Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Two-Phase Flow Behavior and Spinner Data Analysis in Geothermal Wells

Cargado por

Irwan JanuarDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Two-Phase Flow Behavior and Spinner Data Analysis in Geothermal Wells

Cargado por

Irwan JanuarCopyright:

Formatos disponibles

PROCEEDINGS, Thirtieth Workshop on Geothermal Reservoir Engineering

Stanford University, Stanford, California, January 31-February 2, 2005

SGP-TR-176

TWO-PHASE FLOW BEHAVIOR AND SPINNER DATA ANALYSIS IN GEOTHERMAL

WELLS

Jorge A. Acuaa and Brian A. Arcederab

(a) Unocal Geothermal Technology and Services, 1160 N Dutton Ave Suite 200, Santa Rosa, California, 95401

(b) Philippine Geothermal, Inc., 12th Floor, Citibank Tower, 8741 Citibank Plaza, Paseo de Roxas, Makati City,

Philippines 1226

jacuna@unocal.com, barcedera@unocal.com

ABSTRACT

A method has been developed for interpretation of

Pressure-Temperature-Spinner (PTS) surveys. Driftflux and homogenous flow models are evaluated for

application in two-phase flow in geothermal wells. It

was found high fluid velocity makes possible simple

assumptions regarding holdup and friction losses.

The analysis method provides sufficient resolution to

determine mass contribution and enthalpy of

individual feed zones in geothermal wells. Technique

is described and a field example provided.

INTRODUCTION

Pressure-temperature-spinner (PTS) surveys are a

valuable

surveillance

tool

for

diagnosing

performance problems with geothermal wells and

evaluating changes in reservoir conditions.

Interpretation of PTS surveys typically relied heavily

on wellbore simulation. To match a model to

observations a trial and error procedure must be

followed to determine location and individual feed

zone contribution both in terms of mass and enthalpy

in the two-phase part of the well. The contribution of

individual feed zones is usually seen as increases in

fluid velocity. An estimation of the feed zone

enthalpy must be made in order to convert velocity

changes to mass contributions. If a well has a

particularly cold shallow feed zone or a thief zone,

there is a decrease or no change in spinner velocity.

In those circumstances the interpretation becomes

difficult.

In the past we have used pressure gradient of the well

to estimate minimum flowing enthalpy. As long as

the friction losses are small and can be neglected this

method provides an estimate of flowing enthalpy that

agrees reasonably well with measured wellhead

enthalpy. The assumption of small friction losses,

however is only valid in the deeper part of the well

where fluid velocity is small.

We set out to develop a simple method to estimate

the mass and energy distribution in the wellbore so

that we could calculate the location and contribution

of the individual feed zones.

THEORETICAL BACKGROUND

In wellbore simulation for every section of the well

there are two main unknowns: the liquid holdup and

the friction loss. The liquid holdup is the ratio of the

area of the pipe occupied by liquid to the total area.

This ratio depends on the velocity of the individual

phases. Steam is expected to flow faster than liquid.

The difference between the two velocities is called

slip velocity. Instead of liquid holdup (fl), volumetric

gas fraction (fg) can be used, the two are related by

equation (1).

f g + fl = 1

(1)

Modern treatment of two-phase flow in vertical wells

describes four different flow regimes: bubbly, slug,

churn and annular. Some other regimes are also

mentioned such as dispersed bubbly (Hasan and

Kabir, 2002) and wispy annular (Collier and Thome,

1996). For each of those flow regimes holdup and

friction loss expressions are available in Hasan and

Kabir (2002).

For each section of the well the flow regime must be

determined first in order to apply the corresponding

equations of liquid holdup and friction loss. This

requires knowing mass flow and enthalpy. For

geothermal wells these variables are measured only at

the surface, therefore the analysis must start by

defining the feed zone locations and contributions

that determine the mass flow and enthalpy variation

along the well.

The homogenous and drift flux models

To determine liquid holdup two models are available:

homogenous flow and separated flow. The

homogeneous flow model provides a simple

treatment of two-phase flow. It assumes that both

phases can be treated as a single fluid moving at the

same velocity with no slip velocity. Appropriate

expressions for density and viscosity are used. The

mixture density of the two-phase fluid is related to

volumetric gas fraction (fg) as

m = ( f g ) g + (1 - f g ) l

(2)

where is density and the subscripts m, l and g refer

to mixture, liquid and gas. The same expression using

viscosity instead of density can be applied to

calculate average viscosity and corresponds to the

Dukler formulation described in Hasan and Kabir,

(2002). Under non-slip conditions, characteristic of

homogeneous flow, the flowing fluid density or

mixture density is equal to the static density or mass

averaged density.

Contrary to the homogeneous flow model, separated

flow models treat each phase separately. These

models account for different velocity of the phases or

slip velocity. One of the most common models used

to describe two-phase flow is the drift flux model as

described by Hasan and Kabir (2002). This model

can be used without reference to any particular flow

regime for high pressure steam-water mixtures

according to Collier and Thome (1996).

The flowing gas volumetric fraction (fg) according to

the drift flux model can be expressed as follows.

fg =

v sg

Co vm + v (1 f g ) n

(3)

where vsg, vm, C0, v are gas superficial velocity

(volumetric gas rate divided by total pipe area), total

superficial velocity (total volumetric rate divided by

pipe area), flow parameter and terminal-rise velocity

respectively. The exponent n can range from 0 to 3

depending on flow regime (Kleinstreuer, 2003).

Ansari et al. (1994) found that a value of 0.5

provided the best fit to their data.

The flow parameter C0 , also called concentration

factor is an empirical factor that accounts for the

fact that the velocity profile and the void or bubble

concentration profile across the pipe may vary

independently of each other. If the void fraction

profile is uniform across the pipe then the flow

parameter C0 is equal to 1 (Kleinstreuer, 2003). The

recommended value of this parameter, however, is

1.2 based on experiments in 1- to 2-in diameter pipes.

For steam-water flow at elevated pressures a value of

1.13 is recommended (Collier and Thome, 1996).

The terminal-rise velocity is the velocity of a single

bubble rising in an infinite liquid medium. An

expression for this velocity as recommended for high

pressure steam-water mixtures (Collier and Thome,

1996) is the following.

g ( f g )

v = 1.41

2f

0.25

(4)

In this equation , g, are surface tension, gravity

constant and density respectively. The subscripts f

and g refer to liquid and steam respectively. In twophase flow gas and liquid density as well as surface

tension are functions of pressure or temperature as

they are related by saturation conditions. The

terminal-rise velocity varies very little with pressure,

it changes between 0.21 and 0.19 m/s for pressures

between 6 and 30 bar.

According to Collier and Thome (1996), for the drift

flux model to be applicable, the terminal-rise velocity

must be significant with respect to the volumetric

velocity (v > 0.05 vm). This is not the case for many

geothermal wells.

Flow in a typical well occurs mostly in the high

velocity flow regimes: churn and annular. Churn flow

is sometimes also referred to as semi-annular,

annular-slug or froth flow. It is characterized by the

liquid phase being mainly displaced to the pipe wall

with the vapor flowing in a chaotic manner through

the liquid. Annular flow is characterized by the vapor

phase flowing in the core of the pipe while the liquid

phase is dragged along the pipe walls forming an

annulus. A fraction of the liquid, sometimes most of

it, flows as droplets entrained in the gas core (Hasan

and Kabir, 2002).

A volumetric steam fraction of 0.52 is the criteria for

transition from slug to churn flow (Hasan and Kabir,

2002). Figure 1 shows the pressure below which the

volumetric steam fraction is larger than 0.52 as a

function of enthalpy. Figure 1 also shows the flashing

pressure for liquid at that enthalpy.

As can be seen in Figure 1 at low enthalpies there is

very little difference between flashing pressure and

the pressure required to reach churn flow. It can be

shown that a volumetric gas fraction greater than 0.52

is reached less than 200 m above the flashing level

for fluid enthalpy below 1100 kJ/kg. The criteria for

transition from churn to annular flow is when the gas

fraction is greater than 0.52 and the gas velocity

exceeds that given by equation (5).

g ( f g )

v gs = 3.1

g2

0.25

(5)

where the symbols have the same meaning of

equation (4). As the flow gets dryer the terminal-rise

velocity term disappears from equation (3) as fg gets

closer to 1. The flow parameter C0 can be set to 1 in

annular flow according to Kleinstreuer (2003). The

assumption of homogeneous flow is made for the

equivalent of annular flow, called mist flow, in the

Duns and Ros two-phase flow correlation (Hasan and

Kabir, 2002).

Depending on pressure and flow rate a well can

transition directly from slug to annular flow without

going through churn flow.

the pipe area in a large diameter than in a small

diameter pipe.

The working hypothesis for this paper is that flow

velocity is large enough so that there is no slip

velocity and the flow is homogenous. Our experience

in matching PTS surveys shows that this assumption

should be reasonable for volumetric gas fraction

greater than 0.52 and fluid velocities greater than 3

m/s.

Friction factor considerations

180

The equation that describes the total pressure gradient

in a well is composed by three terms: gravity term,

friction losses and acceleration term as shown in

equation (6)

160

P for fg = 0.52

Pressure (bar a)

140

Flashing Pressure

120

100

80

fvm2

v dv

dP

g

= m cos + m

+ m m m

dz

gc

2gc D

g c dz

60

40

(6)

20

0

900

1000

1100

1200

1300 1400 1500

1600 1700

Enthalpy (kJ/kg)

Figure 1: Pressure below which volumetric steam

fraction is larger than 0.52 and flashing

pressure for liquid at that enthalpy.

The gas velocity given by equation (5) is called

terminal velocity in oil and gas literature. It has

been described as the minimum velocity required by

gas to carry liquid droplets in suspension (Coleman et

al. 1991). In gas wells when the gas velocity is below

the terminal velocity the well starts to load up or

accumulate liquid in the wellbore and flow eventually

stops. This usually leads operators to replace the

production tubing with a smaller diameter in order to

extend the well life.

Experimental results have shown that at high fluid

velocity flow behavior evolves towards homogeneous

flow. This is known as the mass velocity effect.

Mass velocity is actually a velocity per unit area and

it is defined as mass flow divided by pipe area.

Experimental evidence suggests that at mass

velocities larger than 1000 kg/m2s fluid behavior

approaches homogeneous flow and results match

predictions of homogeneous flow at mass velocities

of 2000 kg/m2s (Collier and Thome, 1996).

Experimental results for large diameter pipes such as

those used in geothermal wells, however, are not

available. We expect that the transition should occur

at lower mass velocities in large pipes. The reason is

that the wall shear effect that creates the bubble

concentration profile will affect a smaller fraction of

where z, dP/dZ, m, g, D, f, vm, are measured depth,

total pressure gradient, mixture density, gravity

constant, pipe diameter, Moody friction factor,

mixture velocity and angle with respect to vertical. gc

is a conversion factor equal to 1 for metric units and

32.17 for English units.

We can write equation (6) as follows

dP

dz

m =

fvm2

v dv

g

cos +

+ m m

2 g c D g c dz

gc

(7)

In a PTS survey the total pressure gradient (dP/dz) is

known as well as all other variables in the right hand

side of equation (7) with the exception of the Moody

friction factor f.

For the estimation of the Moody friction factor we

will take advantage of our assumption of large fluid

velocity. In this condition Reynolds numbers are

large. For large Reynolds number (Re > 106) the

friction factor depends only on relative pipe rugosity.

For example, in a 0.25 m diameter steel pipe with gas

volumetric fraction of 0.52 the Moody friction factor

will become dependent mostly on pipe relative

rugosity when fluid velocity is greater than 1.1 m/s

for pressure between 6 and 30 bar.

Relative rugosity changes along the well with

diameter and absolute rugosity. To account for these

variations the following approximate relationship

derived from the Coolebrook-White equation can be

applied.

2

f 1 log( 1 ) = f 2 log( 2 )

D1

D2

(8)

In this equation f, and D are Moody friction factor,

absolute pipe rugosity and pipe diameter. Subscripts

1 and 2 refer to two different pipe sections.

Obviously it cannot be used for smooth pipe sections.

At lower fluid velocities the Reynolds number may

not be large enough for the friction factor to be

independent of fluid velocity. In this case, however

friction losses may not be too important and errors in

the friction factor will not affect too much the

estimate of density.

Fluid velocity, mass flow and energy

For fluid velocity we use the spinner calculated fluid

velocity. The spinner fluid velocity has been proven

to be proportional to mass average velocity and not to

mixture velocity (Gang et al., 1990). Both definitions

of velocity in two phase flow, however, are

equivalent for homogeneous flow.

By solving equation (7) for every section of the pipe

we will end up with a profile of calculated fluid

density as a function of measured depth. Since fluid

velocity and pipe cross section are also known, a

graph of mass flow versus depth can be constructed.

Gas mass fraction or flash x can be calculated once

density is known using the following relationship

x=

Vm V f

(9)

Vg V f

where V is the specific volume or inverse of density.

Subscripts m, f and g refer to mixture, liquid and gas

respectively. Liquid and gas specific volume are

calculated at corresponding pressure of pipe section.

Once flash is known enthalpy can be calculated using

standard thermodynamic relationships.

and elevation. gc is set to 1 in metric units and 32.17

in English units. The units of the three terms must be

consistent. The wellhead is a good reference point to

set the elevation term to zero. The kinematic and

elevation energy terms are small compared to

enthalpy. The kinematic term for a fluid velocity of

50 m/s is only 1.25 kJ/kg. The elevation term is -9.81

kJ/kg 1000 m below wellhead elevation. Both terms

decrease with well depth therefore the enthalpy

increases slightly with depth.

Using this method, graphs of mass and internal

energy versus depth can be constructed. The selection

of the friction factor will change the shape of the

curves. Ideally the mass flow rate and internal energy

graphs should look like a sequence of straight lines

with step changes at the feed zones. The size of the

change in each curve makes it possible to calculate

the mass and enthalpy of the feed zones.

Measured wellhead mass flow and enthalpy can also

be used to constraint the friction factor even more.

The wellhead values are used to calculate a curve of

fluid velocity versus depth in the cased part of the

well. This helps in constraining the spinner derived

fluid velocity.

The calculated mass and internal energy curves are

normalized by dividing them by the wellhead mass

and internal energy. This produces two curves that

when the correct friction factor is selected form two

straight lines in the cased part of the well that

coincide at the value of one.

This method in which homogenous flow is assumed

and friction factor calculated to match observed total

pressure gradient has been used before. It is called,

not surprisingly, the friction factor model (Collier

and Thome, 1996). The main difference with our

application is that it will be applied to interpretation

of PTS surveys and the shape of the mass and energy

curves versus depth is used to determine the correct

friction factor. A good matching friction factor

should represent the proper balance between gravity

and friction effects in the total pressure gradient.

APPLICATION OF THE METHOD

Internal energy per unit mass for a section of the pipe

with no feed zones is calculated by adding fluid

enthalpy, heat losses, kinematic and potential energy

components. The internal energy for a given point in

the pipe is given by equation (10)

U =h+q+

vm2

g

+ H

2gc gc

(10)

where U, h, q, vm , g and H are internal energy,

enthalpy, heat loss, fluid velocity, gravity constant

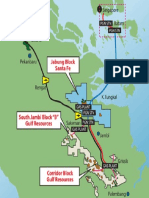

We will apply this method to well A in the Bulalo

geothermal field in the Philippines. Well A is a

directional well cased to 975 m measured depth with

a 0.273 m (10 ) tie back. The slotted liner diameter

is also 0.273 m down to 2195 m and 0.219 m (8 5/8)

down to total depth at 2746 m.

Fluid velocity

We have to correct the fluid velocity obtained from

the spinner to reflect a consistent set for the entire

well. We have observed that in the vertical section of

the well the spinner measures higher velocity than in

the non-vertical section of the well. This is clearly

seen at the directional kick-off of the well and we call

it kick-off effect. It is believed that this is due to

the spinner traveling close to the center of the pipe in

vertical parts of the well where fluid velocity is

larger. In non-vertical parts of the well the spinner

travels close to the pipe wall and fluid velocity is

smaller. Figure 2 shows the well angle in degrees as

well as the uncorrected and angle effect corrected

fluid velocities.

The upper part of the well is cased-off therefore the

estimation of fluid velocity using wellhead pressure,

enthalpy and mass flow should be reliable. The

calculated fluid velocity in the upper part of the well

is also plotted and it serves as a guide to make the

angle correction. This velocity is shown as calculated

in Figure 2. The lower velocity observed below 830

m is due to completion effects.

Fluid density

The next step in the calculation is to apply equation

(7) to calculate fluid density. Then calculate mass

flow rate and internal energy as given by equation

(10). The wellhead measured pressure for this wells

is 18.7 bar a, mass flow is 52.9 kg/s. Wellhead

enthalpy is 1839 kJ/kg and internal energy is 1840

kJ/kg. Calculated mass flow and internal energy are

then normalized by dividing them by the wellhead

values.

For this case we neglected heat losses. We also

neglected the kinematic term in equation (7). This

term was calculated after the solution was reached

and it was confirmed that it represents only a small

fraction of the total pressure gradient.

The process of estimating the friction factor by trial

an error is illustrated in Figure 3. This figure shows

the normalized curves that result from selecting too

low a friction factor (0.005) and too high a friction

factor (0.02).

100

Measured Depth (m)

200

300

400

500

Uncorrected

600

Angle effect corrected

700

Calculated

Well angle

500

900

1000

0

10

20

30

40

50

60

70

80

90

100

Fluid Velocity (m/s)

Measured Depth (m).

800

1000

1500

2000

Figure 2: Comparison of fluid velocity from PTS

survey uncorrected, corrected by angle

effect and calculated using wellhead

measured mass flow and enthalpy and

survey pressure. Well angle is degrees

also shown.

The angle correction is made by dividing the fluid

velocity in the vertical part of the well by a factor

(1.2 in this case). We have found that segments

where the well angle is less than 1.5 degrees can be

approximated as vertical. The angle effect shows

clearly that PTS derived fluid velocities depend on

the location of the tool with respect to the well center.

It is expected that by doing the angle correction we

will end up with a consistent set of velocities for the

entire well. Matching calculated fluid velocities in

the cased part of the well we expect the PTS velocity

to reflect the average fluid velocity for the entire

well.

Energy, f = 0.005

Mass, f = 0.005

Energy, f = 0.02

Mass, f = 0.02

2500

3000

0.0

0.2

0.4

0.6

0.8

1.0 1.2

1.4

1.6

1.8

2.0

Normalized values

Figure 3: Normalized mass and energy curves for

two selections of the Moody friction

factor: 0.005 (circles) too low a value and

0.02 (triangles) too high a value.

Figure 3 shows how the selection of friction factor

does not affect significantly the deepest part of the

well. The reason is that fluid velocity is low enough

for friction to be a small component of the total

pressure gradient although fluid velocity at the

deepest part of the well is still more than 6 m/s. The

mass and energy curves move in opposite direction

with variations of the Moody friction factor f. This

makes selection of the correct friction factor easier.

Another important feature is that curves are not

straight when the friction value is not correct. This

may be sometimes difficult to assess due to the noise

characteristic of PTS surveys.

Once the friction factor is selected some additional

interpretation must be done. Feed zones must be

located and their contribution in terms of mass and

enthalpy must be determined to match the flowing

profiles.

Table 1 shows our interpretation of the location and

contribution of each feed zone for well A. A feed

zone at the top of the 10 liner at 831 m was added

to improve the match. To corroborate the thief zone

at 1116 m, the flowing wellbore pressure was

compared to reservoir pressure and it was found that

wellbore pressure is indeed larger than reservoir

pressure at this elevation.

500

Measured Depth (m).

Figure 4 show the normalized curves for a friction

factor on 0.0097. This selection of the Moody friction

factor produces two curves that are composed of

straight segments. The mass curve should increase in

steps from bottom to top of the well unless there is a

thief zone, with the steps corresponding to feed

zone locations. The enthalpy may increase, decrease

or remain the same depending on the enthalpies of

the feed zones. The upper cased part of the well

should show two straight lines coinciding at the value

of 1. This means that the wellhead measured values

are being honored. The possibility of errors in the

wellhead measurements should always be kept in

mind when a match is difficult to achieve.

For the calculation of the slotted liner part of the well

it was assumed that the well diameter is the diameter

of the slotted liner and the pipe rugosity equals that

of the normal steel pipe (0.046 mm) used in the cased

part of the well. We justify this selection by noting

that the absolute pipe rugosity () should be higher

than that of the non-slotted pipe but the diameter

should also be larger than the one used. Therefore

relative pipe rugosity (/D) should not change too

much. This assumption may not work as well for

mass flow calculations. Those depend on using actual

pipe area with fluid velocity and density to obtain

mass flow. This aspect of the calculation can cause

discontinuities at the contact between casing and

slotted liner as well as at different diameter contacts

and it is being revised at this time.

1000

1500

2000

Energy, f = 0.0097

Mass, f = 0.0097

2500

3000

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Normalized values

Figure 4: Normalized mass and energy graphs for

correct selection of Moody friction factor:

0.0097.

Depth

(m)

831

975

1116

1250

1768

2134

2775

Flow

(kg/s)

5

9

-28

19

8

5

38

Enthalpy

(kJ/kg)

2791

2791

N/A

977

2791

1861

1326

Table 1. Depth and contribution of feed zones in well

A

Figure 5 shows the final calculated mass flow and

enthalpy variation with depth compared to the

expected variation assuming the mass and enthalpy

contributions of the feed zones described in Table 1.

This figure shows that assuming constant enthalpy

between feed zones is a good approximation. The

entire well can be matched reasonably well.

Mass flow (kg/s)

0

20

40

60

80

100

120

140

160

500

500

MD (ft)

Measured Depth (m).

1000

1000

Blasius smooth pipe

1500

Assumed

Coolebrook-White rough pipe

1500

2000

2000

Enthalpy

2500

Calculated Enthalpy

2500

Mass flow

Calculated Mass

3000

600

3000

0.000

0.010

0.020

0.030

0.040

0.050

Moody friction factor

800

1000 1200 1400 1600 1800 2000 2200

Enthalpy (kJ/kg)

Figure 5: Interpretation of variation of mass flow

and enthalpy with depth. Feed zone

depths and contributions are shown in

Table 1.

Figure 6: Comparison of assumed Moody friction

factor obtained from this analysis with

values for smooth pipe (Blasius) and

rough pipe (Coolebrook-White).

Pressure (bar) and Fluid Velocity (m/s)

In order to check independently the consistency of

the results with a different method, the feed zone

contributions shown in Table 1 were simulated in our

wellbore simulator using the Duns and Ros

correlation (Hasan and Kabir, 2002) and also the

Orkiszewski correlation (Brill and Beggs, 1991).

Both correlations use the same formulation (Duns

and Ros) for the mist flow regime. The measured

and calculated temperature pressure and mixture

velocity are shown in Figure 7.

10

20

30

40

50

60

70

80

240

260

280

300

500

1000

Measured Depth (m).

Consistency of results

A very valid question is how consistent is the

obtained friction factor with respect to more

conventional ways of calculating it. Figure 6 shows

the comparison of the friction factor calculated using

Blasius smooth pipe friction factor formula,

Colebrook-White equation for rough pipe and the

assumed value obtained with this method.

Interestingly enough the results fall in between the

two values. The absolute rugosity required by the

Colebrook-White equation to match the observed

results is 0.0064 mm.

1500

2000

2500

Temperature

Pressure

Fluid velocity

Duns & Ros

Orkiszewski

3000

3500

140

160

180

200

220

Temperature (C)

Figure 7: Wellbore simulator match of pressure,

temperature and mixture velocity using

Duns & Ros (blue) and Orkiszewski (red)

correlations.

As expected the results are different because the

holdup and friction loss treatment in the correlations

may be different from the one used here. The

Orkiszewski correlation shows a better agreement

than Duns and Ros.

This method has provided an alternative way to

check consistency of feed zone location, enthalpy and

mass flow rate contributions found with our

conventional trial and error wellbore simulator based

method. It has also provided an unprecedented level

of resolution in the interpretation of two-phase

sections in flowing geothermal wells.

CONCLUSIONS

ACKNOWLEDGEMENTS

The method for PTS survey interpretation presented

in this work has been applied to more than 10 wells

in Unocal. In most cases it has shown results that are

consistent with our previous interpretations.

Sometimes, however it shows unexpected results that

offer alternative and interesting interpretations.

Contrary to normal methods of solution in two-phase

flow in which the holdup is calculated separately

from friction losses, this method offers the possibility

of balancing the gravity and friction components of

the total pressure gradient by selecting the friction

factor that makes the profiles of mass and internal

energy consistent.

Including reliable wellhead measurements of mass

and enthalpy improves the precision of the method.

These measurements, however are not strictly

required. It is possible to determine a friction factor

that provides the correct shape of mass and energy

curves with depth without wellhead measured values.

The main limitation of the method is that

assumptions made for its derivation require fluid

velocity to be large enough so homogeneous flow can

be assumed. We have found that as long as the fluid

velocity is larger than 3 m/s the method works well.

In lower enthalpy high diameter wells we found some

inconsistencies possibly related to low flow velocity.

We thank Unocal, Philippine Geothermal, Inc. (PGI)

and National Power Corporation (NPC) for

supporting this project and granting permission to

publish this paper.

REFERENCES

Ansari, A.M., Sylvester, N.D., Sarica, C. and Shoham, O.:

A Comprehensive Mechanistic Model for Upward

Two-Phase Flow in Wellbores. SPE paper 20630,

(1994).

Brill, J.P and Beggs, H.D.: Two-Phase Flow in Pipes.

University of Tulsa, (1991).

Coleman, S.B., Hartley, B.C., McCurdy, D.G., Norris H.L.:

A New Look at Predicting Gas-Well Load-Up, SPE

paper 20280, (1991).

Collier, J.G and Thome, J.R.: Convective Boiling and

Condensation, Clarendon Press, Oxford (1996).

Gang, X.Z., Golan, M and Sveen, J.: Determining

Downhole Flow Rates of Oil and Gas in Oil Wells

Using Pressure Drop and Spinner Response

Measurements. SPE paper 20893, (1990).

Hasan, A.R., and Kabir, C.S.: Fluid Flow and Heat Transfer

in Wellbores, SPE, Richardson, Texas (2002).

Kleinstreuer, C.: Two-Phase Flow Theory and

Applications, Taylor and Francis, New York, (2003).

También podría gustarte

- Basic Coiled Tubing Formulas and Conversions.Documento2 páginasBasic Coiled Tubing Formulas and Conversions.Jeeten G.100% (6)

- Beggs and Brill MethodDocumento26 páginasBeggs and Brill MethodHassanKMAún no hay calificaciones

- Gas-Liquid Flow in Slightly Inclined PipesDocumento11 páginasGas-Liquid Flow in Slightly Inclined PipesBrenda DavisAún no hay calificaciones

- Multi-Phase Flow Calculation of CV - MetsoDocumento10 páginasMulti-Phase Flow Calculation of CV - MetsoJoseph WangAún no hay calificaciones

- Force Field AnalysisDocumento4 páginasForce Field AnalysisIrwan JanuarAún no hay calificaciones

- Two-Phase Flow Behavior and Spinner Data Analysis in Geothermal Wells PDFDocumento8 páginasTwo-Phase Flow Behavior and Spinner Data Analysis in Geothermal Wells PDFWisnu ArdhiAún no hay calificaciones

- Flow Pattern Transition For Vertical Two Phase FlowDocumento4 páginasFlow Pattern Transition For Vertical Two Phase FlowManojAún no hay calificaciones

- THE FLOODING TRANSITION WITH GASSED RUSHTON TURBINES - 1984 - Fluid Mixing IIDocumento9 páginasTHE FLOODING TRANSITION WITH GASSED RUSHTON TURBINES - 1984 - Fluid Mixing IIvane-16Aún no hay calificaciones

- Drift Flux Model For Vapor-Liquid Two-Phase Flow Through Short Tube OrificesDocumento4 páginasDrift Flux Model For Vapor-Liquid Two-Phase Flow Through Short Tube OrificesstoicadoruAún no hay calificaciones

- Experimental Investigation of Two-Phase GAS-Liquid Slug Flow Inclined PipeDocumento13 páginasExperimental Investigation of Two-Phase GAS-Liquid Slug Flow Inclined PipeDauda BabaAún no hay calificaciones

- GP Journal v1n1p70 enDocumento19 páginasGP Journal v1n1p70 enDattatraya ParleAún no hay calificaciones

- Two Phase FlowDocumento22 páginasTwo Phase FlowAdil Khan100% (1)

- SPE-175805-MS - Proper Selection of Multhiphase Flow CorrelationsDocumento20 páginasSPE-175805-MS - Proper Selection of Multhiphase Flow CorrelationsCarlita Guerrero Garcia100% (1)

- Flowing Bottomhole Pressure Calculation For A Pumped Well Under Multiphase FlowDocumento6 páginasFlowing Bottomhole Pressure Calculation For A Pumped Well Under Multiphase Flowciucalata88Aún no hay calificaciones

- Two-Phase Flow PDFDocumento90 páginasTwo-Phase Flow PDFace4200Aún no hay calificaciones

- Beggs and Brill MethodDocumento25 páginasBeggs and Brill MethodHuy Lâm100% (2)

- Wetted Wall ColumnDocumento4 páginasWetted Wall Columnendang dian lestariAún no hay calificaciones

- Fluid Flow Through Randomly Packed Columns and Fluidized BedsDocumento6 páginasFluid Flow Through Randomly Packed Columns and Fluidized BedsalexramquiAún no hay calificaciones

- Zhang 2003Documento10 páginasZhang 2003Luiz EliasAún no hay calificaciones

- Safety Valve Sizing Reliefv PDFDocumento9 páginasSafety Valve Sizing Reliefv PDFLiam MoylanAún no hay calificaciones

- ChE 220 Mod 6 Flow of Compressible FluidDocumento53 páginasChE 220 Mod 6 Flow of Compressible FluidMay May MagluyanAún no hay calificaciones

- Two Phase FlowDocumento4 páginasTwo Phase FlowsindalvaleriAún no hay calificaciones

- Non Isentropic FlowDocumento6 páginasNon Isentropic FlowswatiAún no hay calificaciones

- CFD Simulation of Bubbly Two-Phase Ow in Horizontal Pipes: Chemical Engineering JournalDocumento12 páginasCFD Simulation of Bubbly Two-Phase Ow in Horizontal Pipes: Chemical Engineering JournalReza KHAún no hay calificaciones

- Asst. Prof. Dr. Hayder Mohammad Jaffal: Two Phase Flow - IntroductionDocumento19 páginasAsst. Prof. Dr. Hayder Mohammad Jaffal: Two Phase Flow - IntroductionprasanthiAún no hay calificaciones

- Mfs MfsDocumento13 páginasMfs MfsEbenezer Amoah-KyeiAún no hay calificaciones

- CHE 222 Fluid Mechanics Term ProjectDocumento9 páginasCHE 222 Fluid Mechanics Term ProjecttsevineAún no hay calificaciones

- Fluid Flow in Rocket NozzlesDocumento24 páginasFluid Flow in Rocket NozzlesVenkat AkellaAún no hay calificaciones

- 2004 Yossef ICHEDocumento9 páginas2004 Yossef ICHEVirgilio MartínezAún no hay calificaciones

- Wet Wall AbsorptionDocumento11 páginasWet Wall Absorptionhagt813Aún no hay calificaciones

- Use of Packer Test Results in Hydrogeological Characterization: A Comparison of Calculation Methods For A Representative ValueDocumento18 páginasUse of Packer Test Results in Hydrogeological Characterization: A Comparison of Calculation Methods For A Representative ValuegpsglonassAún no hay calificaciones

- Unified Model For Gas - Liquid Pipe Flow Via Slug Dynamics - Part 1 - Model DevelopmentDocumento8 páginasUnified Model For Gas - Liquid Pipe Flow Via Slug Dynamics - Part 1 - Model DevelopmentleofrazaoAún no hay calificaciones

- Cipc 2009-041Documento10 páginasCipc 2009-041Ralf JonesAún no hay calificaciones

- Convective Mass TransferDocumento46 páginasConvective Mass TransferSandra Enn BahintingAún no hay calificaciones

- Viscous Flow in Pipes PDFDocumento71 páginasViscous Flow in Pipes PDFMuhammad Izzamir FirdausAún no hay calificaciones

- AFT CE Gasflow ReprintDocumento8 páginasAFT CE Gasflow ReprintNacho.pAún no hay calificaciones

- Two-Phase Flow (Gas-Flow) Line SizingDocumento24 páginasTwo-Phase Flow (Gas-Flow) Line SizingvictorvikramAún no hay calificaciones

- Modeling of The How Properties and Discharge of Halon Replacement AgentsDocumento14 páginasModeling of The How Properties and Discharge of Halon Replacement AgentsNikolaos XiradakisAún no hay calificaciones

- Wetted WallDocumento3 páginasWetted WallFrank.JAún no hay calificaciones

- Sesi-15.PDF Example But Old Nozzle FlowDocumento42 páginasSesi-15.PDF Example But Old Nozzle FlowyamakunAún no hay calificaciones

- Mukherjee e Brill 1985 Empirical PDFDocumento17 páginasMukherjee e Brill 1985 Empirical PDFFrancisco Opps100% (2)

- Corrosion: Paper NoDocumento11 páginasCorrosion: Paper NoAlssayhAún no hay calificaciones

- Experiment No-4: Mass Transfer Lab IIT KGPDocumento5 páginasExperiment No-4: Mass Transfer Lab IIT KGPSiddharth MohapatraAún no hay calificaciones

- Banerjee&Turney2013 - Air-Water Gas Transfer and Near-Surface MotionsDocumento37 páginasBanerjee&Turney2013 - Air-Water Gas Transfer and Near-Surface MotionsLeandro DijonAún no hay calificaciones

- Baniamerian Aghanajafi SREDocumento25 páginasBaniamerian Aghanajafi SRESeyedAún no hay calificaciones

- Image Processing To Determine Mass Transfer Coefficient For Gas BubbleDocumento8 páginasImage Processing To Determine Mass Transfer Coefficient For Gas BubbleJeremy DudleyAún no hay calificaciones

- A Spreadsheet Approach To Diverter Design Calculations: LouisianaDocumento12 páginasA Spreadsheet Approach To Diverter Design Calculations: LouisianaMRizwanSadiq313Aún no hay calificaciones

- (Received 2 February Revised Form 9 June: D. BarneaDocumento12 páginas(Received 2 February Revised Form 9 June: D. BarneapeachbananaAún no hay calificaciones

- Void Fractions in Two-Phase FlowsDocumento0 páginasVoid Fractions in Two-Phase FlowsMohsen AghaeiAún no hay calificaciones

- Topic Time Frame: 9 Hours: Learning ModuleDocumento13 páginasTopic Time Frame: 9 Hours: Learning ModuleJea Escabal MosenabreAún no hay calificaciones

- Taitel Et. Al, 1990Documento50 páginasTaitel Et. Al, 1990xowaf70826Aún no hay calificaciones

- Non-Turbulent Perfect Compressible Barotropic: Bernoulli EquationDocumento12 páginasNon-Turbulent Perfect Compressible Barotropic: Bernoulli Equationcristina.sorana.ionescu6397Aún no hay calificaciones

- Yaqub 2018 IOP Conf. Ser. Mater. Sci. Eng. 458 012078Documento10 páginasYaqub 2018 IOP Conf. Ser. Mater. Sci. Eng. 458 012078Daniel MoraesAún no hay calificaciones

- And In: Relative Contributions of Molecular Diffusion Anastomosis Gas Chromatographic ColumnsDocumento6 páginasAnd In: Relative Contributions of Molecular Diffusion Anastomosis Gas Chromatographic Columnsnbson217Aún no hay calificaciones

- Rodrigues 2018Documento27 páginasRodrigues 2018GhulamAún no hay calificaciones

- Paper ID ICLASS06-262 Cooling of Gas by A Water Spray in A Straight Duct - Cross FlowDocumento8 páginasPaper ID ICLASS06-262 Cooling of Gas by A Water Spray in A Straight Duct - Cross FlowpnshrfbAún no hay calificaciones

- Select Best Model Two-Phase Relief Sizing: The ForDocumento9 páginasSelect Best Model Two-Phase Relief Sizing: The ForjowarAún no hay calificaciones

- HYDRAULICSDocumento10 páginasHYDRAULICSLuisito Sta InesAún no hay calificaciones

- Flows and Chemical Reactions in Heterogeneous MixturesDe EverandFlows and Chemical Reactions in Heterogeneous MixturesAún no hay calificaciones

- Transport Phenomena I EssentialsDe EverandTransport Phenomena I EssentialsCalificación: 2.5 de 5 estrellas2.5/5 (3)

- Product Brochure DynaSlot XL Online ViewDocumento6 páginasProduct Brochure DynaSlot XL Online ViewIrwan JanuarAún no hay calificaciones

- Booklet IATMIDocumento16 páginasBooklet IATMIIrwan JanuarAún no hay calificaciones

- FinancialStatement 2019Documento298 páginasFinancialStatement 2019Tonga ProjectAún no hay calificaciones

- Catalog - SS UOMODocumento64 páginasCatalog - SS UOMOIrwan JanuarAún no hay calificaciones

- Pages From Apr-Investor-PresDocumento1 páginaPages From Apr-Investor-PresIrwan JanuarAún no hay calificaciones

- Vdocuments - MX - Session 10 Technical Paul Davies Conocophillips PDFDocumento38 páginasVdocuments - MX - Session 10 Technical Paul Davies Conocophillips PDFIrwan JanuarAún no hay calificaciones

- Pages From 251912087-Talisman-Energy-KinabaluDocumento1 páginaPages From 251912087-Talisman-Energy-KinabaluIrwan JanuarAún no hay calificaciones

- EnergyPoliciesofIEACountriesDenmark2017Review PDFDocumento213 páginasEnergyPoliciesofIEACountriesDenmark2017Review PDFIrwan JanuarAún no hay calificaciones

- LeRoux Wavecalc (2010)Documento28 páginasLeRoux Wavecalc (2010)Irwan JanuarAún no hay calificaciones

- Content Handbook of Energy Economic Statistics of Indonesia 2016 08989 PDFDocumento70 páginasContent Handbook of Energy Economic Statistics of Indonesia 2016 08989 PDFshandyAún no hay calificaciones

- Country Analysis Brief: Australia: Last Updated: March 7, 2017Documento24 páginasCountry Analysis Brief: Australia: Last Updated: March 7, 2017Lizeth CampoAún no hay calificaciones

- Energy Dependency and Energy Security - Role of NREDocumento23 páginasEnergy Dependency and Energy Security - Role of NREIrwan JanuarAún no hay calificaciones

- MapillusDocumento1 páginaMapillusIrwan JanuarAún no hay calificaciones

- Ipcc Wg3 Ar5 FullDocumento1454 páginasIpcc Wg3 Ar5 Fullchoonkiat.leeAún no hay calificaciones

- Key World 2017Documento97 páginasKey World 2017Kien NguyenAún no hay calificaciones

- INAGA Ins For Geothermal Expl 201306 SlidesDocumento14 páginasINAGA Ins For Geothermal Expl 201306 SlidesIrwan JanuarAún no hay calificaciones

- NRE ContributionDocumento74 páginasNRE ContributionIrwan JanuarAún no hay calificaciones

- 2010 Esp Geothermal ApplicationsDocumento7 páginas2010 Esp Geothermal ApplicationsIrwan JanuarAún no hay calificaciones

- INAGA Ins For Geothermal Dev Proj 201306 PaperDocumento7 páginasINAGA Ins For Geothermal Dev Proj 201306 PaperIrwan JanuarAún no hay calificaciones

- UKC CalculationDocumento2 páginasUKC CalculationIrwan JanuarAún no hay calificaciones

- 07 Mar 2017 111739167GF5FKTEUFeasibilityStudyReportbyIITChennai PDFDocumento26 páginas07 Mar 2017 111739167GF5FKTEUFeasibilityStudyReportbyIITChennai PDFYbud0% (1)

- PT SMI's Role in Geothermal Energy Development - For Public - v2Documento8 páginasPT SMI's Role in Geothermal Energy Development - For Public - v2Irwan JanuarAún no hay calificaciones

- UKC CalculationDocumento2 páginasUKC CalculationIrwan Januar0% (1)

- Two Phase FlowDocumento3 páginasTwo Phase FlowIrwan JanuarAún no hay calificaciones

- META Model For Electricity Technology AssessmentDocumento6 páginasMETA Model For Electricity Technology AssessmentIrwan JanuarAún no hay calificaciones

- Kerjasama PT Pelindo I Indonesia Dengan Port of RotterdamDocumento12 páginasKerjasama PT Pelindo I Indonesia Dengan Port of RotterdamIrwan JanuarAún no hay calificaciones

- Titik Karang AsemDocumento9 páginasTitik Karang AsemIrwan JanuarAún no hay calificaciones

- Thermo IsopentaneDocumento51 páginasThermo IsopentaneIrwan JanuarAún no hay calificaciones

- Sustainable Geothermal Power - The Life Cycle of A Geothermal PlantDocumento5 páginasSustainable Geothermal Power - The Life Cycle of A Geothermal PlantIrwan JanuarAún no hay calificaciones

- Suspension - Comparative Oil Weights Table-1Documento8 páginasSuspension - Comparative Oil Weights Table-1Vennia PapadipoulouAún no hay calificaciones

- Drooping Curve of Two Stage PumpDocumento33 páginasDrooping Curve of Two Stage PumpPUMPSAún no hay calificaciones

- Cabeq 2006 1 3Documento16 páginasCabeq 2006 1 3altealodAún no hay calificaciones

- Topic 8 Class Notes1 PDFDocumento6 páginasTopic 8 Class Notes1 PDFMuhammad Adnan LaghariAún no hay calificaciones

- Manning Equation Calculator Open Channel Flow Software: Lmno Engineering Home Page (More Calculations)Documento2 páginasManning Equation Calculator Open Channel Flow Software: Lmno Engineering Home Page (More Calculations)Chris van RensburgAún no hay calificaciones

- Hydraulics Calculations and Field Application of Radial Jet DrillingDocumento11 páginasHydraulics Calculations and Field Application of Radial Jet DrillingAnonymous VNu3ODGavAún no hay calificaciones

- Exercises 5Documento1 páginaExercises 5Jonathhan RecaldeAún no hay calificaciones

- R K Bansal - A Textbook of Fluid Mechanics and Hydraulic Machines.Documento1129 páginasR K Bansal - A Textbook of Fluid Mechanics and Hydraulic Machines.pratt guAún no hay calificaciones

- Industrial Lubricating Oils & GreasesDocumento13 páginasIndustrial Lubricating Oils & GreasesMassimiliano VolaAún no hay calificaciones

- ORIFICE - Fluid MechanicsDocumento7 páginasORIFICE - Fluid MechanicsWilliam67% (3)

- Pressure & DensityDocumento2 páginasPressure & DensityIffi AkramAún no hay calificaciones

- Aquifers and GroundwaterDocumento4 páginasAquifers and GroundwaterAnonymous EvbW4o1U7Aún no hay calificaciones

- Sample Design Fire ProDocumento22 páginasSample Design Fire ProPBDC MEPFSAún no hay calificaciones

- Falling Film Evaporator PDFDocumento28 páginasFalling Film Evaporator PDF^o100% (2)

- Design of Small DamsDocumento5 páginasDesign of Small DamsNarendra Singh BhandariAún no hay calificaciones

- 1 Fundamental Concepts of Fluid Mechanics For Mine VentilationDocumento29 páginas1 Fundamental Concepts of Fluid Mechanics For Mine VentilationRiswan RiswanAún no hay calificaciones

- Iahr (2005)Documento10 páginasIahr (2005)Harris KoftisAún no hay calificaciones

- Experiment 3: Method of Flow MeasurementDocumento7 páginasExperiment 3: Method of Flow MeasurementArif HilmiAún no hay calificaciones

- Boiling and CondensationDocumento39 páginasBoiling and Condensationaranna lalAún no hay calificaciones

- FM IIDocumento2 páginasFM IIephremAún no hay calificaciones

- 93-1315 Deoiling ManualDocumento269 páginas93-1315 Deoiling ManualManash Mudoi100% (2)

- Lab 1St FloorDocumento5 páginasLab 1St FloorAditya PranotoAún no hay calificaciones

- Computer Aided Design Boundary Conditions: Dr. Ahmed Nagib ElmekawyDocumento31 páginasComputer Aided Design Boundary Conditions: Dr. Ahmed Nagib ElmekawyMega Games100% (1)

- Calculation of Suction Lift in Open Systems (Water) ExampleDocumento1 páginaCalculation of Suction Lift in Open Systems (Water) ExampleGeancarlo GutierrezAún no hay calificaciones

- Harga Lube Naffcool Jan21Documento2 páginasHarga Lube Naffcool Jan21Empy SumardiAún no hay calificaciones

- Bernoulli's Theorem ProofDocumento2 páginasBernoulli's Theorem ProofSourav Das50% (4)

- Axial Thrust in Single-Stage PumpsDocumento2 páginasAxial Thrust in Single-Stage PumpsShayan MehboobAún no hay calificaciones

- r5220303 Mechanics of Fluids r5 2-2Documento4 páginasr5220303 Mechanics of Fluids r5 2-2sivabharathamurthyAún no hay calificaciones

- DiscussionDocumento3 páginasDiscussionmayhem65Aún no hay calificaciones