Documentos de Académico

Documentos de Profesional

Documentos de Cultura

A Comparison of Op Strategies, Chlorine Vs UV

Cargado por

adalcayde2514Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

A Comparison of Op Strategies, Chlorine Vs UV

Cargado por

adalcayde2514Copyright:

Formatos disponibles

WEFTEC.

06

A Comparison of Operating Strategies Chlorine vs UV

Scott Hamby

City of Scotts Valley

700 Lundy Lane

Scotts Valley, CA 95066

ABSTRACT

City of Scotts Valley owns and operates a 1.5 mgd activated sludge wastewater

treatment plant. Currently about 0.3 mgd of the secondary effluent is diverted to the

recycled water facility.

Two chlorine disinfection alternatives (both using liquid sodium hypochlorite) and UV

disinfection were considered to all the facility to achieve high level (Title 22) disinfection

requirements from the recycled water facility. Alternatives were evaluated on the basis

of capital cost, operability, O&M costs, maximization of existing facilities, and potential

for future expansion. The existing sodium hypochlorite system was left in place for

effluent discharged to the receiving stream.

With two disinfection systems on site, the City was able to compare the actual operating

cost of both chlorine and UV.

KEYWORDS

Disinfection, UV Radiation, Sodium Hypochlorite

INTRODUCTION

The City of Scotts Valley owns and operates a 1.5 MGD activated sludge wastewater

treatment plant. The treatment process train includes influent bar screens with a washer

compactor, influent flow equalization with returned activated sludge, fine bubble

aeration, secondary clarification, and chlorine contact. Dewatered sludge is landfilled.

Currently about 75% of the plants 1.0 MGD flow is diverted to the recycled water

facility where it is filtered, disinfected and reused for landscape irrigation at local parks

and schools.

In 1996, the City entered into an agreement with the Scotts Valley Water District

(SVWD) where the district agreed to fund the construction of a recycled water facility at

the Citys wastewater treatment plant. The City owns and operates the recycled water

facility and is permitted by the California Regional Water Control Board to produce up to

1.0 MGD of recycled water. Recycled water must meet the States Title 22 regulations of

not to exceed 2.2 total coliform concentrations and not to exceed a daily average turbidity

of 2.0 NTU. The SVWD holds a permit to distribute the recycled water to its end users.

Copyright 2006 Water Environment Foundation. All Rights Reserved

6396

WEFTEC.06

The recycled water facility uses a Tetra denitrification down-flow sand media tertiary

filtration system. Denitrification is achieved by adding methanol as a carbon source for

the remaining nitrifying bacteria to complete the process of turning nitrate to nitrogen

gas. Denitrification is a condition of the Citys permit as a portion of the Citys

watershed area flows to the densely populated non-sewered San Lorenzo Valley area.

As the Citys wastewater facility occupies a compact site adjacent to commercial and

residential development with little space for expansion, site constraints played a key role

in the planning process for the recently constructed recycled water facility. The City

evaluated disinfection alternatives, UV vs. chlorine (Sodium Hypochlorite, NaOCL).

The evaluation included capital costs, operability, O&M costs, maximization of existing

facilities and future expansion.

Chlorine California Department of Health Services (DOHS) guidelines recommend 5

mg/L residual for 120 minutes for unrestricted irrigation. The existing facility only

allowed for 45 minutes at 1.5 mgd. Existing basins could not be modified due to space

constraints.

ALTERNATIVE 1: SODIUM HYPOCHLORITE EXISTING

Existing off-line rectangular clarifiers (58,000 gallon capacity) would need to be

modified to handle an additional 26,000 gallons to meet the 120 minute contact time at 1

mgd as shown on Figure 1. This alternative was elimated because there was not enough

room to expand to 1.5 mgd.

Figure 1. Alternative 1 Sodium Hypochlorite Existing

Alternative 2: NaOCl New

Construct new NaOCL 84,000 gallon contact basin adjacent to the new TTP as shown

on Figure 2 Both alt. 1 & 2 would require a 3000 gallon NaOCL tank and 3000

gallon Sodium Bisulfite tank. Designed for 10 mg/L residual!

Copyright 2006 Water Environment Foundation. All Rights Reserved

6397

WEFTEC.06

Figure 2 Sodium Hypochlorite New

Alternative 3 UV

Construct UV channel adjacent to new TTP. Channel will be constructed to handle 1.5

mgd, however, only enough UV modules to treat 1.0 mgd as shown on Figure 3.

Figure 3. UV

EVALUATING ALTERNATIVES

Copyright 2006 Water Environment Foundation. All Rights Reserved

6398

WEFTEC.06

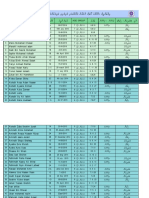

Cost:

Alternative 1) $757,000 capital, $100,000 annual O&M.

Alternative 2) $748,000 capital, $118,000 annual O&M.

Alternative 3) $830,000 capital, $100,000 annual O&M.

Constructability: Due to plant underground piping and the extensive modifications

needed to convert existing structures to accommodate NaOCL, UV represented the

smallest and simplest structure to construct. Same holds true for expandability.

Process Considerations: What is the most appropriate type of disinfection system

relative to the end use of the recycled water? Alts 1&2 utilize NaOCL. The main

concern is salt, especially sodium. The disinfection and de-chlorination both add to the

sodium content, degrading the recycled water quality.

Decision: For Scotts Valley, ultraviolet radiation was the clear choice.

METHODOLOGY

After the selection of the disinfection alternative the type of UV system was evaluated.

Medium Pressure Horizontal

Low Pressure - Horizontal

Low pressure Vertical

The medium pressure horizontal system was the industry standard at the time (1998), but

after a substantial amount of research and reference checks (this is where the product was

sold), Scotts Valley chose the vertical low pressure system. With the vertical system, all

electrical components are above the water surface, simplifying the maintenance of routine

lamp and ballast changes. The UV disinfection industry is highly competitive. Do your

homework and decide what the best application is for your process and have it written in

your projects specifications.

RESULTS

UV versus Chlorine:

Scotts Valley has concurrently used UV and chlorine for the past four years, we can

discuss the pros and cons of each, based on experience. Figure 4 shows the Chlorine

system and Figure 5 the UV system that has been installed

Copyright 2006 Water Environment Foundation. All Rights Reserved

6399

WEFTEC.06

Figure 4: Scotts Valley Chlorine System

Figure 5. Scotts Valley UV System

Capital Cost:

Based on the Scotts Valley study, capital cost for UV ran about 9.5% more than a

chlorine system.

$748,000 for Chlorine

$830,000 for UV

Product Cost:

Chlorine, at a cost of $0.64 per gallon at 175 gallons per day equals $22.40/day

and $40,88087,600/year.

Electrical cost for UV is approximately $20,000/year

Copyright 2006 Water Environment Foundation. All Rights Reserved

6400

WEFTEC.06

O & M:

O & M for the Chlorine system was projected to be 18% more than UV. Both

systems have ongoing maintenance needs that realistically balance each other out.

Real cost for the UV system has turned out to be far less than projected. Total

cost for the City to operate the UV system in fiscal year 2005/2006 was

approximately $30,000. This includes maintenance, lamp and ballast

replacement, and utility costs.

Any system will have maintenance issues; however, preventing leaks in a sodium

hypochlorite system is very difficult. Ongoing cleanup and corrosion of

equipment are inherent to liquid chlorine systems.

Depending on the system, usage, and water quality, maintenance of UV systems

will vary. In Scotts Valley UV lamp sleeves are cleaned every six months. We

have found that by cleaning the sleeves every six months that the acid bath is not

needed. Operators use an over the counter sulfamic and citrus acid based cleaner

(CLR). The cleaner is applied with a kitchen type scour sponge and wiped clean.

This every six month cleaning takes two operators a total of eight hours.

DISCUSSION

Foot Print:

If space is a consideration, UV requires much less real estate. Using less space for

the disinfection system results in more available space for future plant expansion.

Permitting:

Based on Scotts Valleys experience, this is where chlorine gets the nod

Chlorine disinfection is tried and true. Simple calculations will allow any

engineer to design a chlorine contact basin that can satisfy regulatory agencies.

Approved doesnt mean approved for UV?? The system installed for Scotts

Valley was approved (and we have a letter to prove it), but the installation was

not. A lot of time and money was spent on hydraulic and virus testing to get the

system, as installed, approved. During design, work with your permitting agency

to make sure that the system installation design is approved.

CONCLUSIONS

The combined chlorine/UV disinfection system was the best choice for Scotts Valley.

Information on both construction and operating costs have supported this decision.

Copyright 2006 Water Environment Foundation. All Rights Reserved

6401

WEFTEC.06

ACKNOWLEDGMENTS

Author greatly acknowledges the support of Andrew Salveson and Gary Hunter in the

completion of this project.

REFERENCES

Hamby S. (2005) Scotts Valley Disinfection System, WEFTEC Pre-conference

workshop, WEFTEC 2006, Washington DC. October 2005.

Copyright 2006 Water Environment Foundation. All Rights Reserved

6402

También podría gustarte

- Instruction Manual: Downloaded From Manuals Search EngineDocumento36 páginasInstruction Manual: Downloaded From Manuals Search Engineadalcayde2514Aún no hay calificaciones

- Desalination Plant ConstructionDocumento104 páginasDesalination Plant Constructionadalcayde2514Aún no hay calificaciones

- Mega DaltanDocumento1 páginaMega Daltanadalcayde2514Aún no hay calificaciones

- Construction Method StatementDocumento9 páginasConstruction Method Statementadalcayde2514100% (2)

- A Case Study: Industrial Water Treatment Plant - Maáden Waád Al Shamal Phosphate Project-Turaif, KSADocumento2 páginasA Case Study: Industrial Water Treatment Plant - Maáden Waád Al Shamal Phosphate Project-Turaif, KSAadalcayde2514Aún no hay calificaciones

- Microtunneling Pipe Jacking Construction Specification PDFDocumento16 páginasMicrotunneling Pipe Jacking Construction Specification PDFadalcayde2514Aún no hay calificaciones

- Api Oil Water Separators 2013Documento6 páginasApi Oil Water Separators 2013adalcayde2514Aún no hay calificaciones

- Taco Pump - VT Series - Vertical Turbine PumpsDocumento8 páginasTaco Pump - VT Series - Vertical Turbine Pumpsadalcayde2514Aún no hay calificaciones

- MBR Vs SBR Vs Conventional Treatment PDFDocumento9 páginasMBR Vs SBR Vs Conventional Treatment PDFadalcayde2514Aún no hay calificaciones

- Bulk Water Supply CodeDocumento38 páginasBulk Water Supply Codeadalcayde2514Aún no hay calificaciones

- Escalante Water District: 2 Escalante City, Negros Occidental Telefax (034) 454-0563Documento4 páginasEscalante Water District: 2 Escalante City, Negros Occidental Telefax (034) 454-0563adalcayde2514Aún no hay calificaciones

- Water Meter Size CalculationsDocumento3 páginasWater Meter Size Calculationsadalcayde2514Aún no hay calificaciones

- Eaton Eaton Basket Screen DataDocumento2 páginasEaton Eaton Basket Screen Dataadalcayde2514Aún no hay calificaciones

- DR900 Multiparameter Portable Colorimeter: Fastest and Simplest Water Testing For The Most Demanding Field EnvironmentsDocumento2 páginasDR900 Multiparameter Portable Colorimeter: Fastest and Simplest Water Testing For The Most Demanding Field Environmentsadalcayde2514Aún no hay calificaciones

- Tornado - FLuence - AeromixDocumento2 páginasTornado - FLuence - Aeromixadalcayde2514Aún no hay calificaciones

- Maximum Dissolved Oxygen Concentration Saturation TableDocumento3 páginasMaximum Dissolved Oxygen Concentration Saturation Tableadalcayde2514Aún no hay calificaciones

- PSD CEU 199may13 PDFDocumento13 páginasPSD CEU 199may13 PDFadalcayde2514100% (1)

- Ds Filtra30015 Ein E1Documento2 páginasDs Filtra30015 Ein E1adalcayde2514Aún no hay calificaciones

- Song Words For Yr 6 7 BookletsDocumento7 páginasSong Words For Yr 6 7 Bookletsadalcayde2514Aún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Glossary of Important Islamic Terms-For CourseDocumento6 páginasGlossary of Important Islamic Terms-For CourseibrahimAún no hay calificaciones

- Chapter 11: Re-Situating ConstructionismDocumento2 páginasChapter 11: Re-Situating ConstructionismEmilio GuerreroAún no hay calificaciones

- Project Driven & Non Project Driven OrganizationsDocumento19 páginasProject Driven & Non Project Driven OrganizationsEkhlas Ghani100% (2)

- Correctional Case StudyDocumento36 páginasCorrectional Case StudyRaachel Anne CastroAún no hay calificaciones

- Ifm 8 & 9Documento2 páginasIfm 8 & 9Ranan AlaghaAún no hay calificaciones

- Retirement SpeechDocumento11 páginasRetirement SpeechRayan Castro100% (1)

- 01-Cost Engineering BasicsDocumento41 páginas01-Cost Engineering BasicsAmparo Grados100% (3)

- 05 Vision IAS CSP21 Test 5Q HIS AM ACDocumento17 páginas05 Vision IAS CSP21 Test 5Q HIS AM ACAvanishAún no hay calificaciones

- Core Values Behavioral Statements Quarter 1 2 3 4Documento1 páginaCore Values Behavioral Statements Quarter 1 2 3 4Michael Fernandez ArevaloAún no hay calificaciones

- Basic Accounting Equation Exercises 2Documento2 páginasBasic Accounting Equation Exercises 2Ace Joseph TabaderoAún no hay calificaciones

- (MX) Public Figures, Private LivesDocumento3 páginas(MX) Public Figures, Private LivesbestatemanAún no hay calificaciones

- DepEd Red Cross 3 4 Seater Detached PoWs BoQsDocumento42 páginasDepEd Red Cross 3 4 Seater Detached PoWs BoQsRamil S. ArtatesAún no hay calificaciones

- Hunting the Chimera–the end of O'Reilly v Mackman_ -- Alder, John -- Legal Studies, #2, 13, pages 183-20...hn Wiley and Sons; Cambridge -- 10_1111_j_1748-121x_1993_tb00480_x -- 130f73b26a9d16510be20781ea4d81eb -- Anna’s ArchiveDocumento21 páginasHunting the Chimera–the end of O'Reilly v Mackman_ -- Alder, John -- Legal Studies, #2, 13, pages 183-20...hn Wiley and Sons; Cambridge -- 10_1111_j_1748-121x_1993_tb00480_x -- 130f73b26a9d16510be20781ea4d81eb -- Anna’s ArchivePrince KatheweraAún no hay calificaciones

- "If It Ain't Cheap, It Ain't Punk": Walter Benjamin's Progressive Cultural Production and DIY Punk Record LabelsDocumento21 páginas"If It Ain't Cheap, It Ain't Punk": Walter Benjamin's Progressive Cultural Production and DIY Punk Record LabelsIsadora Mandarino OteroAún no hay calificaciones

- Nuclear Power Plants PDFDocumento64 páginasNuclear Power Plants PDFmvlxlxAún no hay calificaciones

- Calendario General 2Documento1 páginaCalendario General 2Santiago MuñozAún no hay calificaciones

- How To Write A Driving School Business Plan: Executive SummaryDocumento3 páginasHow To Write A Driving School Business Plan: Executive SummaryLucas Reigner KallyAún no hay calificaciones

- 99 Names of AllahDocumento14 páginas99 Names of Allahapi-3857534100% (9)

- TO 1C-130H-2-33GS-00-1: Lighting SystemDocumento430 páginasTO 1C-130H-2-33GS-00-1: Lighting SystemLuis Francisco Montenegro Garcia100% (1)

- Specpro.09.Salazar vs. Court of First Instance of Laguna and Rivera, 64 Phil. 785 (1937)Documento12 páginasSpecpro.09.Salazar vs. Court of First Instance of Laguna and Rivera, 64 Phil. 785 (1937)John Paul VillaflorAún no hay calificaciones

- Prince Baruri Offer Letter-1Documento3 páginasPrince Baruri Offer Letter-1Sukharanjan RoyAún no hay calificaciones

- Open Quruan 2023 ListDocumento6 páginasOpen Quruan 2023 ListMohamed LaamirAún no hay calificaciones

- 11 January 2022 Dear Mohammed Rayyan,: TH TH RDDocumento5 páginas11 January 2022 Dear Mohammed Rayyan,: TH TH RDmrcopy xeroxAún no hay calificaciones

- General Concepts and Principles of ObligationsDocumento61 páginasGeneral Concepts and Principles of ObligationsJoAiza DiazAún no hay calificaciones

- Chapter 12Documento72 páginasChapter 12Samaaraa NorAún no hay calificaciones

- "Working Capital Management": Master of CommerceDocumento4 páginas"Working Capital Management": Master of Commercekunal bankheleAún no hay calificaciones

- An Introduction: by Rajiv SrivastavaDocumento17 páginasAn Introduction: by Rajiv SrivastavaM M PanditAún no hay calificaciones

- Final Seniority List of HM (High), I.s., 2013Documento18 páginasFinal Seniority List of HM (High), I.s., 2013aproditiAún no hay calificaciones

- Coursework Assignment: Graduate Job ImpactDocumento13 páginasCoursework Assignment: Graduate Job ImpactmirwaisAún no hay calificaciones

- People v. Bandojo, JR., G.R. No. 234161, October 17, 2018Documento21 páginasPeople v. Bandojo, JR., G.R. No. 234161, October 17, 2018Olga Pleños ManingoAún no hay calificaciones