Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Bored Pile QC Flow Chart

Cargado por

Chung Yiung YungDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Bored Pile QC Flow Chart

Cargado por

Chung Yiung YungCopyright:

Formatos disponibles

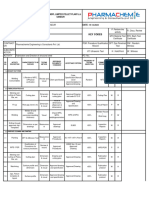

<Company> Approved by: Checked by: Prepared by: Revision:

Rev Date Remark

QC Flow Chart <Project>

- Bored Pile <Name> <Name> <Name>

<Position> <Position> <Position>

Client

No. Flow of Activities Checking Points Acceptance Criteria* Checking Method Reference Frequency Record MRCB Subcon Remark

Rep

1. Boundary survey As per drawing received from Client Theodolite Consultant survey Before Piling Survey drawing W I PM, Surveyor - Licensed Surveyor

setting out dwg.

Preparation

Underground services No UG services/ UG services diverted/ Visual/ theodolite UG services mapping Before Piling Survey drawing - I Surveyor, CM - Licensed Surveyor

mapped dwg.

Gridline setting out As per architect drawing Visual/ theodolite Consultant survey Before Piling Survey drawing W I Surveyor, CM - Licensed Surveyor

setting out dwg.

Dilapidation survey Completed (if required) Visual Specification Before Piling Dilap. Survey report W I PM, CM - Licensed Loss Adjuster

Piling machine platform Firm ground. Provide steel plate if required Visual - Before Piling - - I CM I

Drilling fluid Approved by Consultant Visual Specification Before Piling Approved calculation, A I QC I

brochure, etc.

Concrete Design Mix Approved by Consultant Visual Specification Every concrete grade Approved design mix A I QC I

Grade: _____

Concrete Trial Mix Done, approved by Consultant Visual, plant visit Specification Every concrete grade Trial mix result - slump, A I QC I

& conducted 28 days cube test, etc.

before 1st casting

2. Rebar condition No rust scale, correct strength Visual, mill cert Drawing/ Specification Every delivery DO W I Supervisor I

Material Receiving Rebar testing Pass test (bend, re-bend, tensile) Rebar tests at 3rd Drawing/ Specification 1 test every ____ ton Test report W I Supervisor I

Rebar storage yard Lean con, elevated from ground party

Visuallab - All - - I Supervisor -

Stabilizing fluid Viscosity: _________ Mash Funnel Test Drawing/ Specification Every delivery Test report W I QC, Supervisor I

PH: ________

Density: __________

Fluid loss: _________

Steel casing Uniform section, not dented/ damaged Measuring tape Approved MS/ steel Every delivery Inspection checklist W I Supervisor I

Inner diameter: ________ mm casing calculation

Wall thickness: ________ mm

Hoisting hole location and design

3. Main rebar size & nos. As per construction drawing Visual, measuring tape Construction dwg Every rebar cage Inspection checklist W I Supervisor I

Rebar Cage Rebar cage length As per construction drawing Measuring tape Construction dwg Every rebar cage Inspection checklist W I Supervisor I

Fabrication

Cage diameter Correct diameter as per construction drawing Measuring tape Construction dwg Every rebar cage Inspection checklist W I Supervisor I

Spiral link size & spacing Size: ______ Measuring tape Construction dwg Every rebar cage Inspection checklist W I Supervisor I

Spacing : _______ mm 10mm

Additional reinforcement to prevent cage from

Concrete cover spacer distorting

Outer diameter: ______ mm Measuring tape Construction dwg Every rebar cage Inspection checklist W I Supervisor I

Inner diameter: _____ mm

Spacing: 3m c/c

Lapping Lapping length: ____ D 10mm Measuring tape Construction dwg Every rebar cage Inspection checklist W I Supervisor I

Correct lapping location

Welding At top 1000mm for hoisting Measuring tape Approved MS Every rebar cage Inspection checklist W I Supervisor I

Use sacrificial rebar for other location

4. Center of Pile Center of Pile 10mm Theodolite, measuring Approved shopdwg Every point Inspection checklist W I Surveyor I

Setting Out Pile tape

Position Offset point at X and Y direction Theodolite, measuring Approved shopdwg Every point Inspection checklist W I Surveyor I

tape

5. Conditions Not dented/ damaged Visual - Every point Inspection checklist W I Supervisor I

Install Steel Casing Size Diameter: _____ mm Measuring tape Approved MS Every point Inspection checklist W I Supervisor I

Length: _______ m

Position (setting-out) - Offset Center of Pile 10mm Theodolite, measuring Approved shopdwg Every point Inspection checklist W I Surveyor I

position tape

Verticality 1/____ Theodolite, vertical Approved MS Every point Inspection checklist W I Supervisor I

plumb

Casing top level RL ________ or ______ mm above ground Level instrument, Approved MS Every point Inspection checklist W I Supervisor I

level measuring tape

6. Auger/ bucket size Correct size - as per bored pile diameter Measuring tape Approved MS Every point Inspection checklist W I Supervisor I

Verticality 1/____ Theodolite, vertical Approved MS Every point Inspection checklist W I Supervisor I

Drilling

plumb

Soil profile Record depth at changes in soil profile Visual, sample SI report Change in soil profile Inspection checklist W I Supervisor I Keep soil sample

Pile depth (initial) Min depth as per drawing Measuring tape Approved shopdwg Every point Inspection checklist W I Supervisor I

Pile toe (bottom of pile) Clean from sediment/ loose soil, correct soil Visual SI report Every point Inspection checklist W I Supervisor I Clean using cleaning bucket

type as per SI

7. Properties Viscosity: _________ Mash Funnel Test Drawing/ Specification Before use Test report W I Supervisor I

Pump in Stabilizing PH: ________

Fluid Density: __________

Fluid loss: _________

Volume Min 2 x bored pile volume Visual Approved MS Before use - - I Supervisor I

Soil embankment in place 500mm from ground level Visual Approved MS Before use - I Supervisor I To retain fluid during drilling

Top of stabilizing fluid level 1.5m from top of casing or 1m from ground Measuring tape Approved MS Every bucket pull out Inspection checklist W I Supervisor I

level during drilling

8. Sediment thickness (30 mins _____ mm Measuring tape Drawing/ Specification Every point Inspection checklist W I Supervisor I

Sediment Check 1

after complete drilling)

9. Final cleaning Pile toe clean of sediment Visual Approved MS Every point Inspection checklist W I Supervisor I

Final Cleaning

Pile depth (final) Min depth as per drawing Measuring tape Approved shopdwg Every point Inspection checklist W I Supervisor I

10. Rebar size, spacing, etc. Correct rebar cage for the particular bored hole Measuring tape Construction dwg Every rebar cage Inspection checklist W I Supervisor I

Concrete cover spacer Available at 3m c/c and not damaged Measuring tape Construction dwg Every rebar cage Inspection checklist W I Supervisor I

Install Rebar Cage

Rebar cage condition Not distorted, additional reinforcement added to Visual - Every rebar cage Inspection checklist W I Supervisor I

prevent cage from being distorted

Verticality 1/____ Theodolite, vertical Approved MS Every point Inspection checklist W I Supervisor I

plumb

Top of rebar cage level Top level +50mm/ -0mm Level instrument Approved shopdwg Every point Inspection checklist W I Supervisor I Take note top of rebar level

will be different for test pile

11. Sediment thickness (after install _____ mm Measuring tape Drawing/ Specification Every point Inspection checklist W I Supervisor I

Sediment Check 2

rebar cage)

12. Pipe size Min 6 x max aggregate or 200mm Measuring tape Approved MS Before casting Inspection checklist W I Supervisor I

Install Tremie Pipe Pipe length Until pile toe (200mm from pile toe) Measuring tape Approved MS Before casting Inspection checklist W I Supervisor I

Pipe plunger/ bottom plug Provided Visual Approved MS Before casting Inspection checklist W I Supervisor I

13. Sediment thickness (after install _____ mm Measuring tape Drawing/ Specification Every point Inspection checklist W I Supervisor I

Sediment Check 3

tremie pipe)

14. Concrete grade, slump Concrete grade: _____ Visual, DO Drawing/ Specification Before casting Inspection checklist W I Supervisor I

Slump: _____ mm 25mm

Concreting Concrete cube taking 1 sample every bored pile, Visual Drawing/ Specification Before casting Inspection checklist W I Supervisor I

3 nos. tested at 7 days

3 nos. tested at 14 days

3 nos. tested at 28 days

Delivery time _____ hours Visual, DO Drawing/ Specification Before casting Inspection checklist W I Supervisor I

Stabilizing fluid Pump back to recycling tank Visual, measuring tape Approved MS During casting Inspection checklist W I Supervisor I

Maintain 1.5m from top of casing or 1m

from ground level

Withdrawal of tremie pipe To keep 6m and 1.5m from concrete Measuring tape Approved MS During casting Inspection checklist W I Supervisor I

Concrete top level surface

1000 mm above cut-off level Visual, measuring tape Approved shopdwg During casting Inspection checklist W I Supervisor I Check lapping length, top of

concrete for test pile will be

different

Actual concrete volume > theoretical concrete volume Casting record, DO Approved shopdwg During casting Inspection checklist W I Supervisor I

Top of rebar level Same as before concreting Measuring tape Approved shopdwg During casting Inspection checklist W I Supervisor I

15. Steel casing removal time 1.5 hours after casting Timer Approved MS After casting Inspection checklist W I Supervisor I

Bottom of steel casing level 2m below tremie pipe Measuring tape Approved MS After casting Inspection checklist W I Supervisor I

Casing Removal

Top of concrete level Top-up top of concrete level if level drop after Visual, measuring tape Approved MS After casting Inspection checklist W I Supervisor I

extracting steel casing

Backfilling of bored hole Min 6 hours after casting Timer Approved MS After casting Inspection checklist W I Supervisor I

Curing No activity within 6m of completed bored pile for Visual, barricade Approved MS After casting Inspection checklist W I Supervisor I

the first 24 hours

16. As-built position As-built position within 75mm Theodolite Approved shopdwg All As-built drawing W I Surveyor I By Licensed Surveyor

Pile As-Built As-built verticality 1/____ Theodolite Drawing/ Specification All As-built drawing W I Surveyor I

As-built cut-off level As-built cut-off level within 10mm Level instrument Approved shopdwg All As-built drawing W I Surveyor I

I Inspect/ Record/ Main Responsibility, A Approve, W Witness, R Random Check

* Acceptance criteria/ tolerance might differ from project to project. Check Consultants Specifications for actual requirements.

También podría gustarte

- Excavation Earthwork and FillingDocumento5 páginasExcavation Earthwork and FillingZaleha AzlanAún no hay calificaciones

- ITP & Ceklis Bored PileDocumento5 páginasITP & Ceklis Bored Pilefari_civil06Aún no hay calificaciones

- Inspection and Test PlanDocumento6 páginasInspection and Test PlanMadison ChanAún no hay calificaciones

- Bored PilingDocumento3 páginasBored PilingAdonis AlabiAún no hay calificaciones

- Execution Plan PDFDocumento60 páginasExecution Plan PDFASAD MALIKAún no hay calificaciones

- Sewer Line MosDocumento6 páginasSewer Line MosToyEn MEgat100% (1)

- Part417 Continuous Flight Auger PilesDocumento5 páginasPart417 Continuous Flight Auger PilesNaga RjkAún no hay calificaciones

- Bored Pile - Method StatementDocumento13 páginasBored Pile - Method Statementbtcong93100% (2)

- Department of Public Works and HighwaysDocumento17 páginasDepartment of Public Works and HighwaysRolly Marc G. SoteloAún no hay calificaciones

- Rev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectDocumento11 páginasRev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectM Waqas HabibAún no hay calificaciones

- 01 ITP TemplateDocumento6 páginas01 ITP TemplateHelsy FuentesAún no hay calificaciones

- Method Statement SurveyDocumento3 páginasMethod Statement SurveyBadhur ZamanAún no hay calificaciones

- Method Statement For Pile DrivingDocumento2 páginasMethod Statement For Pile DrivingLim Han Jian100% (5)

- Method Statement of Driven PileDocumento5 páginasMethod Statement of Driven Pilenght794233% (3)

- MS-001-Form Work, Reinforcement Steel & Concrete WorksDocumento12 páginasMS-001-Form Work, Reinforcement Steel & Concrete WorksFrancis Phillip CapistranoAún no hay calificaciones

- Concreting MethodologyDocumento2 páginasConcreting Methodologyervnglen08Aún no hay calificaciones

- Qa QC ChecklistDocumento1 páginaQa QC ChecklistCeedee ValenciaAún no hay calificaciones

- Method Statement For Installation of Soil Nails With For Slope StabilizationDocumento11 páginasMethod Statement For Installation of Soil Nails With For Slope StabilizationDelon Yau100% (2)

- Ms For ShotcreteDocumento12 páginasMs For ShotcreteAnonymous ExWAN2xjFJ100% (1)

- Method Statement of Bored Pile Construction On Land (For Const.)Documento82 páginasMethod Statement of Bored Pile Construction On Land (For Const.)Nguyen Hai Linh100% (2)

- Itp Civil WorkDocumento9 páginasItp Civil WorkChristian Albert Sinaga RumajarAún no hay calificaciones

- Method Statement For Construction of EmbankmentDocumento6 páginasMethod Statement For Construction of EmbankmentRabnawaz Imam100% (1)

- Pour CardDocumento2 páginasPour Cardrana pratap Singh100% (1)

- Method Statement For Excavation: Skandhanshi Infra Projects PVT LTDDocumento6 páginasMethod Statement For Excavation: Skandhanshi Infra Projects PVT LTDVinod MasaniAún no hay calificaciones

- Method Statement of Overwatervilla and WalkwayDocumento10 páginasMethod Statement of Overwatervilla and WalkwayMuhammad Uwais100% (1)

- ITP-00010 Pavement Road WorksDocumento3 páginasITP-00010 Pavement Road WorksIsmail MydeenAún no hay calificaciones

- Method of Statement (Open Cut)Documento14 páginasMethod of Statement (Open Cut)Syed FaizAún no hay calificaciones

- Method Statement For Setting Up Anchor Bolts in Steel StructureDocumento3 páginasMethod Statement For Setting Up Anchor Bolts in Steel StructureIbrahim AlrabibAún no hay calificaciones

- Method Statement For Piling Works PDFDocumento2 páginasMethod Statement For Piling Works PDFrozaidiabdulrahim100% (1)

- MS For BoredDocumento18 páginasMS For BoredsinlekmAún no hay calificaciones

- 027 ITP For Pre Cast Concrete PDFDocumento27 páginas027 ITP For Pre Cast Concrete PDFlinga2014Aún no hay calificaciones

- Method Statement of Bored Piles 21Documento40 páginasMethod Statement of Bored Piles 21Dharma Pratap LamgadeAún no hay calificaciones

- Back FillingDocumento7 páginasBack FillingCheng EngiAún no hay calificaciones

- Method Statement For Earthwork Excavation & BackfillingDocumento6 páginasMethod Statement For Earthwork Excavation & Backfillingjing aytonaAún no hay calificaciones

- 7503-2 - Checklist For Precast StructureDocumento8 páginas7503-2 - Checklist For Precast StructureKannan KamalAún no hay calificaciones

- QA-QC PlanDocumento18 páginasQA-QC PlanSen IMO67% (3)

- Civil Quality Control Plan EarthworksDocumento3 páginasCivil Quality Control Plan Earthworksroekyat hendrawanAún no hay calificaciones

- BoredPile CHecklist UpdateDocumento3 páginasBoredPile CHecklist UpdateGnabBang75% (12)

- Bottom Slab Method StatementDocumento22 páginasBottom Slab Method Statementfehmi-fjr4696Aún no hay calificaciones

- Method Statement For Construction of Access Bridge by MVVDocumento12 páginasMethod Statement For Construction of Access Bridge by MVVPhong Trần100% (1)

- Method Statement For Sonic Logging Test-naga3-Rev.01-Dc230321Documento24 páginasMethod Statement For Sonic Logging Test-naga3-Rev.01-Dc230321Shafiq ZakariahAún no hay calificaciones

- Pile Driving RecordDocumento3 páginasPile Driving Recordtinkerman02100% (1)

- ITP - Civil WorkDocumento5 páginasITP - Civil WorkShabeer Shaarim Abdul JabbarAún no hay calificaciones

- T211 Method Statement - RC SlabDocumento11 páginasT211 Method Statement - RC SlabStephen David GozunAún no hay calificaciones

- ITP-FW For Civil & Building WorksDocumento17 páginasITP-FW For Civil & Building WorksRajnath Rajbhar Pancham86% (7)

- Bored Pile Construction - ChrisDocumento38 páginasBored Pile Construction - ChrisTerry Choi100% (2)

- Method Statement For Ground Improvement: (Bidor To Ipoh Package)Documento8 páginasMethod Statement For Ground Improvement: (Bidor To Ipoh Package)MAYMODERN STEELAún no hay calificaciones

- Method Statement For BACK FILLING FinalDocumento4 páginasMethod Statement For BACK FILLING FinalEngr Muhammad SohailAún no hay calificaciones

- Excavation MethodDocumento11 páginasExcavation MethodKrm ChariAún no hay calificaciones

- Static and PDA Load Test Method StatementDocumento20 páginasStatic and PDA Load Test Method StatementMikiRoniWijaya100% (1)

- Item Rate Boq: Validate Print HelpDocumento12 páginasItem Rate Boq: Validate Print Helpvishnumani3011Aún no hay calificaciones

- Ultrasonic Pile Integrity TestDocumento15 páginasUltrasonic Pile Integrity TestPipim PogiAún no hay calificaciones

- Method Statement For Surveying WorkDocumento3 páginasMethod Statement For Surveying WorkShenbagaraja PandianAún no hay calificaciones

- Fitp For Civil and Structure ConstructionDocumento13 páginasFitp For Civil and Structure ConstructionSofda ImelaAún no hay calificaciones

- 525027-MTP-FO-004-Steel Structure Erection (R0)Documento1 página525027-MTP-FO-004-Steel Structure Erection (R0)parwotoAún no hay calificaciones

- QAP1Documento2 páginasQAP1akshaymehra2354Aún no hay calificaciones

- Checklist For VDF WorksDocumento1 páginaChecklist For VDF WorksGabriel Gabe100% (2)

- ITP - ErectionDocumento6 páginasITP - ErectionvijayAún no hay calificaciones

- I1912 Ai Opr JC 0070 00 JC For Pelmet WorkDocumento1 páginaI1912 Ai Opr JC 0070 00 JC For Pelmet WorkAiplshubh ChavanAún no hay calificaciones

- Itp For For Excavation, Backfilling & Compaction For Building WorksDocumento4 páginasItp For For Excavation, Backfilling & Compaction For Building WorksBleep NewsAún no hay calificaciones

- CHP 5 CONSTDocumento56 páginasCHP 5 CONSTGreg VarneyAún no hay calificaciones

- Wolff 5020 enDocumento72 páginasWolff 5020 enChung Yiung YungAún no hay calificaciones

- Data Centers Best PracticesDocumento84 páginasData Centers Best Practicesmnt6176Aún no hay calificaciones

- JV Agreement ChecklistDocumento21 páginasJV Agreement ChecklistChung Yiung YungAún no hay calificaciones

- Contractual JV AgreementDocumento115 páginasContractual JV AgreementtomarasAún no hay calificaciones

- JV Agreement ChecklistDocumento21 páginasJV Agreement ChecklistChung Yiung YungAún no hay calificaciones

- Tekcon - Spun Piles PropertiesDocumento10 páginasTekcon - Spun Piles PropertiesChung Yiung YungAún no hay calificaciones

- 2005 National Design Specification (NDS) For Wood ConstructionDocumento4 páginas2005 National Design Specification (NDS) For Wood ConstructiontocunbotaAún no hay calificaciones

- Dark Red Meranti PropertiesDocumento4 páginasDark Red Meranti PropertiesChung Yiung YungAún no hay calificaciones

- NG ChoongDocumento12 páginasNG ChoongRoberta S.Aún no hay calificaciones

- 2005 National Design Specification (NDS) For Wood ConstructionDocumento4 páginas2005 National Design Specification (NDS) For Wood ConstructiontocunbotaAún no hay calificaciones

- 2005 National Design Specification (NDS) For Wood ConstructionDocumento4 páginas2005 National Design Specification (NDS) For Wood ConstructiontocunbotaAún no hay calificaciones

- 2005 National Design Specification (NDS) For Wood ConstructionDocumento4 páginas2005 National Design Specification (NDS) For Wood ConstructiontocunbotaAún no hay calificaciones

- How The Dilatancy of Soils Affects Their BehaviourDocumento30 páginasHow The Dilatancy of Soils Affects Their Behaviouragentradio24Aún no hay calificaciones

- 2005 National Design Specification (NDS) For Wood ConstructionDocumento4 páginas2005 National Design Specification (NDS) For Wood ConstructiontocunbotaAún no hay calificaciones

- Opss 919Documento17 páginasOpss 919Chung Yiung YungAún no hay calificaciones

- BCA - Design Guide On Use of Structural SteelDocumento89 páginasBCA - Design Guide On Use of Structural Steelsazkha2100% (1)

- Meranti PropertiesDocumento4 páginasMeranti PropertiesChung Yiung YungAún no hay calificaciones

- Code of Practice-FormworkDocumento32 páginasCode of Practice-FormworkChung Yiung YungAún no hay calificaciones

- Kamper PropertiesDocumento4 páginasKamper PropertiesChung Yiung YungAún no hay calificaciones

- Meranti PropertiesDocumento4 páginasMeranti PropertiesChung Yiung YungAún no hay calificaciones

- Kamper PropertiesDocumento4 páginasKamper PropertiesChung Yiung YungAún no hay calificaciones

- Kamper PropertiesDocumento4 páginasKamper PropertiesChung Yiung YungAún no hay calificaciones

- CH 6 153 002Documento6 páginasCH 6 153 002Chung Yiung YungAún no hay calificaciones

- DG RoofingDocumento12 páginasDG RoofingChung Yiung YungAún no hay calificaciones

- PCA Concrete Floors On GradeDocumento32 páginasPCA Concrete Floors On Gradeaelmer1100% (6)

- Lump SumDocumento5 páginasLump SumCraven CottageAún no hay calificaciones

- 005 Stablzn of Expansive Soils Using F ADocumento10 páginas005 Stablzn of Expansive Soils Using F AVinay RajAún no hay calificaciones

- In-Situ Density Determination by Sand Replacement MethodDocumento11 páginasIn-Situ Density Determination by Sand Replacement MethodkillerhAPPyAún no hay calificaciones

- Machine Design II: Prof. K.Gopinath & Prof. M.M.MayuramDocumento4 páginasMachine Design II: Prof. K.Gopinath & Prof. M.M.Mayurampredrag10Aún no hay calificaciones

- Clinical Algorithms in General Surgery PDFDocumento786 páginasClinical Algorithms in General Surgery PDFLaura Campaña100% (5)

- V. Aa. Gram A/S: DescriptionDocumento2 páginasV. Aa. Gram A/S: Descriptioncontango O&GAún no hay calificaciones

- 6 Instrumentation PDFDocumento144 páginas6 Instrumentation PDFWanderley MandruzatoAún no hay calificaciones

- RBC Disorder BcqsDocumento68 páginasRBC Disorder BcqsMukhtiar AhmedAún no hay calificaciones

- Lead in Water: Standard Test Methods ForDocumento17 páginasLead in Water: Standard Test Methods ForAMMARAún no hay calificaciones

- Electric Vehicle in IndonesiaDocumento49 páginasElectric Vehicle in IndonesiaGabriella Devina Tirta100% (1)

- Fitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsDocumento24 páginasFitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsIrisha AnandAún no hay calificaciones

- VW Golf 8 Variant WD EngDocumento664 páginasVW Golf 8 Variant WD EngLakhdar BouchenakAún no hay calificaciones

- MB Marine Product Guide 2022 RevNDocumento35 páginasMB Marine Product Guide 2022 RevNamir sadighiAún no hay calificaciones

- BIS Ventilation Brochure enDocumento16 páginasBIS Ventilation Brochure enBruno SantosAún no hay calificaciones

- On December 1 Curt Walton Began An Auto Repair Shop PDFDocumento1 páginaOn December 1 Curt Walton Began An Auto Repair Shop PDFhassan taimourAún no hay calificaciones

- Joey Agustin (Price Tag)Documento2 páginasJoey Agustin (Price Tag)AGUSTIN JOENALYN MAE M.Aún no hay calificaciones

- Midterm2 KeyDocumento6 páginasMidterm2 KeyHungDoAún no hay calificaciones

- 432.01 Managing HSE in A Geophysical Nov 2017Documento138 páginas432.01 Managing HSE in A Geophysical Nov 2017Andrei Savu100% (1)

- Material SelfDocumento9 páginasMaterial Selfic perlasAún no hay calificaciones

- 8-Critical Appraisal of An ArticleDocumento20 páginas8-Critical Appraisal of An ArticleMohmmed Abu MahadyAún no hay calificaciones

- 5 Natural Sore Throat RemediesDocumento5 páginas5 Natural Sore Throat Remedieslisa smithis100% (1)

- Lesson 3.3 Inside An AtomDocumento42 páginasLesson 3.3 Inside An AtomReign CallosAún no hay calificaciones

- Tutorials 2016Documento54 páginasTutorials 2016Mankush Jain100% (1)

- Lithium Primary Batteries (Jauch)Documento72 páginasLithium Primary Batteries (Jauch)MedSparkAún no hay calificaciones

- Biological Activity of Bone Morphogenetic ProteinsDocumento4 páginasBiological Activity of Bone Morphogenetic Proteinsvanessa_werbickyAún no hay calificaciones

- 1101259L 580.752830 Pressure Washer ManualDocumento64 páginas1101259L 580.752830 Pressure Washer Manualgork1roguesAún no hay calificaciones

- Pay Slip SampleDocumento3 páginasPay Slip SampleJoseph ClaveriaAún no hay calificaciones

- Highest Efficiencies For Various Industrial Applications: PumpsDocumento8 páginasHighest Efficiencies For Various Industrial Applications: Pumpsahmed MareiAún no hay calificaciones

- Exam G-9 CookeryDocumento5 páginasExam G-9 Cookeryaileenarcabal01Aún no hay calificaciones

- Arma 2018 047Documento7 páginasArma 2018 047Lígia BrumAún no hay calificaciones

- Water Distiller - ManualDocumento2 páginasWater Distiller - ManualSanjeevi JagadishAún no hay calificaciones

- Grade 10 Chemistry Week 1Documento3 páginasGrade 10 Chemistry Week 1Nikoli MajorAún no hay calificaciones

- Using The Time Domain Reflectometer To Check For and Locate A FaultDocumento5 páginasUsing The Time Domain Reflectometer To Check For and Locate A FaultSikandar MasoodAún no hay calificaciones