Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Tolerances for Cylindrical Gear Teeth

Cargado por

Luciano FontesTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Tolerances for Cylindrical Gear Teeth

Cargado por

Luciano FontesCopyright:

Formatos disponibles

UDC 621.833.1 : 621.753.

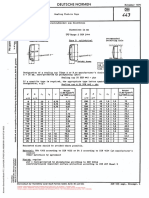

DEUTSCHE NORMEN

August 1978

Tolerances for Cylindrical Gear Teeth

Tolerances for Working Deviations

DIN

3963

Toleranzen fr Stirnradverzahnungen;Toleranzen fr Wlzabweichungen

1 scope

The tolerances listed in this Standard apply t o the amounts of the deviations defined in DIN 3960.

It contains tolerances for:

- two-flank working deviation Fi'

- two-flank working error f;'

- singleflank working deviation Fi

- singleflank working error fi

2 Other relevant Standards

DIN 3960 Definitions and parameters for cylindrical gears and cylindrical gear pairs with

involute teeth

DIN 3961 Tolerances for cylindrical gear teeth; bases

25

GU

F i

z58

-a

so

oe:

Continued on page 2 t o 18

Explanations on page 18

2

,

D m

80

c g

oco

% O

7ZZ

::rn

+ Y I

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Sole sale rightsof Cienan Standards (DIN-Normen) are with BeuthVerlag CImbH. Betlln 30

03.81

www.bzxzw.com

DIN 3963 eng/. Prekgr. 11

Vertr.-Nr.0111

Page 2 DIN 3963

3 Tolerance data

Normal module from 1 to 2 mm

Tolerances in pm

Deviation

FI'

fi'

Gear tooth quality

over

upto

10

50

over

upto

125

E

E

over

125

-a

over

upto

280

560

.-C

L

al

50

4d

al

.-E

U

al

2

.O

oC

Q

a>

+

al

up to 1000

over 1000

up to 1600

__-

over 1600

upto 2500

over 2500

upto 4000

over 4000

upto 6300

11

16

22

32

45

3,5

10

14

20

12

18

25

36

50

12

16

22

~

over 2500

up to 4000

9

12

16

25

32

45

2,5

5,5

10

14

over 4000

upto 6300

12

18

25

36

50

5,5

11

16

over 6300

up to 10000

10

14

20

28

40

56

4.5

12

18

over 6300

up to 1O000

Q

YQ

www.bzxzw.com

DIN 3963 Page 3

Normal module from 1 to 2 mm

Tolerances in pm

1

Deviation

f I'

Fi'

1 0 1 1 1 2

10

18

25

36

50

71

100

10

50

over

50

up

to

125

-over

125

upto 280

over

280

u ~ t o 560

Over

560

UD to 1000

22

32

45

63

90

125

12

28

40

56

80

110

160

12

16

32

45

63

90

125

180

14

20

36

50

71

100

140

200

16

22

Gear tooth quality

up to

over

upto

.-c

'z1

&

+

W

.-Q

U

.-ro

al

W

0

c

L

W

.

I

-

I 1 I

63

45

63

I I I

80

110

160

220

I I

18

25

125

180

250

20

28

I 1 Li 1 1 1 1 1

'Ooo

up to 1600

Over

Over

UDtO

45

l6Oo

2500

over 2500

up to 4000

__over 4000

upto 6300

over 6300

up to 10000

__

I 1

100

56

80

110

160

220

320

25

36

63

90

125

180

250

360

28

40

71

100

140

200

280

400

32

45

50

~~

71

1 I 1

140

200

10

upto

--

25

32

32

over

50

50

22

32

Deviation

I

10

I

1

Fi

Gear tooth quality

over

upto

280

fl

10

11

12

10

11

12

45

80

125

200

14

20

28

45

71

110

45

63

100

160

250

14

20

28

45

71

110

36

50

71

110

180

280

16

22

28

45

80

125

56

80

110

180

280

450

18

25

36

56

90

140

-g

upto 1600

m

!t

over 1600

u p t o 2500

63

80

125

180

320

500

18

28

36

63

100

160

4o)

2

o:

over 2500

upto 4000

63

90

125

200

320

500

20

28

40

63

100

160

over 4000

upto 6300

71

100

140

220

360

560

22

32

45

71

110

180

over 6300

up to 10000

80

110

160

250

400

630

25

36

50

80

125

200

.-o

E

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

www.bzxzw.com

Page4 DIN3963

Normal module over 2 up to 3.55mm

Tolerances in pm

Deviation

fl'

FI'

Gear tooth quality

over

upto

10

50

3,5

io

14

18

1,5

5.5

over

upto

50

125

11

16

22

1,5

2.5

3.5

over

upto

125

280

14

18

25

5,5

11

over

upto

280

560

11

14

20

28

2,5

3.5

4.5

12

over

560

up to 1000

over 1000

up to 1600

12

16

22

32

2,5

3,5

10

14

14

18

25

36

11

16

E

E

.-C

P

w

al

.-m

U

-al

.-Eo

over 1600

u p t o 2500

io

14

20

28

40

33

4,5

12

18

*E!

over 2500

u p t o 4000

11

16

22

32

45

3,5

10

14

20

over 4000

u p t o 6300

12

18

25

36

50

5,5

11

16

22

over 6300

up to 1O000

i4

18

28

36

50

4,5

12

18

25

al

al

Deviation

1

Gear tooth quality

up to

E

E

.-C

?

al

over

up to

50

125

over

up to

125

280

Over

280

560

upto

10

12

14

c

al.

.-E

U

-al

.-c!o

'Ooo

up to 1600

Over

al

over 1600

up to 2500

f

al

Over

O

S

Y-

2500

u ~ t o4000

I I I

8

12

16

12

18

1 I 1

I I 1

I 1 I

10

14

~~

18

.

'

I

I

over 4000

u p t o 6300

6300

up to 1O000

Over

10

14

20

11

16

22

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

www.bzxzw.com

fl

DIN3963 Page5

Normal module over 2 up to 3.55mm

Tolerances in pm

~-

Deviation

fi'

FI'

Gear tooth qualitv

10

11

12

10

11

12

over

upto

10

50

25

36

50

71

100

140

11

14

20

28

40

56

over

upto

50

125

32

45

63

90

125

160

14

18

25

36

50

71

over

upto

125

280

36

50

71

100

140

200

16

22

32

40

56

80

over

upto

280

560

40

56

80

110

160

220

18

25

36

50

71

100

over

560

up to 1000

45

63

90

125

180

250

20

28

40

56

80

110

over 1000

up to 1600

50

71

100

140

200

280

22

32

45

63

90

125

over 1600

upto 2500

56

80

110

160

220

280

25

36

50

71

100

140

63

90

125

160

250

320

28

40

56

80

100

160

over 4000

upto 6300

71

100

140

200

280

400

32

45

63

90

125

180

over 6300

up to 1O000

71

110

140

220

280

400

36

50

71

100

140

200

over 2500

up to 4000

I

I

Deviation

Gear tooth quality

10

11

12

10

11

12

over

upto

10

50

36

50

71

110

180

280

18

25

32

50

90

140

over

upto

50

125

40

56

80

125

200

320

18

25

36

56

90

140

over

upto

125

280

45

63

90

140

250

360

18

25

36

56

90

140

over

upto

280

560

50

71

100

160

250

400

18

25

36

56

90

160

over

560

upto 1000

56

80

110

180

280

450

20

28

40

63

100

160

po

over 1000

up to 1600

63

90

125

200

320

500

20

28

40

63

100

160

over 1600

upto 2500

71

90

125

220

320

560

22

32

40

71

110

180

over 2500

upto 4000

71

100

140

220

360

560

22

32

45

71

110

180

over 4000

up to 6300

80

110

160

250

400

630

25

36

50

80

125

200

6300

up to 10000

90

125

180

280

450

710

28

36

56

90

140

220

.-E

;

.0

.-

y.

over

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

www.bzxzw.com

Page 6 DIN 3963

Normal module over 3.55 up to 6mm

Tolerances in k m

Deviation

Fi'

fi'

Gear tooth quality

over

upto

10

50

5.5

11

14

20

1,5

2,5

4.5

over

upto

50

125

4,5

12

18

25

5,5

11

over

upto

125

280

10

14

20

28

2,5

4.5

12

over

up to

280

560

12

16

22

32

2,5

3,s

10

14

over

560

up to 1000

12

18

25

36

11

16

over 1000

up to 1600

10

14

20

28

40

4,5

12

18

over 1600

upto 2500

11

16

22

32

40

3,5

10

14

18

over 2500

upto 4000

12

18

25

32

45

5,5

11

16

22

over 4000

up to 6300

12

18

25

36

50

' 4

12

16

22

over 6300

up to 10000

10

14

20

28

40

56

4,5

12

18

25

fi

Fi

Gear tooth quality

over

up to

10

50

5,5

10

14

20

28

2'5

5,5

10

14

over

up to

50

125

12

18

25

32

5,5

11

14

over

upto

125

280

10

14

20

28

36

5,5

11

16

-u

over

upto

280

560

11

16

22

28

40

11

16

over

560

up to 1000

12

16

22

32

45

4,5

12

16

over 1000

up to 1600

12

18

25

36

50

4,5

12

18

over 1600

up to 2500

10

14

20

28

40

56

3,5

4,5

14

18

E!

al

*

o)

over 2500

up to 4000

11

14

20

28

40

56

3'5

10

14

18

over 4000

up to 6300

over 6300

up to 1O000

11

16

22

32

45

63

3,5

10

14

20

12

16

25

32

45

63

5,5

11

16

22

E

.-c

L.

w

a

l

.-!mi

.-eo

DIN3963 Page7

Normal module over 3.55 up to 6 mm

Tolerances in pm

I

Deviation

fi'

Fi'

,Gear tooth quality

E

E

.-

Over

UD~O

125

280

Over

up to

280

560

Over

UD to

560

1000

Over

UP to

'Ooo

1600

-u

I

m

.m

-al

.-o2

o

C

E

Yo>

o>

I

I

1

1

40

45

50

I

1

1

I

56

63

71

56

I

I

1

I

11

12

50

63

56

80

80

63

90

90

71

110

100

80

125

110

90

125

80

upto 2500

over 2500

UD to 4000

125

160

220

320

28

36

50

71

100

140

180

250

360

32

40

56

80

110

160

200

280

400

32

45

63

90

125

180

220

320

450

36

50

71

100

140

200

Deviation

Gear tooth quality

.-

-u

I

3

o>

-al

.-o2

oC

E

ao>l

'c

8 1 9

56

80

125

200

320

20

28

40

50

125

45

63

90

140

250

360

20

28

40

over

upto

125

280

52

71

100

160

250

400

22

32

40

over

upto

280

560

56

80

110

180

280

450

22

32

45

over

560

63

90

125

200

320

500

22

32

45

71

100

140

220

360

560

25

32

50

71

100

140

220

360

630

25

36

50

over 2500

upto 4000

80

110

160

250

400

630

25

36

50

over 4000

upto 6300

90

125

180

280

450

710

28

40

56

over 6300

up to 10000

90

140

180

280

450

710

32

45

63

over

) 1 0 1 1 1 ) 1 2

40

upto

-

1 8 1 9

10

50

over

upto

fi

Fi

upto lo00

-

over 1000

up to 1600

over 1600

upto 2500

'

Page8 DIN3963

L

Normal module over 6 up to 10 mm

Tolerances in prn

Deviation

._

12

18

25

36

5,5

11

16

10

14

20

28

40

4.5

12

18

1000

upto 1600

11

16

22

32

40

3,5

10

14

18

over 1600

upto 2500

12

16

22

32

45

5,5

10

14

20

over 2500

up to 4000

14

18

25

36

50

11

16

22

over 4000

upto 6300

10

14

20

28

40

56

4,5

12

18

25

over 6300

up to 1O000

11

16

22

28

40

63

10

14

20

28

upto 560

over

560

up to 1000

L

al

.-E - -over

2

V

.-V

0C

L

0E

fi'

Deviation

fi

F;

E

E

.-C

-u

E

.-m

-J

Q>

.-2

V

8c

e!

al

Gear tooth quality

over

upto

10

50

12

16

22

32

3,5

4,5

12

18

over

up to

50

125

10

14

20

28

40

3,5

14

18

over

upto

125

280

11

16

22

32

45

3,5

10

14

18

over

upto

280

560

12

18

25

32

45

3.5

10

14

20

over

560

upto 1000

10

14

18

25

36

50

3,5

10

14

20

over 1000

up to 1600

10

14

20

28

40

56

10

14

20

1600

2500

Il

16

22

32

40

56

5,5

11

16

22

2500

4000

12

16

22

32

45

63

11

16

22

over 4000

upto 6300

12

18

25

36

50

71

12

16

22

over 6300

up to 1O000

14

18

25

36

50

71

4,5

12

18

25

over

- up to

over

upto

DIN 3963 Page 9

Normal module over 6 up to 10 mm

Tolerances in pm

10

11

12

10

11

12

32

45

63

90

125

180

14

20

28

40

56

80

40

56

71

110

140

200

18

25

32

45

63

90

45

63

80

120

160

250

20

28

40

56

71

50

71

100

140

180

250

22

32

45

63

80

125

56

71

110

140

200

280

25

32

50

63

90

125

over 1000

up to 1600

56

80

110

160

250

320

28

36

50

71

100

140

over

upto

over

upto

63

90

125

180

250

360

28

40

56

80

110

160

71

100

140

180

280

360

32

45

63

90

125

180

80

110

160

220

320

450

36

50

71

100

140

200

over

up to

over

up to

E

C

.'D

over

upto

over

up to

m

m

.-

.-2

10

50

50

125

125

280

280

560

560

1000

1600

2500

2500

4000

over 4000

upto 6300

over 6300

up to 10000

0

C

EQ>!

fi'

over

upto

_.

+,

m

FI'

7

Gear tooth quality

Deviation

'

100

--

%i

a:

80

125

160

250

320

450

40

56

80

110

160

220

Deviation

fi

Fi

Gear tooth quality

over

upto

10

50

over

upto

.-

.-f

50

125

over

125

upto 280

over

280

upto 560

over

560

up to 1000

.O

0t

$

I ? - -

10

11

12

10

11

12

45

63

90

140

220

360

25

36

50

80

125

200

56

71

100

160

280

450

25

36

50

80

125

200

63

80

110

180

280

500

25

36

50

80

125

220

--___---~

63

90

125

200

320

500

28

36

50

80

140

220

71

100

140

220

360

560

28

40

56

90

140

220

80

110

160

250

400

630

28

40

56

90

140

220

over 1600

upto 2500

80

110

160

250

400

630

28

40

56

90

140

250

over 2500

upto 4000

90

125

180

280

450

710

32

45

63

100

160

250

over 4000

upto 6300

100

140

200

320

500

800

32

45

63

100

160

250

over 6300

up to 1O000

100

140

200

320

500

800

36

50

71

110

180

280

- over

1000

upto 1600

--

Page 10 DI N 3963

Normal moduleover l o u p to 16mm

,

Deviation

FI'

Gear tooth quality

50

over

upto

125

125

over

upto

-

280

over

upto

280

560

over

560

up to 1000

f I'

5,5

11

16

22

32

2,5

3,5

10

14

12

18

25

36

11

16

10

14

20

28

40

3,5

4,5

12

18

11

16

22

28

40

3.5

10

14

20

-

over 1000

upto 1600

12

16

22

32

45

5,5

11

14

20

over 1600

upto 2500

12

18

25

36

50

11

16

22

over 2500

upto 4000

10

14

20

28

40

56

4,5

12

18

25

over 4000

upto

6300

-

IO

i4

20

28

40

56

4,5

14

18

28

over 6300

up to 1 O000

Il

16

22

32

45

63

10

14

20

28

o>

E

f

Lc

--

Deviation

fl

Fi

1

11

16

22

32

45

4.5

12

16

22

12

18

25

36

50

4.5

12

16

25

10

14

20

28

40

56

4.5

12

18

25

11

16

22

28

40

56

4.5

12

18

25

12

16

22

32

45

63

4,5

12

18

25

12

18

25

36

45

63

10

14

18

25

14

18

25

36

50

71

10

14

20

28

over 4000

upto 6300

14

20

28

40

56

80

10

14

20

28

over 6300

up to 10000

14

20

28

40

56

80

5.5

11

14

22

28

Gear tooth quality

over

upto

--

over

upto

E

.-

over

upto

over

upto

-2aJ

'O

f

w-

over

up to

over

upto

over

upto

50

125

125

280

280

560

560

1000

1000

1600

1600

2500

2500

4000

DIN 3963 Page 1 1

Normal moduleover l o u p to 16mm

Tolerances in prn

12

110

125

-

125

140

160

160

180

over 4000

up to 6300

80

110

160

220

320

450

36

56

71

110

160

220

over 6300

up to 10000

90

125

180

250

360

500

40

56

80

110

160

220

Deviation

1

Gear tooth quality

over

UD to

50

125

I I 1

90

63

125

up to

.-f

over

upto

280

560

1O0

upto 1600

over

1600

'k

UDtO

2500

-oo

over 6300

up to 10000

125

I

110

160

220

PI

Page 12 DIN 3963

Normal module over 16 up to 25 mm

Tolerances in pm

Deviation

fi'

F;'

Gear tooth quality

over

up to

50

125

125

280

280

560

560

over

upto

~~

E

E

G

over

upto

over

upto 1000

i

ui

-

upto 1600

____-

w

W

fo

cc

over

1000

over 1600

upto 2500

over 2500

upto 4000

over 4000

upto 6300 over 6300

up to 1 O000

12

18

25

36

4,5

12

16

10

14

20

28

36

3'5

4,5

12

18

11

16

22

28

40

3,5

10

14

20

12

16

22

32

45

5,5

11

16

22

12

18

25

36

50

4,5

12

16

22

IO

14

20

28

40

56

4,5

12

18

25

11

14

20

28

40

56

10

14

20

28

11

16

22

32

45

63

10

14

20

28

12

18

25

36

50

71

5,5

11

16

22

32

Deviation

fI

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Gear tooth quality

12

18

25

36

50

5.5

11

16

22

32

10

14

20

28

40

56

5,5

11

16

22

32

11

16

22

32

45

63

11

16

22

32

12

18

25

32

45

63

12

16

22

32

over 1000

upto 1600

14

18

25

36

50

71

12

16

22

32

over 1600

upto 2500

14

20

28

40

56

71

12

16

25

32

over 2500

upto 4000

14

20

28

40

56

80

12

18

25

32

over 4000

upto 6300

16

22

32

45

63

90

12

,I8

25

36

over 6300

up to 1O000

16

22

32

45

63

90

14

18

25

36

over

upto

.-

-a

I

p!

al

-e

50

125

over

125

upto 280

over

280

upto 560

over

560

upto 1000

--

al

W

?I

.c

al

DIN 3963 Page 13

Normal module over 16 up to 25 mm

Tolerances in pm

Deviation

Fi'

Gear tooth quality

fi'

10

11

12

10

11

12

over

up to

50

125

50

71

90

125

180

250

22

32

45

63

90

125

over

up to

125

280

56

71

100

140

200

280

25

36

50

71

100

140

over

up to

280

560

56

80

110

160

250

320

28

40

56

80

110

140

over

560

up to 1000

63

90

125

180

250

360

32

40

56

80

110

160

over 1000

up to 1600

71

100

140

200

280

360

32

45

63

90

110

160

over 1600

upto 2500

71

100

140

200

280

400

36

50

71

100

140

180

over 2500

up to 4000

80

110

160

220

320

450

36

50

71

100

140

200

over 4000

up to 6300

90

125

180

250

360

500

40

56

80

110

160

220

over 6300

up to 1O000

100

140

200

280

400

560

45

63

90

125

180

250

.-E

3

W

E

-e

5

W

'

W

2

EW

.t

Fi

Gear tooth quality

E

E

c

.-

v

&

+

E

(D

5

W

2

W

w-

cc

Deviation

fi

10

11

12

i0

11

12

over

upto

50

125

71

100

140

220

360

560

40

56

80

140

220

320

over

up to

125

280

80

110

160

250

400

630

45

63

80

140

220

360

over

upto

280

560

90

125

160

280

450

710

45

63

90

140

220

360

over

560

up to 1000

90

125

180

280

450

710

45

63

90

140

220

360

over 1000

up to 1600

100

140

200

320

500

800

45

63

90

140

220

360

over 1600

upto 2500

110

140

200

320

500

800

45

63

90

140

220

360

over 2500

upto 4000

110

160

220

360

560

900

45

63

90

140

250

400

over 4000

up to 6300

125

180

250

400

630

1000

50

71

100

160

250

400

6300

125

180

250

400

630

1000

50

71

100

160

250

400

over

up to 1O000

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 14 DIN 3963

1

Normal module over 25 up to 40 mm

Tolerances in pm

Deviation

Fi'

.-G

u

'G

'Z.

fi'

over 1000

up to 1600

10

14

20

28

40

56

10

14

18

25

over 1600

upto 2500

11

16

22

28

40

56

IO

14

20

28

over 2500

upto 4000

12

16

25

32

45

63

5,5

11

16

22

32

over 4000

upto 6300

12

18

25

36

50

71

5,5

11

16

22

32

over 6300

up to 1 O000

14

18

25

36

50

71

12

18

25

36

Deviation

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

fi

DIN 3963 Page 15

I

Normal module over 25 up to 40 mm

Tolerances in pm

Deviat ion

Gear tooth quality

Over

up to

E

E

.-C

w

i

c

al

.-

over

upto

280

560

over

560

UD to 1000

over 1000

up to 1600

10

11

12

56

80

110

160

63

90

125

I'

8o

80

over 2500

upto 4000

90

125

over 4000

upto 6300

1 O0

140

over 6300

up to 1 O000

1 O0

140

E!

a3

al

180

-

over 1600

upto 2500

al

PI'

-al

.-L

Fi'

1 1 1 1 1 1 1 90

90

125

180

100

140

200

110

140

200

180

250

320

450

110

160

220

200

280

400

560

125

180

250

200

280

400

560

140

200

280

-

12

-

50

1 O0

Deviation

fi

Fi

Gear tooth quality

10

11

12

10

11

over

upto

90

125

180

280

450

710

56

80

110

180

280

over

upto

125

280

280

560

450

-

100

140

200

320

500

800

56

80

110

180

280

450

450

500

500

500

500

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 16 DIN 3963

r-

Normal module over 40 up to 70 mm

Tolerances in pm

Deviation

fi'

ii

.-E

2

.-(i!

O

al

L

al

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

over 1000

up to 1600

11

16

22

32

45

63

5.5

11

16

22

32

over 1600

upto 2500

12

16

22

32

45

63

5,5

11

16

22

32

over 2500

upto 4000

-

12

18

25

36

50

71

12

18

25

36

over 4000

upto 6300

14

18

28

36

56

71

t2

18

25

38

10

14

20

28

40

over 6300

up to 10000

14

20

28

40

56

80

Deviation

fi

Gear tooth quality

over

upto

125

280

14

20

28

40

56

80

10

14

20

28

40

56

over

upto

280

560

16

22

32

45

63

90

11

14

22

28

40

56

.-

over

560

up to 1000

16

25

32

45

63

90

11

16

22

32

40

63

over 1000

up to 1600

18

25

36

50

71

100

11

16

22

32

45

63

18

25

36

50

71

100

11

16

22

32

45

63

.-u

s

over 1600

upto 2500

over 2500

upto 4000-

20

28

40

56

80

110

11

16

22

32

45

63

over 4000

upto 6300

20

28

40

56

80

110

11

16

22

32

45

63

over 6300

up to loo00

22

32

45

63

90

125

11

16

22

32

45

63

E

C

TI

+

al

-o(i!

C

.a2

c

DIN3963 Pagel7

Normal module over 40 up to 70 mm

Tolerances in pm

Deviation

FI'

fi'

12

-

Gear tooth quality

over

125

u ~ t o 280

over

upto

280

560

over

560

u p t o 1000

220

-

over 1000

UP to 1600

250

over 1600

u p t o 2500

250

-

over 2500

u p t o 4000

280

200

220

over 4000

u p t o 6300

280

over 6300

UD to 1O000

320

Deviation

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Gear tooth quality

E

E

C

a

.-eo

!?

over

upto

280

560

over

560

u p t o 1000

I.'

E

%

125

280

~~~

.-

over

upto

- -

over

up to

over

upto

-over

1000

1600

1600

2500

2500

upto 4000

over

4000

upto 6300

over 6300

up to 1O000

180

250

360

560

900

1400

90

125

180

280

450

710

Page 18 DIN 3963

Further Standards and Codes

Part 1 Tolerances for cylindrical gear teeth; tolerances for deviations of individual parameters

Part 2 Tolerances for cylindrical gear teeth; tolerances for tooth trace deviations

Part 3 Tolerances for cylindrical gear teeth; tolerances for pitch-span deviations

Centre distance allowances and shaft position tolerances of housings for cylindrical gear transmissions

System of gear fits; backlash, tooth thickness allowances and tooth thickness tolerances; bases,

calculation of tooth thickness allowances, conversion of allowances for the different measuring methods

Symbols for gear teeth

DIN 3999

VDI/VDE 2605 Circular pitches and plane angles. Fundamental terms for angle dimensions, angle measurements, angle

standards and their errors

VDI/VDE 2608 Single-flankand two-flank working test for straight and helical cylindrical gears with involute profile

VDI/VDE 3336 Cutting cylindrical gears with involute profile, metal-removal processes

DIN 3962

DIN 3962

DIN 3962

DIN 3964

DIN 3967

Explanations

When the Gear tooth tolerances Sub-committeestarted

revising the DIN Standards on tolerances for cylindrical

gear teeth it was faced with the question whether the

tolerances contained in I S 0 1328 - 1975 could be taken

over complete. After a thorough examination the committee came to the conclusion that this would not be

expedient for the purposes of German industry.

The DIN gear tooth tolerance system in use so far, the

principlesof which have not altered, has for the most

part proved itself in practice. Only with regard to a few

points was a general redifining of tolerances necessary.

This applies particularly to the tolerances for single-flank

working deviations, tooth trace deviations and, to some

extent, for pitch-span deviations.

Apart from this, it has been shownin practice that for

the same module the profile deviations do not become

larger with increasingdiameter (increasing number of

teeth). The profile tolerances therefore remain only

moduledependent and no longer diameterdependent.

A general review of the alterations undertaken is given

in the Explanations in DIN 3961.

The terms, designations and symbols have been redefined

in accordance with DIN 3960,DIN 3998 and DIN 3999.

Newly added parameters are the total profile deviation,

pitch-span deviation, tooth trace form deviation and

tooth trace total deviation.

The numerical specifying of tolerances derives from the

equations in DIN 3961.Additional alterations of the

tabulated numerical data result from the f a c t that the

module and diameter ranges have been regraded and

from the fact that the values in the old DIN Standards

calculated from the tolerance equations had for the

most part been rounded upwards, whereas in t h e new

Standard they have been rounded up or down to the

nearest preferred number.

The diameter range has been enlarged in the upward

direction to module rn = 70 mm and diameter

d = 10 O00 mm. Regardless of whether all deviations

are measurable, the numerical values in the Tables of

DIN 3962 Part 1 and DIN 3963 have been listed com

pletely in the interests of future applications. The

module range rn < 1 has been deleted, see in this

connection DIN 58 405.The arrangement of the tolerance Standards has been altered so that the tooth trace

deviations have been grouped with the individual deviations in DIN 3962 Part 2,whilst DIN 3963 contains

only working deviations and DIN 3967 only the system

of gear fits.

In the opinion of German industry, the large tolerances

for the two-flank working deviation, concentricity deviation and pitch-span deviation and the large amount of

spread in their relationship to the pther tolerances,

which were features objected to in I S 0 1328 1975,

are defined more in keeping with practical requirements

in DIN 3962 and DIN 3963.

Literature

Winter, H.; Seifried, A.: Verzahnungsfehler. Statistische Ermittlung natrlicher Zusammenhnge und Normung von

Toleranzen. (Gear tooth errors. Statistical determinationof natural relationships and standardizing of tolerances).

WERKSTATT UND BETRIEB 98 (1965)NO. IO, pp. 765-771.

Seifried, A.: Zahnrad-Teilungsfehler. Statistische Ermittlung der Zusammenhnge mit anderen Verzahnungsfehlern.

(Gear tooth pitch errors. Statistical determinationof relationships with other gear tooth errors). VDI-Berichte No. 105

(1967)pp. 141-143.

Kagerl, H. G.; Wrpel, H.: Fertigungsgerechte Relationenzwischen den geometrischen Abweichungen an Stirnrdern.

(Production-orientedrelationships between the geometrical deviations on cylindrical gears). WISSENSCHAFTL. ZEITSCHR. d. TH. Magdeburg 1 1 (1976)No. 2,pp. 201-210.

Kagerl, H. G.; Dulich, W.: Fertigungsgerechte RelationenEinflankenwlzabweichung/Einflankenwlzsprung Einzelabweichungen. (Production-orientedrelationships single-flank working deviation/single-flankworking error individual

deviations). FERTIGUNGSTECHNIK UND BETRIEB 21 (1971) No. 8, pp. 455-458.

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

También podría gustarte

- Din - 3962 1 1978Documento18 páginasDin - 3962 1 1978Carlos Cortes100% (3)

- Tolerances for Pitch-Span DeviationsDocumento2 páginasTolerances for Pitch-Span Deviationsdanielk32100% (1)

- Din 3962 Part 3Documento2 páginasDin 3962 Part 3Garapati Murarji100% (3)

- Din 3967-1978 EngDocumento24 páginasDin 3967-1978 EngLatha Pundi100% (4)

- Spline DIN 5480Documento27 páginasSpline DIN 5480ewillia13100% (3)

- Din 3961Documento12 páginasDin 3961Garapati Murarji100% (2)

- DIN 5480-2.PDF - Engineering Tolerance - GearDocumento25 páginasDIN 5480-2.PDF - Engineering Tolerance - GearDeniz Tuncbilek0% (2)

- Din 58405-1-1972Documento12 páginasDin 58405-1-1972prasanna67% (3)

- Norma Din 3961 PDFDocumento12 páginasNorma Din 3961 PDFJosé Francisco Ramos TeixeiraAún no hay calificaciones

- Tolerances for Cylindrical Gear TeethDocumento2 páginasTolerances for Cylindrical Gear TeethBruno Guariento86% (7)

- Agma Iso 10064-1Documento34 páginasAgma Iso 10064-1Mohammad Ali Taghdiri100% (2)

- Gear K Chart Inspection 1005Documento5 páginasGear K Chart Inspection 1005knvsureshbabu100% (4)

- DIN3975 - Terms Worm GearsDocumento15 páginasDIN3975 - Terms Worm GearsGonçalo Nogueira100% (2)

- DIN 5480 Nazubljena OsovinaDocumento27 páginasDIN 5480 Nazubljena OsovinaNikola MilojevicAún no hay calificaciones

- ISO Involute Spline Dimensions and StandardsDocumento7 páginasISO Involute Spline Dimensions and StandardsSaurabh Samal100% (1)

- Gears Standards-1Documento10 páginasGears Standards-1maheshmbelgavi100% (1)

- Din 3963Documento18 páginasDin 3963Garapati Murarji100% (1)

- Din 5480-06Documento4 páginasDin 5480-06Miomir JovanovićAún no hay calificaciones

- ISO 10064-6-2009 Code of Inspection Practice - Part 6 Bevel Gear Measurement Methods (Đo Bánh Răng Côn)Documento42 páginasISO 10064-6-2009 Code of Inspection Practice - Part 6 Bevel Gear Measurement Methods (Đo Bánh Răng Côn)Màu Đen Cuộc SốngAún no hay calificaciones

- 5480 2Documento40 páginas5480 2Ashutosh Singh80% (10)

- Gleason 1207Documento8 páginasGleason 1207FilippinAún no hay calificaciones

- AGMA Technical PaperDocumento14 páginasAGMA Technical PaperLuis TestaAún no hay calificaciones

- Gear Metrology ChartDocumento1 páginaGear Metrology Chartvijaykhandge50% (2)

- DIN5480 2006 EnglishDocumento34 páginasDIN5480 2006 EnglishAnatolii100% (1)

- Din 5480 15Documento2 páginasDin 5480 15roscilla57% (7)

- Din 3962 Part 2Documento18 páginasDin 3962 Part 2Garapati Murarji100% (3)

- Din 5480Documento27 páginasDin 5480MiguelAún no hay calificaciones

- Gear Tester, Rebuilding & PC RetrofitDocumento4 páginasGear Tester, Rebuilding & PC RetrofitPramod PatilAún no hay calificaciones

- Din 867Documento3 páginasDin 867danielk32Aún no hay calificaciones

- SKF Lock Nuts PDFDocumento22 páginasSKF Lock Nuts PDFgrupa2904Aún no hay calificaciones

- Gear Adendum Modification CoefficientDocumento8 páginasGear Adendum Modification CoefficientRobert StuartAún no hay calificaciones

- International Standards - Gears - International Standards, Metric Gear Standards - TandwielDocumento5 páginasInternational Standards - Gears - International Standards, Metric Gear Standards - Tandwielmanimecz100% (1)

- Spline DesignDocumento5 páginasSpline DesignRuchira Chanda Indu100% (2)

- GM Gear Inspection Handbook ISO DRAFT FINALDocumento39 páginasGM Gear Inspection Handbook ISO DRAFT FINALnestor100% (1)

- Iso 4156 1 2005 en PDFDocumento11 páginasIso 4156 1 2005 en PDFDavide FregniAún no hay calificaciones

- Din 867Documento3 páginasDin 867Murali Krishnan Selvaraja0% (1)

- Splines - Design and Application: AGMA Information SheetDocumento9 páginasSplines - Design and Application: AGMA Information SheetrezaAún no hay calificaciones

- Ansi B92.1Documento10 páginasAnsi B92.1idrisbooks0% (2)

- Mecanic AsDocumento6 páginasMecanic AsAnderson SantosAún no hay calificaciones

- Insulator PDFDocumento11 páginasInsulator PDFmanoj_2027100% (1)

- Chapter5 - Drive CouplingsDocumento90 páginasChapter5 - Drive Couplingsvijay219100% (1)

- M-LOK Specification ManualDocumento18 páginasM-LOK Specification ManualLorin LaverdureAún no hay calificaciones

- Pulleys TechDocumento8 páginasPulleys TechashkansoheylAún no hay calificaciones

- Motor M2BA Cat. 315 355 Frame PGDocumento5 páginasMotor M2BA Cat. 315 355 Frame PGdhaval3gAún no hay calificaciones

- Continental TorquesDocumento13 páginasContinental Torquesfredtanner100% (2)

- J300P-7 (1) - Spicer Tube ShaftsDocumento24 páginasJ300P-7 (1) - Spicer Tube ShaftsPrasadAún no hay calificaciones

- Coupling PDFDocumento7 páginasCoupling PDFAnkur GaurAún no hay calificaciones

- Honda XR200 engine tuning optionsDocumento14 páginasHonda XR200 engine tuning optionsCamilo Gomez100% (1)

- Spidex OperatingDocumento10 páginasSpidex Operatingwalk001Aún no hay calificaciones

- Die springs catalogDocumento11 páginasDie springs catalogAnonymous 8lxxbNcA0sAún no hay calificaciones

- BYG Teeth Cat Side Pin TeethDocumento12 páginasBYG Teeth Cat Side Pin TeethteicooyAún no hay calificaciones

- Pilkington Profilit Techn Info enDocumento12 páginasPilkington Profilit Techn Info enSalmonelo Abdul RamosAún no hay calificaciones

- AMRI ISORIA 16 Type Series Booklet DataDocumento20 páginasAMRI ISORIA 16 Type Series Booklet Datarudiskw456Aún no hay calificaciones

- DT GF4C IngDocumento8 páginasDT GF4C IngFrancisco HernandezAún no hay calificaciones

- Catalog New Motor 1LG0Documento40 páginasCatalog New Motor 1LG0bajricaAún no hay calificaciones

- 2500 Brass Ball Valve ISO 5211Documento1 página2500 Brass Ball Valve ISO 5211Andrew Newham (AK Valves Limited)Aún no hay calificaciones

- ABB CatalogueDocumento6 páginasABB CatalogueNavneet SinghAún no hay calificaciones

- Aerostar Maintenance Manual ATA-91-Charts and Wiring DiagramsDocumento145 páginasAerostar Maintenance Manual ATA-91-Charts and Wiring DiagramsNsafetyalwaysoffAún no hay calificaciones

- Cupling Gear 02Documento22 páginasCupling Gear 02Ilse Achanty Barradas100% (1)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PDe EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PAún no hay calificaciones

- Din 17671Documento0 páginasDin 17671Niculescu Marian50% (2)

- Din 7168 PDFDocumento8 páginasDin 7168 PDFLuciano FontesAún no hay calificaciones

- DIN 2391-2393 - Composição e Resistência Mecânica PDFDocumento4 páginasDIN 2391-2393 - Composição e Resistência Mecânica PDFLuciano FontesAún no hay calificaciones

- Iso For Roundbar PDFDocumento1 páginaIso For Roundbar PDFkumaras1Aún no hay calificaciones

- Din 443 PDFDocumento1 páginaDin 443 PDFLuciano Fontes100% (1)

- Din 5401 PDFDocumento12 páginasDin 5401 PDFLuciano FontesAún no hay calificaciones

- Din 1693Documento11 páginasDin 1693vitor7hugo100% (3)

- Din 934Documento0 páginasDin 934mjinspectorAún no hay calificaciones

- Norma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesDocumento13 páginasNorma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesJuan Rivera100% (1)

- Hot Rolled Steel Bar Size VariationsDocumento4 páginasHot Rolled Steel Bar Size VariationsAnonymous ep7LE5ZdP5Aún no hay calificaciones

- Din 267-24 PDFDocumento7 páginasDin 267-24 PDFLuciano FontesAún no hay calificaciones

- Din 509 PDFDocumento6 páginasDin 509 PDFLuciano FontesAún no hay calificaciones

- Astm A29Documento22 páginasAstm A29Brad BorgesAún no hay calificaciones

- Gray Iron Castings: Standard Specification ForDocumento5 páginasGray Iron Castings: Standard Specification ForgeejokodAún no hay calificaciones

- Din 470 PDFDocumento6 páginasDin 470 PDFLuciano FontesAún no hay calificaciones

- Iso For Roundbar PDFDocumento1 páginaIso For Roundbar PDFkumaras1Aún no hay calificaciones

- En 10045-1Documento9 páginasEn 10045-1Elton Sanchez100% (2)

- Astm A47 A47m (1999)Documento5 páginasAstm A47 A47m (1999)Narendrasinh JadejaAún no hay calificaciones

- A 971 PDFDocumento7 páginasA 971 PDFLuciano FontesAún no hay calificaciones

- Astm A31 (1995)Documento4 páginasAstm A31 (1995)gsb2100% (1)

- Steel Castings, Carbon, For General ApplicationDocumento4 páginasSteel Castings, Carbon, For General ApplicationJosé Ramón GutierrezAún no hay calificaciones

- Astm A36 PDFDocumento3 páginasAstm A36 PDFYudi Popo Fadhillah100% (3)

- Astm A21 1999Documento10 páginasAstm A21 1999Nguyễn Duy BiênAún no hay calificaciones

- Din 509Documento6 páginasDin 509Luciano FontesAún no hay calificaciones

- A002 Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocumento3 páginasA002 Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDaniel Alonso Flores MezaAún no hay calificaciones

- Lined Portrait A4 CollegeDocumento1 páginaLined Portrait A4 Collegejunior_allmeidaAún no hay calificaciones

- Din 267-24Documento7 páginasDin 267-24Luciano FontesAún no hay calificaciones

- Auto CadDocumento21 páginasAuto CadMohammed AminAún no hay calificaciones

- M T10000FS 02 05Documento104 páginasM T10000FS 02 05Lari Simi100% (1)

- Eaton TransmissionDocumento124 páginasEaton TransmissionPhụ Tùng DaewooAún no hay calificaciones

- Screw Thread N GearsDocumento71 páginasScrew Thread N Gearshyundai310100% (3)

- 1pf2gf - Pgf-Int-Gp-Re10213Documento20 páginas1pf2gf - Pgf-Int-Gp-Re10213Johnny JessingAún no hay calificaciones

- Automatic Transmission Problems and SolutionsDocumento3 páginasAutomatic Transmission Problems and SolutionsMakuetewo EmmanuelAún no hay calificaciones

- Transmission of Motion & Power3Documento67 páginasTransmission of Motion & Power3Vinay GaikwadAún no hay calificaciones

- Gear Quality - What It's All AboutDocumento5 páginasGear Quality - What It's All AboutFemi FadeyiAún no hay calificaciones

- Dynamics of Machinery Question BankDocumento8 páginasDynamics of Machinery Question BankArun ShawnAún no hay calificaciones

- Driving Dynamics: ZF Axle Drives For CarsDocumento10 páginasDriving Dynamics: ZF Axle Drives For Carssardhan.rajender84Aún no hay calificaciones

- Conveyor Belt Technique: Design and CalculationDocumento161 páginasConveyor Belt Technique: Design and CalculationMarianne Hernández100% (1)

- Guia de Especificaciones InglesDocumento56 páginasGuia de Especificaciones Inglesjalvarez_385073Aún no hay calificaciones

- GearingBasic 03Documento14 páginasGearingBasic 03Jojee MarieAún no hay calificaciones

- 1000series - Hyd. WinchDocumento7 páginas1000series - Hyd. Winchadrianram1Aún no hay calificaciones

- An Accurate and Numerically Efficient Time-Varying Mesh Stiffness Model For Modified Straight Bevel Gear Under LoadDocumento29 páginasAn Accurate and Numerically Efficient Time-Varying Mesh Stiffness Model For Modified Straight Bevel Gear Under Load王磊Aún no hay calificaciones

- 2007 Nissan Quest Power Steering Repair ManualDocumento26 páginas2007 Nissan Quest Power Steering Repair ManualService Manual50% (2)

- Pulsar 220 Workshop Manual ENGLISHDocumento45 páginasPulsar 220 Workshop Manual ENGLISHTim ChesbroAún no hay calificaciones

- Scope of Engine RebuildEMDDocumento61 páginasScope of Engine RebuildEMDSreenath S Kallaara100% (2)

- 85362A0Documento127 páginas85362A0Urip S. SetyadjiAún no hay calificaciones

- Katalog Product SumitomoDocumento5 páginasKatalog Product SumitomoIwan GoeltomAún no hay calificaciones

- Premium Transmission - Profile CatalogueDocumento8 páginasPremium Transmission - Profile CatalogueSanjib GhoshAún no hay calificaciones

- Folklift ProjectDocumento15 páginasFolklift Projectemlynmuriuki29Aún no hay calificaciones

- Corrective Apron Feeder Mechanical Parts State ReportDocumento5 páginasCorrective Apron Feeder Mechanical Parts State ReportMalek Anas MahmoudAún no hay calificaciones

- Fabrication of Multi Purpose Machine Drilling Cutting Milling ShapingDocumento73 páginasFabrication of Multi Purpose Machine Drilling Cutting Milling ShapingKrishna Mouli KasimiAún no hay calificaciones

- Detroit Engine Service Manual DD S V 71 SerDocumento12 páginasDetroit Engine Service Manual DD S V 71 SerAndrey PomazanovAún no hay calificaciones

- Lego BasicsDocumento39 páginasLego BasicsPio_ChronicleAún no hay calificaciones

- Shark Screw Air Compressor: Installation, Maintenance and User ManualDocumento43 páginasShark Screw Air Compressor: Installation, Maintenance and User ManualSatria Baru Perkasa RetesterAún no hay calificaciones

- Additions, Revisions, or Updates: Subject DateDocumento10 páginasAdditions, Revisions, or Updates: Subject DateEduardo TorresAún no hay calificaciones

- Ring and Pinion Contact PatternsDocumento2 páginasRing and Pinion Contact Patterns92vmax4Aún no hay calificaciones