Documentos de Académico

Documentos de Profesional

Documentos de Cultura

2539 4046 02 A1001 003 - Datasheet For Manual Valve - Rev B

Cargado por

Nguyễn ThựcDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

2539 4046 02 A1001 003 - Datasheet For Manual Valve - Rev B

Cargado por

Nguyễn ThựcCopyright:

Formatos disponibles

Client Name PETROVIETNAM FERTILIZER AND

CHEMICALS CORPORATION (PVFCCo)

Project Name AMMONIA PLANT REVAMP PROJECT

Plant Location PHU MY, VIET NAM

Job No. 2539

Requisition No. 4046-02

Service Name COAGULANT FLOCCULENT DOSING PACKAGE

Item No. 30-PK-3005

For Review

Doc. Title Data sheet for Manual Valves

Doc. No. 2539-4046-02-A1001-003 Rev: B

VENDOR DOCUMENT REVIEW

1 REVISE AND RESUBMIT

PROJ: AMMONIA PLANT REVAMP PROJECT 2 TO BE ISSUED AS FINAL PROVIDED

CLIENT: PETROVIETNAM FERTILIZER AND COMMENTS ARE CORPORATED

CHEMICALS CORPORATION (PVFCCo)

Material Requisition No. 3 NO COMMENT FINAL ISSUE

2539 MR 4 0 4 6 - 0 2 4 FOR INFORMATION ONLY

ITEM: 30-PK-3005

SR Doc Code: A1001 U.O:

P. O NO: 2539-00-PO-4046-02-0-92024 BY: DATE:

B 28/02/2017 ISSUED FOR APPROVAL NXT NTS LCH

A 16/01/2017 ISSUED FOR REVIEW NXT NTS LCH

REV. DATE STATUS WRITTEN BY CHECKED BY APPROV./AUTHOR. BY

(name & visa) (name & visa) (name & visa)

AMMONIA PLANT REVAMP PROJECT

THIEN PHU ENGINEERING CO., LTD.

Suite 02, 6thFloor, 20/13 Nguyen Truong To Str., Ward 12, District 4, Ho Chi Minh City, Vietnam

Tel.: (84-8) 3 826 6081 Fax.: (84-8) 3 826 6085

BALL VALVE DATA SHEET

VALVE TYPE: VALVE SIZE (NPS) : MIN. 1" - MAX. 1 1/2" PRESSURE / TEMPERATURE RATINGS

MAX DESIGN TEMP - C -29/38 50 100

800# FULL BORE, SW, BALL VALVE Q'TY (EA): REFER VALVE LIST

MAX DESIGN PRES - kPag 11030 10670 9280

DESIGN REQUIREMENTS

1 DESCRIPTIONS:

2 VALVE RATING : ANSI CLASS 800#

3 DESIGN TEMP. RANGE : -29oC MIN TO 100oC MAX

4 BORE : FULL BORE

5 END STYLE / CON'N : SW ENDS w/2 PE NIPPLES - PIPE SCH 40S, 100 mm LENGTH

6

7 PIPING CLASS : B50AN

8 VALVE DESIGN STD : API 608

9 DESIGN / CONSTRUCT'N : 2 OR 3 PCS SPLIT BODY SIDE ENTRY, BOLTED CONNECTION

10 : LONG PATTERN

11 : FLOATING BALL

12 : FIRE SAFE AS PER API 607

13

14 MATERIALS:

15 BODY / BONNET : FORGINGS - ASTM A182 Gr.F304/304L

16 BALL : STAINLESS STEEL - AISI 304

17 STEM : STAINLESS STEEL - AISI 304

18 STEM SEAL : PRIMARY PTFE/ SECONDARY GRAPHITE

19 SEAT RINGS : RPTFE

20 SEAT INSERTS : RPTFE

21 SEALS/PACKING/GASKETS : SPRIRAL WOUND AISI 316/GRAPHITE

22 BOLTING : A193 Gr B8/ A194 Gr. 8

23 OPERATOR : LEVER OPERATOR

24 PAINTING : NOT REQUIRED

25 SPECIAL REQ'TS : NOT REQUIRED

26

27

28 INSPECTION & TESTING REQUIREMENTS

29 REQ'D INSPECTION & TESTING NOTES

(a)

30 VISUAL EXAMINATION 100% (a) WHERE VISUAL EXAMINATION INDICATES AREAS OF

31 MAGNETIC PARTICLE EXAMINATION NONE UNACCEPTABILITY, LIQUID PENETRANT EXAMINATION

32 LIQUID PENETRANT EXAMINATION(a) 10% SHALL BE APPLIED IN ACCORDANCE WITH ASME V

33 RADIOGRAPHIC EXAMINATION 100% OF B.W's ARTICLE 6

34

35 PRESSURE TEST (b) - BODY API 6D (b) TEST PRESSURES SHALL BE IN ACCORDANCE WITH

36 - SEAT - HIGH PRESS API 6D ANSI B16.34, TEST DURATION & ACCEPTANCE

37 - LOW PRESS API 6D CRITERIA SHALL BE IN ACCORDANCE WITH API -6D

38 SEAT LEAKAGE RATE API 6D

39 (c) API 607 CERTIFICATION REQUIRED

40 FIRE TEST CERTIFICATION (c) API 607

41

DATA SHEET No.

2539-4046-02-A1001-003

B 28/02/2017 ISSUED FOR APPROVAL NXT NTS LCH

A 16/01/2017 ISSUED FOR REVIEW NXT NTS LCH

PAGE 1 OF 1 REV : B

REV DATE DESCRIPTION BY CHK APP

BALL VALVE DATA SHEET

VALVE TYPE: VALVE SIZE (NPS) : 1" PRESSURE / TEMPERATURE RATINGS

MAX DESIGN TEMP - C -29/38 50 100

800# FULL BORE, SW, BALL VALVE Q'TY (EA): REFER VALVE LIST

MAX DESIGN PRES - kPag 11030 10670 9280

DESIGN REQUIREMENTS

1 DESCRIPTIONS:

2 VALVE RATING : ANSI CLASS 800#

3 DESIGN TEMP. RANGE : -29oC MIN TO 100oC MAX

4 BORE : FULL BORE

5 END STYLE / CON'N : SW ENDS w/2 PE NIPPLES - PIPE SCH 40S, 100 mm LENGTH

6

7 PIPING CLASS : B52A

8 VALVE DESIGN STD : API 608

9 DESIGN / CONSTRUCT'N : 2 OR 3 PCS SPLIT BODY SIDE ENTRY, BOLTED CONNECTION

10 : LONG PATTERN

11 : FLOATING BALL

12 : FIRE SAFE AS PER API 607

13

14 MATERIALS:

15 BODY / BONNET : FORGINGS - ASTM A182 Gr.F316/316L

16 BALL : STAINLESS STEEL - AISI 316L

17 STEM : STAINLESS STEEL - AISI 316L

18 STEM SEAL : PRIMARY PTFE/ SECONDARY GRAPHITE

19 SEAT RINGS : RPTFE

20 SEAT INSERTS : RPTFE

21 SEALS/PACKING/GASKETS : SPRIRAL WOUND AISI 316/GRAPHITE

22 BOLTING B: A193 Gr B8M/ A194 Gr. 8M

23 OPERATOR : LEVER OPERATOR

24 PAINTING : NOT REQUIRED

25 SPECIAL REQ'TS : NOT REQUIRED

26

27

28 INSPECTION & TESTING REQUIREMENTS

29 REQ'D INSPECTION & TESTING NOTES

(a)

30 VISUAL EXAMINATION 100% (a) WHERE VISUAL EXAMINATION INDICATES AREAS OF

31 MAGNETIC PARTICLE EXAMINATION NONE UNACCEPTABILITY, LIQUID PENETRANT EXAMINATION

32 LIQUID PENETRANT EXAMINATION(a) 10% SHALL BE APPLIED IN ACCORDANCE WITH ASME V

33 RADIOGRAPHIC EXAMINATION 100% OF B.W's ARTICLE 6

34

35 PRESSURE TEST (b) - BODY API 6D (b) TEST PRESSURES SHALL BE IN ACCORDANCE WITH

36 - SEAT - HIGH PRESS API 6D ANSI B16.34, TEST DURATION & ACCEPTANCE

37 - LOW PRESS API 6D CRITERIA SHALL BE IN ACCORDANCE WITH API -6D

38 SEAT LEAKAGE RATE API 6D

39 (c) API 607 CERTIFICATION REQUIRED

40 FIRE TEST CERTIFICATION (c) API 607

41

DATA SHEET No.

2539-4046-02-A1001-003

B 28/02/2017 ISSUED FOR APPROVAL NXT NTS LCH

A 16/01/2017 ISSUED FOR REVIEW NXT NTS LCH

PAGE 1 OF 1 REV : B

REV DATE DESCRIPTION BY CHK APP

BALL VALVE DATA SHEET

VALVE TYPE: VALVE SIZE (NPS) : MIN. 3/4" - MAX. 1" PRESSURE / TEMPERATURE RATINGS

MAX DESIGN TEMP - C -29/38 50 100

800# REDUCER BORE, SW, BALL VALVE Q'TY (EA): REFER VALVE LIST

MAX DESIGN PRES - kPag 11030 10670 9280

DESIGN REQUIREMENTS

1 DESCRIPTIONS:

2 VALVE RATING : ANSI CLASS 800#

3 DESIGN TEMP. RANGE : -29oC MIN TO 100oC MAX

4 BORE : REDUCER BORE

5 END STYLE / CON'N : SW ENDS w/2 PE NIPPLES - PIPE SCH 40S, 100 mm LENGTH

6

7 PIPING CLASS : B50AN

8 VALVE DESIGN STD : API 608

9 DESIGN / CONSTRUCT'N : 2 OR 3 PCS SPLIT BODY SIDE ENTRY, BOLTED CONNECTION

10 : LONG PATTERN

11 : FLOATING BALL

12 : FIRE SAFE AS PER API 607

13

14 MATERIALS:

15 BODY / BONNET : FORGINGS - ASTM A182 Gr.F304/304L

16 BALL : STAINLESS STEEL - AISI 304

17 STEM : STAINLESS STEEL - AISI 304

18 STEM SEAL : PRIMARY PTFE/ SECONDARY GRAPHITE

19 SEAT RINGS : RPTFE

20 SEAT INSERTS : RPTFE

21 SEALS/PACKING/GASKETS : SPRIRAL WOUND AISI 316/GRAPHITE

22 BOLTING : A193 Gr B8/ A194 Gr. 8

23 OPERATOR : LEVER OPERATOR

24 PAINTING : NOT REQUIRED

25 SPECIAL REQ'TS : NOT REQUIRED

26

27

28 INSPECTION & TESTING REQUIREMENTS

29 REQ'D INSPECTION & TESTING NOTES

(a)

30 VISUAL EXAMINATION 100% (a) WHERE VISUAL EXAMINATION INDICATES AREAS OF

31 MAGNETIC PARTICLE EXAMINATION NONE UNACCEPTABILITY, LIQUID PENETRANT EXAMINATION

32 LIQUID PENETRANT EXAMINATION(a) 10% SHALL BE APPLIED IN ACCORDANCE WITH ASME V

33 RADIOGRAPHIC EXAMINATION 100% OF B.W's ARTICLE 6

34

35 PRESSURE TEST (b) - BODY API 6D (b) TEST PRESSURES SHALL BE IN ACCORDANCE WITH

36 - SEAT - HIGH PRESS API 6D ANSI B16.34, TEST DURATION & ACCEPTANCE

37 - LOW PRESS API 6D CRITERIA SHALL BE IN ACCORDANCE WITH API -6D

38 SEAT LEAKAGE RATE API 6D

39 (c) API 607 CERTIFICATION REQUIRED

40 FIRE TEST CERTIFICATION (c) API 607

41

42

DATA SHEET No.

2539-4046-02-A1001-003

B 28/02/2017 ISSUED FOR APPROVAL NXT NTS LCH

A 16/01/2017 ISSUED FOR REVIEW NXT NTS LCH

PAGE 1 OF 1 REV : B

REV DATE DESCRIPTION BY CHK APP

BALL VALVE DATA SHEET

VALVE TYPE: VALVE SIZE (NPS) : MIN. 3/4" - MAX. 1" PRESSURE / TEMPERATURE RATINGS

MAX DESIGN TEMP - C -29/38 50 100

800# REDUCER BORE, SWxFNPT, BALL VALVE Q'TY (EA): REFER VALVE LIST

MAX DESIGN PRES - kPag 11030 10670 9280

DESIGN REQUIREMENTS

1 DESCRIPTIONS:

2 VALVE RATING : ANSI CLASS 800#

3 DESIGN TEMP. RANGE : -29oC MIN TO 100oC MAX

4 BORE : REDUCER BORE

5 END STYLE / CON'N : SW ENDS w/1 PE NIPPLES - PIPE SCH 40S, 100mm LENGTH. OTHERS F.NPT

6

7 PIPING CLASS : B50AN

8 VALVE DESIGN STD : API 608

9 DESIGN / CONSTRUCT'N : 2 OR 3 PCS SPLIT BODY SIDE ENTRY, BOLTED CONNECTION

10 : LONG PATTERN

11 : FLOATING BALL

12 : FIRE SAFE AS PER API 607

13

14 MATERIALS:

15 BODY / BONNET : FORGINGS - ASTM A182 Gr.F304/304L

16 BALL : STAINLESS STEEL - AISI 304

17 STEM : STAINLESS STEEL - AISI 304

18 STEM SEAL : PRIMARY PTFE/ SECONDARY GRAPHITE

19 SEAT RINGS : RPTFE

20 SEAT INSERTS : RPTFE

21 SEALS/PACKING/GASKETS : SPRIRAL WOUND AISI 316/GRAPHITE

22 BOLTING : A193 Gr B8/ A194 Gr. 8

23 OPERATOR : LEVER OPERATOR

24 PAINTING : NOT REQUIRED

25 SPECIAL REQ'TS : NOT REQUIRED

26

27

28 INSPECTION & TESTING REQUIREMENTS

29 REQ'D INSPECTION & TESTING NOTES

30 VISUAL EXAMINATION(a) 100% (a) WHERE VISUAL EXAMINATION INDICATES AREAS OF

31 MAGNETIC PARTICLE EXAMINATION NONE UNACCEPTABILITY, LIQUID PENETRANT EXAMINATION

32 LIQUID PENETRANT EXAMINATION(a) 10% SHALL BE APPLIED IN ACCORDANCE WITH ASME V

33 RADIOGRAPHIC EXAMINATION 100% OF B.W's ARTICLE 6

34

35 PRESSURE TEST (b) - BODY API 6D (b) TEST PRESSURES SHALL BE IN ACCORDANCE WITH

36 - SEAT - HIGH PRESS API 6D ANSI B16.34, TEST DURATION & ACCEPTANCE

37 - LOW PRESS API 6D CRITERIA SHALL BE IN ACCORDANCE WITH API -6D

38 SEAT LEAKAGE RATE API 6D

39 (c) API 607 CERTIFICATION REQUIRED

40 FIRE TEST CERTIFICATION (c) API 607

41

42

DATA SHEET No.

2539-4046-02-A1001-003

B 28/02/2017 ISSUED FOR APPROVAL NXT NTS LCH

A 16/01/2017 ISSUED FOR REVIEW NXT NTS LCH

PAGE 1 OF 1 REV : B

REV DATE DESCRIPTION BY CHK APP

BALL VALVE DATA SHEET

VALVE TYPE: VALVE SIZE (NPS) : MIN. 1/2" - MAX. 1" PRESSURE / TEMPERATURE RATINGS

MAX DESIGN TEMP - C -29/38 50 100

800# REDUCER BORE, SW, BALL VALVE Q'TY (EA): REFER VALVE LIST

MAX DESIGN PRES - kPag 11030 10670 9280

DESIGN REQUIREMENTS

1 DESCRIPTIONS:

2 VALVE RATING : ANSI CLASS 800#

3 DESIGN TEMP. RANGE : -29oC MIN TO 100oC MAX

4 BORE : REDUCER BORE

5 END STYLE / CON'N : SW ENDS w/2 PE NIPPLES - PIPE SCH 40S, 100 mm LENGTH

6

7 PIPING CLASS : B52A

8 VALVE DESIGN STD : API 608

9 DESIGN / CONSTRUCT'N : 2 OR 3 PCS SPLIT BODY SIDE ENTRY, BOLTED CONNECTION

10 : LONG PATTERN

11 : FLOATING BALL

12 : FIRE SAFE AS PER API 607

13

14 MATERIALS:

15 BODY / BONNET : FORGINGS - ASTM A182 Gr.F316/316L

16 BALL : STAINLESS STEEL - AISI 316L

17 STEM : STAINLESS STEEL - AISI 316L

18 STEM SEAL : PRIMARY PTFE/ SECONDARY GRAPHITE

19 SEAT RINGS : RPTFE

20 SEAT INSERTS : RPTFE

21 SEALS/PACKING/GASKETS (2) : SPRIRAL WOUND AISI 316/GRAPHITE

22 BOLTING B : A193 Gr B8M/ A194 Gr. 8M

23 OPERATOR : LEVER OPERATOR

24 PAINTING : NOT REQUIRED

25 SPECIAL REQ'TS : NOT REQUIRED

26

27

28 INSPECTION & TESTING REQUIREMENTS

29 REQ'D INSPECTION & TESTING NOTES

(a)

30 VISUAL EXAMINATION 100% (a) WHERE VISUAL EXAMINATION INDICATES AREAS OF

31 MAGNETIC PARTICLE EXAMINATION NONE UNACCEPTABILITY, LIQUID PENETRANT EXAMINATION

32 LIQUID PENETRANT EXAMINATION(a) 10% SHALL BE APPLIED IN ACCORDANCE WITH ASME V

33 RADIOGRAPHIC EXAMINATION 100% OF B.W's ARTICLE 6

34

35 PRESSURE TEST (b) - BODY API 6D (b) TEST PRESSURES SHALL BE IN ACCORDANCE WITH

36 - SEAT - HIGH PRESS API 6D ANSI B16.34, TEST DURATION & ACCEPTANCE

37 - LOW PRESS API 6D CRITERIA SHALL BE IN ACCORDANCE WITH API -6D

38 SEAT LEAKAGE RATE API 6D

39 (c) API 607 CERTIFICATION REQUIRED

40 FIRE TEST CERTIFICATION (c) API 607

41

DATA SHEET No.

2539-4046-02-A1001-003

B 28/02/2017 ISSUED FOR APPROVAL NXT NTS LCH

A 16/01/2017 ISSUED FOR REVIEW NXT NTS LCH

PAGE 1 OF 1 REV : B

REV DATE DESCRIPTION BY CHK APP

BALL VALVE DATA SHEET

VALVE TYPE: VALVE SIZE (NPS) : MIN. 1/2" - MAX. 1" PRESSURE / TEMPERATURE RATINGS

MAX DESIGN TEMP - C -29/38 50 100

800# REDUCER BORE, SWxFNPT, BALL VALVE Q'TY (EA): REFER VALVE LIST

MAX DESIGN PRES - kPag 11030 10670 9280

DESIGN REQUIREMENTS

1 DESCRIPTIONS:

2 VALVE RATING : ANSI CLASS 800#

3 DESIGN TEMP. RANGE : -29oC MIN TO 100oC MAX

4 BORE : REDUCER BORE

5 END STYLE / CON'N : SW ENDS w/1 PE NIPPLES - PIPE SCH 40S, 100mm LENGTH. OTHERS F.NPT

6

7 PIPING CLASS : B52A

8 VALVE DESIGN STD : API 608

9 DESIGN / CONSTRUCT'N : 2 OR 3 PCS SPLIT BODY SIDE ENTRY, BOLTED CONNECTION

10 : LONG PATTERN

11 : FLOATING BALL

12 : FIRE SAFE AS PER API 607

13

14 MATERIALS:

15 BODY / BONNET : FORGINGS - ASTM A182 Gr.F316/316L

16 BALL : STAINLESS STEEL - AISI 316L

17 STEM : STAINLESS STEEL - AISI 316L

18 STEM SEAL : PRIMARY PTFE/ SECONDARY GRAPHITE

19 SEAT RINGS : RPTFE

20 SEAT INSERTS : RPTFE

21 SEALS/PACKING/GASKETS (2) : SPRIRAL WOUND AISI 316/GRAPHITE

22 BOLTING B : A193 Gr B8M/ A194 Gr. 8M

23 OPERATOR : LEVER OPERATOR

24 PAINTING : NOT REQUIRED

25 SPECIAL REQ'TS : NOT REQUIRED

26

27

28 INSPECTION & TESTING REQUIREMENTS

29 REQ'D INSPECTION & TESTING NOTES

30 VISUAL EXAMINATION(a) 100% (a) WHERE VISUAL EXAMINATION INDICATES AREAS OF

31 MAGNETIC PARTICLE EXAMINATION NONE UNACCEPTABILITY, LIQUID PENETRANT EXAMINATION

32 LIQUID PENETRANT EXAMINATION(a) 10% SHALL BE APPLIED IN ACCORDANCE WITH ASME V

33 RADIOGRAPHIC EXAMINATION 100% OF B.W's ARTICLE 6

34

35 PRESSURE TEST (b) - BODY API 6D (b) TEST PRESSURES SHALL BE IN ACCORDANCE WITH

36 - SEAT - HIGH PRESS API 6D ANSI B16.34, TEST DURATION & ACCEPTANCE

37 - LOW PRESS API 6D CRITERIA SHALL BE IN ACCORDANCE WITH API -6D

38 SEAT LEAKAGE RATE API 6D

39 (c) API 607 CERTIFICATION REQUIRED

40 FIRE TEST CERTIFICATION (c) API 607

41

DATA SHEET No.

2539-4046-02-A1001-003

B 28/02/2017 ISSUED FOR APPROVAL NXT NTS LCH

A 16/01/2017 ISSUED FOR REVIEW NXT NTS LCH

PAGE 1 OF 1 REV : B

REV DATE DESCRIPTION BY CHK APP

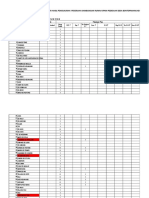

VALVE LIST

No. Name Size (Inch) Description Class Unit Rev Q'ty Remark

Ball Valve SWxFNPT with 1 Nipples & 1 FNPT,

1 Ball Valve (BA) 1/2 REDUCER BORE, Body-Forged/Cast ASTM A182 800 EA A 2 Class: B50AN

Gr.F304/304L. Stem SS304

Ball Valve SWxFNPT with 1 Nipples & 1 FNPT,

2 Ball Valve (BA) 1/2 REDUCER BORE, Body-Forged/Cast ASTM A182 800 EA A 2 Class: B52A

Gr.F316/316L. Stem SS316L

Ball Valve SWxFNPT with 1 Nipples & 1 FNPT,

3 Ball Valve (BA) 3/4 REDUCER BORE, Body-Forged/Cast ASTM A182 800 EA A 4 Class: B50AN

Gr.F304/304L. Stem SS304

Ball Valve SWxSW with 2 Nipples, REDUCER BORE,

4 Ball Valve (BA) 3/4 Body-Forged/Cast ASTM A182 Gr.F304/304L. Stem 800 EA A 4 Class: B50AN

SS304

Ball Valve SWxFNPT with 1 Nipples & 1 FNPT

5 Ball Valve (BA) 3/4 ,REDUCER BORE, Body-Forged/Cast ASTM A182 800 EA A 4 Class: B52A

Gr.F316/316L. Stem SS316 L

Ball Valve SWxSW with 2 Nipples,REDUCER BORE,

6 Ball Valve (BA) 3/4 Body-Forged/Cast ASTM A182 Gr.F316/316L. Stem 800 EA A 4 Class: B52A

SS316 L

Ball Valve SWxFNPT with 1 Nipples & 1 FNPT,

7 Ball Valve (BA) 1 REDUCER BORE, Body-Forged/Cast ASTM A182 800 EA A 1 Class: B50AN

Gr.F304/304L. Stem SS304

Ball Valve SWxSW with 2 Nipples, REDUCER BORE,

8 Ball Valve (BA) 1 Body-Forged/Cast ASTM A182 Gr.F304/304L. Stem 800 EA A 2 Class: B50AN

SS304

Ball Valve SWxSW with 2 Nipples, FULL BORE, Body-

9 Ball Valve (BA) 1 800 EA A 4 Class: B52A

Forged/Cast ASTM A182 Gr.F316/316L. Stem SS316L

Ball Valve SWxFNPT with 1 Nipples & 1

10 Ball Valve (BA) 1 FNPT,REDUCER BORE, Body-Forged/Cast ASTM 800 EA A 1 Class: B52A

A182 Gr.F316/316L. Stem SS316 L

Ball Valve SWxSWwith 2 Nipples, REDUCER BORE,

11 Ball Valve (BA) 1 Body-Forged/Cast ASTM A182 Gr.F316/316L. Stem 800 EA A 2 Class: B52A

SS316L

Ball Valve SWxSW with 2 Nipples, FULL BORE, Body-

12 Ball Valve (BA) 1 1/2 800 EA A 4 Class: B50AN

Forged/Cast ASTM A182 Gr.F304/304L. Stem SS304

También podría gustarte

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- PN416655 - 150B Inergen Design Manual UnlockDocumento187 páginasPN416655 - 150B Inergen Design Manual UnlockAob AprilAún no hay calificaciones

- Pricelist - March 2017Documento91 páginasPricelist - March 2017Almira Vania100% (2)

- SENTRY Pulsation DampenerDocumento2 páginasSENTRY Pulsation DampenerIntezar AliAún no hay calificaciones

- 966H 972H Hydraulic Schematic RENR8828Documento2 páginas966H 972H Hydraulic Schematic RENR8828Freddy Quispe100% (1)

- Greenline International Hydraulic AdaptersDocumento32 páginasGreenline International Hydraulic AdaptersBien Nguyen VanAún no hay calificaciones

- Check ValveDocumento99 páginasCheck ValvepganoelAún no hay calificaciones

- Cyl Lift 580SNDocumento3 páginasCyl Lift 580SNhandokoAún no hay calificaciones

- SSC Cat - Steam Relief ValvesDocumento15 páginasSSC Cat - Steam Relief ValvesArief sitompulAún no hay calificaciones

- Proportional Relief ValvesDocumento9 páginasProportional Relief ValvesSemeer AliAún no hay calificaciones

- Cong Ty Co Phan Au T Phat Trien Phuc Ien Phuc Dien Development Investment Joint Stock CompanyDocumento1 páginaCong Ty Co Phan Au T Phat Trien Phuc Ien Phuc Dien Development Investment Joint Stock CompanyHoan TrươngAún no hay calificaciones

- Bomba 4Documento2 páginasBomba 4Juan Carlos Moncada PáezAún no hay calificaciones

- Dokumen - Tips Cths430 02spcr2231394 01Documento82 páginasDokumen - Tips Cths430 02spcr2231394 01Higor Bisinella100% (1)

- Trabajo Semana 45 PH03Documento195 páginasTrabajo Semana 45 PH03Derlis Diego Yaringaño PerezAún no hay calificaciones

- Part List K7Documento27 páginasPart List K7negma6099Aún no hay calificaciones

- Review High Pressure Pump HawkDocumento1 páginaReview High Pressure Pump HawkbayuAún no hay calificaciones

- KSB Machine Directive Voor AfsluitersDocumento1 páginaKSB Machine Directive Voor AfsluitersSean FlanderhijnAún no hay calificaciones

- Curvas y PartesDocumento434 páginasCurvas y PartesPAHOLA ANDREA ARDILA PUERTOAún no hay calificaciones

- Manual HydraulicVentValveDocumento4 páginasManual HydraulicVentValvebentsopoAún no hay calificaciones

- DESMI CtalogDocumento28 páginasDESMI CtalogJoel Jeffery SarkarAún no hay calificaciones

- Fluid Mechanics & Machinery: Topic: Water Hammer in PipesDocumento12 páginasFluid Mechanics & Machinery: Topic: Water Hammer in PipesLoga MadishAún no hay calificaciones

- Data Hasil Pengukuran Pekerjaan Sambungan Rumah Spam Pedesaan Desa Bontoparang Kecamatan MangarabombangDocumento8 páginasData Hasil Pengukuran Pekerjaan Sambungan Rumah Spam Pedesaan Desa Bontoparang Kecamatan MangarabombangAkbarOdjaMappagalaAún no hay calificaciones

- Compression Fittings: Technical Helpline: +44 (0) 1473 277 460 Technical Helpline: +44 (0) 1473 277 460Documento56 páginasCompression Fittings: Technical Helpline: +44 (0) 1473 277 460 Technical Helpline: +44 (0) 1473 277 460thingsneededforAún no hay calificaciones

- P&id Boiler DrawingDocumento22 páginasP&id Boiler Drawingmanh hung leAún no hay calificaciones

- WWE Filter Press OperationDocumento4 páginasWWE Filter Press OperationMf LuiAún no hay calificaciones

- CALCULATION OF PIPING-01 - TableDocumento15 páginasCALCULATION OF PIPING-01 - TableAa W. Setiawan TheaAún no hay calificaciones

- Basic Pump ConstructionDocumento90 páginasBasic Pump ConstructionMariaEzzaSyUyAún no hay calificaciones

- Diaphragm Operated Pressure Flow Control Valve OmDocumento7 páginasDiaphragm Operated Pressure Flow Control Valve OmAnupmaAún no hay calificaciones

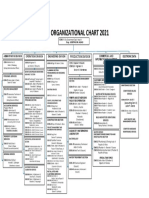

- Icws Organizational Chart 2021: Production Division Electronic Data Processing DivisionDocumento1 páginaIcws Organizational Chart 2021: Production Division Electronic Data Processing Divisionjanuary3196 :DAún no hay calificaciones

- Hydraulic Systems VI Handout PDFDocumento39 páginasHydraulic Systems VI Handout PDFMalik ForbesAún no hay calificaciones

- 3K Pump 26.2.2015Documento65 páginas3K Pump 26.2.2015TamAún no hay calificaciones