Documentos de Académico

Documentos de Profesional

Documentos de Cultura

2015 Oilfield Technology Apr

Cargado por

arietilangDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

2015 Oilfield Technology Apr

Cargado por

arietilangCopyright:

Formatos disponibles

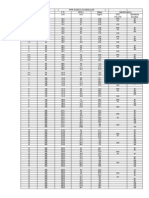

Title

Doc.no.

Piping and Valve Specification

Operator

Sec.no.

5060

Project

Piping Class Sheet:

DESIGN CODE:

AD20

150

lb

ASME B31.3 a)

Maximum Design Pressure:

At Temperature:

Rev.no.

Corr. Allow:

Barg

C

Rev.date

03

0.0 mm

Page: Of:

01.09.2008

Material Selection : TCD 4650

20.0 20.0 19.5 17.7 15.8 14.0 12.1

-46 38

50 100 150 200 250

PIPE SIZE AND WALL THICKNESS

Nom.Size(in)

Dia.(mm)

Wall th.(mm)

Schedule

0.5

0.75

1.5

10

12

14

16

18

20

24

30

36

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457.2

508.0

609.6

762.0

914.0

2.77

2.87

3.68

2.77

3.05

3.05

3.40

3.76

4.19

4.57

4.78

4.78

4.78

5.54

6.35

7.92

7.92

3.38

40S

WALL THICKNESS UNDER TOLERANCES:

LONGITUDINAL WELD EFFICIENCY:

ELEMENT

NAME

DIMENSION STANDARDS

PIPE

BRANCHES

ASME B36.19M

ASME B36.19M

ASME B36.10M

Made from pipe

ASME B16.9

MSS SP-75

Olets

PIPE NIPPLE

ASME B16.9

ASTM A733

BENDING

FITTINGS

10S

12.5%, see note c)

0.8 see note e)

ASME B16.11

NOTES:

See page 2

MDS

incl incl

0.5

8 Seamless, PE

1 30 Welded, PE

36 36 Welded, PE

A790 S31803

A928 S31803 CL5

D41

D42

D42

24

36

A928 S31803 CL5

A815 S31803 S/WX

A815 S31803 S/WX

A815 S31803 S/WX

As fittings

0.5 1.5 Sch 80S BOE/TOE A790 S31803 SMLS

Bev to match sch 40S

A182 F51

2 36 150lb RF WN

ORIF.FLANGES ASME B16.36

RED. THR'D

ASME B16.5

FLANGE

LINE BLINDS Spect bl.

Spect bl.

Spade/spacer

Spade/spacer

BOLTING

ASME B16.5

PLUGS

SAFETY

BLEED PLUG

MATERIAL

NAME

A182 F51

MSS SP-44

ASME B16.20

NOM. SIZE TYPE

FROM TO

0.5

30

REINFORCED Drilled to

NIPOFLANGE ASME B16.5

FLANGES

ASME B16.5

MSS SP-44

FLG. BLIND

ASME B16.5

GASKET

10

d)

0.5

30

0.5

0.5

30

30

0.5

0.75

24

36

24

24

36

36

24

2

0.5

0.5

14

14

0.5

0.5

0.5

0.5

0.5

12

12

36

36

36

36

36

36

36

150lb RF WN

150lb RF WN

150lb RF

150lb RF

150lb RF

150lb RF

300lb RF NPT (F)

A182 F51

A182 F51

A182 F51

A240 S31803

A240 S31803

A182 F51

A182 F51

A182 F51

A182 F51

150lb RF

A240 S31803

150lb RF

A182 F51

150lb RF

A240 S31803

150lb RF

A320 L7

Stud bolts galv.

A194 7

Hex. nuts galv.

A276 S32760

Stud bolts

A276 S32760

Hex. Nuts

4.5 mm thk. SPW 316L w/Exp.

Graphite int/ext. ring 316L SS

A182 F51

0.5

1 Hex. head

0.5 0.75 NPT (M)

B446 N06625

Annealed

D43

D43

D44

D43

D41

D44

D44

D44

D44

D45

D45

D44

D44

D44

EDS

NBE1

EFI1

EBR3/

NOL1

EBR3

EPI1

EBR3/

NOL1

NAF1

NAF1

NAF1

NAF1

NAF1

NAF1

NAF1

d) NAF1

D44

D45

D44

D45

C100

C100

D57X

D57X

NLB1

NLB1

NLB1

NLB1

NBO1

NBO1

NBO1

NBO1

EGA1

D44

EPI1

EFI4/

EPI1

g)

g)

Title

Doc.no.

Piping and Valve Specification

Operator

5060

Project

Piping Class Sheet:

VALVE OR

EQUIPMENT

TYPE

GATE

BUTTERFLY

GLOBE

CHECK

BALL

MODULAR

NOTES:

a)

b)

c)

d)

e)

f)

g)

VSM

AD20

150

Rev.no.

lb

NOMINAL SIZE

FROM TO

incl

incl

0.5

1.5

0.5

1

0.5

2

2

36

2

36

2

36

2

36

3

36

3

36

12

36

0.5

1.5

0.5

2

2

24

0.5

1.5

0.5

2

2

36

2

36

0.5

10

0.5

8

2

36

2

36

4

36

4

36

0.5

2

0.5

4

0.5

4

0.5

2

0.5

2

Sec.no.

03

Rev.date

Page: Of:

01.09.2008

VDS

REMARKS

GTRD00B

GTRD00D

GTAD00R

GTAD10R

GTAD30R

GTAD40R

GTAD70R

BUAD20R

BUAD30R

BUAD80R

GBDD00B

GBAD00R

GBAD10R

CHDD00B

CHAD00R

CHAD50R

CHAD90R

BLAD00R

BLAD10R

BLAD30R

BLAD40R

BLAD50R

BLAD60R

CBAD20D

CBAD00R

CBAD10R

CBAD70D

CBAD90D

BW

BW/TE

RF

RF

RB, Through conduit slab, Max. 200C, RF

FB, Through conduit slab, Max. 200C, RF

Through conduit, Double expanding, Max. 200C, RF

Wafer, Max 150C, RF

Wafer, Metal seated, Max. 200C, RF

Metal Seated, Max. 200C, RF

BW

RF

RF

BW

RF

Wafer, Dual disc, RF

Non-slam, RF

RB, Max 150C, RF

FB, Max 150C, RF

RB, Max 150C, RF

FB, Max 150C, RF

RB, Metal seat, Max. 200C, RF

FB, Metal seat, Max. 200C, RF

SB, DB&B, Max. 150C, RF/TE

RB, DB&B, Max. 150C, RF

FB, DB&B, Max. 150C, RF

SB, Metal seat, DB&B, RF/TE

SB, DB&B, Max. 150C, RF/TE

Manufacturer of the piping components shall perform a conformity assessment

fulfilling PED (97/23/EC) category III.

This piping class is generally suitable for sour service according to NACE MR-01-075.

The tolerance is used for design and is not part of the purchase specification

when deviating from the individual piping item.

ASME B16.5 NPT threaded flanges shall only be used complete with safety bleed plug as

described in Piping Detail Standard, Doc. no. KE-P-T-008

Pipe to A928 CL.5 may utilize longitudinal weld efficiency 0.9.

Deleted

To be used on continuous flow seawater cooling supply lines,

or on other normally cold lines where water can condense.

The final selection to be done by the COPSAS TAG material engineer and the project process engineer.

También podría gustarte

- Piping Code ComparisonDocumento5 páginasPiping Code ComparisonAndy Hakim83% (6)

- Gaseous Hydrogen Piping SpecificationDocumento5 páginasGaseous Hydrogen Piping SpecificationAndri DoemeriAún no hay calificaciones

- A270 PDFDocumento5 páginasA270 PDFHansSarmientoAún no hay calificaciones

- Piping BasisDocumento32 páginasPiping Basislowermine100% (2)

- Secification For Clad Carbon Steel Bends Manufactured by Induction HeatingDocumento19 páginasSecification For Clad Carbon Steel Bends Manufactured by Induction HeatingAdvisAún no hay calificaciones

- Technical Specifications BAMULDocumento133 páginasTechnical Specifications BAMULjaya100% (1)

- Fmea Failure Mode Effects AnalysisDocumento93 páginasFmea Failure Mode Effects AnalysisCHANDUAún no hay calificaciones

- A 949 - A 949M - 01 Qtk0os9botq5tqDocumento4 páginasA 949 - A 949M - 01 Qtk0os9botq5tqsachinguptachdAún no hay calificaciones

- Calculations SheetDocumento3 páginasCalculations SheetSami SawalhaAún no hay calificaciones

- Carl Zeiss GDxPRODocumento254 páginasCarl Zeiss GDxPROPandula MaddumageAún no hay calificaciones

- PmsDocumento94 páginasPmssdk1978100% (1)

- API 2H Grade 50 Steel Plate SpecificationDocumento3 páginasAPI 2H Grade 50 Steel Plate SpecificationJym GensonAún no hay calificaciones

- Welding Procedure Specification For 24'' PipeDocumento2 páginasWelding Procedure Specification For 24'' Pipeenels77100% (1)

- Volime II of II Mechanical Piping-GAILDocumento245 páginasVolime II of II Mechanical Piping-GAILBathi Hari PrasadAún no hay calificaciones

- 000 L Ee 0020129Documento2433 páginas000 L Ee 0020129avaisharmaAún no hay calificaciones

- Valve Procurement SpecsDocumento39 páginasValve Procurement Specsjoseph.maquez24100% (2)

- PN01CS1B02Documento5 páginasPN01CS1B02ger80100% (1)

- Shell and Tube Heat Exchanger DesignDocumento41 páginasShell and Tube Heat Exchanger DesignAhmad Budiman100% (2)

- Flow CalculatorDocumento45 páginasFlow CalculatorIndrajit BorikarAún no hay calificaciones

- Piping Material SpecificationDocumento36 páginasPiping Material Specificationravirawat15100% (2)

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocumento10 páginasA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaAún no hay calificaciones

- 01NU0B01Documento4 páginas01NU0B01raobabar21Aún no hay calificaciones

- Flange Selection GuideDocumento11 páginasFlange Selection GuidebandithaguruAún no hay calificaciones

- Tender9 Vol II o II Pig Launcher and Receiver by MeconDocumento31 páginasTender9 Vol II o II Pig Launcher and Receiver by MeconVeena S VAún no hay calificaciones

- Instrument Index and Io List Worksheet1Documento5 páginasInstrument Index and Io List Worksheet1arietilang100% (2)

- Astm A 106 - 08Documento9 páginasAstm A 106 - 08Alvin Irfani AzharAún no hay calificaciones

- WOM Subsea Brochure 8Documento40 páginasWOM Subsea Brochure 8arietilangAún no hay calificaciones

- Technical Data NRL 02301Documento8 páginasTechnical Data NRL 02301Attiq Ahmad ChoudhryAún no hay calificaciones

- Brown Tonality and Form in Debussey PDFDocumento18 páginasBrown Tonality and Form in Debussey PDFShawn SherwoodAún no hay calificaciones

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalDocumento643 páginas6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85Aún no hay calificaciones

- AP-NozzleTutorial R01 PDFDocumento31 páginasAP-NozzleTutorial R01 PDFbalumagesh1979Aún no hay calificaciones

- Ductile Iron Casting Specfications and Details All StandardsDocumento15 páginasDuctile Iron Casting Specfications and Details All StandardsN.Palaniappan100% (1)

- Welding of Duplex Stainless SteelDocumento7 páginasWelding of Duplex Stainless SteelAnthony YUAún no hay calificaciones

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceCalificación: 5 de 5 estrellas5/5 (1)

- Esab DublexDocumento8 páginasEsab DublexSuphi YükselAún no hay calificaciones

- Welding Procedure Specification For 24'' PipeDocumento2 páginasWelding Procedure Specification For 24'' Pipeenels77100% (2)

- WPS Asme IxDocumento4 páginasWPS Asme Ixjcarlosherrerac7100% (1)

- Groove DesignDocumento4 páginasGroove DesignElizabeth SpenceAún no hay calificaciones

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Documento6 páginasPCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroAún no hay calificaciones

- SPC-0804.02-50.09 Rev D2 Welding of Pipe For Station ConstructionDocumento14 páginasSPC-0804.02-50.09 Rev D2 Welding of Pipe For Station ConstructionAbdul Hakam Mohamed YusofAún no hay calificaciones

- ASTM-A106-A106M-19Documento6 páginasASTM-A106-A106M-19Milady OyuelaAún no hay calificaciones

- Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSDocumento2 páginasFab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSabidaliabid1100% (1)

- PIPELINE WELDING PROCEDURE SPECIFICATION TITLEDocumento17 páginasPIPELINE WELDING PROCEDURE SPECIFICATION TITLEBenjamin Alvarez MedinaAún no hay calificaciones

- p22MNVMB MN Gtaw+Smaw (Pipe)Documento2 páginasp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1Aún no hay calificaciones

- Structural Steel SpecificationDocumento15 páginasStructural Steel SpecificationBùi Văn HợpAún no hay calificaciones

- WN SA-105 B16 5 TT Rev0Documento2 páginasWN SA-105 B16 5 TT Rev0Aço SalgueiroAún no hay calificaciones

- ASTM A106 A106M Standard Specification For Seamless Carbon Steel Pipe For High-Temperature ServiceDocumento21 páginasASTM A106 A106M Standard Specification For Seamless Carbon Steel Pipe For High-Temperature ServiceRifqi AdityaAún no hay calificaciones

- Att 2 - EdsDocumento30 páginasAtt 2 - Eds정동현Aún no hay calificaciones

- DNO Piping SpecificationDocumento2 páginasDNO Piping SpecificationDurgesh GuptaAún no hay calificaciones

- rc61180 b09Documento9 páginasrc61180 b09eww08Aún no hay calificaciones

- CDA110 Specifaction SheetDocumento5 páginasCDA110 Specifaction SheetGendakensAún no hay calificaciones

- 2005-05 - WPS & PQR C5Documento6 páginas2005-05 - WPS & PQR C5misthahAún no hay calificaciones

- A 949 - A 949M - 00 Qtk0os0wmeeDocumento4 páginasA 949 - A 949M - 00 Qtk0os0wmeesachinguptachdAún no hay calificaciones

- Din 2393-2Documento0 páginasDin 2393-2Yalavarthi ChandrasekharAún no hay calificaciones

- Ductile Iron SpecificationsDocumento12 páginasDuctile Iron SpecificationsDouglas BooyensAún no hay calificaciones

- The Welding of Structural Steels Without PreheatDocumento10 páginasThe Welding of Structural Steels Without PreheatHouman HatamianAún no hay calificaciones

- Gas Pipeline SpecDocumento4 páginasGas Pipeline SpecA_bener100% (1)

- Casting MaterialsDocumento42 páginasCasting MaterialsTirta BudiawanAún no hay calificaciones

- All B31 Code Cases in Effect As of September 21, 2007 Will Remain Available For Use Unless Annulled by The B31 Standards CommitteeDocumento39 páginasAll B31 Code Cases in Effect As of September 21, 2007 Will Remain Available For Use Unless Annulled by The B31 Standards CommitteeEl FashelAún no hay calificaciones

- Caracteristicas API 2HGr50 PDFDocumento3 páginasCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezAún no hay calificaciones

- Critical PipingDocumento7 páginasCritical PipingFRAN0026Aún no hay calificaciones

- Astm A216Documento3 páginasAstm A216preanandAún no hay calificaciones

- Boq For RSP Ccas PipingDocumento3 páginasBoq For RSP Ccas Pipingkoushikdey_2011Aún no hay calificaciones

- A 216 - A 216M - 93 R03 Qtixni9bmje2tqDocumento3 páginasA 216 - A 216M - 93 R03 Qtixni9bmje2tqStuartAún no hay calificaciones

- 9952T 1311 F0001 PD2 A CDocumento169 páginas9952T 1311 F0001 PD2 A CBarbara HowellAún no hay calificaciones

- Technical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsDocumento11 páginasTechnical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsMunish100% (1)

- Specification For Fire Pump - Part 10Documento5 páginasSpecification For Fire Pump - Part 10Melisa MackAún no hay calificaciones

- Handbook Flow Measurement PDFDocumento78 páginasHandbook Flow Measurement PDFarietilangAún no hay calificaciones

- Tramore Sewerage Outfall Design PlansDocumento7 páginasTramore Sewerage Outfall Design PlansarietilangAún no hay calificaciones

- Appendix T Route Selection Matrix PDFDocumento9 páginasAppendix T Route Selection Matrix PDFarietilangAún no hay calificaciones

- Plot Plan Flow Loop Test PDFDocumento1 páginaPlot Plan Flow Loop Test PDFarietilangAún no hay calificaciones

- ArcelorMittal Offshore Structural Steel Stock ProgramDocumento12 páginasArcelorMittal Offshore Structural Steel Stock ProgramCemil GüneşAún no hay calificaciones

- AGA Report 9 - USM, 2nd Edition, April 2007 PDFDocumento109 páginasAGA Report 9 - USM, 2nd Edition, April 2007 PDFAnderson Widmer Morales VillarrealAún no hay calificaciones

- 29-Horizontal Subsea Xmas Tree en PDFDocumento2 páginas29-Horizontal Subsea Xmas Tree en PDFarietilangAún no hay calificaciones

- Handbook Flow MeasurementDocumento78 páginasHandbook Flow MeasurementarietilangAún no hay calificaciones

- Design of An Outfall Diffuser: Experiment 9Documento2 páginasDesign of An Outfall Diffuser: Experiment 9arietilangAún no hay calificaciones

- HDPE InstallationDocumento12 páginasHDPE InstallationJohari A. KasimAún no hay calificaciones

- Ultrasonic Scanning Report: Client: Description: Location: Serial/Tag No: Date of TestDocumento3 páginasUltrasonic Scanning Report: Client: Description: Location: Serial/Tag No: Date of TestarietilangAún no hay calificaciones

- Appendix T Route Selection Matrix PDFDocumento9 páginasAppendix T Route Selection Matrix PDFarietilangAún no hay calificaciones

- ESDVDocumento48 páginasESDVPipitlyAún no hay calificaciones

- ABS Guide For Offshore InstallationsDocumento332 páginasABS Guide For Offshore InstallationsDang Dinh ChiAún no hay calificaciones

- LINCOLN Kawat LasDocumento8 páginasLINCOLN Kawat LasarietilangAún no hay calificaciones

- MGP CPCN Vol3 Set 3 SDocumento44 páginasMGP CPCN Vol3 Set 3 SarietilangAún no hay calificaciones

- Holding Time Pressure ChartDocumento3 páginasHolding Time Pressure ChartarietilangAún no hay calificaciones

- 2007 Catalog WebDocumento5 páginas2007 Catalog WebarietilangAún no hay calificaciones

- Pressure Drop in Water PipesDocumento1 páginaPressure Drop in Water PipesarietilangAún no hay calificaciones

- MTO Instrument CSRMDocumento14 páginasMTO Instrument CSRMarietilangAún no hay calificaciones

- Geothermal Facility Reliability and Integrity Engineering Services Contract in Salak and Drajat Area Operation CONTRACT No: CW1005676Documento1 páginaGeothermal Facility Reliability and Integrity Engineering Services Contract in Salak and Drajat Area Operation CONTRACT No: CW1005676arietilangAún no hay calificaciones

- Instrument IndexDocumento4 páginasInstrument IndexarietilangAún no hay calificaciones

- Pipe Sizes and ScheduleDocumento2 páginasPipe Sizes and Schedulechupacid0% (1)

- Piping Handbook Contents and Chapter OverviewDocumento5 páginasPiping Handbook Contents and Chapter OverviewnamasralAún no hay calificaciones

- Front End Engineering Design for Gas Metering at Pemping IslandDocumento2 páginasFront End Engineering Design for Gas Metering at Pemping IslandarietilangAún no hay calificaciones

- 20 Questions On Aircraft Asked in Indian Air Force InterviewDocumento9 páginas20 Questions On Aircraft Asked in Indian Air Force InterviewPreran PrasadAún no hay calificaciones

- Project ScopeDocumento2 páginasProject ScopeRahul SinhaAún no hay calificaciones

- G-Series Pneumatic and Hydraulic Actuators: The Compact, Lightweight and Reliable SolutionDocumento12 páginasG-Series Pneumatic and Hydraulic Actuators: The Compact, Lightweight and Reliable SolutionRoo Fa100% (1)

- The Apparatus of RepressionDocumento221 páginasThe Apparatus of RepressionAndrew Charles Hendricks100% (3)

- KomatsuHydraulicBreaker8 29Documento22 páginasKomatsuHydraulicBreaker8 29Ke HalimunAún no hay calificaciones

- Bill of Materials for Gate ValveDocumento6 páginasBill of Materials for Gate Valveflasher_for_nokiaAún no hay calificaciones

- DXX-790-960/1710-2180-65/65-17i/18.5 - M/M: Model: ADU451807v01Documento3 páginasDXX-790-960/1710-2180-65/65-17i/18.5 - M/M: Model: ADU451807v01jhon mirandaAún no hay calificaciones

- The Service Owner Role in ITIL v3: by Kai HolthausDocumento6 páginasThe Service Owner Role in ITIL v3: by Kai HolthausSavitha MohanAún no hay calificaciones

- Report on Industrial Visit to ACC Limited Chaibasa Cement WorksDocumento8 páginasReport on Industrial Visit to ACC Limited Chaibasa Cement WorksRohit Vishal PandeyAún no hay calificaciones

- Automatic Temperature Controlled FanDocumento27 páginasAutomatic Temperature Controlled Fankannan100% (2)

- Solucionario - Termodinamica - Cengel - 7ed (1) - 519-528Documento10 páginasSolucionario - Termodinamica - Cengel - 7ed (1) - 519-528Lizeth Maria lizarazoAún no hay calificaciones

- Strategic MGMT 4Documento33 páginasStrategic MGMT 4misbahaslam1986Aún no hay calificaciones

- Xeon c5500 c3500 Non Transparent Bridge PaperDocumento28 páginasXeon c5500 c3500 Non Transparent Bridge Papersureshr_42Aún no hay calificaciones

- The Changing Face of The NewsDocumento2 páginasThe Changing Face of The NewsYanaAún no hay calificaciones

- Industry 4.0 CourseDocumento49 páginasIndustry 4.0 CourseThiruvengadam CAún no hay calificaciones

- Atheros Valkyrie BT Soc BriefDocumento2 páginasAtheros Valkyrie BT Soc BriefZimmy ZizakeAún no hay calificaciones

- M.tech Lab Manual JNTUHDocumento80 páginasM.tech Lab Manual JNTUHSivarama Prasad PamarthyAún no hay calificaciones

- Narrative Report 2BDocumento14 páginasNarrative Report 2BMarc Edson CastroAún no hay calificaciones

- Pundit Transducers - Operating Instructions - English - HighDocumento8 páginasPundit Transducers - Operating Instructions - English - HighAayush JoshiAún no hay calificaciones

- 23 - Eave StrutsDocumento2 páginas23 - Eave StrutsTuanQuachAún no hay calificaciones

- Libro Desarrollo Organizacional Xady Nieto - AntiCopy - CompressedDocumento190 páginasLibro Desarrollo Organizacional Xady Nieto - AntiCopy - Compressedleandro cazarAún no hay calificaciones

- Tm3 Transm Receiver GuideDocumento66 páginasTm3 Transm Receiver GuideAl ZanoagaAún no hay calificaciones

- C - TurretDocumento25 páginasC - TurretNathan BukoskiAún no hay calificaciones

- Flow Through a Convergent-Divergent Duct ExperimentDocumento4 páginasFlow Through a Convergent-Divergent Duct ExperimentfongAún no hay calificaciones

- mp4 Manual PDFDocumento162 páginasmp4 Manual PDFStella AntoniouAún no hay calificaciones

- WarpriestDocumento8 páginasWarpriestBenguin Oliver MasonAún no hay calificaciones

- Ds - PDF Circuito Integrado Driver Par La Bobina D IgnicionDocumento8 páginasDs - PDF Circuito Integrado Driver Par La Bobina D Ignicionjavy_846058987Aún no hay calificaciones