Documentos de Académico

Documentos de Profesional

Documentos de Cultura

South Pars Gas Field Tank Inspection Plan

Cargado por

shankarmech04@gmail.comDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

South Pars Gas Field Tank Inspection Plan

Cargado por

shankarmech04@gmail.comCopyright:

Formatos disponibles

SOUTH PARS GAS FIELD DEVELOPMENT

(PHASES 9&10)

Inspection & Test Plan for

Atmospheric Tank Work

GS / OIEC/ IOEC

CONSORTIUM Doc. No. : ONS-09-0-PR-5254 Rev. No. : 3 Class : 1

TABULATION OF REVISED PAGES

PAGE Rev.0 Rev.1 Rev.2 Rev.3 PAGE

1 * * * *

2 * * * *

3 * *

4 * * * *

5 * * *

6 * * * *

7 * * * *

8 * * *

9 * * *

10 * * *

South Pars Gas Field Development (Phases 9 & 10) Page 2 of 10

SOUTH PARS GAS FIELD DEVELOPMENT

(PHASES 9&10)

Inspection & Test Plan for

Atmospheric Tank Work

GS / OIEC/ IOEC

CONSORTIUM Doc. No. : ONS-09-0-PR-5254 Rev. No. : 3 Class : 1

CONTENTS

Page

1. PURPOSE 4

2. TERMS AND DEFINITIONS 4

3. REFERENCES 4

4. RESPONSIBILITY 5

5. ATTACHMENTS 5

South Pars Gas Field Development (Phases 9 & 10) Page 3 of 10

SOUTH PARS GAS FIELD DEVELOPMENT

(PHASES 9&10)

Inspection & Test Plan for

Atmospheric Tank Work

GS / OIEC/ IOEC

CONSORTIUM Doc. No. : ONS-09-0-PR-5254 Rev. No. : 3 Class : 1

1. PURPOSE

The purpose of this Inspection & Test Plan (ITP) is to describe the methods and establish the Quality

Plan for the Inspection & Test Plan for Atmospheric Tank Work Activities for South Pars 9&10 Project.

2. TERMS AND DEFINITIONS

COMPANY: NATIONAL IRANIAN OIL COMPANY(NIOC) / Pars Oil and Gas Company(POGC) or

his nominated representative.

CONTRACTOR: The party (GS/OIEC/IOEC CONSORTIUM) which entered under Contract Agreement

with COMPANY for the Design, Engineering, Procurement and Construction of the Onshore and

Offshore Facilities regarding the South Pars Field Development Project 9&10.

SUBCONTRACTOR: shall mean any company, firm or person with whom CONTRACTOR enters into

a subcontract.

TPA (Third Party Authorities): any inspection service person or company who is independent from

COMPANY, CONTRACTOR AND SUBCONTRACTOR.

SITE: The location for installation of the facilities at ASSALUYEH or the vicinity thereof in the IRAN.

3. REFERENCES

3.1 Specification & Procedure

RP-6340S-999-6600-001 Shop and Field Painting Specification

RP-6340S-999-2500-001 Cylindrical Storage Tanks Small and Medium Size

RP-6340S-999-6300-0001 Welding of Pressure Containing Piping and Equipment

RP-6340S-999-P332-003 Field Erection Pressure Testing

COM-07-0-PR-0002 Field Material Control Procedure

ONS-09-0-PR-5300 Work Instruction for Material Receiving

ONS-09-0-PR-5400 Material Control Procedure

ONS-09-0-PR-4505 Flushing Procedure

ONS-09-0-PR-5208 Work Procedure for Welder and Welding Operator Qualification

ONS-09-0-PR-5210 Work Procedure for Welding Qualification

ONS-09-0-PR-4600 Work Procedure for Blasting & painting Application

ONS-09-0-PR-5200,1,2,3,4,7 NDT Procedures

ONS-09-0-PR-5211 PWHT Procedure

ONS-09-0-PR-5252 Inspection & Test Plan for Tank Lining Work

ONS-09-0-PR-4503 Work Procedure for Pressure Test

ONS-O9-0-PR-4506 Welding Consumable Control Procedure

3.2 Standards

API 650 Welded Steel Tanks for Oil Storage

API 620 Design and Construction of Large, Welded Low-Pressure

Storage Tanks

API 2000 Venting Atmospheric and Low-Pressure Storage Tanks

South Pars Gas Field Development (Phases 9 & 10) Page 4 of 10

SOUTH PARS GAS FIELD DEVELOPMENT

(PHASES 9&10)

Inspection & Test Plan for

Atmospheric Tank Work

GS / OIEC/ IOEC

CONSORTIUM Doc. No. : ONS-09-0-PR-5254 Rev. No. : 3 Class : 1

4. RESPONSIBILITIES

4.1 SUBCONTRACTOR Field QA/QC Manager is responsible for Quality Control for all kinds of

Equipment Installation Work Activities.

4.2 SUBCONTRACTOR Field QC Inspector is responsible as follows:

a) Prepare & Implement details of the field inspection requirements or activities in

accordance with the Project Specifications and the other code and standards of the Contract.

b) Perform inspection and document review.

c) Comply with any instructions or comments by the COMPANYs Mechanical Supervisor and

Field Inspector/CONTRACTORs field inspector and Issue all field inspection reports to the

COMPANY/CONTRACTOR for review/information.

d) Maintain regular contact with the COMPANY/CONTRACTOR, including reporting all field

inspection activities.

e) Prepare ITP or Procedures (if required).

f) Prepare an updated list of Inspection/Test status and schedule.

g) Request the inspection & witness to COMPANYs Mechanical Supervisor and Field Inspector

/CONTRACTORs field inspector as per the ITP required for inspection on witness and hold

point(At least one day in advance).

h) Perform Inspection.

i) Submit to COMPANY/CONTRACTOR the inspection/test records showing that all required

inspection/test activities are completed.

4.3 SUBCONTRACTOR Construction superintendent/supervisor has the responsibility for

implementing in Accordance with this procedure requirements.

5. ATTACHMENTS

1. Inspection & Test Plan tables --- 5 Sheets

2. Inspection Report Forms ------ 24 Sheets

South Pars Gas Field Development (Phases 9 & 10) Page 5 of 10

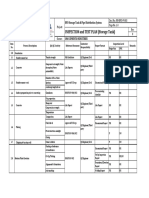

INSPECTION & TEST PLAN

FOR

ATMOSPHERIC TANK WORK

Doc. No. : ONS-09-0-PR-5254

DISCIPLINE : TANK

INSPECTION & TEST PLAN FOR SITE SUBCON. : Rev. : 3

DESCRIPTION OF WORK : TANK

Applicable Spec. REPORTING PARTICIPATION BY

NO. DESCRIPTION OF INSPECTION / TEST or Procedure FORMAT SUBCON. CONTRACTOR COMPANY TPA

REMARK

A MATERIAL VERIFICATION

Related Drawing

1 Verify the material condition before installation , & Vendor Manual & Material MRI-001/EQP- X W SW

Welding Consumable Control Control Procedure 016

B Foundation Inspection EQP-020,EQP- X W SW

RP-6340S-999-2500-001, 009

1 Levelness of Ring Wall Related DWGs , API 650

2 Center Point and Radius

3 Flatness & Slope

4 Orientation(Zero point, Drain sump) X W SW

5 Anchor bolts(Distance, Projection,etc.) as required

C Erection and Fabrication

1 Welding ONS-09-0-PR- WPS-001

1) WPS/PQR 5208,5210,4506 PQR-001~003 X W W W

2) Welder/Welding operator qualification RP-6340S-999-6300- WQT-001 X W W W

3) Welding Process (Baking Electrode/Preheat/Weld ) 0001,ASME Sec. IX,API 650 X W W W

4) NDT (if applicable) ONS-09-0-PR-5200,1,2,3,4,7 X R/SW R/SW R

5) NDT Operator Qualification Cert. Check X R R R

LEGEND : R : Review SW : Spot Witness W : Witness H : Hold X: Execution of Inspection & Test

South Pars Gas Field Development (Phases 9 & 10) Page 6 of 10

INSPECTION & TEST PLAN

FOR

ATMOSPHERIC TANK WORK

Doc. No. : ONS-09-0-PR-5254

DISCIPLINE : TANK

INSPECTION & TEST PLAN FOR SITE SUBCON. : Rev. : 3

DESCRIPTION OF WORK : TANK

Applicable Spec. REPORTING PARTICIPATION BY

NO. DESCRIPTION OF INSPECTION / TEST or Procedure FORMAT

REMARK

SUBCON. CONTRACTOR COMPANY TPA

2 Erection Approved Vendor s Tank

2.1 Bottom and Annular Plate Erection Procedure

1) Fit-up of bottom plates. . RP-6340S-999-2500-001, EQP-010 X W SW

2) Welding sequence implementation RP-6340S-999-6300- X W SW

3) Visual inspection of weldment 0001 X W SW

4) Vacuum box test of bottom plate API 650 EQP-011 X H W

5) Annular plate orientation check Applicable DWG. X W W

6) Fit - up & welding of annular plate . . EQP-017 X R/W R/W

7) NDT of annular plate / Vacuum Test(If required) EQP-010/017 X W W R

8) Annular erection marking check

2.2 Shell plate RP-6340S-999-2500-001

1) Fit-up & first course shell plate tack welding Approved Vendors Tank EQP-010 X W SW

2) Check of roundness / plumbness / Levelness Erection Procedure EQP-008,12,13 X H W

3) Fit-up & tack welding of second course shell EQP-010 X W SW

Plate API 650

4) Check of plumbness RP-6340S-999-2500-001 EQP-012 X W W

5) Fit-up & tack welding of third course shell plate EQP-010 X W SW

6) Check of plumbness Applicable DWG. EQP-012 X W W

7) Welding of first course after assembling of EQP-011 X W W

second & third course

8) Check of plumbness / banding / peaking EQP-012,014,015 X H W

9) NDT ( if applicable) ONS-09-0-PR- X R/W R/W R

5200,1,2,3,4,7

LEGEND : R : Review SW : Spot Witness W : Witness H : Hold X: Execution of Inspection & Test

South Pars Gas Field Development (Phases 9 & 10) Page 7 of 10

INSPECTION & TEST PLAN

FOR

ATMOSPHERIC TANK WORK

Doc. No. : ONS-09-0-PR-5254

DISCIPLINE : TANK

INSPECTION & TEST PLAN FOR SITE SUBCON. : Rev. : 3

DESCRIPTION OF WORK : TANK

Applicable Spec. REPORTING PARTICIPATION BY

NO. DESCRIPTION OF INSPECTION / TEST or Procedure FORMAT

REMARK

SUBCON. CONTRACTOR COMPANY TPA

10) Welding of second course after assembling EQP-011 X W SW

fourth course

11) Check of plumbness / banding / peaking EQP-012,014,015 X H W

12) NDT (if applicable) ONS-09-0-PR- X R/W R/W R

13) Fit-up & welding of other course 5200,1,2,3,4,7 EQP-010 X W SW

14) Check of plumbness / banding / peaking EQP-012,014,015 X H W

15) NDT (if applicable) EQP-011 X R/W R/W R

16) Welding of shell plate to annular plate after X W W

welding of third course

15) Oil test of shell plate to annular plate ONS-09-0-PR- EQP-017 X H W

16) Check of manhole, nozzle & other accessories 5200,1,2,3,4,7

16.1) orientation and location EQP-018 X H W R

16.2) welding & NDT ( if applicable) EQP-011 X W W H

16.3) air test of reinforcements Approved Vendors Tank EQP-019 X H W

2.3 Roof Erection Erection Procedure

RP-6340S-999-2500-001

2.3.1 Floating Roof API 650,

1) Check of deck plates & pontoon roof orientation X W W

2) Fit-up & welding of deck plates , pontoon roof , Rim , EQP-010 X H SW

Compart , Center plate, etc.

3) Oil test deck plates EQP-017 X H W

4) Check of distance between primary seal & inside Applicable DWG. X W W

of shell plate

5) Arrangement of roof structure X W W

LEGEND : R : Review SW : Spot Witness W : Witness H : Hold X: Execution of Inspection & Test

South Pars Gas Field Development (Phases 9 & 10) Page 8 of 10

INSPECTION & TEST PLAN

FOR

ATMOSPHERIC TANK WORK

Doc. No. : ONS-09-0-PR-5254

DISCIPLINE : TANK

INSPECTION & TEST PLAN FOR SITE SUBCON. : Rev. : 3

DESCRIPTION OF WORK : TANK

Applicable Spec. REPORTING PARTICIPATION BY

NO. DESCRIPTION OF INSPECTION / TEST or Procedure FORMAT

REMARK

SUBCON. CONTRACTOR COMPANY TPA

6) Welding of roof plates EQP-011 X W W

7) Check nozzles & other accessories orientation EQP-018 X H W

8) Cutting & welding of nozzle & other accessories EQP-011 X W SW

9) Air test of roof plate EQP-019 X H W

10) Air test of reinforcements EQP-019 X W W H

11) Roof Drain System X W W

12) Floating Roof Seal X W W

2.3.2 Fixed Roof

1) Arrangement of roof structure X W W

2) Check the roof plate & compression ring & roof structure X W W

orientation

3) Fit-up & welding compression ring & roof plate EQP-010 X H SW

4) Welding of roof plates EQP-011 X W W

5) Check nozzles & other accessories orientation EQP-018 X H W

6) Cutting & welding of nozzle & other accessories EQP-011 X W SW

7) Air test of roof plate EQP-019 X H W

8) Air test of reinforcements EQP-019 X W W H

2.3.3 Miscellaneous Accessories X W SW

1) Location check and VT of weldment( Spiral Stairway /

Ladder / Platform / Handrail / Anchor Chair / Earth Lug / etc.)

LEGEND : R : Review SW : Spot Witness W : Witness H : Hold X: Execution of Inspection & Test

South Pars Gas Field Development (Phases 9 & 10) Page 9 of 10

INSPECTION & TEST PLAN

FOR

ATMOSPHERIC TANK WORK

Doc. No. : ONS-09-0-PR-5254

DISCIPLINE : TANK

INSPECTION & TEST PLAN FOR SITE SUBCON. : Rev. : 3

DESCRIPTION OF WORK : TANK

Applicable Spec. REPORTING PARTICIPATION BY

NO. DESCRIPTION OF INSPECTION / TEST or Procedure FORMAT

REMARK

SUBCON. CONTRACTOR COMPANY TPA

D Hydrostatic test / Seal check Approved Vendors EQP-020~23

1) Verify the welding work and NDE work before test Tank erection X H W

2) Internal cleaning before test procedure, Approved X W W

3) Verify shell opening and external piping condition Vendors Hydrostatic X W W

before test test, RP-6340S-999-

4) Water Filling P332-003, ONS-09-0- X W W H

5) Hydro test(Water level/Holding time) PR-4505, ONS-09-0- X H W H

6) Settlement check (Refer to applicable procedure) PR-4503 X H W

7) Roof test (Pneumatic leak test) X W W H

8) Water discharge X W W

9) Cleaning check X W W

10) Seal check X W W

11) Floating roof and roof support check X W SW

12) Air-foam water spray system check X W W

E Painting work ONS-09-0-PR-4600 PAI-006/007 . .

1) Painting material identification/check RP-6340S-999-6600- MRI-001 X W SW

2) Weather condition & Surface Preparation (Blasting) 001 X W W

3) Primer Layer Inspection(Including Wet & Dry X W W

Thickness check)

4) Intermediate/Final Layer Inspection (Including Wet & X W SW/W

Dry Thickness check)

F Tank Calibration/gauge (Marking & Measuring) Applicable Code/ DWG. Tank Table X H W H F.R.T Tanks

G Final Inspection( Ensure the completion of all activities) Final Book X R R

LEGEND : R : Review SW : Spot Witness W : Witness H : Hold X: Execution of Inspection & Test

South Pars Gas Field Development (Phases 9 & 10) Page 10 of 10

También podría gustarte

- Vaccum Box Test Procedure For All TanksDocumento6 páginasVaccum Box Test Procedure For All Tanksויליאם סן מרמיגיוסAún no hay calificaciones

- Tie in Procedure Rev. BDocumento8 páginasTie in Procedure Rev. BgenjiAún no hay calificaciones

- TANK INSPECTION PROCEDUREDocumento4 páginasTANK INSPECTION PROCEDUREzahid_497Aún no hay calificaciones

- 24.tank Oil Chalk TestDocumento3 páginas24.tank Oil Chalk TestShubham ShuklaAún no hay calificaciones

- Hydro TestDocumento36 páginasHydro TestFasil Paruvanath100% (1)

- STS Co. storage tank fabrication methodologyDocumento15 páginasSTS Co. storage tank fabrication methodologypurshottam GHAún no hay calificaciones

- FSK-E290-006-A4-0 Quality Control Plan (QC Plan)Documento4 páginasFSK-E290-006-A4-0 Quality Control Plan (QC Plan)Amir Reza RashidfarokhiAún no hay calificaciones

- Dry Bulk Storage Tank SpecificationDocumento7 páginasDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimAún no hay calificaciones

- New Bottom PlateDocumento9 páginasNew Bottom PlateEmmanuel kusimo100% (1)

- Jms Demolishing RGTP p20220019 Esb Con Jms 9243 0002 ADocumento14 páginasJms Demolishing RGTP p20220019 Esb Con Jms 9243 0002 Aamir hakimAún no hay calificaciones

- Method of Statement For RadiationDocumento4 páginasMethod of Statement For RadiationFiras AlbaweiAún no hay calificaciones

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Documento22 páginas15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuAún no hay calificaciones

- Hydrotest Procedure For PipingDocumento4 páginasHydrotest Procedure For Pipingsuria qaqcAún no hay calificaciones

- Tank Fabrication SpecsDocumento21 páginasTank Fabrication Specsjlcheefei9258100% (1)

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocumento6 páginasF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoAún no hay calificaciones

- Pmi Procedure: Superflow Pumps Pvt. LTDDocumento6 páginasPmi Procedure: Superflow Pumps Pvt. LTDashish tiwariAún no hay calificaciones

- Helium Leak TestDocumento8 páginasHelium Leak TestHiren Panchal50% (2)

- Hydrotest ProcedureDocumento6 páginasHydrotest Procedurebagusu_6Aún no hay calificaciones

- 30 Mainline Hydrotesting 111Documento25 páginas30 Mainline Hydrotesting 111rexAún no hay calificaciones

- Process Tank Fabrication Work StepsDocumento4 páginasProcess Tank Fabrication Work StepsMuhammad ZubairAún no hay calificaciones

- Vessel Cleaning ProcedureDocumento6 páginasVessel Cleaning ProcedureZool HilmiAún no hay calificaciones

- Methods Statement Procedure Carbon Steel Tank 2Documento22 páginasMethods Statement Procedure Carbon Steel Tank 2yuwantoni100% (1)

- Tank Erection Itp Org ChartDocumento34 páginasTank Erection Itp Org Chartvasantha kumar100% (1)

- P&ID, PFD, Plot PLant List DrawingDocumento27 páginasP&ID, PFD, Plot PLant List Drawingjayan perkasaAún no hay calificaciones

- Itp Existing Pressure VesselDocumento3 páginasItp Existing Pressure Vesselmuhammad afrizal100% (1)

- Diaphragm Pumps SOWDocumento30 páginasDiaphragm Pumps SOWalliancemarine2011Aún no hay calificaciones

- Job Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocumento5 páginasJob Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaAún no hay calificaciones

- Procedure for hydro & pneumatic tank testingDocumento3 páginasProcedure for hydro & pneumatic tank testingNupesh katreAún no hay calificaciones

- Installation Procedure For Air Heater CoolerDocumento4 páginasInstallation Procedure For Air Heater CoolerRachel FloresAún no hay calificaciones

- Qot BD 1 22 Me SPC 10364 00Documento16 páginasQot BD 1 22 Me SPC 10364 00Hamid MansouriAún no hay calificaciones

- SPC-0804.02-20.06 Rev D2 Field-Erected Low Pressure Storage TankDocumento14 páginasSPC-0804.02-20.06 Rev D2 Field-Erected Low Pressure Storage TankswehcctkAún no hay calificaciones

- Inspection & Test Plan TankDocumento3 páginasInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- Procedure of Tank RepairDocumento4 páginasProcedure of Tank RepairCepi Sindang KamulanAún no hay calificaciones

- Vacuum Box Testing ProcedureDocumento6 páginasVacuum Box Testing ProcedureKandula Raju100% (1)

- Cairn Energy India underground piping installation procedureDocumento12 páginasCairn Energy India underground piping installation procedurevpsimbu86Aún no hay calificaciones

- R057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpoolDocumento16 páginasR057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpooldharwinAún no hay calificaciones

- Pressure TestDocumento36 páginasPressure TestvinothAún no hay calificaciones

- Hydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkDocumento8 páginasHydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkCipta Adikarya100% (1)

- Pre Comm ProcedureDocumento8 páginasPre Comm ProcedurewahyuAún no hay calificaciones

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Documento7 páginasS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராAún no hay calificaciones

- PTS 12.30.02 MCF Change Justification Form 2017 (B)Documento5 páginasPTS 12.30.02 MCF Change Justification Form 2017 (B)Nasir ZainiAún no hay calificaciones

- Cat Loading by Sock Method in Inert AtmosphereDocumento5 páginasCat Loading by Sock Method in Inert Atmospherevishal bailurAún no hay calificaciones

- Pttep Painitng of Offshore FacilitiesDocumento66 páginasPttep Painitng of Offshore FacilitiesSufianAún no hay calificaciones

- TDI41 Tank Inspection Repair & Alteration API 653 Sec 9Documento13 páginasTDI41 Tank Inspection Repair & Alteration API 653 Sec 9Faizal Sattu100% (2)

- Roundness Check Record of 1St Shell CourseDocumento1 páginaRoundness Check Record of 1St Shell CourseRhannie GarciaAún no hay calificaciones

- Floating Roof Seal Selection ChecklistDocumento3 páginasFloating Roof Seal Selection ChecklistRoshin99100% (2)

- Inspection Cleaning Flushing TestingDocumento8 páginasInspection Cleaning Flushing Testingadel rihanaAún no hay calificaciones

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Documento6 páginasQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- Shell and Tube Heat Exchanger TPIDocumento9 páginasShell and Tube Heat Exchanger TPIpstechnical_43312697Aún no hay calificaciones

- FW3315 - Centrifugal Pump Check ListDocumento1 páginaFW3315 - Centrifugal Pump Check ListRachel FloresAún no hay calificaciones

- Tank ProcedureDocumento5 páginasTank ProcedurejacquesmayolAún no hay calificaciones

- AST Nozzle Repair Req.Documento10 páginasAST Nozzle Repair Req.Irvansyah RazadinAún no hay calificaciones

- Vortex BreakerDocumento2 páginasVortex Breakernaruto256Aún no hay calificaciones

- EGP3-10.00 Storage TanksDocumento53 páginasEGP3-10.00 Storage TanksMathias OnosemuodeAún no hay calificaciones

- Qap HPCLDocumento13 páginasQap HPCLdarshan100% (1)

- SA-JER-DSAAA-TRJR- 509104 Quality Procedure for Asphalt PavDocumento13 páginasSA-JER-DSAAA-TRJR- 509104 Quality Procedure for Asphalt PavFrancis Phillip CapistranoAún no hay calificaciones

- Pneumatic ProcedureDocumento5 páginasPneumatic ProcedurekumaraguruAún no hay calificaciones

- Hydrotesting of RTR PipesDocumento9 páginasHydrotesting of RTR PipesMd ShariqueAún no hay calificaciones

- ML-01 Work Procedure For Row SurveyDocumento7 páginasML-01 Work Procedure For Row SurveyBrijesh Katariya VCSAún no hay calificaciones

- Survey, Clearing & Grading JPDocumento5 páginasSurvey, Clearing & Grading JPSarfaraz AhmadAún no hay calificaciones

- PR-1247 - Project Management of Change ProcedureDocumento27 páginasPR-1247 - Project Management of Change Procedureshankarmech04@gmail.com100% (2)

- Project Control Manual PDFDocumento133 páginasProject Control Manual PDFprateekchopra10% (1)

- Preview of Communicating in BusinessDocumento10 páginasPreview of Communicating in Businessshankarmech04@gmail.comAún no hay calificaciones

- Spherical Roller Thrust Bearings-29352 EDocumento1 páginaSpherical Roller Thrust Bearings-29352 Eshankarmech04@gmail.comAún no hay calificaciones

- Reference (Woodside - Standards)Documento23 páginasReference (Woodside - Standards)shankarmech04@gmail.com100% (1)

- Defensive Driving TrainingDocumento29 páginasDefensive Driving Trainingshankarmech04@gmail.comAún no hay calificaciones

- Special Piping Materials Brochure PDFDocumento9 páginasSpecial Piping Materials Brochure PDFshankarmech04@gmail.comAún no hay calificaciones

- 11-8127-CC-Economics-V882 - FINAL PDFDocumento1 página11-8127-CC-Economics-V882 - FINAL PDFshankarmech04@gmail.comAún no hay calificaciones

- Nippon Steel PDFDocumento49 páginasNippon Steel PDFshankarmech04@gmail.comAún no hay calificaciones

- GB-T 11263-2010Documento17 páginasGB-T 11263-2010shankarmech04@gmail.comAún no hay calificaciones

- Rental Agreement SampleDocumento5 páginasRental Agreement Samplemkkumar7Aún no hay calificaciones

- EMMS SpecificationsDocumento18 páginasEMMS SpecificationsAnonymous dJtVwACc100% (2)

- A Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsDocumento22 páginasA Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsNathy Slq AstudilloAún no hay calificaciones

- Prof. Michael Murray - Some Differential Geometry ExercisesDocumento4 páginasProf. Michael Murray - Some Differential Geometry ExercisesAnonymous 9rJe2lOskxAún no hay calificaciones

- Universal Robina Co. & Bdo Unibank Inc.: Research PaperDocumento25 páginasUniversal Robina Co. & Bdo Unibank Inc.: Research PaperSariephine Grace ArasAún no hay calificaciones

- Mythic Magazine 017Documento43 páginasMythic Magazine 017William Warren100% (1)

- Ne 01 20 09 2018Documento436 páginasNe 01 20 09 2018VaradrajAún no hay calificaciones

- Manual Bombas CHWDocumento16 páginasManual Bombas CHWFred GarciaAún no hay calificaciones

- The Wafer-God and the Bloody History of the VaticanDocumento58 páginasThe Wafer-God and the Bloody History of the VaticanMin Hotep Tzaddik BeyAún no hay calificaciones

- Class 9th Chemistry Unit#4 Structure of MoleculesDocumento8 páginasClass 9th Chemistry Unit#4 Structure of MoleculesIrfanullahAún no hay calificaciones

- Estwani ISO CodesDocumento9 páginasEstwani ISO Codesनिपुण कुमारAún no hay calificaciones

- Introduction To Streering Gear SystemDocumento1 páginaIntroduction To Streering Gear SystemNorman prattAún no hay calificaciones

- Electrocardiography - Wikipedia, The Free EncyclopediaDocumento18 páginasElectrocardiography - Wikipedia, The Free Encyclopediapayments8543Aún no hay calificaciones

- Understanding Culture, Society and PoliticsDocumento62 páginasUnderstanding Culture, Society and PoliticsTeds TV89% (84)

- COT EnglishDocumento4 páginasCOT EnglishTypie ZapAún no hay calificaciones

- E PortfolioDocumento76 páginasE PortfolioMAGALLON ANDREWAún no hay calificaciones

- Where On Earth Can Go Next?: AppleDocumento100 páginasWhere On Earth Can Go Next?: Applepetrushevski_designeAún no hay calificaciones

- Bitcoin MambaDocumento17 páginasBitcoin MambaJean MilenixAún no hay calificaciones

- Credit Risk Management Practice in Private Banks Case Study Bank of AbyssiniaDocumento85 páginasCredit Risk Management Practice in Private Banks Case Study Bank of AbyssiniaamogneAún no hay calificaciones

- 99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudDocumento6 páginas99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudPavankumar PuvvalaAún no hay calificaciones

- VARCDocumento52 páginasVARCCharlie GoyalAún no hay calificaciones

- Merchandise Floor Ready Standards - Supplier InformationDocumento46 páginasMerchandise Floor Ready Standards - Supplier InformationGarmentLearner100% (1)

- Zhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Documento24 páginasZhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Carlos Caicedo-Russi100% (1)

- Storytelling ScriptDocumento2 páginasStorytelling ScriptAnjalai Ganasan100% (1)

- Body Scan AnalysisDocumento9 páginasBody Scan AnalysisAmaury CosmeAún no hay calificaciones

- 9 - NCP Computer Science PGDocumento19 páginas9 - NCP Computer Science PGM AmbreenAún no hay calificaciones

- RestrukturisasiDocumento17 páginasRestrukturisasimuhammad hayel wallaAún no hay calificaciones

- Ipo Exam Revised SyllabusDocumento1 páginaIpo Exam Revised Syllabusজ্যোতিৰ্ময় বসুমতাৰীAún no hay calificaciones

- Riedijk - Architecture As A CraftDocumento223 páginasRiedijk - Architecture As A CraftHannah WesselsAún no hay calificaciones

- Tugas B InggrisDocumento6 páginasTugas B Inggrisiqbal baleAún no hay calificaciones

- W1inse6220 PDFDocumento11 páginasW1inse6220 PDFpicalaAún no hay calificaciones