Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Hydraulics Basic Level

Cargado por

Indhusekaran NatarajanDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Hydraulics Basic Level

Cargado por

Indhusekaran NatarajanCopyright:

Formatos disponibles

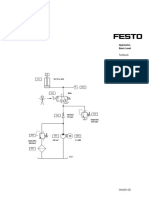

Hydraulics

Basic Level

Textbook TP 501

Festo Didactic

093281 en

093281_cover_textbook_tp501_en.indd 1 11.04.2005 17:00:09

Order No.: 093281

Description: HYDRAUL.LEHRB

Designation: D:LB-TP501-1-GB

Edition: 11/2003

Author: D. Merkle, B.Schrader, M. Thomes

Graphics: D. Schwarzenberger

Layout: 25.11.2003, M. Göttfert, G. Heigl, W. Schreiner

© Festo Didactic GmbH & Co. KG, 73770 Denkendorf/Germany, 2003

Internet: www.festo.com/didactic

e-mail: did@festo.com

The copying, distribution and utilization of this document as well as the

communication of its contents to others without expressed authorization is

prohibited. Offenders will be held liable for the payment of damages. All rights

reserved, in particular the right to carry out patent, utility model or ornamental

design registration.

Table of contents

1 Tasks of a hydraulic installation __________________________________ 7

1.1 Stationary hydraulics____________________________________________ 8

1.2 Mobile hydraulics _____________________________________________ 10

1.3 Comparison of hydraulics with other control media __________________ 11

2 Fundamental physical principles of hydraulics _____________________ 13

2.1 Pressure _____________________________________________________ 13

2.2 Pressure transmission __________________________________________ 18

2.3 Power transmission ____________________________________________ 19

2.4 Displacement transmission _____________________________________ 21

2.5 Pressure transfer ______________________________________________ 23

2.6 Flow rate_____________________________________________________ 25

2.7 Continuity equation ____________________________________________ 26

2.8 Pressure measurement _________________________________________ 30

2.9 Temperature measurement______________________________________ 31

2.10 Measurement of flow rate _______________________________________ 31

2.11 Types of flow _________________________________________________ 31

2.12 Friction, heat, pressure drop ____________________________________ 35

2.13 Energy and power _____________________________________________ 41

2.14 Cavitation ____________________________________________________ 51

2.15 Throttle points ________________________________________________ 53

3 Hydraulic fluid________________________________________________ 57

3.1 Tasks for hydraulic fluids _______________________________________ 57

3.2 Types of hydraulic fluid _________________________________________ 58

3.3 Characteristics and requirements_________________________________ 59

3.4 Viscosity _____________________________________________________ 60

4 Components of a hydraulic system _______________________________ 67

4.1 Power supply section __________________________________________ 67

4.2 Hydraulic fluid ________________________________________________ 67

4.3 Valves _______________________________________________________ 68

4.4 Cylinders (linear actuators) ______________________________________ 70

4.5 Motors (rotary actuators) _______________________________________ 71

© Festo Didactic GmbH & Co. KG • TP 501 3

Table of contents

5 Graphic and circuit symbols_____________________________________ 73

5.1 Pumps and motors_____________________________________________ 73

5.2 Directional control valves _______________________________________ 74

5.3 Methods of actuation __________________________________________ 75

5.4 Pressure valves _______________________________________________ 76

5.5 Flow control valves ____________________________________________ 78

5.6 Non-return valves _____________________________________________ 79

5.7 Cylinders ____________________________________________________ 80

5.8 Transfer of energy and conditioning of the pressure medium __________ 82

5.9 Measuring devices_____________________________________________ 83

5.10 Combination of devices _________________________________________ 83

6 Design and representation of a hydraulic system ___________________ 85

6.1 Signal control section __________________________________________ 86

6.2 Hydraulic power section ________________________________________ 87

6.3 Positional sketch ______________________________________________ 90

6.4 Circuit diagram________________________________________________ 91

6.5 Components plus technical data__________________________________ 92

6.6 Function diagram ______________________________________________ 94

6.7 Function chart ________________________________________________ 95

7 Components of the power supply section __________________________ 97

7.1 Drive ________________________________________________________ 97

7.2 Pump _______________________________________________________ 99

7.3 Coupling ____________________________________________________ 107

7.4 Reservoir ___________________________________________________ 107

7.5 Filters ______________________________________________________ 109

7.6 Coolers _____________________________________________________ 120

7.7 Heaters_____________________________________________________ 122

8 Valves______________________________________________________ 123

8.1 Nominal sizes________________________________________________ 123

8.2 Design _____________________________________________________ 125

8.3 Poppet valves________________________________________________ 126

8.4 Spool valves_________________________________________________ 127

8.5 Piston overlap _______________________________________________ 129

8.6 Control edges________________________________________________ 134

4 © Festo Didactic GmbH & Co. KG • TP 501

Table of contents

9 Pressure valves ______________________________________________ 137

9.1 Pressure relief valves _________________________________________ 137

9.2 Pressure regulators ___________________________________________ 144

10 Directional control valves______________________________________ 149

10.1 2/2-way valve _______________________________________________ 153

10.2 3/2-way valve _______________________________________________ 157

10.3 4/2-way valve _______________________________________________ 159

10.4 4/3-way valve _______________________________________________ 162

11 Non-return valves ____________________________________________ 167

11.1 Non-return valve _____________________________________________ 168

11.2 Piloted non-return valve _______________________________________ 172

11.3 Piloted double non-return valve _________________________________ 175

12 Flow control valves ___________________________________________ 179

12.1 Restrictors and orifice valves ___________________________________ 180

12.2 One-way flow control valve _____________________________________ 184

12.3 Two-way flow control valve _____________________________________ 185

13 Hydraulic cylinders ___________________________________________ 193

13.1 Single-acting cylinder _________________________________________ 194

13.2 Double-acting cylinder ________________________________________ 196

13.3 End position cushioning _______________________________________ 199

13.4 Seals_______________________________________________________ 200

13.5 Types of mounting ____________________________________________ 202

13.6 Venting _____________________________________________________ 202

13.7 Characteristics _______________________________________________ 203

13.8 Buckling resistance ___________________________________________ 205

13.9 Selecting a cylinder ___________________________________________ 207

14 Hydraulic motors_____________________________________________ 211

© Festo Didactic GmbH & Co. KG • TP 501 5

Table of contents

15 Accessories _________________________________________________ 215

15.1 Flexible hoses _______________________________________________ 217

15.2 Pipelines____________________________________________________ 223

15.3 Sub-bases __________________________________________________ 226

15.4 Bleed valves_________________________________________________ 228

15.5 Pressure gauges _____________________________________________ 229

15.6 Pressure sensors _____________________________________________ 230

15.7 Flow measuring instruments____________________________________ 231

16 Appendix ___________________________________________________ 233

6 © Festo Didactic GmbH & Co. KG • TP 501

1. Tasks of a hydraulic installation

What do we mean Hydraulic systems are used in modern production plants and manufacturing

by hydraulics? installations.

By hydraulics, we mean the generation of forces and motion using hydraulic fluids.

The hydraulic fluids represent the medium for power transmission.

The object of this book is to teach you more about hydraulics and its areas of

application. We will begin with the latter by listing the main areas for the application

of hydraulics.

The place held by hydraulics in (modern) automation technology illustrates the wide

range of applications for which it can be used. A basic distinction is made between:

• stationary hydraulics

• and mobile hydraulics

Mobile hydraulic systems move on wheels or tracks, for example, unlike stationary

hydraulic systems which remain firmly fixed in one position. A characteristic feature

of mobile hydraulics is that the valves are frequently manually operated. In the case

of stationary hydraulics, however, mainly solenoid valves are used.

Other areas include marine, mining and aircraft hydraulics. Aircraft hydraulics

assumes a special position because safety measures are of such critical importance

here. In the next few pages, some typical examples of applications are given to

clarify the tasks which can be carried out using hydraulic systems.

© Festo Didactic GmbH & Co. KG • TP 501 7

1. Tasks of a hydraulic installation

1.1 The following application areas are important for stationary hydraulics:

Stationary hydraulics • Production and assembly machines of all types

• Transfer lines

• Lifting and conveying devices

• Presses

• Injection moulding machines

• Rolling lines

• Lifts

Machine tool construction is a typical application area.

Lathe

In modern CNC controlled machine tools, tools and work pieces are clamped by

means of hydraulics. Feed and spindle drives may also be effected using hydraulics.

8 © Festo Didactic GmbH & Co. KG • TP 501

1. Tasks of a hydraulic installation

Press with elevated reservoir

© Festo Didactic GmbH & Co. KG • TP 501 9

1. Tasks of a hydraulic installation

1.2 Typical application fields for mobile hydraulics include:

Mobile hydraulics • Construction machinery

• Tippers, excavators, elevating platforms

• Lifting and conveying devices

• Agricultural machinery

There is a wide variety of applications for hydraulics in the construction machinery

industry. On an excavator, for example, not only are all working movements (such as

lifting, gripping and swivelling movements) generated hydraulically, but the drive

mechanism is also controlled by hydraulics. The straight working movements are

generated by linear actuators (cylinders) and the rotary movements by rotary

actuators (motors, rotary drives).

Mobile hydraulics

10 © Festo Didactic GmbH & Co. KG • TP 501

1. Tasks of a hydraulic installation

1.3 There are other technologies besides hydraulics which can be used in the context of

Comparison of hydraulics control technology for generating forces, movements and signals:

with other control media • Mechanics

• Electricity

• Pneumatics

It is important to remember here that each technology has its own preferred

application areas. To illustrate this, a table has been drawn up on the next page

which compares typical data for the three most commonly used technologies –

electricity, pneumatics and hydraulics.

This comparison reveals some important advantages of hydraulics:

• Transmission of large forces using small components, i.e. great

power intensity

• Precise positioning

• Start-up under heavy load

• Even movements independent of load, since liquids are scarcely

compressible and flow control valves can be used

• Smooth operation and reversal

• Good control and regulation

• Favourable heat dissipation

Compared to other technologies, hydraulics has the following disadvantages:

• Pollution of the environment by waste oil (danger of fire or accidents)

• Sensitivity to dirt

• Danger resulting from excessive pressures (severed lines)

• Temperature dependence (change in viscosity)

• Unfavourable efficiency factor

© Festo Didactic GmbH & Co. KG • TP 501 11

1. Tasks of a hydraulic installation

Electricity Hydraulics Pneumatics

Leakage Contamination No disadvantages apart from

energy loss

Environmental Risk of explosion in certain areas, Sensitive in case of temperature Explosion-proof,

influences insensitive to temperature. fluctuation, risk of fire in case of insensitive to temperature.

leakage.

Energy storage Difficult, only in small quantities Limited, with the help of gases. Easy

using batteries.

Energy transmission Unlimited with power loss. Up to 100 m, Up to 1000 m,

flow rate v = 2 – 6 m/s, flow rate v = 20 – 40 m/s,

signal speed up to 1000 m/s. signal speed 20 – 40 m/s.

Operating speed v = 0.5 m/s v = 1.5 m/s

Power supply costs Low High Very high

0.25 : 1 : 2.5

Linear motion Difficult and expensive, small Simple using cylinders, good speed Simple using cylinders, limited

forces, speed regulation only control, very large forces. forces, speed extremely, load-

possible at great cost dependent.

Rotary motion Simple and powerful. Simple, high turning moment, low Simple, inefficient, high speed.

speed.

Positioning accuracy Precision to ±1 µm and easier to Precision of up to ±1 µm can be Without load change precision of

achieve achieved depending on 1/10 mm possible.

expenditure.

Stability Very good values can be achieved High, since oil is almost Low, air is compressible.

using mechanical links. incompressible, in addition, the

pressure level is considerably

higher than for pneumatics.

Forces Not overloadable. Protected against overload, with Protected against overload,

Poor efficiency due to downstream high system pressure of up to 600 forces limited by pneumatic

mechanical elements. bar, very large forces can be pressure and cylinder diameter

Very high forces can be realized. generated F < 3000 kN. F < 30 kN at 6 bar.

12 © Festo Didactic GmbH & Co. KG • TP 501

2. Fundamental physical principles of hydraulics

2.1 Hydraulics is the science of forces and movements transmitted by means of liquids.

Pressure It belongs alongside hydro-mechanics. A distinction is made between hydrostatics –

dynamic effect through pressure times area – and hydrodynamics – dynamic effect

through mass times acceleration.

Hydro-mechanics

Hydrostatic pressure Hydrostatic pressure is the pressure which rises above a certain level in a liquid

owing to the weight of the liquid mass:

ps = h ⋅ ρ ⋅ g

T

T

psT

T

= hydrostatic pressure (gravitational pressure) [Pa]

h = level of the column of liquid [m]

ρ = density of the liquid [kg/m3] T

T

g = acceleration due to gravity [m/s2]

T

T

In accordance with the SI international system of units, hydrostatic pressure is given

in both Pascal and bar. The level of the column of liquid is given the unit “metre”,

the density of the liquid “kilograms per cubic metre” and the acceleration due to

gravity “metres per second squared”.

© Festo Didactic GmbH & Co. KG • TP 501 13

2. Fundamental physical principles of hydraulics

The hydrostatic pressure, or simply “pressure” as it is known for short, does not

depend on the type of vessel used. It is purely dependent on the height and density

of the column of liquid.

Hydrostatic pressure

Column: h = 300 m

ρ = 1000 kg/m3 T

T

g = 9.81 m/s2 = 10 m/s2

T

T

T

T

kg m m ⋅ kg ⋅ m N

pS = h ⋅ ρ ⋅ g = 300 m ⋅ 1000 3

⋅ 10 2 = 3 000 000 3 2

= 3 000 000 2

m s m ⋅s m

T

T

pS = 3 000 000 Pa = 30 bar

T

T

Reservoir: h = 15 m

ρ = 1000 kg/m3 T

T

g = 9.81 m/s2 = 10 m/s2

T

T

T

T

kg m m ⋅ kg ⋅ m N

pS = h ⋅ ρ ⋅ g = 15 m ⋅ 1000 3

⋅ 10 2 = 150 000 3 2

= 150 000 2

m s m ⋅s m

T

T

pS = 150 000 Pa = 1,5 bar

T

T

Elevated tank: h = 5 m

ρ = 1000 kg/m3 T

T

g = 9.81 m/s2 = 10 m/s2 T

T

T

T

kg m m ⋅ kg ⋅ m N

pS = h ⋅ ρ ⋅ g = 5 m ⋅ 1000 3

⋅ 10 2 = 50 000 3 2

= 50 000 2

m s m ⋅s m

T

T

pS = 50 000 Pa = 0,5 bar

T

T

14 © Festo Didactic GmbH & Co. KG • TP 501

También podría gustarte

- Hydraulics Basic Level PDFDocumento276 páginasHydraulics Basic Level PDFIwan Sb100% (1)

- Basic Principles of Pneumatics and Electropneumatics Textbook 573030Documento24 páginasBasic Principles of Pneumatics and Electropneumatics Textbook 573030Htoon Zaw LinnAún no hay calificaciones

- FESTO Hydraulics CourseDocumento236 páginasFESTO Hydraulics Coursemadmax2222100% (17)

- Hydraulic Control of Machine ToolsDe EverandHydraulic Control of Machine ToolsCalificación: 4.5 de 5 estrellas4.5/5 (4)

- Transparencies Electrohydraulics FestoDocumento64 páginasTransparencies Electrohydraulics FestoJosue CarpioAún no hay calificaciones

- Components for Pneumatic Control Instruments: The Static and Dynamic Characteristics of Pneumatic Resistances, Capacitances and Transmission LinesDe EverandComponents for Pneumatic Control Instruments: The Static and Dynamic Characteristics of Pneumatic Resistances, Capacitances and Transmission LinesAún no hay calificaciones

- Pneumatic and Hydraulic Control Systems: Seminar on Pneumohydraulic AutomationDe EverandPneumatic and Hydraulic Control Systems: Seminar on Pneumohydraulic AutomationCalificación: 4 de 5 estrellas4/5 (3)

- 02 Textbook TP501 enDocumento236 páginas02 Textbook TP501 enAlexander PenadoAún no hay calificaciones

- Fluid Power, Mechatronics, and ControlDocumento31 páginasFluid Power, Mechatronics, and ControlVinoth KumarAún no hay calificaciones

- Festo Solenoid Valve model MFH โซลินอยด์วาล์วเฟสโต้Documento66 páginasFesto Solenoid Valve model MFH โซลินอยด์วาล์วเฟสโต้Parinpa Ketar100% (1)

- Electrohydraulics Basic LevelDocumento202 páginasElectrohydraulics Basic LevelSavio Fernandes100% (9)

- Hydraulics and Pneumatics SystemsDocumento4 páginasHydraulics and Pneumatics SystemsKrista JacksonAún no hay calificaciones

- 99 Examples Pneumatic Applications PDFDocumento120 páginas99 Examples Pneumatic Applications PDFAndres RodriguezAún no hay calificaciones

- Pneumatic and Hydraulic Control Systems: Seminar on Pneumohydraulic Automation (First Session)De EverandPneumatic and Hydraulic Control Systems: Seminar on Pneumohydraulic Automation (First Session)Calificación: 1 de 5 estrellas1/5 (1)

- FESTO Electro-Hydraulics - Basic LevelDocumento203 páginasFESTO Electro-Hydraulics - Basic LevelAnonymous nOqqYoDvz100% (2)

- MX-0908537-Design of Hydraulic and Pneumatic Lab-Feb-2016-SpringDocumento104 páginasMX-0908537-Design of Hydraulic and Pneumatic Lab-Feb-2016-SpringIVÁN ARAYAAún no hay calificaciones

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDe EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideCalificación: 4 de 5 estrellas4/5 (8)

- Servo Valve Coloring BookDocumento18 páginasServo Valve Coloring BooksaikatmeAún no hay calificaciones

- 2 Sim Hydraulics ReferenceDocumento430 páginas2 Sim Hydraulics ReferenceEnrico GambiniAún no hay calificaciones

- Datasheet VT Modular enDocumento52 páginasDatasheet VT Modular enTimon2005Aún no hay calificaciones

- Industrial HydraulicsDocumento89 páginasIndustrial Hydraulicsnishhhengg100% (2)

- Festo-Close Loop HydraulicsDocumento356 páginasFesto-Close Loop HydraulicsGiorgio MackenzieAún no hay calificaciones

- Process Automation Festo DidacticDocumento28 páginasProcess Automation Festo DidacticHAMIT100% (8)

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansDe EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansCalificación: 4 de 5 estrellas4/5 (8)

- Hydraulics FestoDocumento232 páginasHydraulics FestoCHRISTOPHER100% (10)

- Festo Study MaterialDocumento70 páginasFesto Study Materialrammysi100% (3)

- Certified Manufacturing Engineer A Complete Guide - 2020 EditionDe EverandCertified Manufacturing Engineer A Complete Guide - 2020 EditionAún no hay calificaciones

- Some Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentDe EverandSome Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentCalificación: 3.5 de 5 estrellas3.5/5 (2)

- IHT Manual08031003Documento135 páginasIHT Manual08031003Geta100% (1)

- DS3 enDocumento164 páginasDS3 enBevy IndicioAún no hay calificaciones

- Fluid Power, Mathematical Design of Several Components (2014)Documento450 páginasFluid Power, Mathematical Design of Several Components (2014)MauricioYoshiharaGamezAún no hay calificaciones

- Basic Pneumatic Examen PDFDocumento34 páginasBasic Pneumatic Examen PDFRosalino Leonides Martinez Marquez100% (1)

- Proportional Hydraulics Decoded PDFDocumento63 páginasProportional Hydraulics Decoded PDFRobert MarkovskiAún no hay calificaciones

- Festo Pneumatics Basic Level LDocumento274 páginasFesto Pneumatics Basic Level LNaser Arbaby100% (4)

- Pneumatic and Hydraulic Components and Instruments in Automatic Control: Proceedings of the IFAC Symposium, Warsaw, Poland, 20-23 May 1980De EverandPneumatic and Hydraulic Components and Instruments in Automatic Control: Proceedings of the IFAC Symposium, Warsaw, Poland, 20-23 May 1980H. J. LeskiewiczCalificación: 1 de 5 estrellas1/5 (1)

- Mechatronics Lab ManualDocumento54 páginasMechatronics Lab ManualAjay Chacko100% (1)

- Fluid Power Ebook Fluid Power BasicsDocumento233 páginasFluid Power Ebook Fluid Power Basicspatil_raaj7234Aún no hay calificaciones

- PLC Stepper Motor ControllerDocumento12 páginasPLC Stepper Motor ControllerSibtain Ul Hassan100% (1)

- Electro Hydraulics Decoded PDFDocumento101 páginasElectro Hydraulics Decoded PDFRobert Markovski100% (1)

- SimHydraulics-User S Guide PDFDocumento64 páginasSimHydraulics-User S Guide PDFHéctor Ramiro Pérez RodríguezAún no hay calificaciones

- Hydraulics Workbook Basic Level TP 501-551141 - ResumoDocumento33 páginasHydraulics Workbook Basic Level TP 501-551141 - ResumoPcfs50% (4)

- HYdraulics Lab Manual - New1Documento115 páginasHYdraulics Lab Manual - New1Fati Mah100% (2)

- Hydraulic System:-: Chapter-2 Hydraulic, Pneumatic and Electrical Telemetry SystemsDocumento7 páginasHydraulic System:-: Chapter-2 Hydraulic, Pneumatic and Electrical Telemetry SystemsMayur ParmarAún no hay calificaciones

- Fluid Power SystemsDocumento142 páginasFluid Power SystemsAbel AregayAún no hay calificaciones

- FESTO Basic PLCDocumento180 páginasFESTO Basic PLCapi-3769014100% (25)

- Hidraulika FESTO 2019 PDFDocumento232 páginasHidraulika FESTO 2019 PDFKresimir Coric100% (1)

- ServiceManual - FB10-20-30 SM01 - 80-000007 - V01.01 - RIS - 2013-12-20Documento72 páginasServiceManual - FB10-20-30 SM01 - 80-000007 - V01.01 - RIS - 2013-12-20XaviAlonsoAún no hay calificaciones

- Hidrolik PDFDocumento236 páginasHidrolik PDFSuci SetianingsihAún no hay calificaciones

- Car Ed2011 enDocumento37 páginasCar Ed2011 enเปี๊ยก คนเดิมAún no hay calificaciones

- 0060739001156253276Documento14 páginas0060739001156253276rharihar26597Aún no hay calificaciones

- Id Motors: Operation and Maintenance ManualDocumento64 páginasId Motors: Operation and Maintenance ManualJose Maria Redondo CarsiAún no hay calificaciones

- EcodialAdvanceCalculation HelpDocumento53 páginasEcodialAdvanceCalculation HelpcauvongkhongmauAún no hay calificaciones

- 580 Hc107r O&mmanengDocumento193 páginas580 Hc107r O&mmanengMario Garcia67% (6)

- Y. Evaporator TC 15000 PDFDocumento187 páginasY. Evaporator TC 15000 PDFGloria Del Carmen MuñozAún no hay calificaciones

- DBA Service Manual Rev3Documento97 páginasDBA Service Manual Rev3manAún no hay calificaciones

- Hino 500 Series - Brochure PDFDocumento6 páginasHino 500 Series - Brochure PDFraaspoy2007100% (1)

- Turbo Generator & Its AuxiliariesDocumento89 páginasTurbo Generator & Its AuxiliariesPapun ScribdAún no hay calificaciones

- Spec Sheets - Cat 3126 PropulsionDocumento14 páginasSpec Sheets - Cat 3126 Propulsionhallohendra100% (6)

- Waukesha Gas Engines: Control SystemsDocumento15 páginasWaukesha Gas Engines: Control SystemsKilienAún no hay calificaciones

- VW Fluid Capacity Chart 2003Documento5 páginasVW Fluid Capacity Chart 2003Lalo Barajas GarciaAún no hay calificaciones

- Paul Dempsey-Home Generator Selection, Installation, and RepairDocumento241 páginasPaul Dempsey-Home Generator Selection, Installation, and RepairKhanh Quoc100% (2)

- MS Samsung Ar9000 Inverter AirconditioningDocumento2 páginasMS Samsung Ar9000 Inverter AirconditioningMacSparesAún no hay calificaciones

- 30 May - STEERING-SYSTEM SERVICEDocumento20 páginas30 May - STEERING-SYSTEM SERVICEHarry DaogaAún no hay calificaciones

- Komatsu PumpDocumento64 páginasKomatsu PumpAhmed Rezk98% (40)

- 30 - Methods of Taper TurningDocumento4 páginas30 - Methods of Taper Turningbhagirath360100% (2)

- I & M Hpto 14WDocumento53 páginasI & M Hpto 14Wdaniel100% (3)

- Chapter 2:components of Pneumatic Component Unit 1:the Air Service Unit ComponentDocumento5 páginasChapter 2:components of Pneumatic Component Unit 1:the Air Service Unit ComponentEdrian Rey Tablante BrizoAún no hay calificaciones

- Mitsubishi Diesel Generator Set KU Series SpecsDocumento1 páginaMitsubishi Diesel Generator Set KU Series SpecsJay-Mart Dela Cruz0% (1)

- Wiring Diagram - AutodataDocumento6 páginasWiring Diagram - AutodataHenry Wilian De La Cruz SandovalAún no hay calificaciones

- CHP 22Documento13 páginasCHP 22Abhiram Reddy100% (1)

- Rotary Disconnects: V5-T8-2 V5-T8-2 V5-T8-3Documento60 páginasRotary Disconnects: V5-T8-2 V5-T8-2 V5-T8-3mini2018Aún no hay calificaciones

- MX 516Documento5 páginasMX 516Хелфор УкраинаAún no hay calificaciones

- Código P0171Documento4 páginasCódigo P0171Transmisiones Automáticas ChepeAún no hay calificaciones

- Vehicle: Electrical Diagrams Engine Controls SchematicsDocumento21 páginasVehicle: Electrical Diagrams Engine Controls SchematicsFrancisco López Rosas100% (1)

- D6E/D7E Engine: 1. Check Sensor Value by VCADS Pro. or SDU A. Boost PressureDocumento3 páginasD6E/D7E Engine: 1. Check Sensor Value by VCADS Pro. or SDU A. Boost PressureyuoryAún no hay calificaciones

- Brake Checklist A4 L enDocumento1 páginaBrake Checklist A4 L enNantha Kumara PeriasamyAún no hay calificaciones

- AixamDocumento156 páginasAixamdockerwatsonAún no hay calificaciones

- CJ TN - : Deluge Valve, External ResettingDocumento16 páginasCJ TN - : Deluge Valve, External ResettingLeinner RamirezAún no hay calificaciones

- MACAPPB Standard System Components. Continuous Vibration, PDFDocumento21 páginasMACAPPB Standard System Components. Continuous Vibration, PDFmika cabelloAún no hay calificaciones

- Bonfiglioli Geared MotorDocumento584 páginasBonfiglioli Geared MotorProdip SarkarAún no hay calificaciones

- Lunati CatalogDocumento340 páginasLunati Catalogfreek76Aún no hay calificaciones

- Trane Scroll Compressor ComparisonsDocumento176 páginasTrane Scroll Compressor ComparisonsAnnika Cass100% (1)

- Collection and Conveyance of Raw Water From Source: Intake StructuresDocumento3 páginasCollection and Conveyance of Raw Water From Source: Intake StructuresAllana Grace RevecheAún no hay calificaciones

- Turbojet-Performance AnalysisDocumento6 páginasTurbojet-Performance AnalysisRajath ShettyAún no hay calificaciones