Documentos de Académico

Documentos de Profesional

Documentos de Cultura

7SecIX IX.2.04 Plastering

Cargado por

Anonymous 7ZYHilDDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

7SecIX IX.2.04 Plastering

Cargado por

Anonymous 7ZYHilDCopyright:

Formatos disponibles

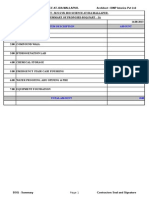

TECHNICAL SPECIFICATIONS OF

PLASTERING

J P MUKHERJI & ASSOCIATES PVT LTD

TSFP

TECHNICAL SPECIFICATIONS

PLASTERING

Section-IX

Sub-Section-IX.2.04

Page - 1 / 3

BID DOCUMENT FOR

CIVIL WORKS FOR FOUNDATIONS OF EQUIPMENT

AND PLANT BUILDINGS

4.00.00

4.01.00

4.02.00

4.03.00

4.04.00

SCOPE ................................................................................................................... 2

MIX.......................................................................................................................... 2

APPLICATION ........................................................................................................ 2

CURING .................................................................................................................. 3

PLASTER OF PARIS FINISH ................................................................................. 3

J P MUKHERJI & ASSOCIATES PVT LTD

TSFP

TECHNICAL SPECIFICATIONS

PLASTERING

Section-IX

Sub-Section-IX.2.04

Page - 2 / 3

BID DOCUMENT FOR

CIVIL WORKS FOR FOUNDATIONS OF EQUIPMENT

AND PLANT BUILDINGS

4.00.00

SCOPE

The specification covers the plastering work on brick/ hollow concrete block

masonry or concrete faces of specified thickness with architectural features

wherever necessary. This also covers the application of lime punning (Neru)

or plaster of paris treatment.

The specification covers the plastering work on brick/ hollow concrete block

masonry or concrete faces of specified thickness with architectural features

wherever necessary. This also covers the application of lime punning (Neru)

or plaster of paris treatment.

4.01.00

MIX

Mortar for plastering in the proportion as specified on drawings/specification,

shall be mixed in a dry state and then wetted and mixed thoroughly to obtain

the required consistency. The mortar shall be mixed in an approved manner

including machine mixing if desired by the Engineer in-charge and in

batches so that the mortar is consumed within half an hour of mixing. Any

mortar for plaster, which is partially set, shall be rejected and removed from

site.

The mix for plastering shall be as follows:

Brick wall:

Out side plaster

18 mm thick - 1:6

(Or rough side)

(1 cement:: 6 sand)

Inside Plaster

12 mm thick 1:6

(Or plain face)

(1 cement: :6 sand )

Concrete ceiling:

Plaster

6 mm thick 1:4

(1 cement: :4 sand)

Hollow concrete block

12 mm thick 1:6

(1 cement:: 6 Sand)

4.02.00

APPLICATION

Before application of plaster, the surface shall be prepared as per British

Standards.

In all plaster work mortar shall be applied in a uniform layer slightly more than

the required thickness and well pressed into the joint and in the surface and

rubbed and levelled with a flat wooden rule to give required thickness.

Plaster, when more than 15 mm thick, shall be applied in two coats, base coat

followed by the finishing coat. Thickness of base coat shall be just sufficient to

fill up all uneveness in the surface; no single coat, however, shall exceed 12

mm in thickness. The under-coat shall be thicker than the upper coat. The

J P MUKHERJI & ASSOCIATES PVT LTD

TSFP

TECHNICAL SPECIFICATIONS

PLASTERING

Section-IX

Sub-Section-IX.2.04

Page - 3 / 3

BID DOCUMENT FOR

CIVIL WORKS FOR FOUNDATIONS OF EQUIPMENT

AND PLANT BUILDINGS

overall thickness of the plaster shall not be less than the minimum thickness

shown on the drawings. The undercoat shall be allowed to dry and shrink

before applying the second coat of plaster.

The undercoat shall be scratched or roughened before it is fully hardened to

form a mechanical key. The method of application shall be 'thrown on' rather

than 'applied by trowel'. The finished surface shall be true to line and plumb

and the Contractor shall without any extra cost to the Employer, make up any

irregularity in the masonry/concrete work with plaster. The mortar shall adhere

to the surface intimately when set and there should be no hollow sound when

struck.

All vertical edges of pillars, door jambs etc. shall be chamfered or rounded off

as directed by the Engineer. All corners must be finished to their true angles

or rounded. Any plastering that is damaged shall be repaired and left in good

condition at the completion of the job without any extra cost to the Employer.

4.03.00

CURING

All plastered surfaces after laying and sufficiently hardened shall be kept wet

for a minimum period of seven days and shall be protected from excessive

heat and sunlight by suitable approved means.

4.04.00

PLASTER OF PARIS FINISH

The plaster of Paris shall be Calcium Sulphate hemi-hydrate variety. Its initial

setting shall be less than 13 minutes.

The material shall be mixed with water to workable consistency. Plaster of

Paris shall be applied to the surface in a uniform layer slightly more than 2

mm thick and shall be finished to an even and smooth surface with a steel

trowel. 'Thickness of finish shall not be less than 2 mm. All corners, arises,

angle and junctions shall be carefully and neatly finished.

También podría gustarte

- 6SecIX IX.2.03 Masonry&Allied WorksDocumento12 páginas6SecIX IX.2.03 Masonry&Allied WorksAnonymous 7ZYHilDAún no hay calificaciones

- Appendix G - Specification For FlooringDocumento19 páginasAppendix G - Specification For FlooringAnil WadileAún no hay calificaciones

- Squash ReboundSpecDocumento20 páginasSquash ReboundSpecGoranPerovicAún no hay calificaciones

- API BasementDocumento3 páginasAPI BasementJustin SloanAún no hay calificaciones

- Project Scope / Specification: Concrete WorksDocumento11 páginasProject Scope / Specification: Concrete WorksSaravanaperumal RajuAún no hay calificaciones

- VOL-If C1606-10 Floor FinishDocumento22 páginasVOL-If C1606-10 Floor Finishkomala2447Aún no hay calificaciones

- Method Statement Pu FlooringDocumento3 páginasMethod Statement Pu Flooringengrjaydelosantos6969Aún no hay calificaciones

- Particular Specification Plastering Work: (For Building & Area Development Work) Indian StandardsDocumento15 páginasParticular Specification Plastering Work: (For Building & Area Development Work) Indian StandardsRamesh KomiriAún no hay calificaciones

- Specifications For Flooring WorkDocumento14 páginasSpecifications For Flooring WorkErMelvinDiasAún no hay calificaciones

- Tata Projects Limited, Hyderabad: ClientDocumento7 páginasTata Projects Limited, Hyderabad: ClientBibhuti Bhusana BisoyiAún no hay calificaciones

- List of Icons: Product InfoDocumento11 páginasList of Icons: Product InfoniroAún no hay calificaciones

- Dramix - JointlessDocumento25 páginasDramix - Jointlesswidayat81100% (1)

- Method Statement: For Internal & External Plastering Works: Rev. Date Prepared by Checked & Approved byDocumento9 páginasMethod Statement: For Internal & External Plastering Works: Rev. Date Prepared by Checked & Approved byEyutt Hghgh100% (1)

- Qcs 2010 Part 24.05 TilesDocumento6 páginasQcs 2010 Part 24.05 TilesRotsapNayrb100% (1)

- Guide Specifications For Portland Cement PlasterDocumento5 páginasGuide Specifications For Portland Cement PlasterUmang sharmaAún no hay calificaciones

- Procedure For Flooring WorksDocumento4 páginasProcedure For Flooring WorksAkhilesh Kumar0% (1)

- Method Statement For Finishing Work of Ramp Joint Rectification & Cement RenderingDocumento8 páginasMethod Statement For Finishing Work of Ramp Joint Rectification & Cement Renderingdinidu3priyankara3saAún no hay calificaciones

- Sika Chapdur® - Premix PDFDocumento2 páginasSika Chapdur® - Premix PDFmariutza_luciaAún no hay calificaciones

- 1.09 Item Wise Detailed DescriptionDocumento37 páginas1.09 Item Wise Detailed DescriptionRajesh ChowhanAún no hay calificaciones

- 0809201713-Tender For Civil Work - Price Bid - 07.09.2020Documento7 páginas0809201713-Tender For Civil Work - Price Bid - 07.09.2020Prakash InteriorsAún no hay calificaciones

- BOQ - GVK Bio Campus Additional Work-Package-IADocumento49 páginasBOQ - GVK Bio Campus Additional Work-Package-IAdeepthikuppuswamyAún no hay calificaciones

- Plastering Works Method StatementDocumento7 páginasPlastering Works Method StatementYan Belarmino33% (6)

- Technical DataDocumento202 páginasTechnical DataIsaac JebAún no hay calificaciones

- Name of Work: Construction of 300 Gallon Vertical Mixer Building No.4 at SprobDocumento53 páginasName of Work: Construction of 300 Gallon Vertical Mixer Building No.4 at SprobRavi Sobhan100% (1)

- Qcs 2010 Part 24.06 TerrazzoDocumento4 páginasQcs 2010 Part 24.06 TerrazzoRotsapNayrbAún no hay calificaciones

- Method Statement For Cement PlasteringDocumento6 páginasMethod Statement For Cement PlasteringYazhisai SelviAún no hay calificaciones

- Amiantit. Field Installation ProcedureDocumento37 páginasAmiantit. Field Installation ProcedureABAID ULLAHAún no hay calificaciones

- Mapei Screed PDFDocumento40 páginasMapei Screed PDFnmark47100% (1)

- 7.1. Concrete MixDocumento17 páginas7.1. Concrete MixKrishna SankarAún no hay calificaciones

- 7.Ms-External Plaster WorkDocumento6 páginas7.Ms-External Plaster WorkShenbagaraja PandianAún no hay calificaciones

- Ancillary Works - Method StatementDocumento8 páginasAncillary Works - Method Statementmemekenya50% (2)

- Specifications: Farzeen Ahammed S5Documento17 páginasSpecifications: Farzeen Ahammed S5Farzeen Ahammed pAún no hay calificaciones

- Z00-GAC-4628-00 - Spec For Interlocking Paver BlocksDocumento13 páginasZ00-GAC-4628-00 - Spec For Interlocking Paver BlocksRitesh kumarAún no hay calificaciones

- A Guide For Durable Quality Residential Concrete Flatwork 2016 RevisionDocumento4 páginasA Guide For Durable Quality Residential Concrete Flatwork 2016 RevisionMICHAELAún no hay calificaciones

- 2374 - Technical Specification of Flooring Works PDFDocumento17 páginas2374 - Technical Specification of Flooring Works PDFKarthikeyan PanchatcharamAún no hay calificaciones

- 2409-Floor ScreedDocumento3 páginas2409-Floor ScreedRyanAún no hay calificaciones

- 03 - DRDC Interior - Schedule of QtyDocumento31 páginas03 - DRDC Interior - Schedule of QtyAnonymous 1uGSx8bAún no hay calificaciones

- Interior & Exterior PlasteringDocumento7 páginasInterior & Exterior PlasteringGabriel GabeAún no hay calificaciones

- TDS Levelling - PlasterDocumento3 páginasTDS Levelling - PlasterNandhagopal DhandapaniAún no hay calificaciones

- SR - No. Item Description Qty Rate Unit AmountDocumento3 páginasSR - No. Item Description Qty Rate Unit AmountAkshay KambleAún no hay calificaciones

- DPWH Standard Specifications On Prime Coat, TackDocumento8 páginasDPWH Standard Specifications On Prime Coat, TackChesterMercado100% (2)

- 14.0 Method Statement For Application of Cementitious GroutDocumento7 páginas14.0 Method Statement For Application of Cementitious Groutilliasuddin100% (1)

- Construction of Boundary Wall SpecificationsDocumento148 páginasConstruction of Boundary Wall SpecificationsTATATAHER67% (3)

- Final BUA BOQ Tender - OB Plot and Podium - 03.09.21Documento11 páginasFinal BUA BOQ Tender - OB Plot and Podium - 03.09.21Jaysukh N SapraAún no hay calificaciones

- SurfaceProcedure Preparation-085 R3Documento17 páginasSurfaceProcedure Preparation-085 R3Vinu Raveendran100% (1)

- MS - Masonary Block WorkDocumento14 páginasMS - Masonary Block WorkZaheer HussainAún no hay calificaciones

- Branz Appraisal Dampfix 2 & 3 581 2015Documento5 páginasBranz Appraisal Dampfix 2 & 3 581 2015DanielCarletonAún no hay calificaciones

- Sikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedDocumento6 páginasSikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedhvduylinhAún no hay calificaciones

- Terrace Waterproofing QuotationDocumento3 páginasTerrace Waterproofing QuotationYellaturi Siva Kishore Reddy100% (6)

- Bill of Quantity For RCC BuildingsDocumento16 páginasBill of Quantity For RCC BuildingsAaron SolisAún no hay calificaciones

- DSR PuneDocumento5 páginasDSR PunedigvijayjagatapAún no hay calificaciones

- Method Statement - Structural ConcreteDocumento7 páginasMethod Statement - Structural Concretearif_rubinAún no hay calificaciones

- Boq R2 - 290914Documento25 páginasBoq R2 - 290914raviAún no hay calificaciones

- 03 3300 Concrete Recommendations With Polished Concrete (Version 1)Documento5 páginas03 3300 Concrete Recommendations With Polished Concrete (Version 1)vasantsunerkarAún no hay calificaciones

- Dado Rate Analysis and Approximate Estimation of BridgeDocumento14 páginasDado Rate Analysis and Approximate Estimation of BridgeNikhil RathiAún no hay calificaciones

- How to Build a Simple Three Bedroom Shipping Container HouseDe EverandHow to Build a Simple Three Bedroom Shipping Container HouseCalificación: 4 de 5 estrellas4/5 (2)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringDe EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringCalificación: 4 de 5 estrellas4/5 (5)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionDe EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionAún no hay calificaciones

- 1.the PreambleDocumento8 páginas1.the PreambleAnonymous 7ZYHilDAún no hay calificaciones

- Annex F-Form of SecuritiesDocumento1 páginaAnnex F-Form of SecuritiesAnonymous 7ZYHilDAún no hay calificaciones

- Metals and Engineering Corporation: Siddaca Faage 137.5Mw Biomass Fired Thermal Power Plant Project Working ProgressDocumento29 páginasMetals and Engineering Corporation: Siddaca Faage 137.5Mw Biomass Fired Thermal Power Plant Project Working ProgressAnonymous 7ZYHilDAún no hay calificaciones

- Balanced Scorecard TemplatesDocumento67 páginasBalanced Scorecard TemplatesKhuda Buksh100% (1)

- Sixe MONTH REPORTE - New1Documento16 páginasSixe MONTH REPORTE - New1Anonymous 7ZYHilDAún no hay calificaciones

- 5.Covers-division Page of the Annex 26(完整)Documento16 páginas5.Covers-division Page of the Annex 26(完整)Anonymous 7ZYHilDAún no hay calificaciones

- 4.part II Special ConditionsDocumento25 páginas4.part II Special ConditionsAnonymous 7ZYHilDAún no hay calificaciones

- General Manpower Nos.: Total 498 Experts of OEM Personnel Man X MonthsDocumento6 páginasGeneral Manpower Nos.: Total 498 Experts of OEM Personnel Man X MonthsAnonymous 7ZYHilDAún no hay calificaciones

- 1.the PreambleDocumento8 páginas1.the PreambleAnonymous 7ZYHilDAún no hay calificaciones

- Edited Awash Arba Pics PDFDocumento35 páginasEdited Awash Arba Pics PDFAnonymous 7ZYHilDAún no hay calificaciones

- Awash Garage Maintenance ToollsDocumento11 páginasAwash Garage Maintenance ToollsAnonymous 7ZYHilDAún no hay calificaciones

- 1.the PreambleDocumento8 páginas1.the PreambleAnonymous 7ZYHilDAún no hay calificaciones

- 3.part I General ConditionsDocumento36 páginas3.part I General ConditionsAnonymous 7ZYHilDAún no hay calificaciones

- Anytime 4 e 5 Edec 91 B 99 BP 314Documento2 páginasAnytime 4 e 5 Edec 91 B 99 BP 314Anonymous 7ZYHilDAún no hay calificaciones

- Have Not Civele DesigneDocumento2 páginasHave Not Civele DesigneAnonymous 7ZYHilDAún no hay calificaciones

- Sixe MONTH REPORTE - New1Documento16 páginasSixe MONTH REPORTE - New1Anonymous 7ZYHilDAún no hay calificaciones

- 4E@RT-P170011B Design Shedule-2018.01.29 OkDocumento2 páginas4E@RT-P170011B Design Shedule-2018.01.29 OkAnonymous 7ZYHilDAún no hay calificaciones

- General Manpower Nos.: Total 498 Experts of OEM Personnel Man X MonthsDocumento6 páginasGeneral Manpower Nos.: Total 498 Experts of OEM Personnel Man X MonthsAnonymous 7ZYHilDAún no hay calificaciones

- Bill No - Civile Work WeigtageDocumento3 páginasBill No - Civile Work WeigtageAnonymous 7ZYHilDAún no hay calificaciones

- Metals and Engineering Corporation: Siddaca Faage 137.5Mw Biomass Fired Thermal Power Plant Project Working ProgressDocumento29 páginasMetals and Engineering Corporation: Siddaca Faage 137.5Mw Biomass Fired Thermal Power Plant Project Working ProgressAnonymous 7ZYHilDAún no hay calificaciones

- General Manpower Nos.: Total 498 Experts of OEM Personnel Man X MonthsDocumento6 páginasGeneral Manpower Nos.: Total 498 Experts of OEM Personnel Man X MonthsAnonymous 7ZYHilDAún no hay calificaciones

- Selection of GeneratorDocumento11 páginasSelection of GeneratorsbpathiAún no hay calificaciones

- Sixe MONTH REPORTE - New1Documento16 páginasSixe MONTH REPORTE - New1Anonymous 7ZYHilDAún no hay calificaciones

- Genet 1Documento11 páginasGenet 1Anonymous 7ZYHilDAún no hay calificaciones

- Technical Bid - Msil - MM STG & HRSG - 740 PDFDocumento107 páginasTechnical Bid - Msil - MM STG & HRSG - 740 PDFkumarmm1234Aún no hay calificaciones

- Erection Omo-KurazDocumento10 páginasErection Omo-KurazAnonymous 7ZYHilDAún no hay calificaciones

- Book 1Documento2 páginasBook 1Anonymous 7ZYHilDAún no hay calificaciones

- 200 Gen RD D 253pz EnglishDocumento9 páginas200 Gen RD D 253pz EnglishAnonymous 7ZYHilDAún no hay calificaciones

- Current Affairs Material Required-2Documento20 páginasCurrent Affairs Material Required-2Anonymous 7ZYHilDAún no hay calificaciones

- Cover PagesDocumento4 páginasCover PagesAnonymous 7ZYHilDAún no hay calificaciones

- Cult of The Blackness: Lady Wachter SDocumento9 páginasCult of The Blackness: Lady Wachter Sevandro souzaAún no hay calificaciones

- Evaluating Risks of Construction-Induced Building Damage For Large Underground Construction ProjectsDocumento28 páginasEvaluating Risks of Construction-Induced Building Damage For Large Underground Construction ProjectsGiuseppe SquillaciotiAún no hay calificaciones

- Air Admittance ValvesDocumento5 páginasAir Admittance ValvesRami ReddyAún no hay calificaciones

- EN81-20 欧洲最新电梯标准解读Documento100 páginasEN81-20 欧洲最新电梯标准解读babykiss1986Aún no hay calificaciones

- 4x4 HOUSEDocumento26 páginas4x4 HOUSETousif ShaikhAún no hay calificaciones

- Ground Floor Plan First Floor Plan: OTS OTSDocumento1 páginaGround Floor Plan First Floor Plan: OTS OTSAATVIK SHRIVASTAVAAún no hay calificaciones

- Palais BullesDocumento3 páginasPalais BullesPoojaVermaAún no hay calificaciones

- AyadiDocumento2 páginasAyadipardesi1982Aún no hay calificaciones

- D Class DCR Final 20.09.16Documento221 páginasD Class DCR Final 20.09.16Kscsiddhant KscsiddhantAún no hay calificaciones

- Dairy Engineering 1.0Documento136 páginasDairy Engineering 1.0isabeljanuarioAún no hay calificaciones

- Kim Lighting AFL Series Architectural Floodlights Brochure 1992Documento42 páginasKim Lighting AFL Series Architectural Floodlights Brochure 1992Alan MastersAún no hay calificaciones

- My Living Room PDFDocumento2 páginasMy Living Room PDFIsabelitaPintoAún no hay calificaciones

- DL 5022-1993Documento134 páginasDL 5022-1993ecsuperal100% (1)

- Project Planning and Scheduling: Gurugram Sector 48Documento34 páginasProject Planning and Scheduling: Gurugram Sector 48AbhishekPalitAún no hay calificaciones

- Electrical Specification Kim ProjectDocumento14 páginasElectrical Specification Kim Projectsooppasek katruksaAún no hay calificaciones

- Possible Solutions To Clogged NozzleDocumento1 páginaPossible Solutions To Clogged NozzleAsphystraszaAún no hay calificaciones

- M&E IntegrationDocumento18 páginasM&E IntegrationAnonymous wTTx1LAún no hay calificaciones

- Fire Alarm System Installation & TestingDocumento11 páginasFire Alarm System Installation & TestingMahesh Kumar MAún no hay calificaciones

- Grand Bazaar: Cultural Heritage in IstanbulDocumento27 páginasGrand Bazaar: Cultural Heritage in IstanbulZey Kar0% (1)

- Types of Wall PanelingDocumento7 páginasTypes of Wall Panelingsm_jdsAún no hay calificaciones

- Staircase DrawingDocumento1 páginaStaircase Drawingsrinivas pAún no hay calificaciones

- Mathcad - Sulzberger Bases Rectangulares y RomboidalesDocumento3 páginasMathcad - Sulzberger Bases Rectangulares y RomboidalesCarlos Gabriel LopezAún no hay calificaciones

- Assignment: Lightning Protection System DesignDocumento3 páginasAssignment: Lightning Protection System DesignChathura DalugodaAún no hay calificaciones

- Heating System B.O.QDocumento4 páginasHeating System B.O.QHemn Rafiq TofiqAún no hay calificaciones

- Cannington Court, SomersetDocumento95 páginasCannington Court, SomersetWessex ArchaeologyAún no hay calificaciones

- A. Comparative Matrix of PD 1096 and RA 9514Documento23 páginasA. Comparative Matrix of PD 1096 and RA 9514joshua moraAún no hay calificaciones

- August 2016 Link Progress ReportDocumento113 páginasAugust 2016 Link Progress ReportThe UrbanistAún no hay calificaciones

- CRSI Slabs On GroundDocumento1 páginaCRSI Slabs On GroundJason Gross100% (2)

- Portico ArriostradoDocumento31 páginasPortico ArriostradoJoselo LópezAún no hay calificaciones

- A B CD E A B CD E A B CD E: Ground Floor Plan Second Floor Plan Roof PlanDocumento1 páginaA B CD E A B CD E A B CD E: Ground Floor Plan Second Floor Plan Roof PlanPhineas FlynnAún no hay calificaciones