Documentos de Académico

Documentos de Profesional

Documentos de Cultura

TL k3 6 2 02 Xka de en

Cargado por

vladimirkulf2142Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

TL k3 6 2 02 Xka de en

Cargado por

vladimirkulf2142Copyright:

Formatos disponibles

XKA

6.2

X XXKAtestregistrierung

Splitters

Type XKA

For high insertion loss with broadband damping,

even in the high-frequency range

Energy-saving splitters, ready to be used in air conditioning systems

Attenuation effect due to absorption

Energy efficient due to aerodynamically profiled frame (radius > 15 mm)

Acoustic data measured to ISO 7235

Absorption material is biosoluble and hence hygienically safe

Absorption material faced with glass fibre fabric as a protection

against erosion due to airflow velocities up to 20 m/s

Absorption material non-combustible, to EN 13501, fire rating class A1

Splitter frames

with folded edges

Available in standard sizes and many intermediate sizes

Operating temperature up to 100 C

H GE

Optional equipment and accessories

TE

ET

HY

ISC

ST

EN

VD

I 6022

Additional perforated sheet metal to protect the absorption material

Powder-coated

Stainless steel

Brine and salt-water resistant aluminium construction (AlMg3)

Tested to VDI 6022

03/2014 DE/en

K3 6.2 13

Splitters

General information

XKA

Page

Type

XKA

Description

Sound attenuator splitter,

variant XKA-200

General information

Order code

Insertion loss

Quick sizing

Dimensions and weight

Installation details

Specification text

6.2 14

6.2 16

6.2 17

6.2 20

6.2 23

6.2 25

6.2 26

Basic information and nomenclature

6.4 1

Application

Sound attenuator splitters of Type XKA,

used for the reduction of fan noise

and air-regenerated noise

in air conditioning systems

Attenuation effect due to absorption

Broadband attenuation even

in the high frequency range

Hygiene tested and certified to VDI 6022

For use in potentially explosive atmospheres

(ATEX), zones 1, 2, 21 and 22 (outside)

Variants

XKA-100: Splitter thickness 100 mm

XKA-200: Splitter thickness 200 mm

XKA-230: Splitter thickness 230 mm

XKA-300: Splitter thickness 300 mm

Construction

Splitter surface

F: Glass fibre fabric

L: Glass fibre fabric and perforated sheet metal

Nominal sizes

H: 300, 600, 900, 1200, 1500, 1800 mm

(intermediate sizes 400 1700 mm

in increments of 100 mm)

Height subdivided: 1900 5000 mm,

in increments of 100 mm

L: 500, 750, 1000, 1250, 1500 mm

Length subdivided: 1750, 2000, 2250, 2500,

2750, 3000 mm

(intermediate sizes 1501 2999 mm

in increments of 1 mm)

Useful additions

Fitting accessories

for sound attenuator splitters

Special features

Increased insertion loss even

in the high-frequency range

Up to 30 % lower differential pressure

Energy efficient and/or space saving due

to aerodynamically profiled frame

Hygiene tested and certified

Multi-section construction available

for large dimensions

Construction features

Aerodynamically profiled splitter frame

(radius > 15 mm) that enables a reduction

of turbulence both upstream and downstream;

frame with grooves for increased rigidity

Frame edges are folded to protect the infill

Operating temperature up to 100 C

(construction with perforated sheet metal

up to 300 C for 3h max.)

Materials and surfaces

Splitter frames made of galvanised sheet steel

Absorption material is mineral wool

Mineral wool

To EN 13501, fire rating class A1,

non-combustible

RAL quality mark RAL-GZ 388

Biosoluble and hence hygienically safe

according to the German TRGS 905

(Technical Rules for Hazardous Substances)

and EU directive 97/69/EG

Faced with glass fibre fabric as protection

against erosion through airflow velocities

of up to 20 m/s

Inert to fungal and bacterial growth

Installation and commissioning

Splitters are supplied as ready-to-install kits

Observe installation information

and the general codes of good practice

in order to achieve the given performance data

Vertical installation should be preferred,

horizontal installation is possible

up to H = 1200 mm

The length (L) of sound attenuator splitters

and splitter attenuators refers always to the

airflow direction. Remember this with regard

to vertical ducting.

Installation in ducts outside of closed rooms

requires sufficient protection against

the effects of weather

Parts and characteristics

Aerodynamically profiled frame

Absorption material to reduce air-regenerated

noise by absorption

K3 6.2 14

03/2014 DE/en

Splitters

General information

XKA

Standards and guidelines

Insertion loss and sound power level

of air-regenerated noise tested to ISO 7235

Meets the hygiene requirements of VDI 6022,

DIN 1946, parts 1 and 2 as well as of VDI 3803

Directive 94/9/EC: Equipment and protective

systems intended for use in potentially

explosive atmospheres

Technical data

Splitter thickness

100, 200, 230, 300 mm

Nominal sizes

140 500 mm 1800 1500 mm

Operating temperature

Function

Maintenance

Maintenance-free as construction

and materials are not subject to wear

100 C

Functional description

The attenuation effect of the XKA splitters

is due to absorption.

The splitters have a mineral wool infill

as absorption material.

Schematic illustration of XKA-200

Splitter frame, 200 mm wide

Absorption material faced on both sides

with glass fibre fabric

03/2014 DE/en

K3 6.2 15

Splitters

Order code

Order code

The length (L) of sound

attenuator splitters and

splitter attenuators refers

always to the airflow

direction. Remember this

with regard to vertical

ducting.

XKA

XKA

XKA 200 F / 6001500

Type

XKA Sound attenuator splitter

Height H [mm]

Length in airflow direction L [mm]

Splitter thickness [mm]

100

200

230

300

Splitter surface

F

Glass fibre fabric

L

Glass fibre fabric under perforated

sheet metal

Fitting accessories for sound attenuator splitters

SD KBLECH

Part

SD-KBLECH

SD-KAP100

SD-KAP200

SD-KAP230

SD-KAP300

Order example

XKA100L/15001500

Splitter thickness

Splitter surface

K3 6.2 16

Clamp sheet for MKA, XKA, RKA200

U-sheet for MKA-100, XKA-100

U-sheet for MKA-200, XKA-200, RKA200

U-sheet for MKA-230, XKA-230

U-sheet for XKA-300

100 mm

Glass fibre fabric and perforated sheet metal

Height

1500 mm

Length

1500 mm

03/2014 DE/en

Splitters

Insertion loss

XKA

Splitter thickness 100 mm XKA100 / XSA100 Length L = 500 mm

De

8000

4000

2000

1000

De

dB

dB

10

18

37

45

31

23

40

19

29

46

50

39

32

60

16

33

38

25

19

60

16

26

42

47

34

26

100

11

25

23

13

100

19

35

35

22

15

200

14

200

13

22

14

De

4000

2000

1000

500

250

125

Airway width

63

8000

4000

2000

1000

Centre frequency fm [Hz]

500

Centre frequency fm [Hz]

250

XKA100 / XSA100 Length L = 2000 mm

125

XKA100 / XSA100 Length L = 1500 mm

8000

40

Airway width

De

dB

dB

11

27

39

50

50

47

40

40

14

36

50

50

50

50

60

23

35

50

50

42

34

60

12

30

45

50

50

50

41

100

14

27

44

46

31

20

100

19

34

50

50

39

26

200

18

30

19

11

200

11

24

38

24

14

10

De

4000

2000

1000

500

250

125

Airway width

63

8000

4000

2000

1000

500

Centre frequency fm [Hz]

250

Centre frequency fm [Hz]

125

XKA100 / XSA100 Length L = 3000 mm

63

XKA100 / XSA100 Length L = 2500 mm

49

8000

40

Airway width

De

dB

dB

40

18

44

50

50

50

50

50

40

10

21

50

50

50

50

50

50

60

14

37

50

50

50

50

49

60

10

17

44

50

50

50

50

50

100

23

42

50

50

48

32

100

28

49

50

50

50

37

200

13

29

46

30

17

12

200

16

34

50

35

20

13

Splitter thickness 200 mm XKA200 / XSA200 Length L = 500 mm

XKA200 / XSA200 Length L = 1000 mm

De

8000

4000

2000

1000

500

250

125

Airway width

63

8000

Centre frequency fm [Hz]

4000

2000

1000

500

250

125

Airway width

63

Centre frequency fm [Hz]

De

dB

dB

12

18

31

44

42

29

23

50

14

22

44

50

50

36

27

100

20

26

22

16

11

100

15

32

46

38

23

16

200

13

14

11

200

11

22

25

18

11

400

400

13

11

De

4000

2000

1000

500

250

125

Airway width

63

8000

4000

2000

1000

500

Centre frequency fm [Hz]

250

Centre frequency fm [Hz]

125

XKA200 / XSA200 Length L = 2000 mm

63

XKA200 / XSA200 Length L = 1500 mm

8000

50

Airway width

De

dB

03/2014 DE/en

500

250

125

Airway width

63

8000

Centre frequency fm [Hz]

4000

2000

1000

500

250

125

Airway width

63

Centre frequency fm [Hz]

63

Insertion loss values

for other lengths

(intermediate sizes)

and airway widths can be

determined with the Easy

Product Finder design

programme.

XKA100 / XSA100 Length L = 1000 mm

dB

50

20

31

50

50

50

48

33

50

10

27

40

50

50

50

50

100

12

22

47

50

50

31

20

100

16

28

50

50

50

39

24

200

15

31

35

24

14

200

20

41

45

30

17

10

400

11

18

15

400

14

24

19

11

39

K3 6.2 17

Splitters

XKA

De

dB

4000

2000

50

13

34

47

50

50

50

50

45

50

16

42

50

50

50

50

50

50

100

21

34

50

50

50

45

27

100

26

39

50

50

50

50

31

200

11

23

50

50

36

19

11

200

13

27

50

50

41

21

12

400

16

29

21

13

400

18

34

24

14

XKA230 / XSA230 Length L = 1000 mm

De

De

dB

dB

8000

4000

2000

1000

500

250

125

Airway width

62.5

8000

Centre frequency fm [Hz]

4000

2000

1000

500

250

125

Airway width

62.5

Centre frequency fm [Hz]

12

25

34

25

19

18

60

12

20

35

48

40

27

21

18

24

17

13

13

115

16

27

35

27

18

15

230

11

13

230

12

18

20

14

10

460

460

De

4000

2000

1000

500

250

125

Airway width

62.5

8000

4000

2000

1000

De

dB

60

16

27

46

50

50

35

25

115

12

22

36

46

37

24

18

230

16

25

28

19

12

11

460

11

15

10

dB

60

21

35

50

50

50

43

115

15

28

45

50

47

29

21

230

21

32

36

24

14

13

460

14

20

15

De

4000

2000

1000

500

250

125

Airway width

62.5

8000

4000

2000

1000

500

Airway width

250

Centre frequency fm [Hz]

125

XKA230 / XSA230 Length L = 3000 mm

Centre frequency fm [Hz]

62.5

XKA230 / XSA230 Length L = 2500 mm

29

8000

500

Centre frequency fm [Hz]

250

Centre frequency fm [Hz]

125

XKA230 / XSA230 Length L = 2000 mm

62.5

XKA230 / XSA230 Length L = 1500 mm

8000

60

115

Airway width

De

dB

K3 6.2 18

1000

De

dB

Splitter thickness 230 mm XKA230 / XSA230 Length L = 500 mm

500

250

125

Airway width

63

8000

4000

2000

1000

Airway width

500

Centre frequency fm [Hz]

250

Centre frequency fm [Hz]

125

XKA200 / XSA200 Length L = 3000 mm

63

XKA200 / XSA200 Length L = 2500 mm

8000

Insertion loss

60

25

43

50

50

50

50

33

115

19

35

50

50

50

34

24

230

12

26

40

43

28

17

14

460

18

25

19

dB

60

30

50

50

50

50

50

37

115

22

41

50

50

50

40

27

230

14

31

47

50

33

19

16

460

21

31

23

03/2014 DE/en

Splitters

Insertion loss

XKA

Splitter thickness 300 mm XKA300 / XSA300 Length L = 500 mm

XKA300 / XSA300 Length L = 1000 mm

De

De

dB

4

17

25

34

32

22

18

11

16

19

17

12

300

10

600

dB

75

15

24

42

48

50

33

26

150

18

27

34

28

17

11

300

11

15

16

13

600

4000

2000

1000

500

250

125

Airway width

63

8000

4000

2000

1000

500

Centre frequency fm [Hz]

250

Centre frequency fm [Hz]

125

XKA300 / XSA300 Length L = 2000 mm

63

XKA300 / XSA300 Length L = 1500 mm

8000

75

150

Airway width

8000

4000

2000

1000

500

250

125

Airway width

63

8000

Centre frequency fm [Hz]

4000

2000

1000

500

250

125

Airway width

63

Centre frequency fm [Hz]

De

De

dB

dB

8

20

33

50

50

50

44

30

75

10

25

42

50

50

50

50

34

150

14

26

38

46

39

21

13

150

18

33

48

50

50

26

16

300

16

21

21

17

10

300

11

20

26

26

21

12

600

11

12

600

14

16

11

De

De

dB

dB

4000

2000

1000

500

250

125

Airway width

63

8000

4000

2000

1000

Airway width

500

Centre frequency fm [Hz]

250

Centre frequency fm [Hz]

125

XKA300 / XSA300 Length L = 3000 mm

63

XKA300 / XSA300 Length L = 2500 mm

8000

75

75

13

30

50

50

50

50

50

38

75

15

35

50

50

50

50

50

42

150

23

40

50

50

50

30

18

150

28

48

50

50

50

35

20

300

14

25

32

32

25

13

10

300

17

30

38

37

29

15

11

600

17

19

13

600

11

21

23

14

03/2014 DE/en

K3 6.2 19

Splitters

Quick sizing

Quick sizing

sound power level

XKA

Air-regenerated noise MSA, MKA, XSA, XKA, RKA

vs

LWA

The sound power levels

LWA apply to sound

attenuation dampers with

a cross-sectional area

(B H) of 1 m.

m/s

10

12

14

16

18

20

dB(A)

21

31

38

43

47

51

54

57

60

Quick sizing

MKA100 / XKA100 L = 500 mm

differential pressure

Airway width [mm]

Splitter thickness 100 mm

40

60

100

vs

MKA100 / XKA100 L = 1000 mm

Airway width [mm]

200

vs

40

60

pst

m/s

Pa

m/s

Pa

10

35

18

10

10

45

24

12

20

135

70

35

18

20

180

90

45

22

MKA100 / XKA100 L = 2000 mm

Airway width [mm]

vs

40

60

Airway width [mm]

100

200

vs

40

60

pst

m/s

100

200

pst

Pa

m/s

Pa

10

12

10

55

28

14

10

70

35

16

20

225

110

55

26

20

270

135

65

30

MKA100 / XKA100 L = 2500 mm

40

60

Airway width [mm]

100

200

vs

40

60

pst

m/s

MKA100 / XKA100 L = 3000 mm

Airway width [mm]

vs

100

200

pst

Pa

m/s

Pa

14

16

10

80

40

18

10

10

90

45

20

10

20

320

155

70

35

20

365

175

80

40

Splitter thickness 200 mm MKA200 / XKA200 L = 500 mm

MKA200 / XKA200 L = 1000 mm

Airway width [mm]

vs

50

100

Airway width [mm]

200

400

vs

50

100

pst

m/s

K3 6.2 20

200

MKA100 / XKA100 L = 1500 mm

100

pst

200

400

pst

Pa

m/s

Pa

10

12

10

60

14

10

65

16

0

2

20

235

50

16

20

265

60

22

10

03/2014 DE/en

Splitters

Quick sizing

XKA

MKA200 / XKA200 L = 1500 mm

MKA200 / XKA200 L = 2000 mm

Airway width [mm]

vs

50

100

Airway width [mm]

200

400

vs

50

100

pst

m/s

400

pst

Pa

m/s

Pa

12

14

10

75

18

10

85

22

20

300

75

26

14

20

335

85

30

16

MKA200 / XKA200 L = 2500 mm

vs

50

100

Airway width [mm]

200

400

vs

50

100

pst

m/s

MKA200 / XKA200 L = 3000 mm

Airway width [mm]

200

400

pst

Pa

m/s

Pa

16

16

10

90

24

10

10

100

28

10

20

365

95

35

18

20

400

110

40

22

Splitter thickness 230 mm MKA230 / XKA230 L = 500 mm

MKA230 / XKA230 L = 1000 mm

Airway width [mm]

vs

60

115

Airway width [mm]

230

460

vs

60

115

pst

m/s

10

10

55

20

225

m/s

Pa

10

14

10

65

16

55

16

20

260

65

22

10

115

Airway width [mm]

230

460

vs

60

115

pst

m/s

MKA230 / XKA230 L = 2000 mm

Airway width [mm]

60

460

MKA230 / XKA230 L = 1500 mm

vs

230

pst

Pa

230

460

pst

Pa

m/s

Pa

12

14

10

75

20

10

80

22

20

295

75

26

12

20

330

90

30

16

MKA230 / XKA230 L = 2500 mm

MKA230 / XKA230 L = 3000 mm

Airway width [mm]

vs

60

115

m/s

Airway width [mm]

230

460

vs

60

115

pst

03/2014 DE/en

200

230

460

pst

Pa

m/s

Pa

14

16

10

90

26

10

10

100

28

10

20

360

100

35

18

20

395

115

40

20

K3 6.2 21

Splitters

Quick sizing

XKA

Splitter thickness 300 mm XKA300 L = 500 mm

XKA300 L = 1000 mm

Airway width [mm]

vs

75

150

Airway width [mm]

300

600

vs

75

150

300

pst

m/s

600

pst

Pa

m/s

Pa

10

11

10

62

12

10

69

14

20

247

50

14

20

278

58

17

XKA300 L = 1500 mm

XKA300 L = 2000 mm

Airway width [mm]

vs

75

150

Airway width [mm]

300

600

vs

75

150

300

pst

m/s

600

pst

Pa

m/s

Pa

12

14

10

77

16

10

85

18

20

308

65

19

20

339

73

22

10

XKA300 L = 2500 mm

XKA300 L = 3000 mm

Airway width [mm]

vs

75

150

Airway width [mm]

300

600

vs

75

150

pst

m/s

300

600

pst

Pa

m/s

Pa

15

16

10

92

20

10

100

22

0

3

20

369

81

25

11

20

400

89

28

12

K3 6.2 22

03/2014 DE/en

Splitters

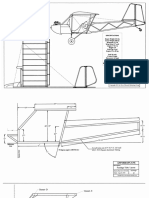

Dimensions and weight

Dimensions

XKA

Dimensional drawing of XKA

The length (L) of sound

attenuator splitters and

splitter attenuators refers

always to the airflow

direction. Remember this

with regard to vertical

ducting.

T:Splitter thickness

L:Length (in airflow direction)

Weight XKA-100

Glass fibre fabric (-F)

Glass fibre fabric and perforated sheet metal (-L)

Height

Length [mm]

500

750

1000

1250

1500

mm

500

750

1000

1250

1500

kg

300

600

11

13

900

10

12

15

18

1200

10

12

16

20

23

1500

10

12

11

15

20

24

28

Weight XKA-200

Glass fibre fabric (-F)

Glass fibre fabric and perforated sheet metal (-L)

Height

Length [mm]

500

750

1000

1250

1500

mm

500

750

1000

1250

1500

kg

300

10

600

11

10

12

15

18

900

11

13

15

10

13

17

21

25

1200

11

13

16

19

12

17

22

27

32

1500

10

13

16

19

22

15

21

27

33

39

Weight XKA-230

Glass fibre fabric (-F)

Glass fibre fabric and perforated sheet metal (-L)

Height

Length [mm]

500

750

1000

1250

1500

mm

03/2014 DE/en

500

750

1000

1250

1500

kg

300

10

11

600

11

12

10

13

16

19

900

10

12

14

17

10

14

19

23

27

1200

12

15

18

21

13

19

24

29

34

1500

11

15

18

22

25

16

23

29

35

42

K3 6.2 23

Splitters

Dimensions and weight

XKA

Weight XKA-300

Glass fibre fabric (-F)

Glass fibre fabric and perforated sheet metal (-L)

Height

Length [mm]

500

750

1000

1250

1500

mm

500

750

1000

1250

1500

kg

300

10

11

14

600

11

14

16

12

16

19

22

900

12

15

18

21

12

17

22

27

31

1200

12

15

19

23

27

16

22

28

34

40

1500

14

19

23

28

33

19

27

34

42

49

K3 6.2 24

03/2014 DE/en

Splitters

Installation details

Upstream conditions Bend

Upstream conditions Junction

Upstream conditions

XKA

1.5H

1.5H

Vertical duct section before the bend:

Splitters vertical; H of duct = H of splitters

Horizontal duct section before the bend:

Splitters horizontal; B of duct = H of splitters

Assembly of

subdivided splitters

Vertical duct section before the junction:

Splitters vertical; H of duct = H of splitters

Horizontal duct section before the junction:

Splitters horizontal; B of duct = H of splitters

Assembly of subdivided splitters

Hmax = 5 000 mm

704

259

U-sheet

Clamp sheet

H or L 750 mm: without clamp sheet

H or L 751 1000 mm: 1 clamp sheet on each side

H or L > 1000 mm:

2 clamp sheets on each side recommended

03/2014 DE/en

K3 6.2 25

Splitters

Specification text

Standard text

This specification text

describes the general

properties of the product.

Texts for variants can be

generated with our Easy

Product Finder design

programme.

Sound attenuator splitters used for the reduction

of fan noise and air-regenerated noise in

air conditioning systems. Attenuation effect due

to absorption. Energy-saving as well as hygiene

tested and certified.

Installation kit consists of an aerodynamically

profiled frame (radius > 15 mm) and absorption

material.

Frame edges are folded to protect

the sound absorbing infill.

Insertion loss and sound power level

of the air-regenerated noise tested to ISO 7235.

Meets the hygiene requirements of VDI 6022,

DIN 1946, parts 2 and 4, as well as of VDI 3803.

Special features

Increased insertion loss even

in the high-frequency range

Up to 30 % lower differential pressure

Energy efficient and/or space saving due

to aerodynamically profiled frame

Hygiene tested and certified

Multi-section construction available

for large dimensions

XKA

Construction

Splitter surface

F: Glass fibre fabric

L: Glass fibre fabric and perforated sheet metal

Technical data

Splitter thickness: 100, 200, 230, 300 mm

Nominal sizes: 140 500 mm 1800 1500 mm

Operating temperature: 100 C

Sizing data

B[mm]

H[mm]

L (in airflow direction)[mm]

[m/h]

De at 250 Hz[dB]

pst[Pa]

Materials and surfaces

Splitter frames made of galvanised sheet steel

Absorption material is mineral wool

Mineral wool

To EN 13501, fire rating class A1,

non-combustible

RAL quality mark RAL-GZ 388

Biosoluble and hence hygienically safe

according to the German TRGS 905

(Technical Rules for Hazardous Substances)

and EU directive 97/69/EG

Faced with glass fibre fabric as protection

against erosion through airflow velocities

of up to 20 m/s

Inert to fungal and bacterial growth

Order options

Type

XKASound attenuator splitter

Splitter thickness [mm]

100

200

230

300

Height H [mm]

Length in airflow direction L [mm]

Splitter surface

FGlass fibre fabric

LGlass fibre fabric under

perforated sheet metal

K3 6.2 26

03/2014 DE/en

6.4

X XBasic

information and nomenclaturetestregistrierung

Sound attenuators

Basic information

and nomenclature

Product selection

Principal dimensions

Nomenclature

Sizing and sizing example

03/2014 DE/en

K3 6.4 1

Sound attenuators

Basic information and nomenclature

Product selection

Type

Splitter sound attenuators

MSA

XSA

Splitters

MKA

XKA

Circular silencers

RKA

CA

CB

CS

CF

CAK

Sound attenuator casing

Rectangular

Circular

Galvanised sheet steel

Aluminium

Plastic

Splitters

Absorption

Resonance

Duct connection

Standard flange

Angle section frame

Spigot

Flange on one end

Flanges on both ends

Socket-type spigots

on both ends

Raised edges at both ends

Nominal sizes

Diameter

100 800 mm

Width

250 1000 mm

80 400 mm

110 400 mm

140 2400 mm

Increment

1 mm

Width subdivided

4800 mm

Height

300 1800 mm

Increment

1 mm

Height subdivided

4800 mm

Length

500 1500 mm

Increment

1 mm

Length subdivided

3000 mm

Splitter surface

Glass fibre fabric

Glass fibre fabric and

perforated metal facing

Possible

Not possible

K3 6.4 2

03/2014 DE/en

Sound attenuators

Basic information and nomenclature

Principal dimensions

D [mm]

Outside diameter of the connecting spigot

B [mm]

Duct width

D [mm]

Outer diameter of circular silencers

H [mm]

Duct height

L [mm]

Length of attenuator/silencer including spigot

(in airflow direction)

n[]

Number of flange screw holes

L[mm]

Length of acoustic cladding

Nomenclature

m [kg]

Weight

fm [Hz]

Octave band centre frequency

[m/h] and [l/s]

Volume flow rate

LWA [dB(A)]

A-weighted sound pressure level

of air-regenerated noise

pst [Pa]

Static differential pressure

De [dB(A)]

Insertion loss

All sound power levels are based on 1 pW.

03/2014 DE/en

K3 6.4 3

Sound attenuators

Basic information and nomenclature

Sizing with the help

of this catalogue

This catalogue provides convenient

quick sizing tables for sound attenuators.

The insertion loss values are provided

for splitters of any thickness.

Sound power levels of the air-regenerated noise

and differential pressures are given for various

airflow velocities.

Sizing data for other dimensions, insertion loss

values, volume flow rates and differential

pressures can be determined quickly

and precisely using the Easy Product Finder

design programme.

Sizing example

Given data

Duct B = 800 mm, H = 900 mm

= 2900 l/s (10440 m/h)

De = 30 dB at 250 Hz

Quick sizing

MSA-200 L = 1000 mm, S = 50 mm

Calculation procedure

A = 0.800 0.9 = 0.72 m

v = A = 2900 0.72 ( 1000) = 4.0 m/s

pst = 12 Pa

LWA = 21 dB(A)

Easy Product Finder

The Easy Product Finder

allows you to size

products using your

project-specific data.

You will find the Easy

Product Finder on our

website.

K3 6.4 4

03/2014 DE/en

También podría gustarte

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- A Necessary Relation Algebra For Mereotopology: Ivo Düntsch Gunther Schmidt, Michael WinterDocumento26 páginasA Necessary Relation Algebra For Mereotopology: Ivo Düntsch Gunther Schmidt, Michael Wintervladimirkulf2142Aún no hay calificaciones

- DPD Accreditation ScopeDocumento1 páginaDPD Accreditation Scopevladimirkulf2142Aún no hay calificaciones

- 1325 WolofDocumento3 páginas1325 Wolofvladimirkulf2142Aún no hay calificaciones

- 2 - Liitije Pait - Iciis EmbracedDocumento3 páginas2 - Liitije Pait - Iciis Embracedvladimirkulf2142Aún no hay calificaciones

- Sea Star 00582glasrDocumento1 páginaSea Star 00582glasrvladimirkulf2142Aún no hay calificaciones

- 14 WobdfbsfdsgDocumento5 páginas14 Wobdfbsfdsgvladimirkulf2142Aún no hay calificaciones

- XCY CPP 001 01 XCy Company Privacy PolicyDocumento2 páginasXCY CPP 001 01 XCy Company Privacy Policyvladimirkulf2142Aún no hay calificaciones

- XKA Series435345234526435234523462354636Documento2 páginasXKA Series435345234526435234523462354636vladimirkulf2142Aún no hay calificaciones

- 88 SdafafsfsdgstsrtseresfsdffsDocumento5 páginas88 Sdafafsfsdgstsrtseresfsdffsvladimirkulf2142Aún no hay calificaciones

- Type Xka Be260142c98aaad9Documento8 páginasType Xka Be260142c98aaad9vladimirkulf2142Aún no hay calificaciones

- Exam Review HS3525452362652345236345634563Documento23 páginasExam Review HS3525452362652345236345634563vladimirkulf2142Aún no hay calificaciones

- H Av B Qwo Q MJ Melv B - Arq Ivq: 'Yb©XwzDocumento3 páginasH Av B Qwo Q MJ Melv B - Arq Ivq: 'Yb©Xwzvladimirkulf2142Aún no hay calificaciones

- Multisplit Twin TripleDocumento4 páginasMultisplit Twin Triplevladimirkulf2142Aún no hay calificaciones

- Doh01 S028775 3450000Documento1 páginaDoh01 S028775 3450000vladimirkulf2142Aún no hay calificaciones

- Alock Basu34524232624526462452Documento3 páginasAlock Basu34524232624526462452vladimirkulf2142Aún no hay calificaciones

- WP XKA HydrometerDocumento2 páginasWP XKA Hydrometervladimirkulf2142Aún no hay calificaciones

- Us 317872034524523452345236265443Documento25 páginasUs 317872034524523452345236265443vladimirkulf2142Aún no hay calificaciones

- X Usd Wer Qe 32432543523452362452645345Documento1 páginaX Usd Wer Qe 32432543523452362452645345vladimirkulf2142Aún no hay calificaciones

- Desai: To The Thesis Entitled Novels of A Study" Devi Done of Previously The ofDocumento1 páginaDesai: To The Thesis Entitled Novels of A Study" Devi Done of Previously The ofvladimirkulf2142Aún no hay calificaciones

- AlphaSpotQWO800 and ST Manual Rev.0 (10.12) enDocumento32 páginasAlphaSpotQWO800 and ST Manual Rev.0 (10.12) envladimirkulf2142Aún no hay calificaciones

- The Clay Paky Alpha Spot QWO 800: Product in DepthDocumento8 páginasThe Clay Paky Alpha Spot QWO 800: Product in Depthvladimirkulf2142Aún no hay calificaciones

- Qwo-Li Driskill, PHD: Academic AppointmentsDocumento20 páginasQwo-Li Driskill, PHD: Academic Appointmentsvladimirkulf2142Aún no hay calificaciones

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Partial DerivativesDocumento2 páginasPartial Derivativesvladimirkulf2142Aún no hay calificaciones

- 1201 Mat 329 R2Documento1 página1201 Mat 329 R2vladimirkulf2142Aún no hay calificaciones

- Lyrics For HairsprayDocumento1 páginaLyrics For Hairsprayvladimirkulf2142Aún no hay calificaciones

- Peggy One Ill Jones Bio 52345324524523452345Documento1 páginaPeggy One Ill Jones Bio 52345324524523452345vladimirkulf2142Aún no hay calificaciones

- Dirac 240 640 480 192Documento11 páginasDirac 240 640 480 192vladimirkulf2142Aún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Fines Reduction Project at Wendling Bowser QuarryDocumento2 páginasFines Reduction Project at Wendling Bowser QuarryMarcos Antonio ParoliniAún no hay calificaciones

- Tuberculosis PowerpointDocumento69 páginasTuberculosis PowerpointCeline Villo100% (1)

- Plans PDFDocumento49 páginasPlans PDFEstevam Gomes de Azevedo85% (34)

- ZF-FreedomLine TransmissionDocumento21 páginasZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- Presentation - Delight Bulb PDFDocumento22 páginasPresentation - Delight Bulb PDFShiva KishoreAún no hay calificaciones

- Guia de CondensadoresDocumento193 páginasGuia de CondensadoresPaola Segura CorreaAún no hay calificaciones

- SP Essay 1Documento14 páginasSP Essay 1api-511870420Aún no hay calificaciones

- Potassium Fixation As Affected by Alternate Wetting and Drying in Some Soil Series of JharkhandDocumento4 páginasPotassium Fixation As Affected by Alternate Wetting and Drying in Some Soil Series of JharkhandDr Amrit Kumar JhaAún no hay calificaciones

- Market AnalysisDocumento4 páginasMarket AnalysisSaniya CharaniyaAún no hay calificaciones

- SCM (Subway Project Report)Documento13 páginasSCM (Subway Project Report)Beast aAún no hay calificaciones

- Hopeless PlacesDocumento1304 páginasHopeless Placesmoreblessingmarvellous659Aún no hay calificaciones

- Fyp-Hydraulic Brakes CompleteDocumento32 páginasFyp-Hydraulic Brakes CompleteRishabh JainAún no hay calificaciones

- Sales 20: Years Advertising Expense (Millions) X Sales (Thousands) yDocumento8 páginasSales 20: Years Advertising Expense (Millions) X Sales (Thousands) ybangAún no hay calificaciones

- Ficha Tecnica-Skyjack SJ3219 8mtDocumento2 páginasFicha Tecnica-Skyjack SJ3219 8mtLESLY MILENA MORENO CORALAún no hay calificaciones

- Mean Variance Portfolio TheoryDocumento85 páginasMean Variance Portfolio TheoryEbenezerAún no hay calificaciones

- SAT Practice TestDocumento77 páginasSAT Practice TestfhfsfplAún no hay calificaciones

- Crouse Hinds XPL Led BrochureDocumento12 páginasCrouse Hinds XPL Led BrochureBrayan Galaz BelmarAún no hay calificaciones

- Hydraulic Fan Speed - Test and AdjustDocumento12 páginasHydraulic Fan Speed - Test and Adjustsyed ahmedAún no hay calificaciones

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentDocumento8 páginasConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준Aún no hay calificaciones

- SSDsDocumento3 páginasSSDsDiki Tri IndartaAún no hay calificaciones

- Catalogo Aesculap PDFDocumento16 páginasCatalogo Aesculap PDFHansAún no hay calificaciones

- Astm C892 - 00Documento5 páginasAstm C892 - 00reneeAún no hay calificaciones

- Inferring The Speaker's Tone, ModeDocumento31 páginasInferring The Speaker's Tone, Modeblessilda.delaramaAún no hay calificaciones

- Elements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesDocumento8 páginasElements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesSadman Shaid SaadAún no hay calificaciones

- Surface TensionDocumento13 páginasSurface TensionElizebeth GAún no hay calificaciones

- Release From Destructive Covenants - D. K. OlukoyaDocumento178 páginasRelease From Destructive Covenants - D. K. OlukoyaJemima Manzo100% (1)

- Soldier of Fortune PDFDocumento208 páginasSoldier of Fortune PDFNixel SpielAún no hay calificaciones

- FYP ProposalDocumento11 páginasFYP ProposalArslan SamAún no hay calificaciones

- 3-History Rock Cut MonumentDocumento136 páginas3-History Rock Cut MonumentkrishnaAún no hay calificaciones

- DOC-20161226-WA0009 DiagramaDocumento61 páginasDOC-20161226-WA0009 DiagramaPedroAún no hay calificaciones