Documentos de Académico

Documentos de Profesional

Documentos de Cultura

2888-Oblique Drilling PDF

Cargado por

syllavethyjimTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

2888-Oblique Drilling PDF

Cargado por

syllavethyjimCopyright:

Formatos disponibles

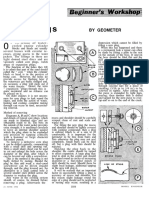

Oblique drilling

SOME EXPERIENCE in

drilling and sharpening

drills has been acquired,

ordinary work with normal-size

drills presents little difficulty. If

a machine drill is available, work

can be mounted on the table, in

vee blocks, or in the machine vice.

In drilling by hand care is essential,

of course, to avoid breakage if the

drill is small; and it is necessary

to maintain reasonable squareness

if the material is thick-which can

usually be done by sighting the

drill against the surface.

There are occasions, however, when

it is necessary to drill obliquely or

out-of-square-and difficulties may

then be met, first in starting the drill

on the sloping surface and, secondly,

in guiding it at the required angle.

HEN

Various methods of guiding a drill for

oblique drilling

To the first problem-starting the

drill-there are several solutions. A

fairly large and deep centre-punch

dot can be made and the drill in a

hand machine may then be started

either- squarely or at a lesser angle

than that required. When the full

diameter of the drill is below the

surface on the low side the drill,

with no forward or in-feed, can be

gradually brought round to the

angle. Alternatively, a larger and

shallow hole can be drilled squarelyand the required hole started in the

bottom of it at an angle.

Again, two holes of the required

size can be started squarely and close

together for a little distance, with the

drill brought round at the required

angle.

In some instances a short

rotary file or mill can be presented

to the surface at an angle to provide

a surface on which the drill can be

started; and on occasion such a

surface can be filed or chiselled. At

times, too, it is possible-or even

desirable-to employ a simple jig

as described. In most instances, with

the hole started, the work can be

completed by hand or transferred to

a machine drill and carefully set up.

A drill, of course, slides off a

sloping surface because it is unsupported on one side and a simple

method of preventing this is to clamp

a small block of the same material

for the point to be retained at the

required position, A. Such a block

can be used on both flat and round

material and provided with a shallow

filed nick, B.

When the opposite side of the

material is also sloping, care and a

fine feed are essential when the drill

is breaking through-otherwise breakage may - occur ; and in this connection it is helpful to clamp a small

block over the position where the

drill point will appear.

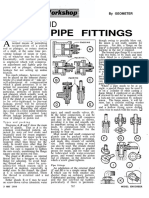

Angle guides

The second problem-guiding the

drill at the required angle--can

usually be overcome fairly easily. It

may be enough to make an angle

gauge from thin cardboard or sheet

metal and hold it against the surface

to get the line for the drill. The

angle for the gauge can be marked

with protractor and pencil on cardboard or with a scriber on metal.

27 SEPTEMBER 1956

439

Jigs for drilling round components

For a fix-on gauge for round stock,

C, a simple clip is first produced,

followed by the angle gauge which is

held and soldered in place. Such a

gauge can be fitted after the hole has

been started to maintain the line

while drilling. For flat stock the

gauge can have the fixing edge turned

at right angles for a clamp, D, and

with both types a piece of tube can

be soldered to the angled edge to

guide the drill if required.

The best type of jig for round

components of moderate size, both to

make and for occasional use, is the

halved or split type, E. To make it

two blocks of metal are drilled down

the joint line. Then using a protractor

the line for the drill is scribed on each

face, each line being deepened with a

three-cornered file. Following this

the blocks are reclamped and the

This

vee-grooves drilled circular.

jig can be used for the big-end lubrication hole from the mainshaft of a

small crankshaft, F.

Angle drilling of another variety is

to cotter-secure a shaft,. G. Without

support it would be rmpossible to

drill the cotter hole. But if the bore

is plugged with tight-fitting material

of the same sort, the hole can be

easily drilled and reamed, H.

q

MODEL ENGINEER

También podría gustarte

- Explain Drilling, Boring, Reaming, Counterboring, Countersinking and Spot Facing OperationsDocumento7 páginasExplain Drilling, Boring, Reaming, Counterboring, Countersinking and Spot Facing OperationsNishit ParmarAún no hay calificaciones

- Boring tools and techniques for accurate hole machiningDocumento4 páginasBoring tools and techniques for accurate hole machiningPuneeth KumarAún no hay calificaciones

- Chapter 2Documento28 páginasChapter 2GemedaAún no hay calificaciones

- Drilling of A Work Piece Held in A ViseDocumento8 páginasDrilling of A Work Piece Held in A ViseFaisal RafiqueAún no hay calificaciones

- "V" Cut: Drilling and BlastingDocumento14 páginas"V" Cut: Drilling and BlastingGen LanggaAún no hay calificaciones

- Drill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderDocumento14 páginasDrill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderAndy L100% (1)

- 149-Workshop Hints & TipsDocumento1 página149-Workshop Hints & TipssyllavethyjimAún no hay calificaciones

- Lecture - 4 Notes: Drilling Basic Mechanical Engineering (Part - B) 1Documento5 páginasLecture - 4 Notes: Drilling Basic Mechanical Engineering (Part - B) 1Roop LalAún no hay calificaciones

- Gundrilling HandbookDocumento49 páginasGundrilling HandbookJealse100% (3)

- Manufacturing Engineering 2Documento7 páginasManufacturing Engineering 2Study SuccessAún no hay calificaciones

- Experiment Name: Study and Operation of Bench Drilling MachineDocumento13 páginasExperiment Name: Study and Operation of Bench Drilling MachineHashim Al-mahdliAún no hay calificaciones

- The Industrial Press 006 - Punch and Die WorkDocumento56 páginasThe Industrial Press 006 - Punch and Die Workeomer1968100% (1)

- The Lathe 6. Drilling and Reaming 6.1 Drilling: Tailstock SetupDocumento9 páginasThe Lathe 6. Drilling and Reaming 6.1 Drilling: Tailstock SetupPuneeth KumarAún no hay calificaciones

- U BendingDocumento31 páginasU BendingbabutyAún no hay calificaciones

- 123 GeometerDocumento27 páginas123 Geometerruralroute5Aún no hay calificaciones

- Quorn: Tool and Cutter GrinderDocumento5 páginasQuorn: Tool and Cutter GrinderDan HendersonAún no hay calificaciones

- Center Punch Grinding JigDocumento2 páginasCenter Punch Grinding JigmododanAún no hay calificaciones

- Lathe Facing Operation Reduces Cylindrical Workpiece LengthDocumento32 páginasLathe Facing Operation Reduces Cylindrical Workpiece Lengthusmaniqbal15Aún no hay calificaciones

- 2XTM Magazine Well Installation GuideDocumento15 páginas2XTM Magazine Well Installation GuidejumikuulaAún no hay calificaciones

- Tool Design #3Documento2 páginasTool Design #3api-26046805Aún no hay calificaciones

- Ug Drilling PatternDocumento30 páginasUg Drilling PatternAlem Anissa100% (1)

- Drilling Machines & Their Static and Dynamic Analysis MEC 302Documento16 páginasDrilling Machines & Their Static and Dynamic Analysis MEC 302Sushil KumarAún no hay calificaciones

- Production Technology: Department of Mechanical EngineeringDocumento17 páginasProduction Technology: Department of Mechanical Engineeringrahul bhattAún no hay calificaciones

- Building: LatheDocumento60 páginasBuilding: LathePierre799es86% (7)

- Drill Press Me Tech OmpoyDocumento2 páginasDrill Press Me Tech OmpoyEm Em LimpalanAún no hay calificaciones

- Gundrilling HandbookDocumento49 páginasGundrilling HandbookBooks for the lot100% (1)

- Methods of New Construction: Design Manual Chapter 14 - Trenchless Construction 14B - New ConstructionDocumento16 páginasMethods of New Construction: Design Manual Chapter 14 - Trenchless Construction 14B - New Constructionroronoa_zorro11Aún no hay calificaciones

- Machine Shop Theory and Practice - LaboratoryDocumento7 páginasMachine Shop Theory and Practice - LaboratoryJerlah RamosAún no hay calificaciones

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocumento27 páginasDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaAún no hay calificaciones

- Record No 050 Improved Combination PlaneDocumento16 páginasRecord No 050 Improved Combination PlaneCamillo FanaAún no hay calificaciones

- Finding centres on the latheDocumento1 páginaFinding centres on the lathekikoliverAún no hay calificaciones

- Underground Blasting TechniquesDocumento29 páginasUnderground Blasting TechniquesYewuhalashet FisshaAún no hay calificaciones

- Press Working OperationsDocumento23 páginasPress Working OperationsKanagaraj Ganesan100% (1)

- 4 Foot PVC Propeller: (Including New Blade Revisions)Documento14 páginas4 Foot PVC Propeller: (Including New Blade Revisions)eu1mister6002Aún no hay calificaciones

- Drilling OperationsDocumento9 páginasDrilling Operationslindobuhledandelion0Aún no hay calificaciones

- Lathe-Milling AttachmentDocumento4 páginasLathe-Milling AttachmentFrenchwolf420Aún no hay calificaciones

- Side Tracking Cased HolesDocumento45 páginasSide Tracking Cased HolesNehomar Jose Brito Guerra100% (4)

- Lathe Cross-Sli Olders.: " DuplexDocumento3 páginasLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- Taper Turning PDFDocumento10 páginasTaper Turning PDFMaria Mehar0% (1)

- JFDD Assignment No - 03Documento5 páginasJFDD Assignment No - 03LowEnd GamerAún no hay calificaciones

- Chapter 4Documento7 páginasChapter 4Senju HashiramaAún no hay calificaciones

- GROUP 3 (Turning, Boring & Related Topics) : Members: Clarice Cabalit Mark Giovanni Cabanero John Clyde Calvo Joseph TeneroDocumento7 páginasGROUP 3 (Turning, Boring & Related Topics) : Members: Clarice Cabalit Mark Giovanni Cabanero John Clyde Calvo Joseph TeneroBenz Andrew RegisAún no hay calificaciones

- 14B-2 Methods of New Construction: Statewide Urban Design and SpecificationsDocumento16 páginas14B-2 Methods of New Construction: Statewide Urban Design and SpecificationsKrishan Kumar AroraAún no hay calificaciones

- Simple Boring BarDocumento3 páginasSimple Boring BarMike Nichlos100% (1)

- Milling MachineDocumento7 páginasMilling MachineNishit ParmarAún no hay calificaciones

- Lapping tapers and seatings to improve fit and finishDocumento1 páginaLapping tapers and seatings to improve fit and finishsyllavethyjimAún no hay calificaciones

- Simple Mini Tube Bender InstructionsDocumento4 páginasSimple Mini Tube Bender InstructionsMartin OngAún no hay calificaciones

- JigDocumento6 páginasJigArun ManoAún no hay calificaciones

- Lathe OperationDocumento13 páginasLathe OperationdevmarineacademyAún no hay calificaciones

- RIVETSDocumento16 páginasRIVETSعبدالرحمن سيدAún no hay calificaciones

- Turning - Wikipedia, The Free EncyclopediaDocumento6 páginasTurning - Wikipedia, The Free EncyclopediaKhateeb Ul Islam QadriAún no hay calificaciones

- Validated TVL Smaw11 q3 M 4Documento11 páginasValidated TVL Smaw11 q3 M 4tibo bursioAún no hay calificaciones

- Blasting Design For Underground ExcavationDocumento43 páginasBlasting Design For Underground ExcavationVassilis PentheroudakisAún no hay calificaciones

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesDe EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesAún no hay calificaciones

- 2886-Stud Fitting & Removal PDFDocumento1 página2886-Stud Fitting & Removal PDFsyllavethyjimAún no hay calificaciones

- Various Types of Operations Performed in Lathe Machine - Education Discussion PDFDocumento13 páginasVarious Types of Operations Performed in Lathe Machine - Education Discussion PDFtinku meenaAún no hay calificaciones

- Failure of Jigs & FixtureDocumento27 páginasFailure of Jigs & FixtureTooling ganeshAún no hay calificaciones

- 2889-Further Drilling Methods PDFDocumento1 página2889-Further Drilling Methods PDFsyllavethyjimAún no hay calificaciones

- 2873-Cotters & Wedges PDFDocumento1 página2873-Cotters & Wedges PDFsyllavethyjimAún no hay calificaciones

- IMP Workshop ManualDocumento336 páginasIMP Workshop Manualsyllavethyjim67% (3)

- 2890-Nuts & Spanners PDFDocumento1 página2890-Nuts & Spanners PDFsyllavethyjimAún no hay calificaciones

- 2871-Circular Clips #1 PDFDocumento1 página2871-Circular Clips #1 PDFsyllavethyjimAún no hay calificaciones

- 2883-Metal Working PDFDocumento1 página2883-Metal Working PDFsyllavethyjimAún no hay calificaciones

- 2886-Stud Fitting & Removal PDFDocumento1 página2886-Stud Fitting & Removal PDFsyllavethyjimAún no hay calificaciones

- 2885-Dent & Bulge Removal PDFDocumento1 página2885-Dent & Bulge Removal PDFsyllavethyjimAún no hay calificaciones

- 2880-Supporting & Steadying PDFDocumento1 página2880-Supporting & Steadying PDFsyllavethyjimAún no hay calificaciones

- 2887-Broken Drills & Taps PDFDocumento1 página2887-Broken Drills & Taps PDFsyllavethyjimAún no hay calificaciones

- 2884-Panel Beating PDFDocumento1 página2884-Panel Beating PDFsyllavethyjim100% (1)

- 2876-Belt Fasteners PDFDocumento1 página2876-Belt Fasteners PDFsyllavethyjimAún no hay calificaciones

- 2881-Radii Functions and Checking PDFDocumento1 página2881-Radii Functions and Checking PDFsyllavethyjimAún no hay calificaciones

- Contours 1: Hile It CannotDocumento1 páginaContours 1: Hile It CannotsyllavethyjimAún no hay calificaciones

- 2879-Clamping & Holding PDFDocumento1 página2879-Clamping & Holding PDFsyllavethyjimAún no hay calificaciones

- 2872-Circular Clips #2 PDFDocumento1 página2872-Circular Clips #2 PDFsyllavethyjimAún no hay calificaciones

- 2870-Simple Screw Assembly PDFDocumento1 página2870-Simple Screw Assembly PDFsyllavethyjimAún no hay calificaciones

- 2875-Belt Drives PDFDocumento1 página2875-Belt Drives PDFsyllavethyjimAún no hay calificaciones

- 2874-Fitting Core Plugs PDFDocumento1 página2874-Fitting Core Plugs PDFsyllavethyjimAún no hay calificaciones

- 2868-Glands & Pipe Fittings PDFDocumento1 página2868-Glands & Pipe Fittings PDFsyllavethyjimAún no hay calificaciones

- 2878-Chains & Sprockets PDFDocumento1 página2878-Chains & Sprockets PDFsyllavethyjimAún no hay calificaciones

- Roller Chains and Sprockets GuideDocumento1 páginaRoller Chains and Sprockets GuidesyllavethyjimAún no hay calificaciones

- 2867 Case HardeningDocumento1 página2867 Case HardeningEr Sukhwinder SinghAún no hay calificaciones

- 2869-Fitting & Joining Pipes PDFDocumento1 página2869-Fitting & Joining Pipes PDFsyllavethyjimAún no hay calificaciones

- 2861-Wheel & Shaft PullersDocumento1 página2861-Wheel & Shaft PullersSandra Barnett CrossanAún no hay calificaciones

- 2865-Testing & Facing Valves PDFDocumento1 página2865-Testing & Facing Valves PDFsyllavethyjimAún no hay calificaciones

- 2866-Hardening & Tempering PDFDocumento1 página2866-Hardening & Tempering PDFsyllavethyjimAún no hay calificaciones

- 2864-Poppet Valves & Seating PDFDocumento1 página2864-Poppet Valves & Seating PDFsyllavethyjimAún no hay calificaciones

- 2863-Valve Seating Tools PDFDocumento1 página2863-Valve Seating Tools PDFsyllavethyjimAún no hay calificaciones

- Multiple Sheet Single Point Incremental Forming For Dual Phase Steel SheetDocumento8 páginasMultiple Sheet Single Point Incremental Forming For Dual Phase Steel SheetK.A.SELVARAJAN AMIEAún no hay calificaciones

- Biw 180626141814Documento22 páginasBiw 180626141814Mahesh KarpeAún no hay calificaciones

- A 653 - A 653M - 15 PDFDocumento13 páginasA 653 - A 653M - 15 PDFabualamal80% (5)

- Copper and Copper Alloy Clad Steel Plate: Standard Specification ForDocumento6 páginasCopper and Copper Alloy Clad Steel Plate: Standard Specification ForAdnan KhanAún no hay calificaciones

- Marine Joinery Outfitting PDFDocumento43 páginasMarine Joinery Outfitting PDFÇÇağdaş_1Aún no hay calificaciones

- Mcnichols Master CatalogDocumento60 páginasMcnichols Master Catalogswoo323Aún no hay calificaciones

- Wade ChannelDocumento24 páginasWade ChannelAbdul NabiAún no hay calificaciones

- Silencers For HVACDocumento12 páginasSilencers For HVACZaw Moe KhineAún no hay calificaciones

- MSC 2011-10S370Documento70 páginasMSC 2011-10S370caraiane100% (2)

- Poster of Unconstrained Cylindrical Bending Die - Spring Back - Hani Aziz AmeenDocumento1 páginaPoster of Unconstrained Cylindrical Bending Die - Spring Back - Hani Aziz AmeenHani Aziz AmeenAún no hay calificaciones

- Planta de AeronaveDocumento18 páginasPlanta de AeronaveKellLuz100% (1)

- Phoenix Metals Product Catalog 2012Documento42 páginasPhoenix Metals Product Catalog 2012Norazmi Abdul RahmanAún no hay calificaciones

- 3-Section 05 10 00 Structural Steel WorkDocumento40 páginas3-Section 05 10 00 Structural Steel WorkAhmad SaadeldinAún no hay calificaciones

- Welding Objective Set 1Documento52 páginasWelding Objective Set 1Ankit kannojia100% (1)

- B02-S05 Rev 3 Sep 2017 Design, Fabri and Inst of GratingsDocumento9 páginasB02-S05 Rev 3 Sep 2017 Design, Fabri and Inst of Gratings15150515715Aún no hay calificaciones

- BS en 10209-2013 - (2016-06-12 - 11-13-08 Am) PDFDocumento30 páginasBS en 10209-2013 - (2016-06-12 - 11-13-08 Am) PDFXiangShi100% (4)

- Introduction, Press & MachiningDocumento327 páginasIntroduction, Press & MachiningLucky DagaAún no hay calificaciones

- A Review On Process of Press Tool Design and Its ManufacturingDocumento5 páginasA Review On Process of Press Tool Design and Its ManufacturingS TAún no hay calificaciones

- Dorman Long S Handbook For Constructional Engineers 1964 PDFDocumento399 páginasDorman Long S Handbook For Constructional Engineers 1964 PDFAlejandro Jose Garcia FernandezAún no hay calificaciones

- Group G-59 Thesis DESIGN, FABRICATION & PERFORMANCE TEST OF A PNEUMATIC SHEET METAL CUTTING MACHINEDocumento21 páginasGroup G-59 Thesis DESIGN, FABRICATION & PERFORMANCE TEST OF A PNEUMATIC SHEET METAL CUTTING MACHINEAmal ChandraAún no hay calificaciones

- Is 7054 1973Documento16 páginasIs 7054 1973m_verma21Aún no hay calificaciones

- Capsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50, 633.50, NS 63, 100, 160Documento4 páginasCapsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50, 633.50, NS 63, 100, 160Joni HartonoAún no hay calificaciones

- 74 032409 00 - CDocumento7 páginas74 032409 00 - CGlory Hilman0% (1)

- Aalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Documento2 páginasAalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Eric Amoakwa-BoaduAún no hay calificaciones

- MPL Pre FeasibilityReportDocumento30 páginasMPL Pre FeasibilityReportATLAS ScaffoldingAún no hay calificaciones

- XCT7 Top Side Data Book 202008Documento510 páginasXCT7 Top Side Data Book 202008BCIAún no hay calificaciones

- Marcegaglia Stainless-Steel en Ott12Documento37 páginasMarcegaglia Stainless-Steel en Ott12lucidbaseAún no hay calificaciones

- Welding Metallurgy and Heat Affected Zone PropertiesDocumento198 páginasWelding Metallurgy and Heat Affected Zone PropertiesAgil SetyawanAún no hay calificaciones

- Examen SPTFExtraordDocumento3 páginasExamen SPTFExtraordIRENE PASCUAL HERANZ BRONCHALOAún no hay calificaciones

- Controlling Flat-Rolled Shape - The FabricatorDocumento10 páginasControlling Flat-Rolled Shape - The FabricatorsobheysaidAún no hay calificaciones