture: Related ConceptsAlexo ManAún no hay calificaciones

- Salting-Out of Acetone From Water Basis of A New Solvent Extraction SystemDocumento7 páginasSalting-Out of Acetone From Water Basis of A New Solvent Extraction SystemAl-Kawthari As-Sunni100% (1)

- Polymer Chemistry PDFDocumento31 páginasPolymer Chemistry PDFAnonymous v6ihpntNAún no hay calificaciones

- Refractive IndexDocumento9 páginasRefractive IndexZirtaeb Cerdena0% (1)

- Aldol Condensation and Synthesis of DibenzalacetoneDocumento8 páginasAldol Condensation and Synthesis of DibenzalacetoneArturo CamañoAún no hay calificaciones

- Design of Process LvaporDocumento11 páginasDesign of Process LvaporGATOMICOAún no hay calificaciones

- CMEM01016FUDocumento13 páginasCMEM01016FUmoracs1975Aún no hay calificaciones

- Enthalpy of Solution of Terfenadine in Ethanol - Water MixturesDocumento5 páginasEnthalpy of Solution of Terfenadine in Ethanol - Water MixturesArtit BoonkoomAún no hay calificaciones

- Distillation Notes-PartVIDocumento64 páginasDistillation Notes-PartVISauravRikunAún no hay calificaciones

- Exp 10 Grp9 20110153Documento14 páginasExp 10 Grp9 20110153Rahul KumarAún no hay calificaciones

- Water y Acetic Acid + N, N-DimethylformamideDocumento6 páginasWater y Acetic Acid + N, N-DimethylformamideGary Kiel Palacios EspinozaAún no hay calificaciones

- OrganoMetSolv PDFDocumento4 páginasOrganoMetSolv PDFHung Quoc DangAún no hay calificaciones

- Chemistry Previous Year Questions 2023-24Documento12 páginasChemistry Previous Year Questions 2023-24riyazfathima81Aún no hay calificaciones

- CLP302 - MT (SG 6) - Merged (1) 2Documento62 páginasCLP302 - MT (SG 6) - Merged (1) 2hedavo3338Aún no hay calificaciones

- What Is %LEL / %UEL /: Lower & Upper Explosive Limits For Flammable Gases & VaporsDocumento11 páginasWhat Is %LEL / %UEL /: Lower & Upper Explosive Limits For Flammable Gases & Vaporskenoly123Aún no hay calificaciones

- Ecuación Wilke-ChangDocumento2 páginasEcuación Wilke-ChangKarla DelgadoAún no hay calificaciones

- SPT 120 Non ElectrolytesDocumento36 páginasSPT 120 Non Electrolytestafadzwachikuni21septemberAún no hay calificaciones

- Synthesis of Dibenzalacetone by Aldol CondensationDocumento15 páginasSynthesis of Dibenzalacetone by Aldol CondensationHasmaye Pinto0% (1)

- Lab Report 10 Friedel CraftsDocumento7 páginasLab Report 10 Friedel CraftsPancho Abarca ZuñigaAún no hay calificaciones

- Exp. 3 Lab ReportDocumento6 páginasExp. 3 Lab ReportMichael PenuelaAún no hay calificaciones

- IdacDocumento7 páginasIdacsagarchawla13Aún no hay calificaciones

- Chem Lab#11 PostlabDocumento5 páginasChem Lab#11 PostlabAthia Ava Luna100% (1)

- Exam 03 Batch B - GEAS 01 ChemistryDocumento6 páginasExam 03 Batch B - GEAS 01 ChemistryJulius Romeo Trinidad, Jr.Aún no hay calificaciones

- (2097) Lecture Notes Solutions and Colligative Proerties eDocumento48 páginas(2097) Lecture Notes Solutions and Colligative Proerties eRamJiPandey100% (2)

- Simple Distillation: Lab ReportDocumento8 páginasSimple Distillation: Lab ReportChiAún no hay calificaciones

- Lecture Notes:4: For Chemisry (Honours) Semester-IV CEMA-CC-4-9-THDocumento6 páginasLecture Notes:4: For Chemisry (Honours) Semester-IV CEMA-CC-4-9-THShreya PramanikAún no hay calificaciones

- Introduction to Applied Colloid and Surface ChemistryDe EverandIntroduction to Applied Colloid and Surface ChemistryAún no hay calificaciones

- Isobaric Vapor Liquid EquilbriumDocumento8 páginasIsobaric Vapor Liquid EquilbriumJosemarPereiradaSilvaAún no hay calificaciones

- PSO Codes MatlabDocumento4 páginasPSO Codes MatlabJosemarPereiradaSilvaAún no hay calificaciones

- Applied Optimization With MatlabDocumento208 páginasApplied Optimization With MatlabIvan StojanovAún no hay calificaciones

- The AzeotropeDocumento14 páginasThe AzeotropeJosemarPereiradaSilvaAún no hay calificaciones

- Determination of Valley Ande Ridge of Isobaric Vapor Liquid Equilibrium For Ternary SystemDocumento10 páginasDetermination of Valley Ande Ridge of Isobaric Vapor Liquid Equilibrium For Ternary SystemJosemarPereiradaSilvaAún no hay calificaciones

- Science PDFDocumento8 páginasScience PDFJosemarPereiradaSilvaAún no hay calificaciones

- Wastewater Guide October 2013 LowresDocumento60 páginasWastewater Guide October 2013 Lowres185412Aún no hay calificaciones

- B.W. Bequette - Process Dynamics - Modeling, Analysis and SimulationDocumento632 páginasB.W. Bequette - Process Dynamics - Modeling, Analysis and SimulationKaren Franke75% (4)

- A New Unifac Parameterization For The Prediction of Liquid Liquid Equilibrium of Biodiesel SystemsDocumento10 páginasA New Unifac Parameterization For The Prediction of Liquid Liquid Equilibrium of Biodiesel SystemsJosemarPereiradaSilvaAún no hay calificaciones

- Uncontrained Gibbs Free Energy Minimization For Phase Equilibrium Calculations in Nonreactive Systems Using An Improved Cuckoo Search AlgorithmDocumento9 páginasUncontrained Gibbs Free Energy Minimization For Phase Equilibrium Calculations in Nonreactive Systems Using An Improved Cuckoo Search AlgorithmJosemarPereiradaSilvaAún no hay calificaciones

- Possible Existence of A Negative (Positive) Homogeneous Azeotrope When The Binary Mixtures Exhibits Positive (Negative) Deviation From Ideal Solution BehaviorDocumento6 páginasPossible Existence of A Negative (Positive) Homogeneous Azeotrope When The Binary Mixtures Exhibits Positive (Negative) Deviation From Ideal Solution BehaviorJosemarPereiradaSilvaAún no hay calificaciones

- Determination of Valley Ande Ridge of Isobaric Vapor Liquid Equilibrium For Ternary SystemDocumento10 páginasDetermination of Valley Ande Ridge of Isobaric Vapor Liquid Equilibrium For Ternary SystemJosemarPereiradaSilvaAún no hay calificaciones

- Wastewater Guide October 2013 LowresDocumento60 páginasWastewater Guide October 2013 Lowres185412Aún no hay calificaciones

- Optimization MATLAB ExercisesDocumento157 páginasOptimization MATLAB ExercisesJosemarPereiradaSilvaAún no hay calificaciones

- DestilacaoDocumento21 páginasDestilacaoJosemarPereiradaSilvaAún no hay calificaciones

- Separation of Acetonitrila Methanol Benzene Ternary Azeotrope Via Triple Column Pressure Swing DistillationDocumento12 páginasSeparation of Acetonitrila Methanol Benzene Ternary Azeotrope Via Triple Column Pressure Swing DistillationJosemarPereiradaSilvaAún no hay calificaciones

- A New Correlation For Thermal Conductivity of LiquidsDocumento9 páginasA New Correlation For Thermal Conductivity of LiquidsJosemarPereiradaSilvaAún no hay calificaciones

- Computation of Isobaric Vapor Liquid Equilibrium Data For Binary and Ternary Mixtures of Methanol, Water and Ethanoic AcidDocumento14 páginasComputation of Isobaric Vapor Liquid Equilibrium Data For Binary and Ternary Mixtures of Methanol, Water and Ethanoic AcidJosemarPereiradaSilvaAún no hay calificaciones

- A Simplified Method For Calculating Saturated Liquid Densities 2004 Fluid Phase EquilibriaDocumento11 páginasA Simplified Method For Calculating Saturated Liquid Densities 2004 Fluid Phase EquilibriaJosemarPereiradaSilvaAún no hay calificaciones

- A New Correlation For Thermal Conductivity of LiquidsDocumento9 páginasA New Correlation For Thermal Conductivity of LiquidsJosemarPereiradaSilvaAún no hay calificaciones

- Vapor-Liquid Equilibria For The Ternary Mixture Co2-1propanol-Propyl Acetato at Elevated PressuresDocumento7 páginasVapor-Liquid Equilibria For The Ternary Mixture Co2-1propanol-Propyl Acetato at Elevated PressuresJosemarPereiradaSilvaAún no hay calificaciones

- Measurement and Calculation of Vapor Liquid Equilibria For Methanol Glycerol and Ethanol Glycerol Systems at 493 573 K 2009 Fluid Phase EquilibriaDocumento6 páginasMeasurement and Calculation of Vapor Liquid Equilibria For Methanol Glycerol and Ethanol Glycerol Systems at 493 573 K 2009 Fluid Phase EquilibriaJosemarPereiradaSilvaAún no hay calificaciones

- Phase Stability Analysis of Liquid Liquid EquilibriumDocumento15 páginasPhase Stability Analysis of Liquid Liquid EquilibriumJosemarPereiradaSilvaAún no hay calificaciones

- Liquid Phase Equilibria of (Water+phosphoric Acid 1 ButanolDocumento5 páginasLiquid Phase Equilibria of (Water+phosphoric Acid 1 ButanolJosemarPereiradaSilvaAún no hay calificaciones

- Phase Stability Analysis of Liquid Liquid Equilibrium PDFDocumento13 páginasPhase Stability Analysis of Liquid Liquid Equilibrium PDFJosemarPereiradaSilvaAún no hay calificaciones

- A Powerful Algorithm For Liquid) Liquid) Liquid EquilibriaDocumento9 páginasA Powerful Algorithm For Liquid) Liquid) Liquid EquilibriaJosemarPereiradaSilvaAún no hay calificaciones

- Phase Stability Analysis of Liquid Liquid EquilibriumDocumento13 páginasPhase Stability Analysis of Liquid Liquid EquilibriumJosemarPereiradaSilvaAún no hay calificaciones

- Phase Stability Analysis of Liquid Liquid Equilibrium PDFDocumento13 páginasPhase Stability Analysis of Liquid Liquid Equilibrium PDFJosemarPereiradaSilvaAún no hay calificaciones

- LVEDocumento5 páginasLVEJosemarPereiradaSilvaAún no hay calificaciones

- Accion Didactica 1st Grade NovemberDocumento3 páginasAccion Didactica 1st Grade NovemberAntonio Abad GutiérrezAún no hay calificaciones

- ConferenceProceedings finalBalHNS2009Documento332 páginasConferenceProceedings finalBalHNS2009kayron limaAún no hay calificaciones

- 302 Decision Science Question - PaperDocumento3 páginas302 Decision Science Question - Paperajay taleAún no hay calificaciones

- AS Level Mathematics Statistics (New)Documento49 páginasAS Level Mathematics Statistics (New)Alex GoldsmithAún no hay calificaciones

- 7931-Article Text-15767-2-10-20191101Documento13 páginas7931-Article Text-15767-2-10-20191101Fatunde BukolaAún no hay calificaciones

- Philippine Board of Nursing Course SyllabusDocumento11 páginasPhilippine Board of Nursing Course SyllabusChin Chan100% (1)

- Astm D 420Documento7 páginasAstm D 420Veronica MongeAún no hay calificaciones

- Prac Res Q2 Module 8Documento12 páginasPrac Res Q2 Module 8Benicel Lane De VeraAún no hay calificaciones

- AE 2018-19 Syll PDFDocumento118 páginasAE 2018-19 Syll PDFHARI KRISHNA SAún no hay calificaciones

- Breathwork Fundamentals GuidebookDocumento148 páginasBreathwork Fundamentals GuidebookJuliana RennerAún no hay calificaciones

- New Section: Jeff Is Quite Tall. Karl Is The Same Height As JeffDocumento6 páginasNew Section: Jeff Is Quite Tall. Karl Is The Same Height As JeffIbrahim MahmoudAún no hay calificaciones

- Life After Ashes: Understanding The Impact of Business Loss To The Livelihood of San Fernando City Wet Market VendorsDocumento10 páginasLife After Ashes: Understanding The Impact of Business Loss To The Livelihood of San Fernando City Wet Market Vendorsalrichj29Aún no hay calificaciones

- Participatory Irrigation ManagementDocumento11 páginasParticipatory Irrigation ManagementSidAún no hay calificaciones

- Cars MasonryDocumento1 páginaCars MasonryAbdullah MundasAún no hay calificaciones

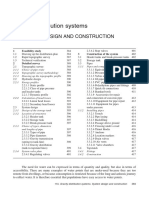

- Gravity Distribution Systems: A System Design and ConstructionDocumento40 páginasGravity Distribution Systems: A System Design and ConstructionTooma DavidAún no hay calificaciones

- Iefem English Guide Reported Speech 3Documento6 páginasIefem English Guide Reported Speech 3Laury Yocely Perea MenaAún no hay calificaciones

- Scaffold 2Documento3 páginasScaffold 2Mahmoud Elsayed MohamedAún no hay calificaciones

- Astm D2777 Determinacion de La Precision y El Sesgo PDFDocumento21 páginasAstm D2777 Determinacion de La Precision y El Sesgo PDFAlvaro Pérez PérezAún no hay calificaciones

- Mechanical Properties of SolidsDocumento7 páginasMechanical Properties of SolidsStudent RequestAún no hay calificaciones

- Soil PHDocumento19 páginasSoil PHElly Paul Andres TomasAún no hay calificaciones

- ADM - DIASS 11 Q4 Weeks 1-8 - LatestDocumento28 páginasADM - DIASS 11 Q4 Weeks 1-8 - LatestjoyceAún no hay calificaciones

- Review Iftekher 2013Documento11 páginasReview Iftekher 2013RezaAún no hay calificaciones

- Exp 3 Rahul Singh 2k20-A18-12Documento8 páginasExp 3 Rahul Singh 2k20-A18-12Dummy Account-Rahul SinghAún no hay calificaciones

- MCR3U Unit #1 NotesDocumento12 páginasMCR3U Unit #1 NotespersonAún no hay calificaciones

- DSS+ SH Risk Management HandbookDocumento20 páginasDSS+ SH Risk Management HandbookAlan PicazzoAún no hay calificaciones

- Test - Reading Explorer 3 8A - QuizletDocumento4 páginasTest - Reading Explorer 3 8A - QuizletTatjana Modea SibulAún no hay calificaciones

- LEPTOSPIRADocumento31 páginasLEPTOSPIRADinar NastitiAún no hay calificaciones

- Calibration Tools ListDocumento5 páginasCalibration Tools ListdianAún no hay calificaciones

- Week 4 and 5 Non-Verbal Communication: 4.1 The Importance of Nonverbal CommunicationDocumento8 páginasWeek 4 and 5 Non-Verbal Communication: 4.1 The Importance of Nonverbal CommunicationNovilia FriskaAún no hay calificaciones

- R.M. M, J. C, S.L. I S.M. H R C. M P J. M G : Aier Horover Verson AND Ayes Odney Aier and Eter C OldrickDocumento1 páginaR.M. M, J. C, S.L. I S.M. H R C. M P J. M G : Aier Horover Verson AND Ayes Odney Aier and Eter C OldrickPeter McGoldrickAún no hay calificaciones