Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Technical Bulletin DTB04 Cold Resistance

Cargado por

canito73Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Technical Bulletin DTB04 Cold Resistance

Cargado por

canito73Copyright:

Formatos disponibles

Technical Bulletin DTB04

COLD RESISTANCE

A GUIDE TO COLD

RESISTANT

CONVEYOR BELTS

When the ambient temperature falls below -0C

rubber begins to lose its elasticity. As the

temperature falls, the rubber continues to lose

flexibility and its ability to resist abrasion, impact

and cutting. Eventually the belt is unable to trough

and pass around pulleys and the belt covers and

the rubber in the carcass begins to crack.

Ultimately, the belt will break because frozen rubber

becomes as brittle as glass.

Where there is a risk of extremely low temperatures

operators of conveyors should always ask the belt

supplier for confirmation of the minimum operating

temperature. Abrasion resistant belts can usually

withstand -30 to -40C. Other cover qualities (such

as oil or fire) are usually only able to withstand a

minimum temperature of -20C. For temperatures

lower than this, conveyors should be fitted with belts

especially designed to withstand extreme cold.

Dunlop Coldstar has been specifically engineered

to operate in extremely cold conditions as well as

providing outstanding resistance to other demands.

COLDSTAR RAS: cold and wear resistant

COLDSTAR ROS: resistant to mineral, animal and

vegetable oils

COLDSTAR ROM: resistant to vegetable and animal oils

COLDSTAR BV K: fire retardant according to EN 12882

Class 2A

COLDSTAR BV S: fire retardant according to EN 12882

Class 2B

COLDSTAR VT: fire retardant according to EN 12882

Class 5A)

Cover

characteristics

Coldstar

Tensile

Mpa

strength

(>)

Elongation

% (>)

at break

Tear

Mpa

strength

(>)

Hardness

Shore

A

3

Abrasion

mm

(aver.)

Min.

C

ambient

temperature

C

RAS

C

ROM

C

ROS

C

BV

K/S

C VT

15

14

18

15

15

400

400

400

500

400

10

5.5

605

605

615

575

605

35

140

85

110

125

-60

-40

-30

-40

-30

The given temperatures indicate the limit until which the belt is still

flexible enough to function normally.

Longer operational lifetime. One of the major

additional advantages of Coldstar is that it has

exceptionally good resistance to wear. For example,

the abrasion resistance of Dunlop RAS is more than

70% better than the international DIN Y standard.

Dunlop Coldstar belts also retain their resistance to

impact and cutting. This means that they provide a

much longer operational lifetime compared to belts

made by other manufacturers.

Splicing. Splicing methods used for cold resistant

belting are the same as for other rubber multi-ply and

steelcord belts. Splicing materials should always be

supplied by the manufacturer of the belt.

Seek advice. As often as not, the quality of a belt

(including its ability to resist extreme cold) is reflected

in its price. It is always worth the effort to check the

original manufacturers specifications very carefully

and ask for documented evidence of actual tested

performance before placing your order.

For more information on this subject please contact

your local Dunlop Sales representative or Dunlops

Application Engineering team on

+31 (0) 512 585 555

All information and recommendations in this bulletin have been supplied to the best of our knowledge, as accurately as possible and

updated to reflect the most recent technological developments. We cannot accept any responsibility for recommendations based solely

on this document.

DUNLOP CONVEYOR BELTING (HEAD OFFICE) Oliemolenstraat 2, PO Box 14 9200 AA Drachten The Netherlands

Tel.: +31 512 585 555 Fax: +31 512 524 599

POLAND Telephone: +48 32218 5070 FRANCE Telephone: +33 13055 3903 SPAIN Telephone: +34 93770 4597

RUSSIA Telephone: +7 49578 088 64 GERMANY Telephone: +49 2821 973405 ITALY Telephone: +39 363 906266

MOROCCO Tel.: +212 522 3465 80/85 GHANA Tel.: +233 302 799 011 THE UNITED ARAB EMIRATES Tel.: +971 4 880 6236

WWW.DUNLOPCONVEYORBELTING.COM

También podría gustarte

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- NWO Plans Exposed by Insider in 1969Documento36 páginasNWO Plans Exposed by Insider in 1969Stig Dragholm100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Human Sociobiology: A Holistic Approach (Dan Freedman)Documento126 páginasHuman Sociobiology: A Holistic Approach (Dan Freedman)Cynthia AndrewsAún no hay calificaciones

- Sidewall Brochure E Oct 14Documento4 páginasSidewall Brochure E Oct 14canito73Aún no hay calificaciones

- Beltwall: Corrugated Sidewall BeltingDocumento8 páginasBeltwall: Corrugated Sidewall Beltingcanito73Aún no hay calificaciones

- 5ede91e1f7025545c8e9e1a6 Fracwall BrochureDocumento4 páginas5ede91e1f7025545c8e9e1a6 Fracwall Brochurecanito73Aún no hay calificaciones

- 6 Impact Lifter BarDocumento2 páginas6 Impact Lifter Barcanito73Aún no hay calificaciones

- Technical Data Sheet For Impact Bar Germanshock® Ip 45Documento1 páginaTechnical Data Sheet For Impact Bar Germanshock® Ip 45canito73Aún no hay calificaciones

- Beltwall - Design Data FormDocumento1 páginaBeltwall - Design Data Formcanito73Aún no hay calificaciones

- Heavy Duty Brochure IMPERIAL PDFDocumento4 páginasHeavy Duty Brochure IMPERIAL PDFmamopiAún no hay calificaciones

- III. Coupling Assembling: Mining Hose SystemDocumento2 páginasIII. Coupling Assembling: Mining Hose Systemcanito73Aún no hay calificaciones

- Gantt Project Planner1Documento1 páginaGantt Project Planner1Cesareo2008Aún no hay calificaciones

- Conveyor BeltDocumento5 páginasConveyor BeltrajeevkumarrajeevAún no hay calificaciones

- Epoxy Ceramic Product BrochureDocumento4 páginasEpoxy Ceramic Product Brochurecanito73Aún no hay calificaciones

- Calma: Your KRAIBURG DealerDocumento1 páginaCalma: Your KRAIBURG Dealercanito73Aún no hay calificaciones

- Barmex FMC Rodillos Cema E4000Documento40 páginasBarmex FMC Rodillos Cema E4000canito73Aún no hay calificaciones

- KEW Plus Installation 0317 enDocumento2 páginasKEW Plus Installation 0317 encanito73Aún no hay calificaciones

- Kraiburg Comfort Mat Type KEW Plus: DLG-Test Report 5830 FDocumento4 páginasKraiburg Comfort Mat Type KEW Plus: DLG-Test Report 5830 Fcanito73Aún no hay calificaciones

- Legg Industrial Conveyor Belts CatalogDocumento17 páginasLegg Industrial Conveyor Belts Catalogcanito73Aún no hay calificaciones

- CordStripper EngDocumento18 páginasCordStripper Engcanito73Aún no hay calificaciones

- Excel Gantt Chart TemplateDocumento3 páginasExcel Gantt Chart Templatecanito73Aún no hay calificaciones

- Conveyor BeltDocumento5 páginasConveyor BeltrajeevkumarrajeevAún no hay calificaciones

- Metal Detector WorksheetDocumento2 páginasMetal Detector Worksheetcanito73Aún no hay calificaciones

- EMT 50 Metal Detector WebDocumento2 páginasEMT 50 Metal Detector Webcanito73Aún no hay calificaciones

- Conveyor BeltDocumento5 páginasConveyor BeltrajeevkumarrajeevAún no hay calificaciones

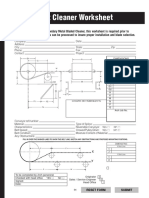

- Belt Cleaner WorksheetDocumento1 páginaBelt Cleaner Worksheetcanito73Aún no hay calificaciones

- Arch Cat2016 DownloadDocumento13 páginasArch Cat2016 Downloadcanito73Aún no hay calificaciones

- Deltahete Technical OverviewDocumento3 páginasDeltahete Technical Overviewcanito73Aún no hay calificaciones

- Dunloflex Leaflet EnglishDocumento2 páginasDunloflex Leaflet EnglishTorranin KansuntisukmongkolAún no hay calificaciones

- MD-T2 Metal DetectorDocumento2 páginasMD-T2 Metal Detectorcanito73Aún no hay calificaciones

- Ros SPS TPSDocumento4 páginasRos SPS TPScanito73Aún no hay calificaciones

- Metcorr117C Screenbrosjyre2006Documento2 páginasMetcorr117C Screenbrosjyre2006canito73Aún no hay calificaciones

- Neicchi 270 ManualDocumento33 páginasNeicchi 270 Manualmits2004Aún no hay calificaciones

- The Information Age CHAPTER 7 StsDocumento7 páginasThe Information Age CHAPTER 7 StsAngel FlordelizaAún no hay calificaciones

- MAUS Catalogue PDFDocumento10 páginasMAUS Catalogue PDFCarolina Garcés MoralesAún no hay calificaciones

- Exam1 Key JMB s06Documento13 páginasExam1 Key JMB s06Steve DangAún no hay calificaciones

- 6 Human Diseases That Cause by VirusesDocumento7 páginas6 Human Diseases That Cause by VirusesJefry JapAún no hay calificaciones

- Conference Proceedings: Inhaled Nitric Oxide: Delivery Systems and MonitoringDocumento27 páginasConference Proceedings: Inhaled Nitric Oxide: Delivery Systems and MonitoringPhanAún no hay calificaciones

- Formula Sheet Pre-MidDocumento4 páginasFormula Sheet Pre-MidUzair KhanAún no hay calificaciones

- Megapower: Electrosurgical GeneratorDocumento45 páginasMegapower: Electrosurgical GeneratorAnibal Alfaro VillatoroAún no hay calificaciones

- Soal Uh English XDocumento1 páginaSoal Uh English XhenniherawatiAún no hay calificaciones

- Excuse Letter1Documento1 páginaExcuse Letter1Myiel AngelAún no hay calificaciones

- Polycystic Ovary Syndrome (PCOS) - Symptoms, Causes, and TreatmentDocumento19 páginasPolycystic Ovary Syndrome (PCOS) - Symptoms, Causes, and TreatmentAkshay HarekarAún no hay calificaciones

- V. Aa. Gram A/S: DescriptionDocumento2 páginasV. Aa. Gram A/S: Descriptioncontango O&GAún no hay calificaciones

- BIS Ventilation Brochure enDocumento16 páginasBIS Ventilation Brochure enBruno SantosAún no hay calificaciones

- CPVC Price ListDocumento8 páginasCPVC Price ListYashwanth GowdaAún no hay calificaciones

- Good Boys Go To Heaven, Bad Boys Go EverywhereDocumento32 páginasGood Boys Go To Heaven, Bad Boys Go Everywherealcantaravic2006Aún no hay calificaciones

- Lithium Primary Batteries (Jauch)Documento72 páginasLithium Primary Batteries (Jauch)MedSparkAún no hay calificaciones

- hw410 Unit 9 Assignment 1Documento8 páginashw410 Unit 9 Assignment 1api-600248850Aún no hay calificaciones

- VEIKK A15PRO Instruction Manual 0714Documento20 páginasVEIKK A15PRO Instruction Manual 0714Corny777 UwUAún no hay calificaciones

- 2016 Specimen Paper 1 PDFDocumento16 páginas2016 Specimen Paper 1 PDFBioScMentor-1Aún no hay calificaciones

- Rotating Driver S Workstation and Rotating Cab: Reliable Solutions For More Ergonomic and Effective WorkingDocumento12 páginasRotating Driver S Workstation and Rotating Cab: Reliable Solutions For More Ergonomic and Effective WorkingEduardo CapeletiAún no hay calificaciones

- Qualification Handbook v1-1Documento92 páginasQualification Handbook v1-1rafael espinosa semperAún no hay calificaciones

- Job Satisfaction and Professional Ethics Practices in Public SectorDocumento13 páginasJob Satisfaction and Professional Ethics Practices in Public SectorMuhammad NafeesAún no hay calificaciones

- Fitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsDocumento24 páginasFitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsIrisha AnandAún no hay calificaciones

- Numerical Modelling of Brine Dispersion in Shallow Coastal WatersDocumento13 páginasNumerical Modelling of Brine Dispersion in Shallow Coastal WatersIAEME PublicationAún no hay calificaciones

- Major Head of AccountsDocumento9 páginasMajor Head of AccountsArun EmmiAún no hay calificaciones

- EN Ultra V Mini STP410S C54 UmhDocumento2 páginasEN Ultra V Mini STP410S C54 Umhjabt4568Aún no hay calificaciones

- UNIT-5 International Dimensions To Industrial Relations: ObjectivesDocumento27 páginasUNIT-5 International Dimensions To Industrial Relations: ObjectivesManish DwivediAún no hay calificaciones

- Human Nutritional RequirementsDocumento3 páginasHuman Nutritional RequirementsAgnesMagadiaAún no hay calificaciones