Documentos de Académico

Documentos de Profesional

Documentos de Cultura

EN13480 Equations

Cargado por

Gajanan Gaikwad0 calificaciones0% encontró este documento útil (0 votos)

102 vistas6 páginasEN13480 Equations

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoEN13480 Equations

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

102 vistas6 páginasEN13480 Equations

Cargado por

Gajanan GaikwadEN13480 Equations

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 6

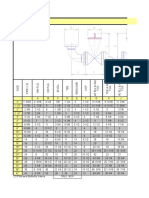

152.2016 EN- 13480 allowable stresses Sh Ilorgragh CADWorx & Analysis

CAESAR II Online Video Training

ONLINE Statics & Fundamentals Courses ee)

ois ainlimited Access - $89.00 per month!

You are not logged in. [Log In]

Home Page » Forums » Analysis Solutions » CAESAR II » EN-13480 allowable stresses

Sh

Register User Forumtist Calendar Active Topics 7 FAQ

Topic Options ¥| Who's Online

[d EN-13480 allowable stresses Sh #16117 - 05/19/08 11:52 PM ||1 registered (Rajith

TL), 12 Guests and 1

corne O ‘Spider online.

Member Hi all, Key: Admin, Global Nos,

Registered Can anybody explain me how the hot allowables in the mee a .

709/07 material database are calculated for the EN-13480

Posts: 385 | materials? March

Loe: The If I do a calculation for Sh according to chapter 5 I get

Netherlands | different (higher) values, so I want to double-check both ||S¥M Tu WTh F Sa

me and CII. 12345

Thanks in advance for your answers. 6 7 8 9 101112

— 13 14 15 16 17 18 19

28 20 21 22 23 24 25 26

Ed Re: EN-13480 allowable stresses Sh (Re: #18124 - 05/20/08 08:25 AM || 27 28 29 30 31

core)

hard Ai Forum Stats

ee rhs is 2 non-trivial, complex computation. These material || 10905 Members

Member properties took months of work and involved collaboration || 13 Forums

between a number of individuals. 14150 Topics

Taos. 63687 Posts

posts: 5544 | Specifically what material are you interested in, and what || go

ce: Hou. 2 lax Online:

eae usa” | SemPerature’ 12/06/09 11:14 aM

Regards,

Richard Ay

Intergraph CAS

Top

@ Re: EN-13480 allowable stresses Sh [Re: #18128 - 05/20/08 09:19 AM

lchard Av)

corne ©

Member Iwas double-checking for the simple $235 material

pegistres: | (1+0345) at 300 degr. Celsius.

07/09/07

ponte: 385 | T've got the fcold where Rm/3 is the minimal value of

lee: The (Rm/3 OR f). f being the minimum value of (ReH/1.5 OR

Netherlands | Rp0.2/1.5 OR Rm/2.4).

For the fh I get a value of 102 N/mm2 though where CII

gets a value of 88 N/mm2

When I calculate the allowable stress range for expansion

stress using CII fh of 88 I get the same result for fa as

CII. So the difference is in the calculation of fh

p65 57.258 421bbteadslubihreads php ?ibo-showfetsNumber= 18117 68

1522016 EN- 13400 allowable

resses Sh. Ilorgraph CADWorx & Analysis

All calculations are done according to chapter 5 and 12 of

EN-13480 and material properties from EN-10028-3,

Top

[@ Re: EN-13480 allowable stresses Sh (ge; #16137 - 05/20/08 03:12 PM

ssorne]

Ray_Delaforce|

Oo Hello Corne

Member

epistered Firstly, I think the material to which you refer is

01/02/03 P235GH 1.0345 not $235. I hope I am correct in this

Posts: 604 assumption. P235GH is a non austenitic steel (in other

Loc: Houston, 1x | words, a carbon steel) so we have to proceed along

these lines, We consider a 16 mm thick section:

From paragraph 5.2.1.1 we have the following

equation at 300C:

f = min(Rp0,2t/1,5: Rm / 2.4) Note: Reh does not

control here

= min(132/1,5; 360/2,4) = 88 MPa

For the flexibility analysis, we go to paragraph

12.1.3.

fe = min(Rm/3; f) = min(360/3; 88) = 88 MPa

fCR = SRTt/ SFCR, but we are not in the creep range,

so this equation is ignored

Finally:

fh = min(fc; f) = 88 MPa.

In the equation from paragraph 5.2.1.1 it is our

opinion that you cannot use Reh, especially as you are

you are considering a temperature of 300C.

I do not profess to be an expert in these matters, but I

consider the consverative approach is the correct one.

However, others may have a differetnt view.

\cerely,

Ray Delaforce

CADWorx & Analysis Solutions

Intergraph Process, Power, & Marine

INTERGRAPH

Too

{@ Re: EN-13480 allowable stresses Sh (ze: #18147 - 05/21/08 02:06 AM

Ray Delaforce

sons ©

Hrenber | Ray, thanks for your answer

seerea, | Which EN do you use to get the RpO,2t value? T think that

Reasteret: | Can be the cverence

meses S05

Netherlands

p65 57.258 42bbtcadsubihreads php ?bo-showfetsNumber= 18117

saz stows

|

resses Sh. Ilorgraph CADWorx & Analysis

G@ Re: EN-13480 allowable stresses Sh (Re: #18164 - 05/21/08 07:40 AM

corne]

Ray Delaforce

oO Hello Corne

Member

egistered We purchase our EN material specifications from the

ones British Standards Institution. We have found the odd

Posts: 604 typo. Do you have a different value for Rp0,2/t at 300C

Loc: Houston, 7x | for example? For P235GH 16 mm thick, our

specification gives the value as 132 MPa

Sincerely,

Ray Delaforce

CADWorx & Analysis Solutions

Intergraph Process, Power, & Marine

INTERGRAPH

Toe

[@ Re: EN-13480 allowable stresses Sh (Re: # 18167 - 05/21/08 08:44 AM

Ray Delaforce!

corne ©

ember | What odd typo have you found?

Realstees: | Imm at home atm and don't have the code here, but by

PeneS@s | head I thought Rp0,2 at 300C was 153 N/mm2. The value

tectme | of 132s at 400C.

Netherlands

Tam

( Re: EN-13480 allowable stresses Sh (Re: #18205 - 05/22/08 07:28 AM

cornel

corne ©

Member Hi Ray,

episterea; | Tthink’T've found the mistake. The plate and strip EN-

Realstret: | 9928-2 and the seamless pipe 10216-2 code give way

Posts: 365 | different allowables for P235.

Loe: The

Netherlands

Toe

[@ Re: EN-13480 allowable stresses Sh [Re: #18206 - 05/22/08 07:43 AM

corn]

Ray Delaforce|

1S Hello Corne

Member

ecistered 1am not saying you are wrong, because I do not know

51702703 what documentation you are looking at. I have in my

Posts: 604 hand the following specification:

Loc: Houston, TX

BS EN 10216-2: 2002(E) - Seamless Steel tubes for

pressure purposes.

1 look at P235GH 1.0345 (16 mm) and I find that

Rp0,2/t at 300C is 132 MPa. If you would like a scan of

that page, you can email me at

techsupport@coade.com. Simpy mention my name in

the subject line, and I shall do the necessary.

p65 57.258 42bbthcadsubihreads php ?ibo-showfetsNumber= 18117

1522016 EN- 13400 allowable

resses Sh. Ilorgraph CADWorx & Analysis

The problem may arise because each European

Community country re-writes the specification in their

own language, thus possibly introducing errors - I but 1

simply do not know.

We have had numerous queries centred around these

European materals.

‘About the typos: The only problem we have

encountered is when the Yield and UTS have been

transposed, and one or two yield values at elevated

temperatures have been transposed

\cerely,

Ray Delaforce

CADWorx & Analysis Solutions

Intergraph Process, Power, & Marine

INTERGRAPH

Top

05/22/08 09:18 AM

{@ Re: EN-13480 allowable stresses Sh (Re: #182:

Ray Delaforce!

core ©

ember | Hi Ray,

Regiewre: | ny this situation It was my mistake (or maybe the code

g7jon/o7= | makers one)

teevthe | I'checked EN-10028 for plate and strip cause that was the

Netherlands | code I had around. For some reason there is a big

difference in between EN-10028, which gives 153 N/mm2,

and EN-10216 (seamless pipe) which has 132 N/mm2.

Top

[ Re: EN-13480 allowable stresses Sh (Re: #22025 - 11/03/08 04:49 AM

come]

oO Ray and corne,

Member

registerea, | ADDreciate for the good work and bringing out the rare and

Revistered: | important topic.

Posts: 67

Loc: india I read the fc and fh calculation,very nice and interesting.

However, I found a correction and the process is re-written

below:

The ruling equation is

Fa = U (1.25 fe + 0.25 fh) [Eh/Ec] [Chapter 12]

‘And we need to find out " fc" and * fh”.

fe = min [ Rm/3 ; f ] Note: “f” is calculated with equation

5.2 at room temp.

&

fh = min [ fe ; f; fer ] “f" is calculated with 5.2 at

calculation temp.

NOW LETS CALCULATE

p65 57.258 421bbteadslubihreads php ?ibo-showfetsNumber= 18117

1522016 EN-13480 allowable stresses Sh Ilorgragh CADWorx & Analysis

1. “fer

According to 5.2,

~f = min( Reh/1.5 or Rp0.2t ; Rm/2.4)

As per the table-4, EN 10216-2, Rm = 360 Mpa and Rp0.2

= 235 Mpa [room temp]

‘Thus “f = min( 235/1.5 ; 360/2.4)

f = 150 Mpa

Therefore,from fe = min [ Rm/3 ; f ]

fe = min [360/3 ; 150]

fe = 120 Mpa

2. "th"

According to 5.2,

f= min( Reh/1.5 or Rp0.2t ; Rm/2.4)

As per the table-4, EN 10216-2, Rm = 360 Mpa and Rp0.2

= 132 Mpa [calculation temp 300 deg C]

Thus “f = min( 132/1.5 ; 360/2.4) = min [ 88 ; 150] = 88

Mpa

[ Fer= can be skipped ]

‘Therefore,from fh = min [Fe; f ; Fer ] = min [120 ; 88 ;

fer]

fh = 88 Mpa

So, the final value for the material P235GH at temp 300

degree C

Fo = 120 Mpa

Fh = 88 Mpa

There is a correction in Fc value with reference to Ray’s

calculation.

Your clarification will be entertained.

Edited by adi singh (11/03/08 07:25 AM)

Toe

G Re: EN-13480 allowable stresses Sh (Re: #22098 - 11/04/08 08:09 AM

‘adi singh)

Richard Ay|

Oo ‘The issue here is not the values of Fc or Fh, which if you

Member look in the CAESAR II material database are the same

egisterea: | Values as you list above:

12/13/99

fests: 5844 _| The difference here is that by default CAESAR II will use

Loc: Houston, | 12.3.4-2 instead of 12.1.3-1 for the expansion load case. If

‘Texas, USA” | you want to use 12.1.3-1 then go back to the input and on

the "Special Execution Options” dialog, turn off (uncheck)

the option for "Liberal Stress Allowable"

Regards,

Richard Ay

Intergraph CAS

INTERGRAPH

p65 57.258 421bbteadslubihreads php ?ibo-showfetsNumber= 18117

1522016 EN-13480 allowable stresses Sh Ilorgragh CADWorx & Analysis

Next Topic

Previous Topic

Moderator: Dave Diehl, Richard Ay Hop to: | CAESAR II

ao

|

Privacy statement - Board Rules - Mark all read

‘GooG_v2_copy_copy_copy

Contact Us - Home Page - Top

Generated in 0.059 seconds in which 0.009 seconds were spent on a total of 15 queries. Zlib compression disabled.

rs 68.

p65 57.258 42ubbtcadslubihreads php bo-showfetsNumber= 18117

PHP Forum

z

2

66

También podría gustarte

- Powerquery Demo StudentsDocumento10 páginasPowerquery Demo StudentsGajanan GaikwadAún no hay calificaciones

- 3.6-6 (7.2) KV MV Cable 1CDocumento1 página3.6-6 (7.2) KV MV Cable 1CGajanan GaikwadAún no hay calificaciones

- Familydatasheet 29907 enDocumento4 páginasFamilydatasheet 29907 enGajanan GaikwadAún no hay calificaciones

- 3.6-6 (7.2) KV MV Cable 3CDocumento1 página3.6-6 (7.2) KV MV Cable 3CGajanan GaikwadAún no hay calificaciones

- Ac SampleDocumento436 páginasAc SampleGajanan GaikwadAún no hay calificaciones

- ReferencesDocumento7 páginasReferencesGajanan GaikwadAún no hay calificaciones

- 3.6-6 (7.2) KV MV Cable 1CDocumento1 página3.6-6 (7.2) KV MV Cable 1CGajanan GaikwadAún no hay calificaciones

- LAPPKABELMainCatalogue 2021 PDFDocumento1094 páginasLAPPKABELMainCatalogue 2021 PDFdebasisAún no hay calificaciones

- In Place Load CaseDocumento12 páginasIn Place Load CaseGajanan GaikwadAún no hay calificaciones

- Product Catalogue 0116Documento239 páginasProduct Catalogue 0116Gajanan GaikwadAún no hay calificaciones

- Estimated Voltage Drop Calculator 1.1 - SIEMENSDocumento6 páginasEstimated Voltage Drop Calculator 1.1 - SIEMENSCipri RengleAún no hay calificaciones

- MultiGrid Support SystemDocumento84 páginasMultiGrid Support SystemGajanan GaikwadAún no hay calificaciones

- In Place Load CaseDocumento12 páginasIn Place Load CaseGajanan GaikwadAún no hay calificaciones

- WLLDocumento2 páginasWLLjillianixAún no hay calificaciones

- BINDER CATALOGUE 2015 COMPLETE WEB Rev 1 PDFDocumento174 páginasBINDER CATALOGUE 2015 COMPLETE WEB Rev 1 PDFRajendran SrnAún no hay calificaciones

- FRP System0712Documento48 páginasFRP System0712Gajanan GaikwadAún no hay calificaciones

- Eassessment in The Myp: Webinar Part IDocumento34 páginasEassessment in The Myp: Webinar Part IGajanan Gaikwad0% (1)

- Black HoleDocumento11 páginasBlack HoleGajanan GaikwadAún no hay calificaciones

- Reducing TeeDocumento4 páginasReducing TeeJevi SeptiawanAún no hay calificaciones

- Flanged Connection - Norsk Standard L-005Documento69 páginasFlanged Connection - Norsk Standard L-005Srdjan VareskicAún no hay calificaciones

- Piping Valve Flange DimensionsDocumento252 páginasPiping Valve Flange DimensionschadAún no hay calificaciones

- Process HeatingDocumento9 páginasProcess HeatingGajanan GaikwadAún no hay calificaciones

- Piping Valve Flange DimensionsDocumento252 páginasPiping Valve Flange DimensionschadAún no hay calificaciones

- Class 150# Flange Dimensions: ANSI B16.5 1/16" Raised Faced - Also Mate With ANSI B16.1 125# Flat Faced FlangesDocumento1 páginaClass 150# Flange Dimensions: ANSI B16.5 1/16" Raised Faced - Also Mate With ANSI B16.1 125# Flat Faced Flanges║║ Joe Beca ║║Aún no hay calificaciones

- Structure Stiffness S13Documento40 páginasStructure Stiffness S13Sandeep BhatiaAún no hay calificaciones

- Coade News Letter-FRP AnalysisDocumento28 páginasCoade News Letter-FRP Analysisshafeeqm3086Aún no hay calificaciones

- Pressure Thrust NotesDocumento2 páginasPressure Thrust NotesDebelmeAún no hay calificaciones

- Piping Codes, Valve Standards and Ball Valve Selection: Ron Manson, March 2015Documento37 páginasPiping Codes, Valve Standards and Ball Valve Selection: Ron Manson, March 2015shameer_febiAún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2102)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)