Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Cable Pulling, Glanding and Terminations

Cargado por

nsadnanTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Cable Pulling, Glanding and Terminations

Cargado por

nsadnanCopyright:

Formatos disponibles

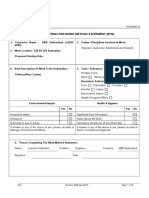

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : Danway EME 3. Trades / Disciplines Involved In Work :

2. Work Location : NEW ABB LAYDOWN Engineer, Supervisor, Electricians and Helpers.

(Near to existing GIS building)

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : 5. Tools / Substance

Portable Tools

CABLE PULLING, GLANDING AND

TERMINATIONS. Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste Significant Dust Generation

Emissions Noise (above 85 DbA)

Discharge to sea or drains Hazardous substances (if yes attach list)

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : G.J. PILLAI Position : Supervisor Company : Danway

Signature : Date : 15-05-2012

File: Revision: 0(26-May-2011) Page 1 of 6

HS.SAF.09.F12

7. Approvals

Contractor Site Rep. Name Signature : Date :

EMAL Representative Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low Severity LP x MS LP x HS

1x1=1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

File: Revision: 0(26-May-2011) Page 2 of 6

SM-CMS.TSK.01.F02

8. Safety Analysis

Identified Hazard(s) Persons Exposed To Precautions and Plan of actions To Be Taken Severity x Probability =

Individual Activities To Associated With Activity Hazard To Remove / Control Hazards Risk

Complete Work. List In

Sequence of Activity Residual Risk

(Use Risk Estimator

Chart)

PREPARATION. Slips, trips and fall at the Emal rep., Engr., Supv. Maintain housekeeping around in the working

1x2=2

same level. Elec, helpers. area.

Emal rep., Engr., Supv. All workers involve in the activity must be

Hot weather. 2x2=4

Elec,helpers aware of heat stress, supervisor to ensure

drinking cold water is available.

Emal rep., Engr., Supv. Wear P.P.E.'s at all times (hard hat, safety

2x2=4

Not using P.P.E.'s Elec, helpers. glass, safety shoes, hand gloves, dust mask,

coverall.

Manual handling hazards Supv. Elec,helpers Supervisor to give tool box talk regarding 1x1=2

proper manual handling.

No approved permit to

CABLE LAYING Engr., Supv., Elec., & 3x1=3

work from emal helpers Supervisor to ensure approved PTW, MS and

(Telephone and power) RA are available on site NO PERMIT NO

WORK.

Ensure that working crew does not enter into

the operational area.

File: Revision: 0(26-May-2011) Page 3 of 6

SM-CMS.TSK.01.F02

Complete the pre-work check list on a daily

basis.

Daily toolbox meetings to be conducted on

days activity, which will include TRA for the

activity..

Maintain good housekeeping around the

area.

Gangway and walk way kept free from

obstractions.

Slip / Trip & Fall Supv., Elect & helpers 1x2=2

Supervisor to conduct daily crew

same level

meeting prior to start the activity.

Post appropriate warning signage.hard

barricade the work area to aviod anauthorized

entry.

Manual handling hazards Elect & helpers Supervisor to give tool box talk regarding 1x2=2

proper manual handling.

Excavation that is more than 1.2 mtrs depth

shall administer protective system. (Sloping of

Cav-ins and collapses of All workers involved in 1:1 ratio or benching not less than 0.6mtr wide

2x2=4

excavation walls the activity level, shoring, etc.)

Keep spoiled sand and other materials atleast

1mter away from the edge of excavation.

Provide warning signs and barricade the

Emal rep., Engr., Supv.

Fall into the treanch treanch to be provided. 2x1=2

Elec, helpers.

File: Revision: 0(26-May-2011) Page 4 of 6

SM-CMS.TSK.01.F02

Emal rep., Engr., Supv. Wear P.P.E.'s at all times (hard hat, safety 2x2=4

Not using P.P.E.'s Elec, helpers. glass, safety shoes, hand gloves, dust mask,

coverall.

Supervisor to ensure approved PTW, MS and

RA are available on site NO PERMIT NO

WORK.

Ensure that working crew does not enter into

GLANDING AND

No approved permit to Engr., Supv., Elec., & the operational area.

TERMINATION OF CABLE: 3x1=3

work from emal helpers Complete the pre-work check list on a daily

basis.

Daily toolbox meetings to be conducted on

days activity, which will include TRA for the

activity.

Inspect the hand tools before use, ensure the

1.Opening of insulation Use of sharp hand tools condition is good

and cut the cable for Competency of Use hand glove

termination electrician Supervisor to ensure the competency of

2.Crimp the lugs to the Use damaged tools may electrician.

cable end slip and injure Inspect heat gun before use, it is in good

Elec., & helpers 1x3=3

3.Remove the bolt from electrician or damage condition, provide fire extinguisher.

the breaker and tight the property

cable lugs with bolts to Use of Heat gun (hot

the breaker blower), electricity /

Fire.

Emal rep., Engr., Supv. Wear P.P.E.'s at all times (hard hat, safety 2x2=4

Not using P.P.E.'s Elec, helpers. glass, safety shoes, hand gloves, dust mask,

coverall.

File: Revision: 0(26-May-2011) Page 5 of 6

SM-CMS.TSK.01.F02

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

File: Revision: 0(26-May-2011) Page 6 of 6

También podría gustarte

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocumento16 páginasPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanAún no hay calificaciones

- Risk Ass. - AD 417 - Installation of SocketDocumento6 páginasRisk Ass. - AD 417 - Installation of SocketnsadnanAún no hay calificaciones

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocumento20 páginasRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanAún no hay calificaciones

- Rectification of Defective High Mast Lighting in Cast House Yard LightingDocumento6 páginasRectification of Defective High Mast Lighting in Cast House Yard LightingnsadnanAún no hay calificaciones

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocumento13 páginasRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanAún no hay calificaciones

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Documento8 páginasFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanAún no hay calificaciones

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocumento6 páginasRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanAún no hay calificaciones

- Cable PullingDocumento10 páginasCable PullingnsadnanAún no hay calificaciones

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocumento4 páginasDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustAún no hay calificaciones

- Activity Hazard AnalysisDocumento4 páginasActivity Hazard AnalysisGerrard Singh100% (1)

- Risk Assess - 98-Installation Fuel Oil ConditioniDocumento4 páginasRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriAún no hay calificaciones

- Doku - Pub Risk-AssessmentDocumento10 páginasDoku - Pub Risk-AssessmentUlviyye ElesgerovaAún no hay calificaciones

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Documento3 páginasRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 páginasRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- 007 - Risk Ass. - CE-0994-MEP WorksDocumento9 páginas007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- JHA Stacks EDG Substation r0 14 August 2017 EdittedDocumento5 páginasJHA Stacks EDG Substation r0 14 August 2017 EdittedJeniffer Ong100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Documento4 páginasThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaAún no hay calificaciones

- Pha ExcavationDocumento13 páginasPha ExcavationirshadAún no hay calificaciones

- JHA for Hill Cutting Activities at Port of SalalahDocumento8 páginasJHA for Hill Cutting Activities at Port of SalalahSreekumarAún no hay calificaciones

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsDocumento5 páginasJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanAún no hay calificaciones

- Near Miss Report: Complete This Form and Email It ToDocumento1 páginaNear Miss Report: Complete This Form and Email It Toloveson709Aún no hay calificaciones

- Jha For - TransformerDocumento7 páginasJha For - Transformermujahid1137Aún no hay calificaciones

- Risk Assessment for Office AreasDocumento9 páginasRisk Assessment for Office AreaszulmaulAún no hay calificaciones

- Safe Working ProcedureDocumento23 páginasSafe Working ProcedureBea MokAún no hay calificaciones

- 4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1Documento4 páginas4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1loveson709Aún no hay calificaciones

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocumento8 páginasSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajAún no hay calificaciones

- Power Cable Jointing: Novatex Limited SOP / E&I / 17Documento3 páginasPower Cable Jointing: Novatex Limited SOP / E&I / 17OSAMAAún no hay calificaciones

- Boom Lift - Working FromDocumento5 páginasBoom Lift - Working Fromwahyu nugrohoAún no hay calificaciones

- Methodstatement and RiskAssessmentDocumento13 páginasMethodstatement and RiskAssessmentAnonymous ExWAN2xjFJ100% (1)

- Jha Solar Transformer ProjectDocumento6 páginasJha Solar Transformer Projectperquino oasanAún no hay calificaciones

- ISC-JSA Grouting Works For Shared FenceDocumento4 páginasISC-JSA Grouting Works For Shared FenceSameer AlmahboubAún no hay calificaciones

- Trade Area: Construction Industry-PaintingDocumento3 páginasTrade Area: Construction Industry-PaintingRam-tech Jackolito FernandezAún no hay calificaciones

- Using Hand Drill (WS)Documento2 páginasUsing Hand Drill (WS)John KalvinAún no hay calificaciones

- JHA-welding Joint PaintingDocumento9 páginasJHA-welding Joint Paintingmansih457Aún no hay calificaciones

- 01 WI HSE 001 - Risk Assessment GroutingDocumento4 páginas01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (1)

- Job Hazard Analysis for Confined Space EntryDocumento6 páginasJob Hazard Analysis for Confined Space EntryArun ArunbolluAún no hay calificaciones

- 459-De-SPADING of Fire Water Line For Deluge Skid and Sprinkler System SAT TestDocumento4 páginas459-De-SPADING of Fire Water Line For Deluge Skid and Sprinkler System SAT TestNasrullah JanAún no hay calificaciones

- Asm Risk Assesment fv2 PDFDocumento3 páginasAsm Risk Assesment fv2 PDFshijadAún no hay calificaciones

- Risk Assessment/Management Form: Section / Dept: ActivityDocumento2 páginasRisk Assessment/Management Form: Section / Dept: ActivityJack PAún no hay calificaciones

- Saline Water Desalination Electrical Work ChecklistDocumento1 páginaSaline Water Desalination Electrical Work ChecklistBRC HSE Dept.Aún no hay calificaciones

- 09.00AM to11.00PM Clear: TCE EffwaDocumento3 páginas09.00AM to11.00PM Clear: TCE EffwaAjayAún no hay calificaciones

- HIRA Electrical Works HRC 002Documento7 páginasHIRA Electrical Works HRC 002syed khaja misbhuddinAún no hay calificaciones

- OCP 12 - Working at HeightDocumento2 páginasOCP 12 - Working at HeightVipin Kumar Parashar100% (1)

- JSA G20 Scaffolding Erection DismantlingDocumento4 páginasJSA G20 Scaffolding Erection DismantlingemmyAún no hay calificaciones

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Documento3 páginasKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelAún no hay calificaciones

- JSA NO 2 Piling WorkDocumento6 páginasJSA NO 2 Piling WorkfadliAún no hay calificaciones

- Project No. 074-10 JHA No. 1Documento20 páginasProject No. 074-10 JHA No. 1Adel SukerAún no hay calificaciones

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocumento4 páginasJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradAún no hay calificaciones

- Very Very Good Risk Assessment EnvironmentDocumento8 páginasVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDocumento17 páginas13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- HiraDocumento4 páginasHiraArshad KhanAún no hay calificaciones

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocumento3 páginasR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalAún no hay calificaciones

- 28.1.1 Mobile Equipment Inspection ChecklistDocumento1 página28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemAún no hay calificaciones

- Jha RebarsDocumento7 páginasJha RebarsJaycee QuinAún no hay calificaciones

- Stand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Documento3 páginasStand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Dwitikrushna Rout100% (1)

- JSA Electrical WiringDocumento10 páginasJSA Electrical WiringWeru Morris100% (1)

- RA MEWP 0003 Dec 2011Documento3 páginasRA MEWP 0003 Dec 2011Anup George Thomas100% (1)

- Modification of Cable Ladder in Bath Processing PlantDocumento14 páginasModification of Cable Ladder in Bath Processing PlantnsadnanAún no hay calificaciones

- Installation of Gi TrunkingDocumento7 páginasInstallation of Gi TrunkingnsadnanAún no hay calificaciones

- D02 MS Ra Pov PDFDocumento35 páginasD02 MS Ra Pov PDFnsadnanAún no hay calificaciones

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocumento5 páginasPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanAún no hay calificaciones

- ONVIF Profile - S Specification v1-2Documento42 páginasONVIF Profile - S Specification v1-2nsadnan0% (1)

- ONVIF Profile Feature Overview v2-2Documento6 páginasONVIF Profile Feature Overview v2-2nsadnanAún no hay calificaciones

- ONVIF Profile T Specification v1-0Documento77 páginasONVIF Profile T Specification v1-0nsadnanAún no hay calificaciones

- BSIA Cyber Secure It January 2019Documento16 páginasBSIA Cyber Secure It January 2019nsadnanAún no hay calificaciones

- Excel Intelligent PduDocumento21 páginasExcel Intelligent PdunsadnanAún no hay calificaciones

- 1 45Documento3 páginas1 45nsadnan0% (1)

- HVAC ManualDocumento107 páginasHVAC ManualWissam JarmakAún no hay calificaciones

- DDC Systems2Documento28 páginasDDC Systems2nsadnan100% (1)

- Checklist For Commissioning of CCTV SystemDocumento2 páginasChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Checklist For Access Control System InstallationDocumento6 páginasChecklist For Access Control System Installationnsadnan71% (7)

- Testing and Commissioning Pre-Check List (ID 1506)Documento1 páginaTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Exc Fibre Installation GuideDocumento38 páginasExc Fibre Installation GuidensadnanAún no hay calificaciones

- Excel Intelligent Pdu User InstructionsDocumento2 páginasExcel Intelligent Pdu User InstructionsnsadnanAún no hay calificaciones

- Exc Installation GuideDocumento1 páginaExc Installation GuidensadnanAún no hay calificaciones

- Exc Fibre Installation GuideDocumento16 páginasExc Fibre Installation GuideMohamad FaifAún no hay calificaciones

- Sensor Line Cable InstallationDocumento6 páginasSensor Line Cable InstallationnsadnanAún no hay calificaciones

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 páginasRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Documento1 páginaCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- 109 Installation CCTV Systems PDFDocumento60 páginas109 Installation CCTV Systems PDFRodelDavidAún no hay calificaciones

- ADDC Electricity Wiring Regulations - Mar.2014Documento276 páginasADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- Checklist For Pre Commissioning of CCTV SystemDocumento1 páginaChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 páginasRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanAún no hay calificaciones

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDocumento14 páginasRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanAún no hay calificaciones

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 páginasRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Installation of Ventilation FanDocumento6 páginasRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocumento6 páginasRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanAún no hay calificaciones

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDocumento5 páginasRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanAún no hay calificaciones

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocumento6 páginasRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 páginasRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- The State of Mental Health in The Philippines PDFDocumento4 páginasThe State of Mental Health in The Philippines PDFKatrina Francesca SooAún no hay calificaciones

- Development of Protein Rich Flavored BarDocumento6 páginasDevelopment of Protein Rich Flavored BarIJRASETPublicationsAún no hay calificaciones

- Assignment 2 HLTH 103 Bhima Devi Poudel Adhikari 220179000Documento10 páginasAssignment 2 HLTH 103 Bhima Devi Poudel Adhikari 220179000api-525310113Aún no hay calificaciones

- Liver Abscess ThesisDocumento7 páginasLiver Abscess Thesisjenniferalexanderfortlauderdale100% (1)

- What Is Healing?Documento33 páginasWhat Is Healing?Chef Jem100% (1)

- Nepal Development Update Post Pandemic Nepal Charting A Resilient Recovery and Future Growth Directions PDFDocumento62 páginasNepal Development Update Post Pandemic Nepal Charting A Resilient Recovery and Future Growth Directions PDFSanjeev PradhanAún no hay calificaciones

- Clinical Manifestation, DiagnosisDocumento13 páginasClinical Manifestation, DiagnosisGeorgiana BlagociAún no hay calificaciones

- Hcin 541 ArtifactDocumento11 páginasHcin 541 Artifactapi-612297093Aún no hay calificaciones

- Window of Tolerance GuideDocumento19 páginasWindow of Tolerance GuideLê Trung DũngAún no hay calificaciones

- Case Study 1 (ENGINEERING OF SOSITY)Documento22 páginasCase Study 1 (ENGINEERING OF SOSITY)mohd irfanAún no hay calificaciones

- NEBOSH HSE Certificate in Process Safety ManagementDocumento2 páginasNEBOSH HSE Certificate in Process Safety ManagementHashem RezayiAún no hay calificaciones

- Careers in Social Work: Outlook, Pay & MoreDocumento9 páginasCareers in Social Work: Outlook, Pay & Morejoel lacayAún no hay calificaciones

- Disaster Readiness and Risk Reduction: Quarter 1-Module 3: Disasters and Its EffectsDocumento11 páginasDisaster Readiness and Risk Reduction: Quarter 1-Module 3: Disasters and Its EffectsRenzelle Guilaran GerocheAún no hay calificaciones

- Drug StudyDocumento3 páginasDrug StudyMelanie Moises JavierAún no hay calificaciones

- Legacy of Tuskegee Syphilis StudyDocumento2 páginasLegacy of Tuskegee Syphilis StudyLcgessamanAún no hay calificaciones

- Progestin Only ContraceptionDocumento4 páginasProgestin Only ContraceptionTareq SawanAún no hay calificaciones

- What Is AmpalayaDocumento5 páginasWhat Is Ampalayarugu0% (1)

- Nebosh: Management of Health and Safety Unit Ig1Documento5 páginasNebosh: Management of Health and Safety Unit Ig1Muhammad Talha0% (1)

- Health Talk On ContraceptionDocumento32 páginasHealth Talk On Contraceptionvaishali TMU studentAún no hay calificaciones

- NURS FPX 6618 Assessment 1 Planning and Presenting A Care Coordination ProjectDocumento5 páginasNURS FPX 6618 Assessment 1 Planning and Presenting A Care Coordination ProjectEmma WatsonAún no hay calificaciones

- Renal Colic and Joint DeformitiesDocumento19 páginasRenal Colic and Joint DeformitiesAhmad Syahmi YZ100% (1)

- Epos2020 PDFDocumento481 páginasEpos2020 PDFHanifa YuniasariAún no hay calificaciones

- Checklist For Writing Audit Proof IepsDocumento2 páginasChecklist For Writing Audit Proof Iepsapi-2307242610% (1)

- LUTSDocumento9 páginasLUTSHatem SadekAún no hay calificaciones

- Pediatric Schedule 3Documento12 páginasPediatric Schedule 3Luis NepomucenoAún no hay calificaciones

- 23 Nov 2022Documento1 página23 Nov 2022Tahir ShahAún no hay calificaciones

- Safety Officer Resume - 6+ Years HSE ExperienceDocumento3 páginasSafety Officer Resume - 6+ Years HSE ExperienceMuhammad Zeeshan Ahmed100% (1)

- Jme by Country May2023Documento347 páginasJme by Country May2023kaysbookishAún no hay calificaciones

- Mammograms and Other Breast Imaging Procedures: What Is A Mammogram?Documento25 páginasMammograms and Other Breast Imaging Procedures: What Is A Mammogram?Marina StosicAún no hay calificaciones

- Tenecteplasa Vs AlteplasaDocumento9 páginasTenecteplasa Vs AlteplasaJefferson Duque MartinezAún no hay calificaciones