Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Hilti CB-G Eg

Cargado por

bDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Hilti CB-G Eg

Cargado por

bCopyright:

Formatos disponibles

Hilti Epoxy Grout (EG)

Solid base to build on.

Epoxy Grout

Advantages

Hilti Epoxy Grout is a Buy American-compliant, three component, 100%

solids, VOC and BGE free, high performance epoxy grouting system. This

specially formulated grout offers high strength providing excellent resistance

to impact and vibration. Using the most advanced amine technology this

grout meets today's needs of an effective and easy to use epoxy grout

designed to help protect people and the environment. Hiltis Epoxy Grout comes with a noncorrosive hardener, avoiding the risk of burns like with other epoxy products and making it a

DOT-non-hazardous product simplifying transportation and storage.

Order Information

Description

Package Contents

Qty

Epoxy Grout

59 lb. bucket

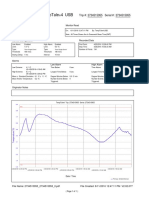

Technical Data

Epoxy Grout

Aspect

Standard

Compressive strength, psi (MPa) at 73F

(23C)

Item No.

00430898

8h

16 h

1 day

3 days

7 days

ASTM C

579 B

Imperial

Metric

6,000

12,000

12,500

14,000

15,000

(41)

(83)

(86)

(97)

(103)

Compressive modulus, psi (MPa)

ASTM D 695

568,000

(3,917)

Flexural strength, psi (MPa)

ASTM C 580

7 days

3,900

(27)

Tensile strength, psi (MPa)

ASTM C 307

7 days

2,100

(14)

Bond to concrete (complete concrete failure),

psi (MPa)

ASTM C 882

550

(4)

2,500

(17)

Adhesion to steel (clean, sandblasted), psi (MPa)

Coefficient of thermal expansion, 10-5 / C

ASTM D 696

1.74

Heat distortion temperature, F (C)

ASTM D 648

170

Working time at 72 F (22 C), min

Gel time at 72 F (22 C), min

ASTM D 2471

Trades and Facilities

Civil projects

Concrete professionals

Energy facilities

General contractors / construction

managers

Industrial plants

Ornamental steel artisans

Steel erectors

Purposes and Uses

(77)

45

90

Yield, 59 lb (26.8 kg)

Non-corrosive hardener no risk of

burns

Non-hazardous per DOT shipping

classification

VOC and BGE free

High early and ultimate strengths

High vibration resistance

Deep pour, low shrinkage

Self-leveling

Easy to use, all-in-one kit

High resistance to a variety of

chemicals

Best in class epoxy grout for worker

safety

0.40 ft3

(0.011 m3)

0.58 gal

0.14 gal

48.0 lb.

(2.18 L)

(0.51 L)

(21.8 kg)

Packaging, three component kit in one plastic

container

Part A: Resin

Part B: Hardener

Part C: Aggregate

Shelf life

24 months from date of manufacture when

stored properly in original unopened container

The data shown above reflect typical results based on laboratory testing under controlled conditions. Reasonable variations from

the data shown above may result.

Grouting of machinery and equipment

with high load requirements

Precision alignment under dynamic

load conditions

Structural grouting of baseplates,

columns, beams, crane rails, bridge

seats, dowels, etc.

Chemical processing facilities

Application Instructions

Read product instructions and MSDS before use.

Preparation

and needs to retain grout without leakage. The forms

should be protected with heavy coats of paste wax,

grease or form release agent.

thereby avoiding air entrapment. Provide vent holes where

needed to prevent air entrapment. Where grout cannot be

adequately worked to fill the cavity (because of large size

or limited space), a head box will greatly assist flow.

The surfaces to be grouted must be solid, clean and free

from oil, grease and other contaminants that may act as

a bond breaker. Remove all loose material and laitance.

Concrete surfaces must be dry, sound and roughened to

obtain proper bond. The grout and the affected grouting

area should be kept between 50 F and 90 F (10 C and 32

C) and shaded from direct sunlight. During cold weather

it is important that the grouted areas be kept warm (above

50 F or 10 C) until the grout has cured completely. Store

material at room temperature (70F-80F) for at least 24

hours before use. Set time and strength development are

dependent on ambient temperature. Hot temperatures

will accelerate the setting process of the grout while cold

temperatures will have a retarding effect. Metal surfaces

to come in contact with the epoxy grout should be

sandblasted to a white metal finish and wiped clean with

solvent before grout is applied. Apply grout immediately to

prevent re-oxidizing or moisture condensation.

Mixing

Pour the hardener into the resin container and mix with

a slow speed mixer (400 - 600 rpm) for approximately

1-2 minutes until thoroughly blended (the mix will show

a uniform color). Keep the mixing paddle submerged to

avoid air entrapment. Pour mixed resin and hardener into

a larger container. While mixing at low speed, slowly add

the included aggregate and mix until thoroughly blended

(aggregate must be completely wet). Always mix in

complete units do not mix smaller batches.

Clean-up

Formwork

Application

Aggregate (Part C) must be kept dry before use

Standard wood or metal forming may be used. The

formwork must provide rapid, continuous grout placement

For baseplates, forms should be at least 1" (2.54 cm)

higher than the bottom of the baseplate. The forms should

have 45 angle chamfer strips at all vertical corners and

horizontal grout grade elevation in order to eliminate sharp

corners. The clearance for remaining sides (distance

between the baseplate and the form) shall be 2-6" (50 to

152 mm).

Immediately after mixing, place grout from one side

allowing it to flow to the opposite and adjacent sides

Minimum application thickness per pour: 1" (25.4 mm)

Maximum application thickness per pour: 8" (203 mm)

Finishing

If a smooth finish is desired, the surface of the grout

may be ground and painted with an appropriate paint or

protective coating.

All tools and equipment may be cleaned with warm water

and a strong detergent solution before material hardens.

Storage

Always keep in closed container in a dry warm place

unexposed to sunlight.

Limitations

Do not use if the container is damaged

Do not add solvent, water or any other material to the

grout

Hilti. Outperform. Outlast.

Hilti, Inc. (U.S.) 1-800-879-8000 www.us.hilti.com en espaol 1-800-879-5000 Hilti (Canada) Corp. 1-800-363-4458 www.hilti.ca

También podría gustarte

- 4008 524 0311 04 Layout Da Cobranca Bradesco Versao InglesDocumento60 páginas4008 524 0311 04 Layout Da Cobranca Bradesco Versao InglesThiago Holanda CavalcanteAún no hay calificaciones

- Your Automatic Payments Schedule: PO Box 3199 Winston Salem, NC 27102-3199Documento4 páginasYour Automatic Payments Schedule: PO Box 3199 Winston Salem, NC 27102-3199Yenny VidalAún no hay calificaciones

- Sally Strausser 333 East Camp Street Mount Carmel, PA, 17851Documento2 páginasSally Strausser 333 East Camp Street Mount Carmel, PA, 17851Sally StrausserAún no hay calificaciones

- 2017 Toyota Camry Le Se Xle XseDocumento4 páginas2017 Toyota Camry Le Se Xle XseGeorge ZabarasAún no hay calificaciones

- Twenty LabsDocumento16 páginasTwenty LabsThe Salt Lake TribuneAún no hay calificaciones

- Hexoskin Patent PDFDocumento34 páginasHexoskin Patent PDFSayantan RahaAún no hay calificaciones

- Os SS 27Documento1 páginaOs SS 27Nard CruzAún no hay calificaciones

- Receipt PDFDocumento2 páginasReceipt PDFPramod ChavanAún no hay calificaciones

- RiteAid Employment ApplicationDocumento4 páginasRiteAid Employment Applicationmdb8778Aún no hay calificaciones

- New CXDocumento1 páginaNew CXAlexandra CortacAún no hay calificaciones

- In N OutDocumento3 páginasIn N OutJenna AmatulliAún no hay calificaciones

- Invoice - Zoya Ali Traders LLC 2023-02-02Documento2 páginasInvoice - Zoya Ali Traders LLC 2023-02-02Bahar AliAún no hay calificaciones

- Rons 438011068Documento4 páginasRons 438011068Jigar PatelAún no hay calificaciones

- Teleapp Final July 2017Documento4 páginasTeleapp Final July 2017Jomar TenezaAún no hay calificaciones

- DWS NEWS RELEASE - Unemployment Insurance Claims Report (1.7)Documento2 páginasDWS NEWS RELEASE - Unemployment Insurance Claims Report (1.7)Jennifer WeaverAún no hay calificaciones

- 46927-Folio BaymontDocumento1 página46927-Folio BaymontOctavio ChableAún no hay calificaciones

- GPDocumento3 páginasGPHarshitAún no hay calificaciones

- Simple ReceiptDocumento4 páginasSimple Receiptbarakasake300Aún no hay calificaciones

- Alvarado, Sandra E: SubscriberDocumento3 páginasAlvarado, Sandra E: SubscriberJohn LarbieAún no hay calificaciones

- InvoiceDocumento1 páginaInvoiceErick MoralesAún no hay calificaciones

- LucidChart MarzoDocumento2 páginasLucidChart MarzoHenry M Gutièrrez SAún no hay calificaciones

- Transcript, Penneast Pipeline Co., LLC v. New Jersey, No. 19-1039 (U.S. April 28, 2021)Documento104 páginasTranscript, Penneast Pipeline Co., LLC v. New Jersey, No. 19-1039 (U.S. April 28, 2021)RHTAún no hay calificaciones

- Tax Invoice: Charge DetailsDocumento3 páginasTax Invoice: Charge DetailsRohit SharmaAún no hay calificaciones

- PENNDOT BOP Strike Off LetterDocumento6 páginasPENNDOT BOP Strike Off LetterbcgpAún no hay calificaciones

- PDFDocumento2 páginasPDFAjay vermaAún no hay calificaciones

- Technical Data Sheet Enphase Microinverter PDFDocumento2 páginasTechnical Data Sheet Enphase Microinverter PDFJustin SitohangAún no hay calificaciones

- NYC - TLC - Driver ApplicationDocumento5 páginasNYC - TLC - Driver ApplicationMahid SamadAún no hay calificaciones

- Payslip To Print 04 29 2017 PDFDocumento1 páginaPayslip To Print 04 29 2017 PDFDoraAún no hay calificaciones

- Anshul Kirti: 839 N Marshall STDocumento1 páginaAnshul Kirti: 839 N Marshall STAnshul KirtiAún no hay calificaciones

- 0Documento1 página0PredaAlinAún no hay calificaciones

- Quark StoreReceipt PDFDocumento1 páginaQuark StoreReceipt PDFandrew234edwardAún no hay calificaciones

- Document Number: LCB-BP45752: Washington State Liquor Cannabis Board Banquet Permit (Does Not Authorize Sale of Alcohol)Documento1 páginaDocument Number: LCB-BP45752: Washington State Liquor Cannabis Board Banquet Permit (Does Not Authorize Sale of Alcohol)Alan ZhanAún no hay calificaciones

- ACFrOgBwQvRHVNt3wkSr-iydMTJjUhN0otU2QiaOeFXKNgOBS1ualGRA - Kc8UvsaB0f7Ives8JzHU3-QYGpyrFZ-czYWYeJHxN6jogwOK3wzaxX7skgOVRzszt-ovdE PDFDocumento3 páginasACFrOgBwQvRHVNt3wkSr-iydMTJjUhN0otU2QiaOeFXKNgOBS1ualGRA - Kc8UvsaB0f7Ives8JzHU3-QYGpyrFZ-czYWYeJHxN6jogwOK3wzaxX7skgOVRzszt-ovdE PDFJade JonesAún no hay calificaciones

- KeyBank Rollover FormDocumento1 páginaKeyBank Rollover FormmicheleAún no hay calificaciones

- Alarm Fkp4n04tb0 0Documento1 páginaAlarm Fkp4n04tb0 0FasiullahAún no hay calificaciones

- Providers - Blue Shield Promise Health Plan PDFDocumento3 páginasProviders - Blue Shield Promise Health Plan PDFMohamed ElmallahAún no hay calificaciones

- Txnelap Lab List PDFDocumento41 páginasTxnelap Lab List PDFFrancisco OdinsonAún no hay calificaciones

- Stelco From Scotia ProductionDocumento8 páginasStelco From Scotia ProductionForexliveAún no hay calificaciones

- Temptale 4 Usb: Sensi Sensi SensitechDocumento1 páginaTemptale 4 Usb: Sensi Sensi SensitechAnca CucuAún no hay calificaciones

- ClaimLetter 2023 4 21Documento17 páginasClaimLetter 2023 4 21cottontop187Aún no hay calificaciones

- Ticket SOADDocumento1 páginaTicket SOADFlorin Goku ComanAún no hay calificaciones

- Controles Remotos CanadaDocumento5 páginasControles Remotos CanadaCristian I. AlvarezAún no hay calificaciones

- Order HistoryDocumento1 páginaOrder HistoryTrenton DunstanAún no hay calificaciones

- Total Merchandise Newest QuoteDocumento3 páginasTotal Merchandise Newest QuoteAnonymous 1dpFmxkGAún no hay calificaciones

- Seth ShipDocumento1 páginaSeth ShipJonathan ThomasAún no hay calificaciones

- In Lai Allen 1200 (Order5)Documento1 páginaIn Lai Allen 1200 (Order5)jonjow22Aún no hay calificaciones

- Câmbio Atividade 12b Esther-OliveiraDocumento3 páginasCâmbio Atividade 12b Esther-OliveiraSabine PessanAún no hay calificaciones

- Acknowledgement Receipt 20190526 151008Documento2 páginasAcknowledgement Receipt 20190526 151008Arman PenalosaAún no hay calificaciones

- Complete With DocuSign App2515089pdf QuotepdDocumento8 páginasComplete With DocuSign App2515089pdf QuotepdSilvia GloverAún no hay calificaciones

- MAPFRE Insurance Terms and Conditions PDFDocumento3 páginasMAPFRE Insurance Terms and Conditions PDFSarah MccoyAún no hay calificaciones

- This Is Your Ticket.: Present This Entire Page at The EventDocumento3 páginasThis Is Your Ticket.: Present This Entire Page at The EventWilliam DowningAún no hay calificaciones

- Moog DINBufferAmplifier G123825001 TechnicalNote enDocumento4 páginasMoog DINBufferAmplifier G123825001 TechnicalNote enMauricio GuanellaAún no hay calificaciones

- Blue Shield CA Employee Enrollment Template v20160101Documento8 páginasBlue Shield CA Employee Enrollment Template v20160101Anonymous RLktVcAún no hay calificaciones

- Asus Mail in RebateDocumento1 páginaAsus Mail in RebateWeijin ZhaoAún no hay calificaciones

- 198826Documento1 página198826Raul Romero Jr.Aún no hay calificaciones

- Nvidia Nano DatasheetDocumento41 páginasNvidia Nano DatasheetASRAAún no hay calificaciones

- Cigna Global GOP ProviderDocumento2 páginasCigna Global GOP ProviderRoyer HyacintheAún no hay calificaciones

- Site Plan Review Application In-N-OutDocumento1 páginaSite Plan Review Application In-N-OutSinclair Broadcast Group - EugeneAún no hay calificaciones

- Devcon Plastic Steel Putty (A) - TDSDocumento3 páginasDevcon Plastic Steel Putty (A) - TDSsibi_s_raj100% (2)

- Grout AlternatesDocumento2 páginasGrout AlternatesAnonymous ua66zYwrpAún no hay calificaciones

- 2019 Chemical Engineering Plant Cost Index Annual Average: 68shareDocumento8 páginas2019 Chemical Engineering Plant Cost Index Annual Average: 68sharebAún no hay calificaciones

- 2008 Cepci PDFDocumento2 páginas2008 Cepci PDFbAún no hay calificaciones

- 2008 Cepci PDFDocumento2 páginas2008 Cepci PDFbAún no hay calificaciones

- Login 4589Documento1 páginaLogin 4589bAún no hay calificaciones

- Structural Engineers Area: ActivitiesDocumento1 páginaStructural Engineers Area: ActivitiesbAún no hay calificaciones

- Time Domain Digital Filter PDFDocumento2 páginasTime Domain Digital Filter PDFbAún no hay calificaciones

- Add To Favorites Contact Us: Home About Us Software Services Training Download Pricing Bolting Info NewsDocumento2 páginasAdd To Favorites Contact Us: Home About Us Software Services Training Download Pricing Bolting Info NewsbAún no hay calificaciones

- SafeRack Catalog Industrial Loading Platforms Safety and Fall Protection ProductsDocumento203 páginasSafeRack Catalog Industrial Loading Platforms Safety and Fall Protection ProductsbAún no hay calificaciones

- Engineered Elastomer - E-A-r Engineering Design GuideDocumento20 páginasEngineered Elastomer - E-A-r Engineering Design GuidebAún no hay calificaciones

- Turn-Of-Nut Bolting MethodDocumento12 páginasTurn-Of-Nut Bolting MethodbAún no hay calificaciones

- PhillyStran DeadEndsDocumento4 páginasPhillyStran DeadEndsbAún no hay calificaciones

- Time Domain Digital FilterDocumento2 páginasTime Domain Digital FilterbAún no hay calificaciones

- Difference Equation IDocumento2 páginasDifference Equation IbAún no hay calificaciones

- EPA Hot Mix Asphalt Plants Mineral Products Industry PDFDocumento63 páginasEPA Hot Mix Asphalt Plants Mineral Products Industry PDFMariano David Pons MerinoAún no hay calificaciones

- Mak Hydrol HLPDocumento2 páginasMak Hydrol HLPAbhimanyaAún no hay calificaciones

- RDT TEMPERATURE TRAINER ManualDocumento7 páginasRDT TEMPERATURE TRAINER ManualSHANKARAún no hay calificaciones

- Super Duplex Stainless Steel PipesDocumento3 páginasSuper Duplex Stainless Steel Pipeskumar sandeepAún no hay calificaciones

- Fluidised Bed ReactorDocumento10 páginasFluidised Bed Reactorshahzadali0786Aún no hay calificaciones

- Final Report 3D Chocolate PrintingDocumento20 páginasFinal Report 3D Chocolate PrintingPrathamesh PatilAún no hay calificaciones

- Mechanical FailureDocumento52 páginasMechanical FailureDirkPons100% (5)

- Cleaning, Casting Defects and Die Castings. CleaningFettling of CastingsDocumento70 páginasCleaning, Casting Defects and Die Castings. CleaningFettling of Castingsmecaunidos7771Aún no hay calificaciones

- ZF-Ecomat and Ecomat 2Documento38 páginasZF-Ecomat and Ecomat 2duongpndng80% (5)

- Tutorial Getting Started With Code AsterDocumento12 páginasTutorial Getting Started With Code Asterjuanpalomo74Aún no hay calificaciones

- CD150MV Wellpoint Pump: FeaturesDocumento2 páginasCD150MV Wellpoint Pump: FeaturesAbcehmu EgiAún no hay calificaciones

- Corrnew NR 3 LRDocumento28 páginasCorrnew NR 3 LRAngelica Alejandra Gonzalez AlvaradoAún no hay calificaciones

- Fire Ratings of Masonry Walls - tcm68-1374563Documento3 páginasFire Ratings of Masonry Walls - tcm68-1374563ervikas34Aún no hay calificaciones

- Manual Generador ENGGADocumento20 páginasManual Generador ENGGAmanuel100% (2)

- Cassida Fluid HFDocumento3 páginasCassida Fluid HFrinthusAún no hay calificaciones

- Silicon Water PellerDocumento2 páginasSilicon Water Pellerpravi3434Aún no hay calificaciones

- CFBC Boiler Bed MaterialDocumento2 páginasCFBC Boiler Bed MaterialmkoelrealAún no hay calificaciones

- Alkylation Complex Start Up Plan: ObjectivesDocumento10 páginasAlkylation Complex Start Up Plan: ObjectivesBikas SahaAún no hay calificaciones

- CEFIC Guidelines Transport Equipment Packed Cargo (2010)Documento7 páginasCEFIC Guidelines Transport Equipment Packed Cargo (2010)sl1828Aún no hay calificaciones

- TEMA Standard PDFDocumento302 páginasTEMA Standard PDFlubangjarumAún no hay calificaciones

- D 004663 PDFDocumento96 páginasD 004663 PDFAmirAmiriAún no hay calificaciones

- E-Catalogue Epoxy Flake Coating Single ColorDocumento49 páginasE-Catalogue Epoxy Flake Coating Single ColorSiti Cleaning100% (1)

- Advanced Lattice Support Structures For Metal Additive ManufacturingDocumento8 páginasAdvanced Lattice Support Structures For Metal Additive Manufacturinghadi32Aún no hay calificaciones

- Introduction To FRP Pipes Their Properties Specification Codes Joining Supporting and Applications WDocumento7 páginasIntroduction To FRP Pipes Their Properties Specification Codes Joining Supporting and Applications WjoecardAún no hay calificaciones

- Chapter 5 Steel and Metal Part 3Documento21 páginasChapter 5 Steel and Metal Part 3Joseph Cloyd LamberteAún no hay calificaciones

- 2.molykote 1000Documento11 páginas2.molykote 1000pichet33Aún no hay calificaciones

- Knauf Sheetrock Firestop 12.5mm-16mm - Technical Datasheet - PB02 - LE - FL - 0422 - V1Documento2 páginasKnauf Sheetrock Firestop 12.5mm-16mm - Technical Datasheet - PB02 - LE - FL - 0422 - V1Matt WilliamsAún no hay calificaciones

- MR366X8423A000Documento128 páginasMR366X8423A000Guillermo MV100% (1)

- LNG Onshore ProductionDocumento4 páginasLNG Onshore ProductionAnil B YadavAún no hay calificaciones

- Bca 2Documento7 páginasBca 2andy3262Aún no hay calificaciones