Documentos de Académico

Documentos de Profesional

Documentos de Cultura

SPE 20430 Mud Gas Separator Sizing and Evaluation PDF

Cargado por

manuelperdomot100%(2)100% encontró este documento útil (2 votos)

1K vistas6 páginasTítulo original

SPE 20430 Mud Gas Separator Sizing and Evaluation.pdf

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

100%(2)100% encontró este documento útil (2 votos)

1K vistas6 páginasSPE 20430 Mud Gas Separator Sizing and Evaluation PDF

Cargado por

manuelperdomotCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 6

Mud/Gas Separator Sizing

and Evaluation

@.R. MacDougall, SPE, Chevron Canada Resources Lid.

‘Summary. Recent wellsite disasters have led to an increased emphasis on properly sized mud/gas separators. This paper reviews

and analyzes existing mud/gas separator technology aod recommends separator configuration, components, design consideration, and

8 sizing procedure, A simple method of evaluating mud/gas separation within the separator vesse has been developed as a bass for

the sizing procedure. A mud/gas separator sizing worksheet will asist drilling personnel with the sizing calculations, The worksheet

provides a quick and easy evaluation of most mid/eus separators for a specific well application. A brief discussion of other mud/gas

separator considerations is provided, including separator components, testing, materials, and oil-based-mud considerations.

Introduction

‘The mud/gas separator is designed to provide effective separation

‘of the mud and gas circulated from the wel by venting the gas and

‘returning the mud to the mud pits. Small amounts of entrsined gas

can then be handled by a vacuum-type degasse located in the mud

pits. The mud/gas separator controls gas cuting during kick situa

‘ons, during drilling with significant drilled gas in the mud returns,

or when trip gas is circulated up,

‘This paper discusses design considerations for mud/gas separa:

tors. The purpose of this paper i 0 allow drilling rg supervisors

to evaluate mod/gas separators propery and wo upgrade (if required)

the separator economically to meet the design criteria outlined in

this paper, and to provide office drilling personnel with guidelines

for designing mud/gas separators before delivery a te drilste

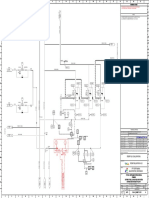

Principle of Operation

The operating principle of a mud/gas separator is relatively sim-

ple. The device is essentially a vertical steel cylindrical body with

‘openings on the top, bottom, and side, as shown in Fig. 1. The

‘mud and gas mixture is fed into the separator inlet and directed

‘a flat stel plate perpendicular to the flow. This impingement

‘late minimizes the erosional wear on te separator’ internal walls

and assists with mud/gas separation. Separation is further assisted

‘as the mud/gas mixture falls over a series of baffles designed to

increase the turbulence within the upper section of the vessel, The

fee gas is then vented through the gas vent line, and mud is retumed

to the mud tanks

Operating pressure within the separator is equal to the frietion

pressure ofthe free gas venting through the vent line. Fluid is main

tained ata specific level (mud leg) within the separator at all times.

If he friction pressure ofthe gas venting through the vent line ex-

‘ceeds the mud-leg hydrostatic pressure within the separator, 2 blow-

‘through condition will result sending a mud/gas mixture t the mod

tanks. As one can readily see, the critical point for separator blow.

‘through exists when peak gas flow rates are experienced in the sepa

rator, Peak gas Now rates should theoretically be experienced when,

‘gs initially reaches the separator.

‘Types of MudiGas Separators.

‘Three types of mod/gas separators commonly are used today: closed

bottom, open bottom, and float ype. The principle of mud/gassepa-

ration within each type of vessel is identical. Differences ean be

found in the method of maintaining the mid leg, as discussed

below.!

“The closed-bottom separator, as the name implies, is closed at

the vessel botiom withthe mud rtum line directed back othe mud

tanks, as shown in Fig. 1. Mud leg is maintained inthe separstor

by installation of an inverted U-shaped bend in the mud return line

Fluid level canbe adjusted by increasing/decreasing the length of

the U-shaped bend.

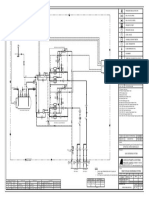

‘Commonly called the poor boy,2 the open-bottom mud/gas

separator is typically mounted on a mud tank or trip tank with the

bottom of the separator body submerged in the mud, as shown in

enya 00 Sooty ot Perce rgoere

‘SPE Dring Engineering, December 191

ig. 2. The Mud level (mud leg) inthe separator is controlled by

adjusting the uid level inthe mu tank or by moving the separa-

{or up or down within the tank, Mud-tank height can restrict the

‘maximum mud leg obtainable for open-bottom mud/ eas separators.

Fluid level (mud leg) is maintained in a floattype md/gas

separator! by a float valve configuration, as shown in Fig. 3. The

float opens and closes a valve on the mud return line to maintain

the muc-leg level. Valves can be operated by 2 manual linkage sys-

tem connected from the oat the valve, or the valve can be ait-

‘operated with rig air. Mud-leg height can be controled by adjast-

‘ng the float assembly.

“There are some inherent problems inthe use of float-ype mudigas

separators. The manual linkage separator has experienced prob-

[ems with linkage failure resulting in improper opening of closing

of the mud-return line valve. Air-operated valves fail to fonction

if rig air s lost, resulting in no control of fluid level within the

separator. Mud-retur-line valves ate prone to plug with solids,

preventing mud flowback to the mud pits

‘Because of these problems, float-type mudl/gas separators ae not

recommended and a closed-botiom separator i preferred. Open:

bottom separators are acceptable; however, one should be aware

that they are restricted to a maximum mud leg, somewhat lower

than the mod-ank height. Although float-type mud/gas separators

are strongly discouraged, these separators can be modified easily

for disconnection of the float, removal of the valve, and install:

tion of a mud leg in the mud return Tine

For the purpose ofthis paper, « closed-bottom mud/gas separa-

tor wil be considered forall separator designs.

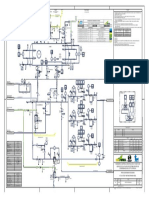

Sizing the Mud/Gas Separator

‘Table 1 shows a mud/gas separator worksheet to assist with the

sizing calculation. The mud’gas separator illustrated in Fig. 4 will,

be evaluated for sufficient sizing in this paper.

Peak Gas Flow Rate. As discussed previously, the eritical time

for separator blow-through exiss when peak gas flow rates are ex-

petienced. Mud/gas separator blow through is defined as inefficient

Separator operation resulting in a mud/gas mixture returning tothe

‘mud tanks through the mud retura line.

"Two situations can cause separator biow-through.

|. Friction pressure of the gas venting through the vent lin ex-

ceeds the mud-leg hydrostatic pressure, resulting in evacuation of|

{uid from the separator. Friction pressure ofthe mud trough the

‘mud retura line is considered negligible because ofits short length,

2. Vessel ID is too small, causing insufficient retention time for

the gas to separate efficiently from the mud. This situation is com-

monly called insufficient separator cut

"To estimate a peak gas flow rate propery, we must consider a

“typical” kick. The typical kick will depend on the wel location,

depth, type size, and component ratios of influx. Kiek data should

be based on previous offet well data and shouldbe a realistic worst-

case gas kick. The well and kick data in Fig. § wil be used in this

Paper.

"The volume and pressure ofthe gas upstream of the choke must

first be calculated. Using the drilling applications module Dril-

x

EES wo « ons unrue

wo

Cas

Fig. 1—Closed:-bottom mud/ges separator.

pro™,S we concluded that Pex

ol

‘The driller's method was used for calculation purposes. Use of

the waitand-weight method would result in a lower peak gas flow

rate. Dile's method calculations provide a worst-case well control

scenario for mud/gas separator sizing

‘The following equation calculates the time necessary to Vent gas:

= Veous! 9h 3 minutes, “

With Boyle's gus law,? calculate the volume of gas downstream

of the choke, V. Assume an atmospheric pressure of 14.7 ps.®

Neglect the effects of gas temperature and compressibility.

750 pst and Veeue =75.9

2

therefore, V-=(1,750%75.9)(14.7)=9,036 bbl

Calculate the peak g88 HOW rate, Guan: 8

@)

Convert barrels per minute to eubie feet per day,

157.2 8,085.62, 887,806 f2/D.

oun

‘Vent-Line Friction Pressure. The formula ued by this paper to

calculate friction pressure of gas trough a vent line i derived fom

the Atkinson-modified Darcy-Weisbach equation:”

hy =fslg 5.24

If we assume an empirical friction factor for smooth, straight,

ste pipe—10% 10" Tome-min2/t¥ and gas density =0.01 lm

al®—the following much simpler equation can be used

27 ~5.0*10- PL oa )

Effective length? Zs can be defined asthe tot vent-tne length

plus equivalent length for various bends, comers, ete. (Table 2),

for the mud/ges separator shown in Fig. 4. The vet line consists

‘0200 ft of a7-in-ID circular stel line with thre sarp right bends.

1, can be calculated 3s

Lp HL Leg =2004BXT)=AO Bes eereeeeeree

Ventline fiction pressure is

(5.0 10-2 4102,887,806)2/7.05 = L.0 pai

Note that effective venttine lengths will be significamily affect

ed by the installation of flame arrstrs or some auto-igniters.® The

cffect of this addtional backpressure shouldbe included inthe cal

calation of ven-line fiction pressure.

280

Fig. 2—Openhottom mudigas separator.

‘Mud Leg. As previously discussed, mud-leg hydrostatic pressure

-mustexcoed vent line friction pressure to prevent a separtor blow.

through condition. Minimum mud-leg hydrostatic pressure would

‘cur if an oilgas kick was taken and the mud leg was filled with

10.26 psi oil.® This minimum condition may of may not occur,

‘depending on the wel location. Offset well data shouldbe evaluat-

ed to establish a minimum mud-leg fuid gradient. For example,

the 0.26-psi/t mud-eg gradient would be considered extremely con-

servative if dy gas were expected forthe sample problem. A more

realistic estimate would approach the gradient of whole mud for

the dry-gas case. A realistic mud-leg gradient for a gas/water kick

‘would be the gradient of native salt water.

In this paper, a worst-case scenario is considered with « mud

leg fluid gradient of 0.26 psi. If we assume a 7-ft mud leg,

Prt hint 70.26% 1.8 psi ©

where Py >Py(1.8> 1.0 psi

Therefore, a blow through condition doesnot exist when vent-line

fiction pressure is calculated at peak gas flow rates

Separator ID. A blow through condition may exist because a small

vessel ID result in insufficient separator cut. Several complicated

‘models exist describe gas movement within a liquid. A sim-

plified approach, taken in this paper, states thatthe gas migration

rate upward within the separator must exceed the liquid velocity

‘downward within the separator to give 100% separator cut and to

prevent a separator blow-through condition. Gas migration rate is

estimated at 500 fh, or 8.4 fmin,? within the separator. This

estimation is conservative and more realistic values would be higher;

however, the slow gas migration rate serves as a worst-case

scenario, Ligud flow rate through the separator can be estimated

1s 2qu; for this paper 2%3=6 bbl/min. This factor of two was

‘determined from gas volume at depth calculations (Boyle's law)

using Drilpro™ for various depts and kick sizes. Correlation of|

the data shows that the mud flow from the well approaches wie

the mud flow into the well kill rate) for various kick size, kill

rates, and wellbore geometries. A more accurate determination of

‘mud’ flow from the well can be incorporated into the design

procedure.

By calculating the liquid velocity downward within the separator

w=2ailCe o

where Cyy=d?/1,029 DOL. IF we assume a 36-in, separator,

vp =10X3)362Y/1 029=4.8 Amin.

SPE Drilling Bapneerng, December 1991

FESS uo cas mxrune

BE wo

TO os

Fig. 3—Float-type mudl/gas separator.

‘We find thatthe gas migration rate is greater than the liquid veloc-

ity in the separator, 8.4>4.8 fUmin. Therefore, a blow-through

condition caused by insuficient separator cut does not exist

[Note that a separator cut < 100% frequently exists with mud/gas|

separators, and under some conditions, is not a major concern. AS

stated earlier, the mud/gas separator is designed 0 provide effec-

‘ive separation of mud and gas with small amounts of entrained

‘gas handled by a vacuum-type degasser located inthe mud pits

Therefore, large active pit volumes may tolerate < 100% separa~

tor cut,

Sizing Conclusion, Having evaluated sizing criteria fr the mud/gas

separator (Fig. 4), we may conclude tat the separator is sized sufi-

ciently to handle’ our worst-case kick properly.

(Oll-Based-Mud Considerations

‘The effects of oil-based mud on the operation ofthe mud/gas sepa-

fation can signifiantly affect sizing and design requirements."

‘These concems are currently being evaluated. However, some con-

clusions can be made at this stage. 10

‘TABLE 1—MUD/GAS SEPARATOR SIZING WORKSHEET

‘Slow pump rate Informatlon, Gace

‘strokes per min 33

ps 90

Bolstroke 0.081

bliin 30

‘Mudigas separator data

‘Separator body 1D in 98

Ges venti ID, din, 70

Gas ventsine effctve length,

Lgntt Log, bag fom Table 2, ft 410

ick data

(Old mud weight, vga! 182

Inia shutinclipipe pressure, ps 520

Iniialshutin easing pressure, pst 640

Pit gain, bol 28

‘Ts vertical depth, t 14.400

Peak gas-iow rate calculation

eras fF crilr’s method, psi 1780

\Veiuine of gas upetream of choke,

Vena. BB 759

‘Time fo pump gas out of wel,

Vena ldagn, MNOS 253

Volume ef gas downstream of choke,

Ve =PenusVena/Pes Dbl 9.096

Peak gas Tow flo, Gnu = Ve8085.61,°1 2.887.808

Venttine ticven-pressure calciation

Pm (5.0% 10~ FHL NA)", PL 10

Miciog ealeulation

Minimum mud leg required, ny ft 38

Separator ID calcusaton

Minimum separator ID, 15:56 [ancy (Bblmin), in, 27

Ifthe mudgas separsior does not meet te sing citra refer

tothe section on troubleshooting for suggested modicatons.

1. Gas kicks in oil-based mud can approach ‘possibly soluble"

conditions while the kick is eiculated from the well.

2. Gas kicks in oil-besed mud that pass through the gas bub-

blepoint while being circulated from the well can experience higher

Pemax 308 Very Vales than were calculated fr a Kick ofthe same

inital pit gain in a water-based mud. This results in higher peak

{gs flow rates through the separator and thus the requirement for

‘more stringent separator design.

3. Gas kicks in ol-based mud that do not pass through the gas

bubblepoint until the gas is downstream ofthe choke will severely

affect mud/gss separator sizing and design. Peak gas flow rates wll

be extremely high relative to those calculated for water-based mud

wo

Dos

Kw

aang x80 12.20 &

Fig. 4—Muaigas separator sizing

‘SPE Dring Boginecring, December 1991

2a

FEE] woe ons uocune

Beno -coTuse,

sie

— 8

CONTRACTION,

expansion, | 1

‘eau ——_

EXPANSION,

10

ME wo

TC as

ae

rator components.

6—Mudigas

Closed-bottom mud/gas separators should be designed with a

minimum I-ft sump a the botiom ofthe vessel. The sump will help

prevent solids from setling and plugging the mud-return-line outlet.

‘A lower manway shouldbe located onthe lower part ofthe sepa

stor to permit sump cleanout or unplugging of the mad retura line.

as cutined in this paper. Additional evaluation ofthe separator sizing

should be completed if these well conditions exist

thor Mud/Gas Separator Considerations'“®

Fig. 6 shows other separator components. A minimum in -D mad

‘eur line is recommended for losed-bottom separators. Smaller

lines may encounter problems with solids plugging the line. A larger-

ID line would be considered beneficial. The impingement plate

should be perpendicular to the separator inlet line and field

replaceable.

Balfles within the separator should be located in the upper part

ofthe separator and may continue into the lower part of the vessel

‘Typically, baffles consist of near-horizontal plates. The plates may

be sold or have holes in them. The baffles should not impede the

flow ofliguid through te separator, which would cause ud buld-

"up above the beffles. Solids buildup in the baffles can also be a

problem if the beffles are too restrictive,

"An upper manway shouldbe located on the upper part ofthe sepa-

rator to permit visual inspection of the interior ofthe separator.

‘The manway shouldbe large enough to permit replacement of the

impingement late and equipped witha replaceable rubber seal to

prevent leakage.

‘The manway should be equipped witha replaceable rubber seal to

prevent leakage.

‘The mud/gas separator should be equipped with a valved inlet

con te lower section of the vessel to permit mud to be pumped into

the separator. Mud ean be pumped into the lower section of the

separator during operation to decrease the possibilty of solids

Settling inthe mud return line. The valved inlet also permits clean-

ing solids from the lower portion ofthe separator, especially after

separator use.

‘A siphon breaker or antisiphon tube may be required to prevent

having to siphon mud from the separator into the mud tanks, espe-

cially with configurations that require the mud return ie to be ex-

tended below the separator elevation to allow mod to return tothe

‘mud tanks. The siphon breaker i simply an upward-directed open

ended pipe attached 10 the highest point of the mud retum line.

All separators must be builtin compliance withthe ASME Boil-

er and Pressure Vessel Code, Sec. VIM, Div. I with all materials

meeting requirements of NACE Standard MRO1-75-84' (1980

Revision. All welding on the vessel must meet ASME requirement.

Fig. 7—Effect of clrulating kill rate on minimum separator ID.

| Fig. 8—Ettect of kil rate on ventine fiction pressure.

am

SPE Diiling Engineering, December 191

)

“ a

4

oe al

eng to

S—Etfect of mud-eg height on mudsieg hydrostatic

pressure.

New mud/gas separators should be hydrostatically tested to 188

psi to give a maximum working pressure of 150 psi, as recom-

‘mended by ASME." Periodic nondestructive testing should in-

clude radiographic examination of wall thickness and ultrasound

‘verification of weld continuity. At each intial hookup, every

separator should be circulated through with water atthe maximum

possible flow rate to check for possible leaks in the connections.

Frequency of testing should depend on anticipated and historical

tse of the separator.

‘Bracing the mud/gas separator has always been @ major prob-

Tem. When gas reaches the surface, separators tend to vibrate and,

iftnot properly supported, can move, resulting in nea-catastrophic

problems. Thus, its critical that all mad/gas separators be sufi-

ently anchored and properly braced to prevent movement ofboth

the separator body and the lines.

‘Trouble-Shooting an insufficiently

Sized Separator

Frequently, the situation arses where a magus separator is picked

‘up with the rig contract, andthe dling rig supervisor and engi-

‘cer must evaluate the suitability ofthe separator fr the well loca-

tion. This evaluation typically should be conducted during the rig

bid analysis process. If the separator is insufficient or marginal,

itmay be more economical to upgrade the existing separator to meet

the sizing eriteria as an alternative to renting or building a suitable

‘Small Vessel ID. We frequently do our calculations and determine

that our vessel ID is too small. Reducing the Kil rate will improve

this situation; eg., if the kill rate forthe previously sized separa-

tor were reduced from 3 to 1.5 bbl/min, then from Eq. 7

vp =[2X1.5)362/1,029=2.4 funn

Thus, reducing the kil rate also reduces the liquid velocity rate

inthe separator, which increases the mod/gas retention time and

improves the efficiency of mud/gas separation.

‘Also note that a gas migration rate of $00 fbr (8.4 fin) is

‘ worst-case scenario and values could be higher. Therefore, when

vessel ID is considered, a marginal separator probably would be

sufficient because ofthis buil-in safety factor. Higher gas migra-

tion rates may also be used inthe sizing procedure, as previously

discussed. Fig. 7 shows the effect of kill rate on the calculation

‘of minimum separator ID for different gas migration rates

‘Vent-Line Friction Pressure Exceeds Mud-Leg Hydrostate Pres-

sure. Another area of concern is vent-line friction pressure exceod-

ing mud-leg hydrostatic pressure, py >. Several options exist

to help alleviate this problem.

1. Reduce the circulating kil rate, As discussed previously, 3

reduction inthe circulating kill ate may improve a sepurator's op-

tration when vesse ID is considered and also when excessive vent-

line frition pressures are considered. This reduction in kill rate

‘may be the most economical solution to the sizing concern, For

SPE Drilling Eogincerng, December 1991

| Fig. 10—etfect of effective length on ventsine friction |

pressure.

l

Fig. 11—Effect of ventine ID on vent-line fiction pressure.

example, ifthe kill rate forthe previously sized separator were re-

‘duced from 3to 1.5 bbVmin, the peak gas How rate would decreas.

Combining Eqs. 1 and 3 and converting, we obtain

15.91,

and dinar =9,036050.6= 1,443,908 19/D.

‘This decrease in peak gas flow rate would significantly decrease

the excessive vent-line fition pressure and improve the operation

fof the separator (Eq, 4),

‘pg(5.0X10-¥2 410% 1,443,903)2/7.05 =0.25 psi

Fig. 8 shows the effect of kil rate onthe calculation of vent-line

fiction pressure forthe previously sized separator.

2, Increase the mud leg. Another solution may be fo increase the

height ofthe mud eg. For example, if we increased the previously

sized separator froma 7-ft mud leg toa 10 mud leg, the mud-leg

hydrostatic pressure should increase (Eq. 6).

Pri=10X0.26=2.6 psi

‘Ths, the mud-leg hydrostatic pressure increased from 1.8 102.6

pi, allowing the separator to operate more efficiently

"Fig. 9 shows the effect of mud-leg height on the calculation of

smud-leg hydrostatic pressure for different mud-eg gradients. Note

that the mud-leg height cannot exceed the separator height. The

‘ud leg may aso be restricted by bel-nipple elevation. Ifthe mod

Jeg ishigher than the bell nipple, additional surface equipment may

be required to permit the separator to operate when drilling with

significant gas in the mud returns,

3. Adjust vent-lne bends. As shown in Table 1, the type and

number of bends in the vent line significantly affect the effective

vent-line length, which in turn affects the calculation for ven-line

fiction pressure. If we were to replace the targeted T-bends on

‘the previously sized separator with right-rounded bends, the ci

283

0.6 rin

ere

@.R. MacDougall is adriling engineer

ft Chevron Canada Resources Ltd. In

Calgary. Previously, he was an engineer

ft Chevron Services’ Drilling Technolo-

‘9y Contre, He holde @ BS degree in min-

ing engineering from the Technical U. of

Nova Scotia

‘ulations for the effective length (Eq. 5) and vent-line friction pres

‘sure (Eq. 4) would change:

1,=200+(3%1)=203 ft

‘and py =(5.0% 10-12 x203 x2,887,806)2/7.05=0.5 pai

Hence, a ventline frction-pressure decrease from 1.0 to 0.5 psi

increases the efficiency of the separator for a given mud leg. In

‘addition, the vet-lin friction pressure increases proportionally to

the effective length (Fig. 10).

“4 Increase vent-line ID. Increasing the vent-line ID is generally

‘the most expensive alternative but may be the only adjustment pos-

sible to increase separator efficiency. Larger-ID vent lines will

‘decrease the vent-line friction pressure calculation. For the previ-

‘ously sized separator, if an 8.0-in-ID vent line were used, the cal-

‘culation for vent-line friction pressure (Eq. 5) would change to

(Py =(8.010~!2<410%2,887,806)2/7.05 =0.5 pai

‘Again, a vent-line ftiction pressure decrease from 1.0 100.5 psi

‘ill increase separator efficiency fora given mud leg. Fig. 11 shows

the effect of vent-line ID on the calculation of vent-line friction pres-

sure for the previously sized separator.

Conclusions

1. The principle of mud/gas separation within most commonly

‘used mud gas separators is identical. Differences can be found in

the method of maintaining the mud leg.

2. A closed-bortom mud/gas separator is the preferred configu-

ration. Open-bottom and flost-ype separators work well but are

‘subject to limitations and prone to failure.

3. Sizing ofa mud/gas separator should be specific to individual

‘well conditions.

44. Modeling of gas flow through a mud/gas separator can be ap-

proximated by a simple procedure in a limited time.

'5. A complete list of mud/gas separator components and con-

siderations was compiled 1o assist with the design of mud/gas sepa

"ators.

‘6. A trouble-shooting guide was developed to address econom-

cal upgrading ofan existing insufficiently sized separator to meet

sizing guidelines as an alternative to building or renting @ new

separator.

Nomenclature

A = cross-sectional area of gas vent line, t2

separator capacity, BbI/t

f= empirical friction factor, Hom-min?/¢

ar = mudeg fod gradient, pit

Ihny = mmad-leg height,

"E = gas ventlne length, ft

L, = gas Yentlie effective length, f

24

Log = equivalent length of bends,

Pe = pressure of gas downstream of choke=atmospheric

pressure, 14.7 psi

Pens ~ Pressure of gas upstream of choke, psi

"Py = B88 vent-line friction pressure, psi

Pm = mud-leg hydrostatic pressure, psi

"9 = gas flow rate, bbV/min

94 = Kil rate, Bolmin

eax = peak gas flow rate through mud/gas separator,

‘oVmin or 83/0

Qitow = slow pump rate, psi

'5 = gas vent-line perimeter, ft

1 = time venting gas at surface, minutes

vz = liquid velocity in the mud/gas separator, feimin

V, = volume of gas downstream of choke, bbl

Vewx = Volume of gas upstream of choke, bbl

f

Acknowledgments

| thank Chevron Services Co., Chevron Canada Resources, and

‘Chevron’s Drilling Technology Centre for their assistance and per-

‘mission to write and publish this paper.

References

1. Tumer, EB. ““Well Control When Deiling With Oil-Based Mud,”

Oftthore Technology Report OTHBG260, UK. Operations & Safety,

Dept. of Energy, Landon (Oct. 1986).

2, Bulchko, D. ef a: “Design of Atmospheric Open-Bottom Mud/Gas

Sepuruors,” paper SPE 1348 presented the 1985 SPEIIADC Dring

Conference, New Orleans, March 5-8

3. Grigg, P.C.: "The Poor Boy Degnser asa Well Control Too,” paper

pesca at the 1980 IADCICAODC Dring Tecnology Conference,

Dallas, March 17-20.

4, Swaco Mud Gas Separator Operation and Serle Manual, Report No.

(0880-0250, Dresser Industries Ine. (April 1982),

5. Brewton, J., Rau, W-E., and Dearing, H.L.: "Development and Use

‘ofa Drilling Applications Module fra Programamibe Hand-Held Cal

‘alstor,” pope SPE 16657 preseated at the 1987 SPE Annual Techni

‘al Conference and Exhibition, Dallas, Sept. 27-20

6. Engineering Data Boo, ninth edition, Gas Processors Supplies Aso,

‘Tulss (1979) Chap. 16, 141

17, Hartman, H.l.: Mine Veeilation and Air Conditioning, Joba Wiley

48 Sons Inc., New York City (1982) 131-61

8, Spec 12, Speciation for Oil and Gat Separators, sixth ein, API,

alas Gune 1, 1988),

9. Rede, D.W., Bourpoyne, AT. and Ward, RH.

‘Bubble Rise Velcty of Gas Kick

10, O'Bryan, PL. and Bourgoyoe, AT: “Methods for Handling Drilled

Gas in Oi-Based ailing Fis," SPEDE (Sept. 1989) 257-46.

11, Baler and Pressure Coe, Seton VIN Ds. I, Pesure Vessels, ASME,

Dalles (Dec. 1989) 101-36.

12, Standard MROI-75-84, Material Requirement, Sud Stress Cracking

Resistant Metalic Material for Oil Field Equipment, NACE, Houston

(an, 198).

$1 Metric Conversion Factors

actors Affecting

"IPT (Stay 1978) 371-84,

bol x 1.589.873 B-01

Ax 3088" E-O1

WO x 2.831685 E02

gal x 3.785 412

in, x 2.548 E+00

bm x 4.535924 E-O1

psi x 6.894 757 E+00

SPEDE.

gererememmrneninte.s me nensoent ian

Ze ilpnat aaa

ake

SPE Driling Engineering, December 1991

También podría gustarte

- Bulletin 71.4MR108 PDFDocumento20 páginasBulletin 71.4MR108 PDFBledarAún no hay calificaciones

- Process Engineer - PSV Calculation - KD, KC, KB FactorDocumento3 páginasProcess Engineer - PSV Calculation - KD, KC, KB Factorkenoly123Aún no hay calificaciones

- Hook Ups PDFDocumento8 páginasHook Ups PDFAnonymous d7Jde8Aún no hay calificaciones

- Manual PipephaseDocumento202 páginasManual PipephaseWil Vasquez CAún no hay calificaciones

- Evaluate Heat-Exchanger Tube Rupture Scenarios Using Dynamic Simulation PDFDocumento6 páginasEvaluate Heat-Exchanger Tube Rupture Scenarios Using Dynamic Simulation PDFZhen Kai OngAún no hay calificaciones

- Dokumen - Tips - Gpsa 13 Ed Separation PDFDocumento48 páginasDokumen - Tips - Gpsa 13 Ed Separation PDFNovi WulansariAún no hay calificaciones

- Selection of Separator With BootDocumento2 páginasSelection of Separator With BootMaryJane Ayisha Sado-ObahAún no hay calificaciones

- 5 - Demethanizer OperationDocumento5 páginas5 - Demethanizer Operationmaheenkapadia4612100% (1)

- Page 1 of 5 Compressor Blocked Discharge - Chemical EngineersDocumento5 páginasPage 1 of 5 Compressor Blocked Discharge - Chemical EngineersKarthikeyan SivaAún no hay calificaciones

- PSV Releiving TempDocumento3 páginasPSV Releiving TempOthman Mat YamanAún no hay calificaciones

- 15bch027 P&id MainDocumento1 página15bch027 P&id MainMayur ParmarAún no hay calificaciones

- HMB Latest Stream ReporterDocumento20 páginasHMB Latest Stream ReporterConnor SailorAún no hay calificaciones

- Ig N e D: WMV Ral VSM Acp Ags Ral Cle WMV JCF FCM CleDocumento1 páginaIg N e D: WMV Ral VSM Acp Ags Ral Cle WMV JCF FCM Clenestor159357Aún no hay calificaciones

- Wed Apr 08 12:32:21 2020 Case: TEG SIMULATION - HSC Flowsheet: Case (Main)Documento1 páginaWed Apr 08 12:32:21 2020 Case: TEG SIMULATION - HSC Flowsheet: Case (Main)IBIKUNLEAún no hay calificaciones

- Line ListDocumento1 páginaLine Listهيمنت بيلودياAún no hay calificaciones

- Rigorous Method For Fire CaseDocumento4 páginasRigorous Method For Fire CaseFlorin Daniel AnghelAún no hay calificaciones

- Front Matte - 2007 - Ludwig S Applied Process Design For Chemical and Petrochemi PDFDocumento1 páginaFront Matte - 2007 - Ludwig S Applied Process Design For Chemical and Petrochemi PDFKemal Faza HastadiAún no hay calificaciones

- PSV Load Calculation For Gas Expantion Fire Case PDFDocumento2 páginasPSV Load Calculation For Gas Expantion Fire Case PDFAnonymous V5UYBUMaAún no hay calificaciones

- Manual PRO IIDocumento33 páginasManual PRO IIJuan Pablo RocetaAún no hay calificaciones

- Heat ExchangersDocumento66 páginasHeat Exchangersmbabar81Aún no hay calificaciones

- Herbs Cultivation and Medicinal Uses by H. PandaDocumento9 páginasHerbs Cultivation and Medicinal Uses by H. PandaKoushik SekharAún no hay calificaciones

- Guide Document GE P312 4.1.2 I General ConsiderationsDocumento31 páginasGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraAún no hay calificaciones

- 0210-CRB-0002 0210-CNJ-0002 0210-ZMH-0015: Rock Breaker Hydraulic PowerDocumento1 página0210-CRB-0002 0210-CNJ-0002 0210-ZMH-0015: Rock Breaker Hydraulic Powernestor159357Aún no hay calificaciones

- Dynamic Simulation LNGDocumento6 páginasDynamic Simulation LNGRon BoloAún no hay calificaciones

- Gas Processing I - Chapter 3 Rev 1Documento26 páginasGas Processing I - Chapter 3 Rev 1ABULARA2K6Aún no hay calificaciones

- Amine Sweetening Process Problem - Industrial Professionals - Cheresources - Com CommunityDocumento6 páginasAmine Sweetening Process Problem - Industrial Professionals - Cheresources - Com Communitykirankumar9898Aún no hay calificaciones

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocumento127 páginasPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresAún no hay calificaciones

- 000 - PID Revision Mark UpDocumento22 páginas000 - PID Revision Mark UpAzhar BudimanAún no hay calificaciones

- Tower Sizing ProcedureDocumento44 páginasTower Sizing ProceduressiddamAún no hay calificaciones

- A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0Documento2 páginasA44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0m.shehreyar.khanAún no hay calificaciones

- 2-Phase Omega PSV SizingDocumento2 páginas2-Phase Omega PSV SizingABULARA2K6Aún no hay calificaciones

- S-03710 P42118-Rev. 3-P18-Steam DrumDocumento1 páginaS-03710 P42118-Rev. 3-P18-Steam Drumwylie01Aún no hay calificaciones

- PDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia SeparatorDocumento8 páginasPDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia Separatorhgag selimAún no hay calificaciones

- Flow Sic 600Documento16 páginasFlow Sic 600Martijn GrootAún no hay calificaciones

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlDocumento77 páginasAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- 11-4567 JS Activation Tifs RefreshDocumento14 páginas11-4567 JS Activation Tifs Refreshedgardiaz5519Aún no hay calificaciones

- Toyo Stress NotesDocumento63 páginasToyo Stress NotesDhakshina KAún no hay calificaciones

- HS523217 51 PR PID 0018 0001rev1Documento1 páginaHS523217 51 PR PID 0018 0001rev1Nasim MammadovAún no hay calificaciones

- Prico Process PDFDocumento13 páginasPrico Process PDFcorkynhoAún no hay calificaciones

- Heat Exchanger Sizing E-5000 #1Documento2 páginasHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleAún no hay calificaciones

- Flow Assurance With Olga 7Documento47 páginasFlow Assurance With Olga 7Murali MuthuAún no hay calificaciones

- Varicon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDocumento1 páginaVaricon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDeva NaiduAún no hay calificaciones

- Webinar FAQ - Shell and Tube Heat ExchangersDocumento8 páginasWebinar FAQ - Shell and Tube Heat Exchangersrameshkarthik810Aún no hay calificaciones

- Process Equipment Data Sheet: Operating Mechanical Data GAS Liquid UnitDocumento4 páginasProcess Equipment Data Sheet: Operating Mechanical Data GAS Liquid UnitAudhinna ZuffyAún no hay calificaciones

- 7 - V-0801 P-0801 ABC HOT OIL SYSTEM PUMPS - Rev 0Cx PDFDocumento1 página7 - V-0801 P-0801 ABC HOT OIL SYSTEM PUMPS - Rev 0Cx PDFMariaAún no hay calificaciones

- GBH Enterprises, LTD.: Process Engineering GuideDocumento15 páginasGBH Enterprises, LTD.: Process Engineering GuidePaul JamesonAún no hay calificaciones

- Settle Out Pressure Calculations PDFDocumento4 páginasSettle Out Pressure Calculations PDFAlvin SmithAún no hay calificaciones

- Korf Tutorial PDFDocumento17 páginasKorf Tutorial PDFAadi Khan100% (1)

- Heat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryDocumento8 páginasHeat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryaminAún no hay calificaciones

- Flare Gas Recovery PDFDocumento13 páginasFlare Gas Recovery PDFSadad MohamadAún no hay calificaciones

- Simulation of Liquefied Petroleum Gas LPG Producti PDFDocumento7 páginasSimulation of Liquefied Petroleum Gas LPG Producti PDFfarshadAún no hay calificaciones

- Instrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAIDocumento1 páginaInstrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAInastyn-1Aún no hay calificaciones

- Amine Gas SweeteningDocumento5 páginasAmine Gas SweeteningYorman Zambrano SilvaAún no hay calificaciones

- What Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoDe EverandWhat Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoAún no hay calificaciones