Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Improvement Plant Layout Using Systematic Layout Planning SLP For Increased Productivity PDF

Cargado por

Alejandro YugchaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Improvement Plant Layout Using Systematic Layout Planning SLP For Increased Productivity PDF

Cargado por

Alejandro YugchaCopyright:

Formatos disponibles

World Academy of Science, Engineering and Technology

Vol:4 2010-12-27

Improvement Plant Layout Using Systematic

Layout Planning (SLP) for Increased

Productivity

W. Wiyaratn, and A. Watanapa

International Science Index Vol:4, No:12, 2010 waset.org/Publication/3804

AbstractThe objective of this research is to study plant layout

of iron manufacturing based on the systematic layout planning

pattern theory (SLP) for increased productivity. In this case study,

amount of equipments and tools in iron production are studied. The

detailed study of the plant layout such as operation process chart,

flow of material and activity relationship chart has been investigated.

The new plant layout has been designed and compared with the

present plant layout. The SLP method showed that new plant layout

significantly decrease the distance of material flow from billet

cutting process until keeping in ware house.

KeywordsPlant layout, Systematic Layout Planning, Flow

analysis, Activity relationship chart

I. INTRODUCTION

ITH rapid increasing of demand in production,

industrial factories need to increase their potentials in

production and effectiveness to compete against their market

rivals. At the same time, the production process needs to be

equipped with the ability to have lower cost with higher

effectiveness. Therefore, the way to solve the problem about

the production is very important. There are many ways i.e.

quality control (QC), total quality management (TQM),

standard time, plant layout to solve the problems concerning

productivity. For example, a case studies from the lamp

industry [1]. The found problem was that the staff did not

work in orderly manner, resulting in confusion and no

standard time nor facilitating tool. The staff spent too much

time on work. The way to solve these problems was to

improve the steps in working and the area where they worked

through observation and fieldwork as well as proposing tools

to facilitate the work to set balance and find the standardized

time. In additional Yookkasemwong et al. [2] studied the

production process for Cable box to form metal. The problem

was that the work could not be finished within 8 hours. The

problem was then studied from data collection, the actual time

W. Wiyaratn. is with the Production Technology education, Faculty of

Industrial Education and Technology, King Mongkuts University of

Technology Thonburi, Bangkok, Thailand (corresponding author to provide:

e-mail: wisitsree.wiy@ kmutt.ac.th).

A. Watanapa. is with the Production Technology education, Faculty of

Industrial Education and Technology, King Mongkuts University of

Technology Thonburi, Bangkok, Thailand (e-mail: anucha.wat@ kmutt.ac.th)

International Scholarly and Scientific Research & Innovation 4(12) 2010

load, improper plant layout, and the duration of the process.

The principle of ECRS was adapted to reduce the waste and

arrange the repeated steps, resulting in changes in plant layout

and staff workload. The impact of improper plant layout on

the manufacturing process for valve and metal parts

production has been studied. The plant layout was changed to

comply with the international standards through SLP method

[3]. Sucharitkul et al. studied the possibility of plant layout

and installing aluminum foundry [4]. As for the layout of

plant, it was done in accordance with the steps in systematic

plant layout design. Yujie et al. studied the general plane of

long yards using SLP which the best layout showed the good

workflow and practical significance [5].

According to the researches mentioned above, plant layout

is one way to reduce the cost of manufacturing and increase

the productivity. Also increases good workflow in production

route. This research describes original plant layout, material

flow analysis, which includes area and distance between

operation A and B, through such a steel rod factory that was

case study. From the experience in steel rod factory, it was

found that there was wasted time or delay in manufacturing,

that is to say, the movement of the material in long line and

interrupted flow as well as useless area of the plant.

According to these problems, the researchers would like to

analyze the way to solve such problems and find the way to

improve the plant layout. The basic industrial layout planning

is applied to systematic layout planning (SLP) method in

which showed step-by-step of plant design from input data

and activities to evaluation of plant layout. This method

provides the new plant layout that improves the process flow

through the plant, and help to increase space in industries.

II. PROCEDURE FOR PLANT LAYOUT PLANTING

The data were collected and the number of tools/ equipment

for manufacturing was counted in terms of the direction for

raw materials and product. The operation process chart, flow

of material and activity relationship chart have been used in

analysis. The problem of the plant was determined and

analyzed through SLP method to plan the relationship

between the equipments and the area. The framework of SLP

is shown in Fig. 1. Based on the data such as product,

quantity, route, support, time and relationships between

material flow from to chart and activity relation chart are

309

World Academy of Science, Engineering and Technology

Vol:4 2010-12-27

displayed. From the material flow and relationship activity in

foundry production, the relation between each operation unit

can be observed. Then the results were drawn through the

comparison between the existing manufacturing process and

the proposed way.

Warehouse

Scissors to divide Billet

Re-heating Furnace

Data at P, Q, R, S, T levels and activities

Roughing mill

1. Material flow

2. Activity relationship

Intermediate mill

Finishing mill 1

3. Relational map

Finishing mill 2

International Science Index Vol:4, No:12, 2010 waset.org/Publication/3804

4. Needed space

5. Available space

10 miron bar cutter

6. Relational map of space

7. Considerations

for changes

Steel bar bender

Weighing

8. Practical limitations

Checking quality

Plan A

Plan C

Warehouse

Plan B

Customer

9. Result evaluation

Fig. 2 Flow of the operation for billet

Choose the plant

layout

Fig. 1 Systematic Layout Planning Method [3]

III. ANALYSIS OF ORIGINAL PLANT LAYOUT

In this study, the steel rod as production was mostly

made to customers order. The manufacturing process

was shown in Fig. 2 along with the flow of the operation

process. The size of the equipment was relational to the

area as shown in Table 1 and 2. The foundry would

produce rod steel with sizes 10, 16 and 20 mm.

According to the original plant layout, the flow of the

material, the utility of the area in the plant and material

handling equipment could be discussed as follows:

TABLE I

RELATIONSHIP BETWEEN EQUIPMENT SIZE AND AREA

Department

Cutting iron

Re-heating

Roughing

Intermediate

process

Finishing process

1

Finishing process

2

Cutting 10 micron

Bending billet

International Scholarly and Scientific Research & Innovation 4(12) 2010

310

Equipment

area/Working

area (m2)

21

Total

working

area(m2

21

134

134

620

646

13

14

15

17

16.5

18

3.3

109

426

Equipment

type

Number of

equipment

Dividing

scissors

Re-heating

Furnace

Roughing

stand

Intermediate

stand

Finishing

stand 1

Finishing

stand 2

10 micron bar

cutter

Billet bender

World Academy of Science, Engineering and Technology

Vol:4 2010-12-27

TABLE II

THE AMOUNT AND SEQUENCE FOR MANUFACTURING THE BILLET WITH SIZE

A=12 MM AND B=16-20 MM

International Science Index Vol:4, No:12, 2010 waset.org/Publication/3804

Details

1. Ware house

2. Billet was taken to cutting scissors

3. Cutting Billet

4. Putting Billet into furnace

5. Reheating Billet

6. Entering the process of Roughing

stand R1-R6

7. Crossing the Roughing stand R1-R6

8. Taken to Intermediate step

9. Milling at Intermediate M1-M8

10. Entering finish 1 process

11. Milling at finish 1 F1-F6

12. Entering finish 2 process

13. Milling the sign at finish2 F7-F8

14. Attending 10 m

15. Entering the process for cutting 10

m.

16. Dividing 10 m iron bar

17. Entering the bending

18. Bending 10 m iron bar

19. Taken to be weighed

20. Weighing

21. The metal was randomly picked up

for checking quality

22. Checking quality

23. Being stored at Ware house

24. Keeping at Ware house

Total

A:

Distance

(m.)

B: Distance

(m.)

30

19.26

9.78

30

19.26

9.78

20.26

10.43

8.46

22.21

13.89

8.3

8.08

9.38

7.84

20.26

10.43

8.46

22.21

13.89

9.38

7.84

4.94

4.25

37.13

4.94

4.25

37.13

13.40

227.61

13.40

211.23

D. Storage area of billet

Actually warehouse for billet or the raw materials was

1,020 square meters. One pile of billet took up 36 m2 so the

plant could contain billet for 9,310 tons per month. The plant

at the present time could contain only 8,000 tons per month.

After the improvement, it had more space to contain billet or

raw materials.

IV. ANALYSIS PLANT LAYOUT BASED ON SLP

According to the study of the manufacturing process, it was

found that the long distance could be reduced for moving raw

materials and the problem about useless area could be solved.

The way to improve the plant was to apply SLP method to

make the work flow continually by arranging the important

sequence of the manufacturing. Then the relationship of each

activity in closeness area was considered to make the

relationship of each activity in the graph from to chart as

shown in Fig 3 , and the closeness value are defined as A =

absolutely, E = especially important, I = important, O=

ordinary closeness, U= unimportant. The details for each

activity were described in Table 3, as follows:

A: Billet warehouse

B: Scissors to divide Billet

C: Re-heating Furnace

D: Roughing mill

E: Intermediate mill

F: Finishing mill 1

G: Finishing mill 2

H: 10 m. iron bar cutter

I: Steel bar bender

J: Weighing

K: Checking quality

A. The Flow of Materials

Raw materials were carried with long distance and that

means a waste in time and energy, resulting in high cost as

shown in Table 1, 2 such as moving the steel bar from

warehouse to scissors to divide billet for 30 meters, resulting

wasted time and more energy.

B. Utility of the Area

The area was not used to the full potential because old

machine and remaining materials were still there in the

working area, resulting in useless area of the plant.

The department of maintenance was still spacious and

adjacent to the area where the raw materials were kept,

resulting in limited area for storing raw materials

The area to store raw materials before moving to the process

of dividing billet was limited so the area could contain only

600 billets per day. The plant needed to move the raw

materials inside regularly until there were 60 billets per day.

Thus, this affected the cost of energy.

C. Material handling equipment

The material handling equipment of the raw materials was

not good enough, that is to say, fork lift was used to move in

one direction and the pathway was not flexible enough due to

untidy arrangement of the things. This was the reason why the

raw materials were to be carried for a long distance.

International Scholarly and Scientific Research & Innovation 4(12) 2010

Fig. 3 Relational graph of each activity

311

World Academy of Science, Engineering and Technology

Vol:4 2010-12-27

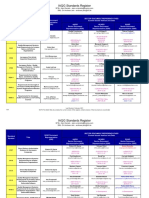

TABLE III

SHOWS THE WORKFLOW OF THE MANUFACTURING PROCESS IN DOUBLE STAGE

Product

(Per month)

Billet with the size of A

mm

Billet with the size of B

mm

Billet with the size of C

mm

3,000

6

4

Routing

A-B-C-D-E-F-G-H-I-J-K

1,500

A-B-C-D-E-F-H-I-J-K

1,000

A-B-C-D-E-F-H-I-J-K

8

9

2

10

11

1

International Science Index Vol:4, No:12, 2010 waset.org/Publication/3804

The important sequence of each activity was rearranged

from the most important one to the least important one as

shown in Fig 4. The intensities of flow from each activity to

another were developed in Fig 5.

A

B

6

K

J

I

H

G

F

E

D

C

B

A

7

8

9

2

11

10

1

C

6

Fig. 4 The sequence of activities in the manufacturing process

7

8

11

9

10

1

Fig. 6 Plant layout between origin and improvement

Fig. 5 The intensities of flow in the manufacturing process

Based on modifying plant layout and practical limitations, a

number of layouts were developed. There were 2 choices to

improve the plant layout as shown in Fig 6. The original plant

layout represents A, while modified plant layout represents B

and C.

International Scholarly and Scientific Research & Innovation 4(12) 2010

According to the analysis of the workflow for the billet

with the size of 10 mm (Table 4), it was found that the

distance from the moving out of the warehouse to dividing the

billet and to keeping at warehouse was 190.08 m., reduced

from 227.61 m. or reduced by 37.53 m. As for the billet with

sizes 16, 20 mm in the new plant layout, the distance for

moving materials was 187.80 m, reduced from 211.23 m. or

reduced by 23.43 m. Finally, rearrange layout decreased flow

of material, resulting in increased production.

312

World Academy of Science, Engineering and Technology

Vol:4 2010-12-27

TABLE IV

WORKFLOW OF THE MANUFACTURING PROCESS FOR BILLET WITH THE SIZE OF

A MM IN THE DOUBLE STAGE PLANT (NEW LAYOUT)

Distance

(meters)

International Science Index Vol:4, No:12, 2010 waset.org/Publication/3804

Details

1. Ware house

2. Billet was taken to cutting scissors

3. Cutting Billet

4. Putting Billet into furnace

5. Reheating Billet

6. Entering the process of Roughing

stand R1-R6

7. Crossing the Roughing stand R1-R6

8. Taken to Intermediate step

9. Milling at Intermediate M1-M8

10. Entering finish 1 process

11. Milling at finish 1 F1-F6

12. Entering finish 2 process

13. Milling the sign at finish2 F7-F8

14. Attending 10 m

15. Entering the process for cutting 10

m.

16. Dividing 10 m iron bar

17. Entering the bending

18. Bending 10 m iron bar

19. Taken to be weighed

20. Weighing

21. The metal was randomly picked up

for checking quality

22. Checking quality

23. Being stored at Ware house

24. Keeping at Ware house

Total

16

19.26

9.78

20.26

10.43

8.46

22.21

13.89

8.30

8.08

9.38

7.84

4.94

4.25

17

10

190.08

REFERENCES

[1]

[2]

[3]

[4]

[5]

S. Tenwong et al., Productivity improvement for the lamp

manufacturing, a dissertation for Masters degree in Manufacturing

Systems Engineering, School of Engineering, King Mongkuts

University of Technology Thonburi, 1991.

S.

Yookkasemwong,

S.

Pitchaya-anankul

and

Areerat

Bussarakamwadee, Process Improvement for increasing efficiency of

Cable Box Process, a project for Bachelors degree in Industrial

Engineering, School of Engineering, King Mongkuts University of

Technology Thonburi, 2005.

M. Khansuwan and C.

Poowarat, A Study on Plant Layout

Improvement: A Case Study at Kritchai Mechanical Company Ltd., a

project for Bachelors degree in Industrial Engineering, Faculty of

Engineering, Thammasat University, 1999.

T. Sucharitkul et al., The feasibility study and aluminium foundry plant

layout design : a case study : Sathien Plastic and Fibre, a dissertation

for Masters degree in Manufacturing Systems Engineering, School of

Engineering, King Mongkuts University of Technology Thonburi,

1999.

Y. Zhu, and F. Wang, , Study on the General Plane of Log Yards

Based on Systematic Layout Planning, IEEE. Computer Society, vol. 4,

pp. 9295, 2009.

International Scholarly and Scientific Research & Innovation 4(12) 2010

313

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- References FinalDocumento33 páginasReferences FinalRavi ShankarAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- Iso 9001-1400Documento26 páginasIso 9001-1400Komal KheroAún no hay calificaciones

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- IT Project ManagementDocumento29 páginasIT Project Managementaadarsh shresthaAún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Educ. 605 School Administration SupervisionDocumento19 páginasEduc. 605 School Administration Supervisionsazkiebonghanoy100% (2)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- IIMA Placement BrochureDocumento60 páginasIIMA Placement BrochureVignesh SelvarajAún no hay calificaciones

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- IFS Food 6.1 Implementation Workbook - Sample PDFDocumento40 páginasIFS Food 6.1 Implementation Workbook - Sample PDFfrmgsAún no hay calificaciones

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Impact of Cost Management On The ComDocumento34 páginasThe Impact of Cost Management On The Comsell easyAún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Afcons QMP 03062021Documento157 páginasAfcons QMP 03062021Adrian FrantescuAún no hay calificaciones

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- MAS Handout - Cost Management PDFDocumento4 páginasMAS Handout - Cost Management PDFDivine VictoriaAún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- TQM Lecture Ppt-1 SetDocumento59 páginasTQM Lecture Ppt-1 SetAshish SurveAún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- CV MallouliDocumento1 páginaCV MallouliMallouli KeremAún no hay calificaciones

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Lecture CombinedDocumento1291 páginasLecture CombinedgeorgeAún no hay calificaciones

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- PPT3-Managing QualityDocumento29 páginasPPT3-Managing QualityIka FitriAún no hay calificaciones

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Project Quality Management Overview For SMEDocumento5 páginasProject Quality Management Overview For SMEmubeen_bahoo11Aún no hay calificaciones

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- IAQG Standards Register Tracking Matrix February 01 2021Documento4 páginasIAQG Standards Register Tracking Matrix February 01 2021sudar1477Aún no hay calificaciones

- Lean Production & QualityDocumento47 páginasLean Production & QualityOckouri BarnesAún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- ISO 9001-2015 ChecklistDocumento16 páginasISO 9001-2015 ChecklistUsamah Bin AwnAún no hay calificaciones

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Ultimate List of ISO Standards For Medical Devices-1Documento34 páginasUltimate List of ISO Standards For Medical Devices-1Sridharan PadmanabhanAún no hay calificaciones

- E S F C: - Oriano Amily OrpDocumento41 páginasE S F C: - Oriano Amily Orpjohneric tuasonAún no hay calificaciones

- UW Water Resources and Innovation Conference 2015Documento61 páginasUW Water Resources and Innovation Conference 2015LungisaniAún no hay calificaciones

- Service Operations Management - Service QualityDocumento10 páginasService Operations Management - Service QualityAymen JarrarAún no hay calificaciones

- TQM Questions With AnswersDocumento54 páginasTQM Questions With AnswersDARK DANGER100% (2)

- Newzeland DairyDocumento11 páginasNewzeland DairyKhaled ArafatAún no hay calificaciones

- Isu Module Template Subject: IT BPO 3Documento13 páginasIsu Module Template Subject: IT BPO 3anne pascuaAún no hay calificaciones

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Supplier Audit ChecklistDocumento28 páginasSupplier Audit Checklist88No1FanAún no hay calificaciones

- Obtained From SQA Difference Between Iso 9001 and As 9100Documento44 páginasObtained From SQA Difference Between Iso 9001 and As 9100Kristian GarcidueñasAún no hay calificaciones

- QMS 9001-2015 Internal Auditor Training Presentation PDFDocumento17 páginasQMS 9001-2015 Internal Auditor Training Presentation PDFRuy MouraAún no hay calificaciones

- Creation of An IEC 62304 Compliant Software Development PlanDocumento10 páginasCreation of An IEC 62304 Compliant Software Development Plancana12Aún no hay calificaciones

- Imdrf Tech 151002 Samd QmsDocumento34 páginasImdrf Tech 151002 Samd QmsErnestoAlcoleaGonzálezAún no hay calificaciones

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- Quality in Hospitality IndustryDocumento12 páginasQuality in Hospitality IndustryKeith Loren ChavezAún no hay calificaciones

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)