Documentos de Académico

Documentos de Profesional

Documentos de Cultura

481 PDF

Cargado por

Vitelio PinzonTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

481 PDF

Cargado por

Vitelio PinzonCopyright:

Formatos disponibles

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 106-S02

Does Strength Test Satisfying Code Requirement for

Nominal Strength Justify Ignoring Size Effect in Shear?

by Zdenek P. Bazant and Qiang Yu

A recent University of Toronto test of a 925 mm (36.4 in.) deep up to 1.1 m (43 in.), and by Iguro et a1. 6 and Shioya and

beam without stirrups showed a shear strength Vc that is only Akiyama7 for depths up to 3.0 m (118 in.). A very systematic

slightly below the value Vc = 2."ff~ required by ACI 318-08, and size effect for beams (of the highest brittleness number so

comfortably above the value rjJ x 2."ff~ (where rjJ = 0.75 is the strength far) was demonstrated by tests of reduced-scale beams at

reduction factor, and Vc and f~ are in psi). On that basis, and in Northwestern University.8 Recently, University of Toronto

view of the safety provisions of the Code, it is often thought that the tests 3.4 of three-point-bend beams without stirrups that were

current shear strength provisions for beams up to 0.2 m (8 in.) approximately geometrically similar and had depths ranging

deep, which neglects the size effect, are safe for beams up to 1 m from 0.11 to 1.89 m (4.3 to 74.4 in.), extended the experimental

(40 in.) deep. This is not true, however, for it must be expected that evidence of size effect and showed that the strength of the

if numerous tests of 1 m (40 in.) deep beams with different shear largest test beam was 53% less than the nominal strength

spans and steel ratios, made of different concretes and under

different hygro-thermal conditions, could be carried out, the beam according to ACI 318-08.9 To guard against such a situation,

strength would exhibit a similar statistical scatter, with approxi- Section 11.4 of ACI 318-08 9 severely penalizes any beams

mately the same coefficient of variation (Co V), as the strength of without stirrups more than 254 mm (10 in.) deep by reducing

beams up to 0.2 m (8 in.) deep, for which there are numerous test the shear strength limit from Vc =2Vtc' (where Vc andfe' are

results in the database. Based on this expected scatter, it is shown in psi) to Vc = ~c' (in effect, this implies a size effect factor

that neglecting the size effect for beams up to 1 m (40 in.) deep is of 2) (refer to Section 11.4.6.1 in ACI 318-08 9).

likely to increase the expected frequency of failures from approxi-

mately 1 in a million to approximately 1 in a thousand when the

In one test series at the University of Toronto,3.4 a single

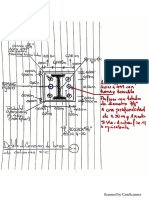

beam depth increases from 0.2 to 1 m (8 to 40 in.). beam was tested for each size; see the diamonds in Fig. l(a),

where d is the effective beam depth (from top face to the

Keywords: deep beams; shear strength; size effect; stirrups. centroid of longitudinal reinforcement at the bottom) and vc

=Vu/bw<J is the nominal shear strength measured (VU is the

INTRODUCTION applied shear force and bw is the beam width). The figure

Although the basic theory of size effect in the shear failure also shows the horizontal line of vc =2Vtc', which represents

of reinforced concrete beams was formulated more than two the nominal strength, that is, the design shear strength, which

decades a 0 and experimental evidence has become over- must exceed the effect of design loads multiplied by their

9

whelming, ,2 the ACI 318 Code has not adopted size effect load factors and divided by the understrength factor $ for

provisions for beams of depths d up to 0.6 m (24 in.) and shear, which is 0.75 according to ACI 318-08.9 The load

even 1 m (40 in.). In support, a recent experiment (Specimen factor is in this figure considered as 1.6, which applies to the

BNl00 at the University of Toront03,4) was invoked, in which live load (refer to a following comment on the combinations of

the strength of such a beam was almost equal to the nominal live and dead loads).

strength required by the Code and was much larger than the Note in Fig. l(a) that all the data points (plotted as diamonds)

strength obtained after applying the understrength (or strength except the last one, that is, all those up to the depth of 1 m

reduction) factor </>. The purpose of this paper is to show (40 in.), lie above the horizontal line of Vc = $ x 2'lfc', where

that such suggestions are unjustified and could likely lead to 2Vtc' is the nominal strength required by the standard ACI

statistically dangerous designs with insufficient safety margins. 318-08. 9 Based on this observation, it has often been

suggested that the size effect need not be taken into account

RESEARCH SIGNIFICANCE for beam depths up to 1 m (40 in.) and that any considerations

The understanding of failure probability is essential for of size effect might simply be avoided by banning beams

improving the design provisions for shear failure of reinforced without stirrups having a depth over I m (40 in.). lithe full

concrete. The importance of this problem is demonstrated by picture is considered, however, it transpires that this suggestion

a number of disasters in which the size effect in shear failure is imprudent, in several respects (note thatfc' is taken as 70%

has recently been shown to have played a role. If the size effect of the required average compressive strengthfcr' from standard

is ignored or not predicted correctly, the failure probability tests, which approximately corresponds to ACI 318-08,9

becomes higher than what the risk analysis experts consider Section 5.3.2.2; the fact that the 70% reduction must be

as acceptable. Because of a trend to larger structures, this is

an issue of paramount significance for concrete engineering.

HOW TO INTERPRET DATABASE FOR SIZE ACI Structural Journal, V. 106, No. I, January-February 2009.

MS No. S-2006-479.R2 received August 22, 2007, and reviewed under Institute

EFFECT IN BEAM SHEAR pUblication policies. Copyright 2009, American Concrete Institute. All rights reserved,

The size effect for beams without stirrups was experimentally including the making of copies unless pennission is obtained from the copyright proprietors.

Pertinent discussion including author's closure, if any, will be published in the November-

demonstrated by KaniS for beams with an effective depth d December 2009 ACI Structural Journal if the discussion is received by July I, 2009.

14 ACI Structural Journal/January-February 2009

Because the laller is the case. the choice ofme pdf type must be

Zd< ... k I'. !Jab nt MCI. I, 'h, MrC"",,,,! I",,,IYI< Pm/usa, "",I W.P. M.rphy

Prof, ,..,, <1 CMI ""gl,.unng altd Ma,uillis Scir",.. 0'

NonhM"<>'"'' Unn~"I,"," empirical. But even if the pdf of scatter originating from

1'0"""". IL 1/. i, a 111'.",,,,1 SJ"",.",1 F-"&u",,, in 1I1i"".,. 1/, ~'" 'h, foil/Itd.,,# material randomness were known. it would apply only to the

CM;, ami;' a ",,,..b,,, <1 /0,,,,~CI.'ISCE C"""","" 4-16. 'ra,:/,," Mr<Mllks <>f

scatter observed in carefully COlUrolied laboratory test series

C"""..". and" """,b", oj ~CJ C_ml",,, 209. C"'f> anJ Sh.u.""r ;n C<nI("" ,.

SIif"'"

jJ8. 5,,,,,,,,,,,,1 "ltd loi'" ACI.... SCIi C"""""'''' JJI. C"",",,5h,lllH#,n such as those conducted at thc Univcrsity of Toronto3A and

lind Co"" ... c<'''''''

US. Sh<o' altd T"rti"" .. "ltd 447. nil". t:/,mtn' ~"al)">" of Nonhwcstcm University8 (refer 10 Fig. I(a) and Fig. I in

R"',jOffrd C(m",,," 5,,,,,,,.,,.. Reference 2. for which the values of the CoY [standard elTor

Q"n~ \"u iI ~ I\j.jJdot:", ..1 R".ntrlt A,,,,,,iau al NO"""""m V";,.. ,..l,y. /I. of regression normalized by data centroid1 are on ly

"c,"'Ni h;s IISfmm Tom Kj; V"i..",j,y. Shangha'. eM"" .. hi' />ISf""" n'"#h"" approximate ly 6.9 and 12%. respectively).

Vnil"<"il}. 8';)lnK. Chi",,: and his !'hl) f""" No"h~..".," V."""i". 1/" , ..",,,h

I"",,,,,, incllUi. fm"o" bt"MI"I<" ~tuI ."...., ,/k<II."""<"" """" 0''''. The crrors of lhe cUlTe m code fOmlU la Vc = 2"-1(/ arc

approximat ely characterized by the scatter seen in thc AC I

445F database20 (Fig. I (b)). which originatcs from male rial

considered in fail ure probability analy sis was establi shed in randomness only 10 a minor ex tenl. Because this formula

detail by Ba~.ant and YulO). muse apply 10 a broad variely of beams used in praccice. lhe

First it sho uld be poi nted oullhal. according 10 lhe theo~ dmabase covers :I wide range of secondary characteristics

now generally accepted in the fracture mechanics community. suc h as the steel ralio. shear-span ralio. and concrete type

beams with Mirrups must also suffer from size effect. albeit (w hich include$ concretc strength. curing environmcnt.

to a lesser edenl. But this issue will beltcr be relegated to u water-ccment ratio. aggreg:lIe-cernelll ratio. ccrnenltype. and

separate stud y. olher mixture proportions). Whil e lhe sea tler of these

Second. severa! kinds of theoretical argu ments based on secondary characleri stic~ is the result of human choices. ic

quasibrittle fracture mech:l11i cs have shown lhat the size roughly reflects lhe range of charact cristic~ occ urrin g in

effect is significanl fo r beam depths from 100 nlln (4 in.) up. pmctice (eve n lhough the dislribUlions of these chamcterislics

This is ev idenced by lhe trend of the data in Fig. I (a). as well in des ign practice might nOt be exactly lhe same as in the

as lhose reponed by other rescarehers.J.8.l2.13 11lis poinl will database. lhere is no beller infonnation co usc).

also be lefl aside because il is atlnly7.ed in depth clsewhcre. t .214 Even if one considered the recently proposed rdincrnent 2

Third. and regardless of lhe previous points. this reasoning in which the effects of the secondary charac teristics such as

is flawed slati stically. The uncenainty in shear of beams of lh e steel ratio. shear-span rmio. and concrele type arc

varying sizes ca nnot be treated as a problem of simple incorporated into lhe fomlU l'l for v(' their represen tat ion

popU!:lIion statistics. Rather. it is n problem of stati stical would be only approximale. wi lh a high degree of uncertai nly.

regression because the data ex hibil a staliSlicaltrend. This is SO. lhe scnller due exclusively to material randomness.

analyzed in the following. exem plified rough ly by the af{lrementioned laboralory !Csts

at the University of Toronto ;md Northwestcrn Univers ity.

WHAT IS STATISTICAL DISTRIBUTION OF SHEAR WOllllt ~t;11 he onl y a minofllart of the ovcral l scalier. This is

STRENGTH OF SMALL BEAMS? revealed by Ihe width of lhe scalier band seen in Fig. 5(b)

While the probability den~ity distribulio n (pdf) of slreng lh through (d) of Reference 2 where the regression does take

scaucrdue to malerial randomnes.~ has recently bccn theoretically lhe secondary characteri stics inlo account. The COY of

established for quasibriltle failures at crac k initiation regression errors in that SC:III!:r band is of the o rder of WI '"

(Type [15-1\ for lhose occulTing after large slab le crack 20%. while the CoY due to material randomness per se is of

growth (Types II or 111 18 19) it still remains unKnown. the order of w2 '" 5 to 10%.

(a) Toronto tests (199B2000) (b) Entire database (c) Portion of database

f~ ", SJ65 psi for small size range

{ in 12 in.

,

" spt.'Cificd compressive

strength

36.4 in.

d(in.) ' 00

Fig. I --{a) Ullil'ersity of Toronto lest~4 of sltear strenglh of beams of I'urious sizes:

(b) ACI 445F (f(llllba.~e of 198 data poims: and (e) pOT/iOIl of lite (fa /abase for

beamsfrolll4 w f2 ill. (JOO to 300 mm) deep (ve' f';. and f[ are ill psi). (Note: ! ill. =

25.4 111111: I MP(I = /45 psi.)

ACI Structural JournaVJanuary-February 2009 15

To make this argument precise, note that if the points of a high value of 0) is a consequence of variability of the

database whose CoY = 0)1 are perturbed by independent secondary characteristics that have nonnegligible influence

random scatter whose Co V = 0)2' then the resulting scatter of on the shear strength.

the perturbed database will have the CoY of 0)3 = (O)? + To determine the appropriate pdf of shear strength for the

O)l)1I2. In the present case, 0)3::::: 20% and 0)2::::: 10%, which small size beams, one can plot the data points from the small

gives 0)1::::: 17.3%. This is only 13% less than 0)3' Obviously, size range as cumulative histograms on various types of

0)2, ensuing from material randomness, has only a minor probability paper. While several methods 23 ,24 to calculate

effect on the overall 0)3, and so its pdf type cannot matter much. the cumulative histogram are used in practice, Gumbel's

To decide which data to use for an empirical basis of the method25 is adopted herein due to clarity of its justification

pdf choice, note that the scatter band in the ACI 445F data- as well as simplicity; the plotting positions are ml(n + 1),

base (Fig. 1(b) with 398 data points 20) has a downward trend where m is the m-th point among the data arranged in the

with respect to depth d (this is also confirmed by the earlier increasing order of normalized shear strength vlYre', and n is

databases of 296 points assembled by Bazant and Kim21 and the total number of 'points in the isolated database.

461 points assembled by Bazant and Sun22 ). The existence Figure 2(a) and (b) shows the cumulative histograms and

of a marked size effect trend becomes even clearer if the their fits by cumulative distribution functions (cdt) in the normal

influences of shear span, steel ratio, and concrete strength are and log-normal probability papers. Now note that the data

taken into account as subsidiary parameters in the regression points fit a straight line on the log-normal probability paper

(refer to Fig. 5 in Reference 2). Therefore, the entire ACI significantly better than they do on the normal probability paper

445F database cannot be treated as a statistical population (for the former, the mean and standard deviation are 3.22 and

from which to identify the pdf of shear strength. 0.895, and for the latter they are 3.22 and 0.885). Also note that

However, if one isolates from the database in Fig. 1 (b) the if the Weibull probability paper were used, the fit of a straight

data in the small size range of depths d ranging from 100 to line would be still worse. Hence, based on the information

300 mm (4 to 12 in.), centered at 200 mm (8 in.) as shown in that exists, a log-normal pdf appears to be the best choice.

Fig. I (c), then the size effect trend is weak enough for The type of pdf for small beams may alternatively be

treating the data as a population with no statistical trend examined by the goodness-of-fit tests. The widely used

(indeed, within this range, the size effect in the Toronto Kolmogorov-Smirnov, or K-S test,26 compares the observed

tests 3,4 causes a strength reduction of only approximately cumulative probability Sn (solid curve) with the assumed

10%). The mean and CoY of this population of data are normal distribution obtained by optimal fit (dashed curve),

found to be = vJ y JJ:'

= 3,2 and 0) = 27%. The relatively and generates a maximum discrepancy Dn = D277 = 0,078

(refer to Fig. 2(c)). This value satisfies the critical value for

4 (a) Normal probability paper 4Jb) Lognormal probability the 5% significance level (D~7o; = 0.081) but exceeds the

paper critical value for the 10% significance level (D~7~O =0.073).

By contrast, the maximum discrepancy for log-normal distribu-

s s tion is D277 = 0.056, which is much less than that observed

in K-S test for normal distribution and satisfies the critical

values for both 5% and 10% significance level (refer to Fig. 2(d)).

Furthermore, the type of pdf for small beams may be

examined by the chi-square test. 2? In this test, one subdivides

(e) K-S test for normal (d) K-S test for Lognormal

10

the range of coordinate vcIYre', which spans from 1.32 to

6.56, into several intervals and compares the frequencies n;

of the small beam data with the assumed frequencies ei for

,"

5"",/ all the intervals in the histogram. Herein, six intervals, labeled

edf edf

0.5 0.5

by 1,2,3,4,5,6, and 7, are considered. They contain 18, 106,

, Normal 107,32, 13, and 1 data points, respectively (referto the histogram

distribution

in Fig. 2(e)). Compared with the frequencies corresponding

Dn = 0.078 Dn = 0.056 to the normal distribution (dashed curve), one obtains L(n;-

eile; = 20.95, which cannot satisfy the critical value Co 953 =

v,/g (e) Chi-square test

v,.ig 7.81 for 5% significance level. On the other hand, L(n; '- eil

0.5 Lognormal e; = 3.45 is obtained for log-normal distribution (solid curve),

distribution which satisfies the critical value for the 5% significance level.

(/)

Ql

The foregoing comparisons demonstrate that the log-

'u

C normal pdf is the best choice for the small beam data from

Q) 0.25

:::>

0'

the ACI 445F database.

~

lL.

WHAT STATISTICAL STRENGTH DISTRIBUTION

MUST BE EXPECTED FOR LARGE BEAMS?

Again, theoretical deductions based on the scatter in one

and the same material l ? are inapplicable because this scatter

Fig. 2-{a) Cumulative histogram 0/ data on normalized beam is overwhelmed by the scatter due to random variability of

shear strength/or small beams extracted/rom the ACI 445F steel ratio, shear span ratio, etc., in the ACI 445F database.

database, plotted on normal probability paper, and their As emphasized by Bazant and Yu,I,2 the database is

straight-line fit; (b) ditto on log-normal probability paper; heteroscedastic in the plot of normalized shear strength vclYrcr'

(c) K-S test/or normal distribution; (d) K-S test/or log-normal (resistance) versus size, but becomes nearly homoscedastic in

distribution; and (e) Chi-square test/or goodness a/fit. the doubly logarithmic plot; in other words, the variance or

16 ACI Structural Journal/January-February 2009

CoY of the data becomes almost independent of the struCture CAN FAILURE PROBABILITY FOR LARGE

size. 2 Furthennore, in view of the aforemen tioned origin of BEAMS BE ALLOWED TO BE GREATER

senner. there is no reason for the type of pd f to change wilh THAN THAT FOR SMALL ONES?

the structure size. Therefore. it is logical 10 assume the pdf of To de termille precisely the conseq ue nces for failure

the normalized shear strength in the ACI445 F database [0 be probability "/ofthe beam, it is necessary to also consider the

log-normal for all the sizes. pdf of!heextreme loads expected to be applied on the structure.

Figure 3(a) shows the same pdf (log-normal. wilh the same which is dcnoted asf(y) To calculate Pf'

a ccnain value of

CoV) superposed on the series of individual [eSL~ of beams the load faclor needs to be considered. he present analysis

of various sizes made al the Univcl"lIity of Toronto. Now. it considers only the lood factor of 1.6. which is applicable to

should be noted Ihm, for the paJ1icul3r Iype of concrele. steel the cases where the live load dom inates. as is the case for

mlio. shear span mlio. elc .. used in the Toronto tesls. the bridge beams up to I m (40 in.) deep (for lood combinations

shear strength value in these tests lies (in the logarithmic wilh a significant dead lood component. for which the

.scaJe)atcertain distance a below the mean ofttle pdf(Fig. 3(a. blended load factor is less th:1Il 1.6. the fa ilure probabilities

Because the width of the scatter band in Fig. I(b) in loga. for both small and large beams would be higher than

rith mic scale does not vary appreciably wit h the beam size. obtained in what follows. but their ratio. which is of main

the same pdf and approximately the same distance II between interest. would be approximately the s:mle).

the pdf mean and the University of Toronto data must be The distribution of thc upplicd extreme loads will be

expected for every beam size d. inchlding the size of d '" considered as log-nomlal (it is debat nble whet her the

925 mm (36.4 in.). for which there is oH ly one data point. aud Gumbel distribu tion might be more rea listic. 211 29 but i(

also the size of 1.89 III (14.4 in.). In other words. if the would mnke little difference for the mlio of probab il ities and

Universi ty of Toronto test for d = 925 mm (J6.4 in.) were would make the calculmion more tedious). The CoV of the

repea ted for ma ny diffcrent types of concrete. stcel nllios. npplied ext reme londs will be considered as 10%.

shear span nL\ios. humidity. and tCJll I)Cmturc conditions. etc .. Under the foregoing (lssull1]llions. and bascd on the under-

one would h:lVe to expect a pdf shifted downward in the strength facler , '" 0.15. the me:H1 of the pdf of extreme

logarithmic scale "I'proximately by the same distance a. as applied loads and funcliollfty) rc presenting this pdf will be

shown in Fig. 3(a).

Instead of a detenninistic shift /I. it would be more realistic to

consider II to be a random variable. To detenlline the mean and

CoV of a. the University of Toronto tests would have to be

repeated at least six times pcr5i7.c. l"hey were not. Nevertheless.

an approximate estimate of the CoV of a can be made. as

shown in Appendix A. Such a more accurJte statistical

estimate. however. gives essentially the same result for

failure probabi lity "/because the CoV of a is far smaller than

the CoV of the d3labase values.

Could the 22 tcst points in the si7.c range 760 \0 1(0) mm (30

to 4(l in.) be used din."Clly \0 dctennine the distance a? No,

because these 22 poims cover only a portion of the entire range

of the influencing parameters of interest and the distribl.uion of

these paramctcrs is very different from thaI in the small size

range. For examplc. the s\L'el ratios in the small si7.c range of the

ACI445F dmabase vary from 0.25% to 6.64%. with the mean of

2.55%. whereas the aforementioned 22 points correspond on

10 d (in.) ,.

(b) FaiItn~

avernge 10 much lighter reinforcemcnt, wilh the steel ratios

varying from 0.14 to 2.1 %. and the mean of 0.96%. A similar Known ,,$l$ta~

discrepancy ex.ists fora/d. 11tcreforc. u~ing the few existing <!at.1

points in this size nUlge would be misleading (yielding for

distallCcllthe v<llue of only 0.01 instead of 0.45).

Now it is inesc~pab l e to rccognize that tile shifted pdf for

,~-

.......

Expeeted res-stance

:;J':' ... : ~;Ji 1

- . J1

d '" 925 nun (36.4 in.) reaches well below the [inc of required

nominal strength 1",. "" 2..Jk ' of y = v,.I..Jfc' '" 2 (whereas the pdf .. .ll :~'i0 J

for the smnll beam runge lies :llm05t entirely above this line). 1', :10 1oIar.s.r.a

This means that if the type of concrete, steel ratio. shear

span. humidity. and temperature conditions used in lhe _q:::;~:::T' 0 ...

", .. 10 1

single University of Toronto test were varied through the

entire range occurring in practice (exemplified by the variation lIisdue " p .

in the small size runge). a large percentage of the beams +-~="~~"'

",,, fIID, and .r. if..

would likely be found to be unsafe.

According to our assumption of log,"onnal pdf and d(in.) ,.

equality of distances I I for 5111311 and large sizes. the proportion of Fig. J-{a) Proixlbilil)' dis/n'bUlion of shear strengll! of

unsafe 925 mm (36.4 in.) deep beams would be approx.imately beams from 4 to 12 ill. (100 10 JOO mill) dee". bused on llie

40%, whereas for small beams 100 to 300 ntm (4 to 12 in.)dcep. ACt 445F tll/woose; (b) dis/ribllliOlr for beams 1 m (40 ill.)

it is only 1.0%. This is not acceptable. A design code knowu 10 dup ilr/uretlfromlJre (/lI/(roost' (v(. f~f ollli f~ are ill psi).

have such an unsafe propcny cannot be acklptcd. (Note: 1 ;'r. '" 25.4 111111: J MPa '" 145 psi.)

AC t Structural JournaVJanuary-February 2009 17

positioned as shown in Fig. 3(b). The failure probability ~ 2. BaZant, Z. P., and Yu, Q., "Designing Against Size Effect on Shear

now be calculated from the well-known reliability integral30- Strength of Reinforced Concrete Beams without Stirrups-II: Verification

and Calibration:' Joumol of Structural Engineering, ASCE, Y. 131, No. 12,

Dec.2oo5,pp.1886-1897.

PI = y(Y)R(y)dy (1) 3. Podgorniak-Stanik, B. A., "The Influence of Concrete Strength,

Distribution of Longitudinal Reinforcement, Amount of Transverse

Reinforcement and Member Size on Shear Strength of Reinforced

where R(y) is the cdf of structural resistance, which is Concrete Members," MASc thesis, Department of Civil Engineering,

University of Toronto, Toronto, ON, Canada, 1998,771 pp.

obtained by integrating the log-normal pdf in Fig. 3(b) and (c). 4. Lubell, A.; Sherwood, T.; Bentz, E.; and Collins, M. P., "Safe Shear

When this integral is evaluated for small beams within the Design of Large, Wide Beams:' Concret~ International, V. 26, No. I, Jan.

range of depths d from 100 to 300 mm (4 to 12 in.) centered 2004, pp. 67~78.

at d =200 mm (8 in.), and also for the large beams of 1 m 5. Kani, G. N. 1., "How Safe Are Our Large Reinforced Concrete

Beams?" ACI JOURNAL, Proceedings V. 58, No.5, May 1967, pp. 591-610.

(40 in.) depth, one obtains the following failure probabilities

6. Iguro, M.; Shioya, T.; Nojiri, Y.; and Akiyama, H., "Experimental

Studies on Shear Strength of Large Reinforced Concrete Beams under

For beams of 200 mm (8 in.) mean depth: Pfr::! 10-6 (2) Uniformly Distributed Load," International Concrete Library of JSCE, No.5

1985, pp. 137-146.

7. Shioya, T., and Akiyama, H., "Application to Design of Size Effect in

For beams of I m (40 in.) depth: Pfr::! 10-3 (3) Reinforced Concrete Structures," Size Effect in Concrete Structures,

Proceedings of the Japan Concrete Institute International Workshop,

H. Mihashi, H. Okamura, and Z. P. BaZant, eds., E&FN Spon, London,

For alternative or more accurate calculations, refer to UK, 1994, pp. 409-416.

Appendixes Band C. The failure probability of 10-6, that is, 8. Bafant, Z. P., and Kazemi, M. T., "Size Effect on Diagonal Shear

Failure of Beams without Stirrups," ACI Structural Journal, V. 88, No.3,

one in a million, which is obtained for small beams, May-June 1991, pp. 268-276.

corresponds to what the risk analysis experts generally 9. ACI Committee 318, "Building Code Requirements for Structural

consider as the maximum acceptable for engineering structures Concrete (ACI 318-08) and Commentary," American Concrete Institute,

in general33-35 because it does not significantly increase the Farmington Hills, MI, 2008, 465 pp.

10. BaZant, Z. P., and Yu, Q., "Reliability, Brittleness and Fringe

inevitable risks that people face anyway. But the probability

Formulas in Concrete Design Codes," Journal of Structural Engineering,

of 10-3 is unacceptable. ASCE, V. 132, No. I, Jan. 2006, pp. 3-12.

Therefore, if the size effect in beam shear were ignored for II. RILEM TC-QFS, "Quasibrittle Fracture Scaling and Size Effect-

beams without stirrups up to 1 m (40 in.) deep, the probability Final Report," Materials and Structures, V. 37, No. 272, 2004, pp. 547-586.

of failure for 1 m (40 in.) depth would be approximately 12. Leonhardt, E, and Walther, R., "Beitriige zur Behandlung der Schub-

probleme in Stahlbetonbau," Beton-und Stahlbetonbau, Berlin, Germany,

1000 times greater than it is for 200 mm (8 in.) depth. This Mar. 1962, pp. 54-64, and June 1962, pp. 141-149.

should not be tolerated. If there should be any difference, it 13. Bhal, N. S., "liber den Einfluss der Balkenh6he auf Schubtragflihigh-

should be in the opposite sense because, for large beams, the keit von einfeldrigen Stalbetonbalken mit und ohne Schubbewehrung,"

failure consequences are usually more serious than for small ones. dissertation, Universitlit Stuttgart, Stuttgart, Germany, 1968.

14. BaZanl, Z. P., and Planas, J., Fracture and Size Effect in Concrete and

Other Quasibrittle Materials, Sections 9.2 and 9.3, CRC Press, London,

CONCLUSIONS UK, 1998.

The main hypothesis of analysis is that, for large beams of 15. BaZant, Z. P., "Probability Distribution of Energetic-Statistical Size

the depth of approximately 1 m (40 in.), which featured in Effect in Quasibrittle Fracture:' Probabilistic Engineering Mechanics, V. 19,

only a few size effect test series, the variations of concrete No.4, 2004, pp. 307-319.

16. Bazant, Z. P., and Pang, S.-D., 2006, "Mechanics Based Statistics

type, steel ratio, and shear span ratio that occur in practice of Failure Risk of Quasibrittle Structures and Size Effect on Safety

would lead to about the same scatter (with the same CoY and Factors," Proceedings of the National Academy of Sciences, V. 103, No. 25,

the same type of probability distribution) as they do for small pp.9434-9439.

beams of approximately 200 mm (8 in.) depth. Under this 17. BaZant, Z. P., and Pang, S.-D., "Activation Energy Based Extreme

hypothesis, the following conclusions can be made: Value Statistics and Size Effect in Brittle and Quasibrittle Fracture,"

Journal of the Mechanics and Physics of Solids, V. 55, 2007, pp. 91-134.

1. If the size effect for beams up to 1 m (40 in.) deep is 18. BaZant, Z. P., "Scaling Theory for Quasibrittle Structural Failure,"

neglected, the percentage of beams whose load capacity is Proceedings of the National Academy of Sciences, V. 101, No. 37, 2004,

less than the nominal strength required by the Code is only pp. 14,000-14,007.

approximately 1.0% for beams of 200 mm (8 in.) depth, but 19. BaZant, Z. P., Scaling of Structural Strength, second edition,

Elsevier, 2005, 336 pp.

increases roughly to 40% for beams of 1 m (40 in.) depth;

20. Reineck, K.-H.; Kuchma, D. A.; Kim, K. S.; and Marx, S., "Shear

2. Failures of beams 1 m (40 in.) deep must be expected to Database for Reinforced Concrete Members without Shear Reinforcement,"

be approximately three orders of magnitude more frequent ACT Structural Journal, V. 100, No.2, Mar.-Apr. 2003, pp. 240-249.

than failures of beams 200 mm (8 in.) deep. From the view- 21. Bazant, Z. P., and Kim, J.-K., "Size Effect in Shear Failure of

point of s~ety, this is unacceptable; and Longitudinally Reinforced Beams," ACI JOURNAL, Proceedings V. 81;

No.5, Sept.-Oct. 1984, pp. 456-468.

3. Design safety requires the size effect to be introduced 22. BaZant, Z. P., and Sun, H.-H., "Size Effect in Diagonal Shear Failure:

into the Code for all beams sizes, including beams less than Influence of Aggregate Size and Stirrups," ACT Materials Journal, V. 84,

1 m (40 in.) deep. No.4, July-Aug. 1987, pp. 259-272.

23. Hazen, A., Flood, Flows, A Study in Frequency and Magnitude, 1. Wiley

& Sons, Inc., New York, 1930.

ACKNOWLEDGMENTS 24. Kimball, B. E, "Assignment of Frequencies to a Completely Ordered

Financial support from the U.S. Department of Transportation through

Set of Sample Data," Transactions, American Geophysical Union, V. 27,

the Infrastructure Technology Institute of Northwestern University under

1946, pp. 843-846.

Grant No. 0740-357-A210 is gratefully acknowledged.

25. Gumbel, E. J., "Statistical Theory of Extreme Values and Some

Practical Applications," Applied Mathematics Series 33, National Bureau

REFERENCES of Standards, Washington, DC, 1954,51 pp.

1. BaZant, Z. P., and Yu, Q., "Designing Against Size Effect on Shear Strength 26. Chakravarti, I. M.; Laha, R. G.; and Roy, J., Handbook of Methods of

of Reinforced Concrete Beams without Stinups--I: Formulation," Journal of Applied Statistics-Techniques of Computation, Descriptive Methods, and

StructuralEngineering,ASCE, y. 131, No. 12,Dec.2005,pp. 1877-1885. Statistical Tnference, V. I, John Wiley and Sons, 1967, pp. 392-394.

18 ACI Structural Journal/January-February 2009

27. Snedecor, G. w., and Cochran, W. G., Statistical Methods, eighth For the ACI 445F database, the CoY (rox) for large sizes

edition, Iowa State University Press, 1989,503 pp. may be estimated from the 22 test points falling in the size

28. Cook, N. J., ''Towards Better Estimates of Extreme Winds," Interna-

tional Journal of Wind Engineering and Industrial Aerodynamics, V. 9,

range of 760 to 1000 nun (30 to 40 in.). This gives rox =

1982, pp. 295-323. 27.9% and is almost the same as rox for the small size range.

29. Naess, A., "Estimation of Long Return Period Design Values for This confirms that the scatter band width in the logarithmic

Wmd Speed:' Journal ofEngineering Mechanics, V. 124, 1998, pp. 252-259. plot does not change significantly with the size.

30. Ang, A. H.-S., and Tang, W. H., Probability Concepts in Engineering The predicted resistance distribution p('l!) for d ::= 1 m,

Planning and Design- Decision, Risk and Reliability, V. II, J. Wiley, New

sketched in Fig. 3, is obtained as the distribution of Z =X -

York, 1984,272 pp.

31.'Madsen, H. 0.; Krenk, S.; and Lind, N. C., Methods of Structural

a + constant, in which the CoY of shift a is the same as roy.

Safety, Prentice Hall, Englewood Cliffs, NJ, 1986, 403 pp. Thus the CoV of Z may be estimated as

32. Haldar, A., and Mahadevan, S., Probability, Reliability and Statistical

Methods in Engineering Design, J. Wiley & Sons, New York, 1999,320 pp.

33. Nordic Committee for Building Structures, "Recommendation for Loading ro z = Jroi + ro~ = J27.9 2 + 7 2 = 28.8% (A-I)

and Safety Regulations for Structural Design;' NKB Report No. 36, 1978.

34. Melchers, R. E., Structural Reliability, Analysis and Prediction,

Wiley, New York, 1987,456 pp. (this value is exact only for normal distributions 32).

35. Duckett, W., "Risk Analysis and the Acceptable Probability of Compared with 27.9%, 28.8% represents an insignificant

Failure," The Structural Engineer, Aug. 2005, pp. 25-26. correction that will not appreciably affect the estimate Pf ::=

36. BaZant, Z. P., "Size Effect in Blunt Fracture: Concrete, Rock, Metal," 10-3 made under the assumption of a deterministic shift a.

Journal of Engineering Mechanics, ASCE, V. 1l0, 1984, pp. 518-535.

37. Bentz, E. C., and Buckley, S., "Repeating a Classic Test of Experiments

on Size Effect in Shear of Members without Stirrups," ACI Structural

APPENDIX B-ALTERNATIVE EQUIVALENT

Journal, V. 102, No.6, Nov.-Dec. 2005, pp. 832-838. CALCULATION OF FAILURE PROBABILITIES

38. Kazemi, M. T., and Broujerdian, V., discussion of "Repeating a Because both the load L and structural resistance R are

Classic Test of Experiments on Size Effect in Shear of Members without assumed to be log-normal (and statistically independent), the

Stirrups," by E. C. Bentz and S. Buckley, ACI Structural Journal, V. 103, failure probabilities in Eq. (2) and (3) would be obtained

No.5, Sept.-Oct. 2006, pp. 757-758. upon assuming the stochastic variable Z = In(RIL) to be

39. Yu, Q., and BaZant, Z. P., discussion of "Repeating a Classic Set of

Experiments on Size Effect in Shear of Members without Stirrups," by

Gaussian. Then the mean and the standard deviation of Z are32

E. C. Bentz and S. Buckley, ACI Structural Journal, V. 103, No.5, Sept.-

Oct. 2006, pp. 756-757.

(B-1)

APPENDIX A-EFFECT OF

UNCERTAINTY IN SHIFT 8 Herein, A. and ~ are the parameters of the log-normal

The values of resistance Y =

vJ'lfc' measured in the distribution for resistance (that is, of vc) and the load,

University of Toronto tests (Fig. 1) represent realizations of respectively. They both have the form

a random variable Y characterized by a certain probability

distribution py(Y). The CoY (roy) is due to the scatter of 1

material properties of one and the same concrete and the

f(x) = __ e-(lnx-A) /2~

2 2

(O$x<oo) (B-2)

same test conditions. The scatter of the database points is J2itx[,

represented by random variable X =vcl'ifc', characterized by

distribution Px(X) with a CoY (rox), which mainly reflects where x stands for either the load or the resistance. Then the

the effects of random variation of the type oit:oncrete, steel failure probability is Pf =Prob(Z < 0). Using, for example, a

ratio, and shear span, and dwarfs roy. table of the error function, one readily finds again that Pffor

Although the five data points from the University of 200 mm (8 in.) deep beams is 10-6 and Pf for 1 m (40 in.)

Toronto tests at different sizes (Fig. 1) represent only a single deep beams is 10-3.

test per size, the CoY (roy) may be estimated from the standard

error of regression of these five data points, obtained by APPENDIX C-MORE ACCURATE CALCULATION

optimally fitting them with Bazant' s36 size effect law. The OF RISK OF DESIGN FORMULA

result is ro ::= 7%. This estimate gives an overall measure of A more precise calculation of failure probability Pf would

scatter for all the sizes. But it may be taken as a rough estimate require distinguishing among several probability density

of roy for d::= 1 m (40 in.) because roy does not appear to vary functions 10, 15: 1) distribution of the applied load, PL(ve ), or

significantly with the size. the distribution of shear strength vc considered as a load

parameter; 2) distribution Pa(a) due to variations of shear

Another estimate can be based on the reduced-scale size

span ratio a = aid used in practice; 3) distribution PS<p) due

effect tests at Northwestern University,8 in which three

to variations of longitudinal steel ratios used in practice;

geometrit.:ally similar beams, made with aggregate of

4) distribution Pv(v c') of Vc due to random variation of

maximum size 4.8 mm (0.19 in.), were tested for each of the

strength fe' of all the concretes used in practice; and 5) distri-

five sizes, spanning the size range of 1:16. The CoY for the

bution Pe( e) of the errors of the design formula. If these

subsequent sizes were 6,7,8,6, and 8%. This again gives the

distributions are assumed to be independent, then

mean value of 7%.

Bentz and Buckley37 conducted partly similar tests, with

normal aggregate size, but with the size range of only 1:4 Pf ;; HHf PL(vJpu(u)p,(p)p,(v/)p,(e)dedpdv/dadv, (C-l)

(refer also to discussions 38 ,39). They tested several specimens L>R

for each size. The CoY was 10.7% for d = 82 mm (3.3 in.),

2.76% for d = 168 mm (6.6 in.) and 2.65% for d =333 mm At present, however, such calculations cannot be meanIng-

(13.1 in.). According to these tests, the value roy::= 7% for fully carried out because the required probability distribution

d::= 1 m (40 in.) is a conservative high estimate. functions are unavailable.

ACI Structural Journal/January-February 2009 19

También podría gustarte

- ACI 446 Code Provisions For Shear DesignDocumento11 páginasACI 446 Code Provisions For Shear Designtrabajosic0% (1)

- Problems 4012 PDFDocumento8 páginasProblems 4012 PDFjonthemesAún no hay calificaciones

- Effects of Fracture Area Measurement Method and Tension Test Specimen Type On Fracture Strain Values of 980 Class AHSSDocumento11 páginasEffects of Fracture Area Measurement Method and Tension Test Specimen Type On Fracture Strain Values of 980 Class AHSSHenrique SeverianoAún no hay calificaciones

- Validity Requirement For The CNT Small Specimen Testing Procedure To Evaluate Fracture ToughnessDocumento6 páginasValidity Requirement For The CNT Small Specimen Testing Procedure To Evaluate Fracture ToughnessaliAún no hay calificaciones

- Effect of Concrete Strength and Minimum Stirrups On Shear Strength of Large MembersDocumento11 páginasEffect of Concrete Strength and Minimum Stirrups On Shear Strength of Large MembersAllie BloxdorfAún no hay calificaciones

- Fatigue Performance of Laser Beam Welded A36 SteelDocumento3 páginasFatigue Performance of Laser Beam Welded A36 SteelDaniel VenturiAún no hay calificaciones

- Design of Large Footings For One Way ShearDocumento8 páginasDesign of Large Footings For One Way ShearAsad SohailAún no hay calificaciones

- Defect Types and Non-Destructive Testing Techniques For Composites and Bonded JointsDocumento19 páginasDefect Types and Non-Destructive Testing Techniques For Composites and Bonded JointsShanker PandeyAún no hay calificaciones

- Abstract Dent and Gouge Defects Assessment A Case Study of Gas PipelineDocumento10 páginasAbstract Dent and Gouge Defects Assessment A Case Study of Gas PipelineTzu Huan PengAún no hay calificaciones

- Elastic Stability of Thin - Walled Cylindrical and Conical Shells Under Axial CompressionDocumento10 páginasElastic Stability of Thin - Walled Cylindrical and Conical Shells Under Axial CompressionChandra PrakashAún no hay calificaciones

- Size Effect On Shear Strength of RC Beams Using HSC Without Shear ReinforcementDocumento16 páginasSize Effect On Shear Strength of RC Beams Using HSC Without Shear ReinforcementHuda JawadAún no hay calificaciones

- Punching of Concrete Slabs Without Shear Reinforcement - GuandaliniDocumento9 páginasPunching of Concrete Slabs Without Shear Reinforcement - GuandaliniAnonymous YAHRBwSYnAún no hay calificaciones

- Birkle, Dilger - 2008Documento9 páginasBirkle, Dilger - 2008David VillalobosAún no hay calificaciones

- Minimum Reinforcement in RC BeamsDocumento7 páginasMinimum Reinforcement in RC BeamsNguyen KhoiAún no hay calificaciones

- Shear Behavior of Thick Slabs-ACIDocumento12 páginasShear Behavior of Thick Slabs-ACIJoão Paulo MendesAún no hay calificaciones

- Spe68420 CT FracDocumento12 páginasSpe68420 CT FracizzybjAún no hay calificaciones

- Effect of Bridges' Width On Optimum Design of Steel Bridges: Firas Ismael Salman, Abdul Muttalib Issa SaidDocumento7 páginasEffect of Bridges' Width On Optimum Design of Steel Bridges: Firas Ismael Salman, Abdul Muttalib Issa SaidyhszaAún no hay calificaciones

- Serviceability and Crack Control in Reinforced ConcreteDocumento9 páginasServiceability and Crack Control in Reinforced Concretebig_one214Aún no hay calificaciones

- Baterlle Two CurveDocumento20 páginasBaterlle Two CurveAdam ThomsonAún no hay calificaciones

- Shear Strength in The New Eurocode 2. A Step ForwardDocumento10 páginasShear Strength in The New Eurocode 2. A Step ForwardChineseAssassinAún no hay calificaciones

- Design of ACI-type Punching Shear Reinforcement To Eurocode 2Documento15 páginasDesign of ACI-type Punching Shear Reinforcement To Eurocode 2ephremAún no hay calificaciones

- Prediction of Maximum Crack Width Formula For RCC Flexural MemberDocumento5 páginasPrediction of Maximum Crack Width Formula For RCC Flexural Membersurajitkundu2002Aún no hay calificaciones

- Fragmentation Study of Interfacial Shear Strength of Single Sic Fiber Reinforced Al After FatigueDocumento8 páginasFragmentation Study of Interfacial Shear Strength of Single Sic Fiber Reinforced Al After FatigueSai SaiAún no hay calificaciones

- Investigation of The Size Effect in Shear of Steel Fiber Reinforced Concrete (SFRC) Slender BeamsDocumento8 páginasInvestigation of The Size Effect in Shear of Steel Fiber Reinforced Concrete (SFRC) Slender Beamsalbertofer123Aún no hay calificaciones

- Determination of True Stress Strain CharacteristicDocumento9 páginasDetermination of True Stress Strain CharacteristicEng Hinji RudgeAún no hay calificaciones

- Acoustic Induced VibrationDocumento6 páginasAcoustic Induced VibrationFelix AlorAún no hay calificaciones

- Numerical Modelling of Large Scale Steel Fibre Reinforcedreinforced Concrete Beams Failing in ShearDocumento11 páginasNumerical Modelling of Large Scale Steel Fibre Reinforcedreinforced Concrete Beams Failing in ShearChris LumyAún no hay calificaciones

- Fatigue and Fracture Assessment of Cracks in Steel Elements Using AEDocumento12 páginasFatigue and Fracture Assessment of Cracks in Steel Elements Using AEОлег ПервейталовAún no hay calificaciones

- Shear Tests On Hollowcore Slabs FinalDocumento22 páginasShear Tests On Hollowcore Slabs FinaljcvalenciaAún no hay calificaciones

- Reinforced High-Strength Concrete Beams in FlexureDocumento11 páginasReinforced High-Strength Concrete Beams in FlexureAndrei IancuAún no hay calificaciones

- VrubfirbDocumento8 páginasVrubfirb9245126694Aún no hay calificaciones

- ACI 232-3 Punching ShearDocumento18 páginasACI 232-3 Punching ShearRandy MillerAún no hay calificaciones

- BMT LAB NEW Final111111 PDFDocumento85 páginasBMT LAB NEW Final111111 PDFmohanAún no hay calificaciones

- Analysis of Simple StressesDocumento39 páginasAnalysis of Simple StressesEduCartAún no hay calificaciones

- Bearing Capacity of Partially Loaded Concrete ElemDocumento9 páginasBearing Capacity of Partially Loaded Concrete ElemJuraj031Aún no hay calificaciones

- 2010 Confinement of Deep Beam Nodal RegionsDocumento9 páginas2010 Confinement of Deep Beam Nodal RegionsKhAún no hay calificaciones

- Prestressed Concrete Girder Bridges Using Large 0.7 Inch StrandsDocumento8 páginasPrestressed Concrete Girder Bridges Using Large 0.7 Inch Strandsmonolith80Aún no hay calificaciones

- Critique of Critical Shear Crack Theory For Fib Model Code Articles On Shear Strength and Size Effect of Reinforced Concrete BeamsDocumento13 páginasCritique of Critical Shear Crack Theory For Fib Model Code Articles On Shear Strength and Size Effect of Reinforced Concrete Beamskrishnarao krishnarao329Aún no hay calificaciones

- Review of Maximum Punching Capacity of Slabs Reinforced With ShearailDocumento23 páginasReview of Maximum Punching Capacity of Slabs Reinforced With ShearailMatthew WoodAún no hay calificaciones

- Research Paper: Gowri Shankar WURITI, Somnath Chattopadhyaya, Grzegorz KROLCZYKDocumento11 páginasResearch Paper: Gowri Shankar WURITI, Somnath Chattopadhyaya, Grzegorz KROLCZYKMalolan VasudevanAún no hay calificaciones

- A New Model For Joint Shear Failure of Reinforced Concrete Interior Beam-To-Column JointDocumento30 páginasA New Model For Joint Shear Failure of Reinforced Concrete Interior Beam-To-Column JointMarimuthu KaliyamoorthyAún no hay calificaciones

- Punching Shear Strength of Slabs and Influence of Low Reinforcement RatioDocumento40 páginasPunching Shear Strength of Slabs and Influence of Low Reinforcement RatioThai DamAún no hay calificaciones

- Evolution of Residual Stresses With Fatigue Crack Growth in A Variable Polarity Plasma Arc-Welded Aluminum Alloy Compact Tension SpecimenDocumento8 páginasEvolution of Residual Stresses With Fatigue Crack Growth in A Variable Polarity Plasma Arc-Welded Aluminum Alloy Compact Tension Specimenbahman.samadiAún no hay calificaciones

- Formulating Constitutive Stress-Strain Relations For Flexural Design of Ultra-High-Performance Fiber-Reinforced ConcreteDocumento9 páginasFormulating Constitutive Stress-Strain Relations For Flexural Design of Ultra-High-Performance Fiber-Reinforced ConcreteShah Zaib FarooqAún no hay calificaciones

- One-Way Shear Strength of Thick Slabs and Wide BeamsDocumento9 páginasOne-Way Shear Strength of Thick Slabs and Wide BeamsWasin WaiyasusriAún no hay calificaciones

- Design of RC Beams With OpeningsDocumento8 páginasDesign of RC Beams With OpeningsVatsal GokaniAún no hay calificaciones

- M 004 ExercisesDocumento33 páginasM 004 ExercisesKannan MuthusamyAún no hay calificaciones

- Romualdi 1964Documento16 páginasRomualdi 1964Isabela LauferAún no hay calificaciones

- AWS Fatigue Strength Lee06 01Documento5 páginasAWS Fatigue Strength Lee06 01Jorge Ayala BacaAún no hay calificaciones

- Oliver Equation Paper-1928Documento38 páginasOliver Equation Paper-1928dps32100% (1)

- 2015 - Prestressed Walls PDFDocumento11 páginas2015 - Prestressed Walls PDFFiras DiknashAún no hay calificaciones

- Powell (1983) - Ductile Anchor Bolts For Tall ChimneysDocumento11 páginasPowell (1983) - Ductile Anchor Bolts For Tall Chimneystimur sibaevAún no hay calificaciones

- The New Penstock For The High Head Hydropower Plant KaunertalDocumento9 páginasThe New Penstock For The High Head Hydropower Plant KaunertalStalyn SimbañaAún no hay calificaciones

- Punching Shear Strength of Reinforced Concrete Slabs Without Transverse Reinforcement by Aurelio Muttoni PDFDocumento16 páginasPunching Shear Strength of Reinforced Concrete Slabs Without Transverse Reinforcement by Aurelio Muttoni PDFNuttawuit BigGyAún no hay calificaciones

- Shielding of Electromagnetic Waves: Theory and PracticeDe EverandShielding of Electromagnetic Waves: Theory and PracticeAún no hay calificaciones

- Reinforced Concrete Buildings: Behavior and DesignDe EverandReinforced Concrete Buildings: Behavior and DesignCalificación: 5 de 5 estrellas5/5 (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryDe EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryAún no hay calificaciones

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingDe EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghAún no hay calificaciones

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDe EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceAún no hay calificaciones

- Proposed Dwelling and 2nd Dwelling Floor PlanDocumento1 páginaProposed Dwelling and 2nd Dwelling Floor PlanVitelio PinzonAún no hay calificaciones

- Designers' Guide To EN 1994-1-1 Composite Steel and ConcreteDocumento235 páginasDesigners' Guide To EN 1994-1-1 Composite Steel and ConcreteLuis Sequeira100% (5)

- Harry: Subject: Gagage Cad Date: February 8, 2023 at 4:36:54 PM ESTDocumento1 páginaHarry: Subject: Gagage Cad Date: February 8, 2023 at 4:36:54 PM ESTVitelio PinzonAún no hay calificaciones

- Erf 3111 Mdantsane 1 of 4Documento1 páginaErf 3111 Mdantsane 1 of 4Vitelio PinzonAún no hay calificaciones

- D FromExp Holmberg July09Documento2 páginasD FromExp Holmberg July09Mongkol JirawacharadetAún no hay calificaciones

- Sdi Ansi NC 2010Documento15 páginasSdi Ansi NC 2010Vitelio PinzonAún no hay calificaciones

- NuevoDocumento 2019-04-23 14.10.26Documento1 páginaNuevoDocumento 2019-04-23 14.10.26Vitelio PinzonAún no hay calificaciones

- Architectural floor plan and elevation drawingsDocumento1 páginaArchitectural floor plan and elevation drawingsVitelio PinzonAún no hay calificaciones

- CD FCorrección Placa BaseDocumento1 páginaCD FCorrección Placa BaseVitelio PinzonAún no hay calificaciones

- SDI Design Aid PDFDocumento6 páginasSDI Design Aid PDFgks6043Aún no hay calificaciones

- Wyckoff Schematics - Visual Templates For Market Timing DecisionsDocumento6 páginasWyckoff Schematics - Visual Templates For Market Timing DecisionssgsgAún no hay calificaciones

- 22218i00601 PDFDocumento1 página22218i00601 PDFVitelio PinzonAún no hay calificaciones

- Check de Capacidad de Pernos Cancha MultiusosDocumento1 páginaCheck de Capacidad de Pernos Cancha MultiusosVitelio PinzonAún no hay calificaciones

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocumento1 páginaYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterVitelio PinzonAún no hay calificaciones

- 481 PDFDocumento6 páginas481 PDFVitelio PinzonAún no hay calificaciones

- 481 PDFDocumento6 páginas481 PDFVitelio PinzonAún no hay calificaciones

- Ultra Precision NTC Epoxy Coated Thermistors with 0.1°C and 0.2°C AccuracyDocumento14 páginasUltra Precision NTC Epoxy Coated Thermistors with 0.1°C and 0.2°C AccuracyVitelio PinzonAún no hay calificaciones

- Reunión de Coordinación Diaria. 10.01.17Documento1 páginaReunión de Coordinación Diaria. 10.01.17Vitelio PinzonAún no hay calificaciones

- UbicacionDocumento1 páginaUbicacionVitelio PinzonAún no hay calificaciones

- Estimate Concrete Strength Using Maturity MethodsDocumento2 páginasEstimate Concrete Strength Using Maturity MethodsRV Vimal100% (1)

- Pile Foundation DesignDocumento82 páginasPile Foundation Designcuongnguyen89% (28)

- C StrucPerformance Gerges June12Documento8 páginasC StrucPerformance Gerges June12Vitelio PinzonAún no hay calificaciones

- Fema 350 - Recommended Seismic Design Criteria For New Steel Moment Frame BuildingsDocumento221 páginasFema 350 - Recommended Seismic Design Criteria For New Steel Moment Frame BuildingsJuan Abdel Ortegon Esparza100% (1)

- A How-To Approach to Modeling Initial Imperfections with Notional LoadsDocumento4 páginasA How-To Approach to Modeling Initial Imperfections with Notional Loadsundf25Aún no hay calificaciones

- 014732Documento208 páginas014732Vitelio PinzonAún no hay calificaciones

- Maryland: Design Guide MD #2 Circular Concrete Storage Facilities For Storage of Animal WasteDocumento36 páginasMaryland: Design Guide MD #2 Circular Concrete Storage Facilities For Storage of Animal WasteDiego Huaman RojasAún no hay calificaciones

- Atc 40Documento346 páginasAtc 40AZ31486% (7)

- MLX90614Documento2 páginasMLX90614sherckuithoAún no hay calificaciones

- A185 06e1Documento6 páginasA185 06e1Vitelio PinzonAún no hay calificaciones

- Bishops Homily - Pentecost SundayDocumento18 páginasBishops Homily - Pentecost SundayMinnie AgdeppaAún no hay calificaciones

- MCT Observation Feedback Salama Mohamed 2Documento2 páginasMCT Observation Feedback Salama Mohamed 2api-382182406Aún no hay calificaciones

- Life Span Development Notes-Chapter 4Documento13 páginasLife Span Development Notes-Chapter 4Kayelita Wu100% (1)

- Vector QuantizationDocumento6 páginasVector QuantizationnavyaraviAún no hay calificaciones

- Text Image Relations Picture BooksDocumento6 páginasText Image Relations Picture Booksjoygmail100% (1)

- JUDAISM Group1 11 Humss3Documento52 páginasJUDAISM Group1 11 Humss3Kurtt TyroneAún no hay calificaciones

- Problem/challenge/misconception: Topic: Approach: Method: StrategyDocumento10 páginasProblem/challenge/misconception: Topic: Approach: Method: StrategysukriAún no hay calificaciones

- Project Proposal E DynamicsDocumento25 páginasProject Proposal E DynamicsRavi Teja ChillaraAún no hay calificaciones

- The Lives of Animals by J.M. CoetzeeDocumento8 páginasThe Lives of Animals by J.M. CoetzeeBhadra GopanAún no hay calificaciones

- AshishDocumento2 páginasAshishAshish SharmaAún no hay calificaciones

- Nationalism and Two Nation Theory ExplainedDocumento5 páginasNationalism and Two Nation Theory ExplainedMuhammadAxadKhataabGujjarAún no hay calificaciones

- Course OutlineDocumento11 páginasCourse Outlinedktravels85Aún no hay calificaciones

- Ecclesiastes WibrayDocumento48 páginasEcclesiastes WibrayManuel Hernan Sanchez Chavez0% (1)

- Tutorial 2Documento4 páginasTutorial 2Chong Sing0% (2)

- Your Kingdom Come: The Doctrine of Eschatology - Lesson 4 - Study GuideDocumento27 páginasYour Kingdom Come: The Doctrine of Eschatology - Lesson 4 - Study GuideThird Millennium MinistriesAún no hay calificaciones

- Power of English Phrasal VerbsDocumento15 páginasPower of English Phrasal VerbsLearn English Online86% (7)

- Governess Penelope and A DukeDocumento110 páginasGoverness Penelope and A DukeJorge Ariel Vásquez BenalcázarAún no hay calificaciones

- Leonardo MercadoDocumento1 páginaLeonardo Mercadoemmanuel esmillaAún no hay calificaciones

- Determiners With Countable and Uncountable NounsDocumento11 páginasDeterminers With Countable and Uncountable NounsDhiman Nath100% (1)

- Wendy Rulnick Real Estate Broker TestimonialsDocumento10 páginasWendy Rulnick Real Estate Broker TestimonialsWendy RulnickAún no hay calificaciones

- 112 GalanterDocumento7 páginas112 GalanterRafaela Teixeira De OliveiraAún no hay calificaciones

- Understanding The Self Lesson 1-7Documento19 páginasUnderstanding The Self Lesson 1-7Gaille Go100% (1)

- A Dynamic Theory of Organizational Knowledge Creation: Ikujiro NonakaDocumento25 páginasA Dynamic Theory of Organizational Knowledge Creation: Ikujiro NonakaDenton ColeAún no hay calificaciones

- Multiculturalism and Its Issues: "Life Is Plurality, Death Is Uniformity."Documento7 páginasMulticulturalism and Its Issues: "Life Is Plurality, Death Is Uniformity."Mihaela OlaruAún no hay calificaciones

- Montesquieu's Influence on the Doctrine of Separation of PowersDocumento24 páginasMontesquieu's Influence on the Doctrine of Separation of PowersRewant MehraAún no hay calificaciones

- Academe Industry Partnership in The Phil PDFDocumento21 páginasAcademe Industry Partnership in The Phil PDFCharmaine ShaninaAún no hay calificaciones

- Lesson Plan APA...Documento4 páginasLesson Plan APA...cess auAún no hay calificaciones

- Sensory DeprivationDocumento10 páginasSensory DeprivationAnusha VergheseAún no hay calificaciones

- Figures of Speech ExplainedDocumento7 páginasFigures of Speech ExplainedRodel Bryan Coronejo Valdez100% (1)

- Unilateral Divorce in Muslim Law An Unjust Towards Women Body PartDocumento42 páginasUnilateral Divorce in Muslim Law An Unjust Towards Women Body PartSharifMahmudAún no hay calificaciones