Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Technical Bulletin: Magnetism and Other Properties of Stainless Steel

Cargado por

ksTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Technical Bulletin: Magnetism and Other Properties of Stainless Steel

Cargado por

ksCopyright:

Formatos disponibles

TECHNICAL BULLETIN

Magnetism and Other Properties of Stainless Steel

Gregg V. Summers, P.E.

Director of Product Development

Ever wondered if stainless steel can be magnetic? Curious

about the various grades and properties of stainless steel?

Below are answers to commonly asked questions regarding

the magnetism, corrosion resistance and heat-treatment of

stainless steel.

Can stainless steel be magnetic?

Yes to varying degrees. The magnetism of stainless steel is

affected by its alloying elements, atomic grain structure, and

the amount of cold-working during fabrication.

What are 18-8, 300-Series and 400-Series

stainless steels?

The American Iron and Steel Institute (AISI) has created

widely accepted grades for stainless steels. These grades

are identified by series numbers 100 through 600 where

each series is organized by alloy and grain structure

properties.

Most common to the electronics fastener industry are

300-series and 400-series stainless steels. The 300-series

steels have an austenitic metallic grain structure while

400-series have ferritic or martensitic structures.

Among other alloying elements, several 300-series stainless

steels contain approximately 18% chromium and 8% nickel.

Thus 18-8 is a loose characterization of stainless steel

grades 302-305, 316, 321 and 347. Even more general is

the acronym CRES which typifies any corrosion-resistant

steel.

What grades of stainless steel are magnetic?

In their basic forms stainless steels have a ferritic grain

structure, similar to carbon steel, and are magnetic. The

addition of nickel in the 300-series stainless steels modifies

the crystal grain structure to austenitic. The austenitic

grades are mostly non-magnetic in the unworked state due

to their nickel content. When 300-series stainless steels are

cold-worked, straining of the atomic lattice structure in the

areas of cold-working forms the magnetic grain structure

martensite.

Generally speaking, the higher the nickel content the more

stable the austenitic structure and less magnetic response

from cold-working. Consequently 316 stainless steel, with

higher amounts of nickel, exhibits virtually no magnetism

after cold-working in most cases. While 304, with lower

nickel content, may become mildly magnetic.

Are there any means of reducing or eliminating

the magnetic properties of stainless steel?

Austenitic (300-series) stainless steels that have become

magnetic due to work hardening can be returned to a nonmagnetic state through annealing or stress-relieving. Brief

heating at elevated temperatures reverts the affected grain

structure from the martensitic state to the austenitic. Since

400-series stainless steels are entirely ferritic or martensitic,

their magnetic properties cannot be reduced through

annealing.

There are no plating or finishing processes, such as passivation, that can reduce or eliminate work hardening induced

magnetism. They are merely superficial and do not change

the affected grain structure.

TB-MAG SS REV B exp. 08/10

Pencom 2008

Technical Bulletin

One of the alloying metals, chromium, causes stainless steel

to have a magnetic grain structure. Another of the possible

alloying elements, nickel, reduces or inhibits magnetic properties. The 300-series stainless steels have varying degrees

of nickel making them mostly non-magnetic. Devoid of

nickel and with a grain structure similar to carbon steel, the

400-series stainless steels are slightly magnetic.

What causes non-magnetic grades of stainless

steel to become magnetic?

1/

(continued)

Is magnetism related to corrosion resistance?

Is stainless steel heat treatable?

Stainless steel, like carbon steel, can rust when exposed

to air. However, the chromium in stainless steel forms a

protective chromium oxide layer (also known as passivation)

which prevents the development of iron oxide rust. The

chromium oxide layer is so thin that it is imperceptible and

thus the metal retains its attractive finish.

Carbon can be added to stainless steel creating a martensitic crystal grain structure. These stainless steels, such as

410 and 416, respond well to heat-treating. Although not

heat-treatable, 301 stainless steel work hardens easily making it useful in applications requiring high tensile strength.

The 300-series stainless steels have a higher chromium

content than the 400-series stainless steels, as well as,

nickel as an alloying element. Nickel enhances chromiums

ability to form a passive surface layer. Consequently,

300-series stainless steels exhibit better corrosion resistance. Corrosion resistance is a function of the chromium

and nickel content and not the metallic grain structure

which causes magnetism.

How do I know which stainless steel to specify

in my application?

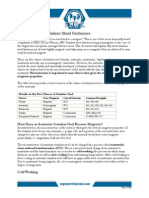

The table below highlights the general usage and property

characteristics of stainless steels commonly used in the

electronics fastener industry.

Most Suitable Manufacturing Process

AISI

Grade

Drawing &

Stamping

Machining

Cold

Forming

Welding

Property

Corrosion Resistance

Good

Excellent

Superior

Heat

Treatable

Non-magnetic

after

Annealing

Magnetic

301/302

303

304

316

410

416

This information may be updated periodically. Contact Pencom for current information or see www.pencomsf.com

Europe

Building 63, Bay 4,

The Pensnett Estate,

Third Avenue, Kingswinford

West Midlands, DY6 7XU

Phone 44-1384-295095

Fax 44-1384-295097

Shanghai

Room 3A Block 12 No.55

XIYA Road Waigaoqiao

Free Trade Zone Pudong

Shanghai 200131

Phone 86-21-50462738

Fax 86-21-50462726

Singapore

629 Aljunied Road #06-21

Cititech Industrial Building

Singapore, 389838

Phone 65-6749-6183

Fax 65-6749-4948

Penang

48A, Jalan Todak 4,

Pusat Perniagaan Bandar,

Seberang, Jaya

13700, Prai, Penang, Malaysia

Phone 604-390-2033

Fax 604-399-4033

Taiwan

3F, No. 118, Sinhu 3rd Road

Neihu District, Taipei City 114

Taiwan (R.O.C)

Phone 886-2-27962877

Fax 886-2-27952863

TB-MAG SS REV B exp. 08/10

Hong Kong

2A World Tech Center

95 How Ming Street,

Kwun Tong, Kowloon,

Hong Kong

Phone 852-2994-6183

Fax 852-2172-6233

Pencom 2008

Technical Bulletin

Americas

1300 Industrial Road, Suite 21

San Carlos, CA 94070

Phone 650-593-3288

Fax 650-593-3299

2/

También podría gustarte

- Application of Stainless SteelDocumento13 páginasApplication of Stainless Steelsweety1188Aún no hay calificaciones

- The Stainless Steel Family - An Overview - Campbell Tip of The MonthDocumento5 páginasThe Stainless Steel Family - An Overview - Campbell Tip of The Monthpeach5Aún no hay calificaciones

- A101 Design Calculation For Foundation of New VCM Storage TankDocumento25 páginasA101 Design Calculation For Foundation of New VCM Storage TankzatenneAún no hay calificaciones

- Engineering Piping Design Guide Fiberglass Reinforced Piping SystemsDocumento36 páginasEngineering Piping Design Guide Fiberglass Reinforced Piping Systemsoscarhdef100% (1)

- II Pipeline Design Codes and standards-MSGDocumento74 páginasII Pipeline Design Codes and standards-MSGAyyappan100% (1)

- AnnealingDocumento9 páginasAnnealingRathne AbeynayakeAún no hay calificaciones

- The Mechanical Properties of SteelDocumento13 páginasThe Mechanical Properties of SteelAddrien DanielAún no hay calificaciones

- AVESTA POLARIT - Stainless Steels - Their Properties and Their Suitability For WeldingDocumento11 páginasAVESTA POLARIT - Stainless Steels - Their Properties and Their Suitability For Weldingmirza_adil99Aún no hay calificaciones

- Centrifugal Pump ImpellerDocumento1 páginaCentrifugal Pump ImpellerksAún no hay calificaciones

- Experiment 2 - Study of Packed Column DistillationDocumento7 páginasExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- Stainless Steel Five TypesDocumento40 páginasStainless Steel Five Typessids82Aún no hay calificaciones

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDe EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonAún no hay calificaciones

- Service Boom Inspection and Repair PDFDocumento60 páginasService Boom Inspection and Repair PDFYadi Kusmayadi100% (1)

- 304L WeldingDocumento6 páginas304L Weldingeedbdmdud100% (1)

- Final Exam in PhysicsDocumento5 páginasFinal Exam in Physicsmvmbapple0% (1)

- Lincoln Stainless Welding GuideDocumento40 páginasLincoln Stainless Welding GuideAnonymous yQ7SQr100% (1)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDe EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelAún no hay calificaciones

- CPM300 MetallurgyDocumento70 páginasCPM300 MetallurgyhadiAún no hay calificaciones

- D.Selvakumaran Course Director/AwtiDocumento83 páginasD.Selvakumaran Course Director/AwtiaravindanAún no hay calificaciones

- Stainless Steels: Gateway Arch in ST Louis - 304 Series SSDocumento16 páginasStainless Steels: Gateway Arch in ST Louis - 304 Series SSAndika RizalAún no hay calificaciones

- 127.study The Effect of Welding Parameters of Tig Welding of PlateDocumento43 páginas127.study The Effect of Welding Parameters of Tig Welding of PlatemoorthikumarAún no hay calificaciones

- Stainless Steel Manufacturing ProcessesDocumento27 páginasStainless Steel Manufacturing Processesmaadhesh100% (1)

- Chemical Bonding ModuleDocumento35 páginasChemical Bonding ModuleMark Paul Lipata Benitez100% (2)

- TB Mag SS PDFDocumento2 páginasTB Mag SS PDFjr_satishAún no hay calificaciones

- Magnetic Response of Cast Stainless SteelsDocumento3 páginasMagnetic Response of Cast Stainless SteelssnorklingmonkeyAún no hay calificaciones

- An Overview of Austenitic and Ferritic Stainless Steels - The FabricatorDocumento7 páginasAn Overview of Austenitic and Ferritic Stainless Steels - The FabricatorAhmadiBinAhmadAún no hay calificaciones

- Stamping 101: Material Guidelines: Properties and Characteristics That Affect FormabilityDocumento5 páginasStamping 101: Material Guidelines: Properties and Characteristics That Affect FormabilityDavid RodriguezAún no hay calificaciones

- Magnetism in Stainless SteelDocumento4 páginasMagnetism in Stainless Steelhyperm2mAún no hay calificaciones

- Welding of Stainless SteelsDocumento3 páginasWelding of Stainless SteelsEswar Enterprises QcAún no hay calificaciones

- Krunal Vora ContentDocumento14 páginasKrunal Vora ContentDevashish JoshiAún no hay calificaciones

- A Complete Guide To Stainless SteelDocumento16 páginasA Complete Guide To Stainless SteelRahul SinghAún no hay calificaciones

- Stainless Steel Applications in Electrical EngineeringDocumento9 páginasStainless Steel Applications in Electrical EngineeringUmang SoniAún no hay calificaciones

- Aalco MaterialsDocumento20 páginasAalco MaterialsMohamed FaragAún no hay calificaciones

- Metals 2Documento13 páginasMetals 2arooj anjumAún no hay calificaciones

- Magnetism in Stainless SteelDocumento4 páginasMagnetism in Stainless Steeltroyel99Aún no hay calificaciones

- CrNiMn - 2XX - ASSDA - 19673001161232771640Documento3 páginasCrNiMn - 2XX - ASSDA - 19673001161232771640Joshua WalkerAún no hay calificaciones

- Chapter 1 - REALDocumento16 páginasChapter 1 - REALShaira CalderonAún no hay calificaciones

- Material Selection Stainless SteelDocumento16 páginasMaterial Selection Stainless SteelmagiesekarAún no hay calificaciones

- Ferrous and NonDocumento13 páginasFerrous and NonIrvansyah RazadinAún no hay calificaciones

- Stainles SteelDocumento66 páginasStainles SteelHarshita DabasAún no hay calificaciones

- Ferrous and Non Ferrous MetalsDocumento31 páginasFerrous and Non Ferrous MetalsadinamdarAún no hay calificaciones

- Aalco Datasheet ST ST SpecificationsDocumento5 páginasAalco Datasheet ST ST SpecificationsAmer Y KAún no hay calificaciones

- Asm - Metalografia de Aço Baixo CarbonoDocumento20 páginasAsm - Metalografia de Aço Baixo CarbonoengetarcioAún no hay calificaciones

- Classification of Stainless SteelsDocumento2 páginasClassification of Stainless Steelshinsome LeeAún no hay calificaciones

- Wrought Metal AlloysDocumento25 páginasWrought Metal AlloysLalit KumarAún no hay calificaciones

- Stainless SteelDocumento4 páginasStainless SteelByronAún no hay calificaciones

- Stainless Steel FastenersDocumento3 páginasStainless Steel FastenersStainless Steel FastenersAún no hay calificaciones

- Effects of Austenitizing and Forging On Mechanical Properties of MIL A-12560/AISI 4340 SteelDocumento6 páginasEffects of Austenitizing and Forging On Mechanical Properties of MIL A-12560/AISI 4340 SteelsatrioherbirowoAún no hay calificaciones

- Wrought AlloysDocumento33 páginasWrought AlloysKanjiMasroorAún no hay calificaciones

- 45 - Microstructure and Mechanical Properties of Ass (304) - FSS (430) Dissimilar Joints in Smaw & Gtaw ProcessDocumento12 páginas45 - Microstructure and Mechanical Properties of Ass (304) - FSS (430) Dissimilar Joints in Smaw & Gtaw Processk.touilebAún no hay calificaciones

- Maraging SteelDocumento4 páginasMaraging SteelJayanthiAAún no hay calificaciones

- SS - LincolnDocumento40 páginasSS - LincolnLuis DuarteAún no hay calificaciones

- Stainless SteelDocumento81 páginasStainless SteelRockey ShrivastavaAún no hay calificaciones

- An Introduction To Stainless SteelsDocumento5 páginasAn Introduction To Stainless SteelsMELVIN MAGBANUAAún no hay calificaciones

- About Stainless Steel PropertiesDocumento8 páginasAbout Stainless Steel Propertiesprajash007Aún no hay calificaciones

- Brass PDFDocumento3 páginasBrass PDFpitrer123Aún no hay calificaciones

- Properties Srainless Steel 309LSDocumento3 páginasProperties Srainless Steel 309LSGabriel BozzaAún no hay calificaciones

- The Magnetic Behavior of MetalsDocumento5 páginasThe Magnetic Behavior of MetalssantanuriniAún no hay calificaciones

- Stainless SteelDocumento2 páginasStainless Steeltablo1234Aún no hay calificaciones

- Is Stainless Steel Magnetic or Non-Magnetic in External FieldDocumento3 páginasIs Stainless Steel Magnetic or Non-Magnetic in External FieldSM Waqas Imam100% (1)

- Maraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownDocumento5 páginasMaraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownVysakh VasudevanAún no hay calificaciones

- KNS1042 Metals Part1 W8Documento29 páginasKNS1042 Metals Part1 W8justine2109Aún no hay calificaciones

- Classifications of Stainless SteelDocumento2 páginasClassifications of Stainless SteelIsmail Mohd FadhlanAún no hay calificaciones

- Materials QuestionsDocumento30 páginasMaterials QuestionsMatheus SouzaAún no hay calificaciones

- CEED 2017 Question PaperDocumento29 páginasCEED 2017 Question Paperks100% (1)

- Drxrmzjxshezsejdrhxhdcf VHJBK,.Documento2 páginasDrxrmzjxshezsejdrhxhdcf VHJBK,.ksAún no hay calificaciones

- Last Time: - Many, Many Modeling TechniquesDocumento23 páginasLast Time: - Many, Many Modeling TechniquesksAún no hay calificaciones

- SfdsfsDocumento3 páginasSfdsfsksAún no hay calificaciones

- Inventorwizard: Miniature Model Steam Engine Horizontal Beam Engine With Centrifugal Pump ColumnDocumento1 páginaInventorwizard: Miniature Model Steam Engine Horizontal Beam Engine With Centrifugal Pump ColumnksAún no hay calificaciones

- Centrifugal Pump ShaftDocumento1 páginaCentrifugal Pump ShaftksAún no hay calificaciones

- Assembly EccentricDocumento1 páginaAssembly EccentricksAún no hay calificaciones

- Seminar On Rapid Prototyping: Presented byDocumento29 páginasSeminar On Rapid Prototyping: Presented byksAún no hay calificaciones

- How To Use LevelDocumento1 páginaHow To Use LevelksAún no hay calificaciones

- Cylinder Cover UpperDocumento1 páginaCylinder Cover UpperksAún no hay calificaciones

- Assembly Cylinder Piping ExitDocumento1 páginaAssembly Cylinder Piping ExitksAún no hay calificaciones

- Effect of Carrageenan Concentration On The Physicochemical and Sensory Properties of Papaya Jelly DrinkDocumento6 páginasEffect of Carrageenan Concentration On The Physicochemical and Sensory Properties of Papaya Jelly DrinkrinrinmaudyAún no hay calificaciones

- A Premium Institute For CBSE, NEET & JEEDocumento33 páginasA Premium Institute For CBSE, NEET & JEEZUHAIB KAMALAún no hay calificaciones

- Is 439 1989Documento11 páginasIs 439 1989rajpd28Aún no hay calificaciones

- Chapter 2 Pharmaceutical Aids and NecessitiesDocumento11 páginasChapter 2 Pharmaceutical Aids and NecessitiesZarah Pauline Jimenez100% (2)

- Measurement System BehaviourDocumento48 páginasMeasurement System BehaviourpitapitulAún no hay calificaciones

- Metalcraft 4Documento90 páginasMetalcraft 4Ana DuranAún no hay calificaciones

- Dental Materials Reviewer Pt. 10Documento5 páginasDental Materials Reviewer Pt. 10Ryo MiyataAún no hay calificaciones

- Notesch # 18Documento11 páginasNotesch # 18ZeeshanMahdiAún no hay calificaciones

- Análisis de Textura en Frutas CongeladasDocumento9 páginasAnálisis de Textura en Frutas CongeladasJORGEAún no hay calificaciones

- SugarcaneDocumento83 páginasSugarcaneabrahanAún no hay calificaciones

- Low Power CMOS VLSI Circuit Design (LPVD) : Dr. Veena S ChakravarthiDocumento43 páginasLow Power CMOS VLSI Circuit Design (LPVD) : Dr. Veena S ChakravarthiVeena SridharAún no hay calificaciones

- Project Work On Water Tank Cleaning MachineDocumento2 páginasProject Work On Water Tank Cleaning MachinePrakash Pokhrel100% (1)

- Ass 1 SDFGHJK DFGHJK DFGHJK Ertyuiop SDFGHJKLDocumento10 páginasAss 1 SDFGHJK DFGHJK DFGHJK Ertyuiop SDFGHJKLriniz92Aún no hay calificaciones

- TurbidityDocumento4 páginasTurbiditylaxminarayanAún no hay calificaciones

- Horizontal/Slant/Vertical Wells: SPE 24352 Analysis of L Nflow Performance Simulation of Solution-Gas Drive ForDocumento10 páginasHorizontal/Slant/Vertical Wells: SPE 24352 Analysis of L Nflow Performance Simulation of Solution-Gas Drive FormaharabdAún no hay calificaciones

- Ur m60Documento3 páginasUr m60Goran JurisicAún no hay calificaciones

- A Review On Techniques To Enhance Electrochemical Remediation of Contaminated SoilsDocumento19 páginasA Review On Techniques To Enhance Electrochemical Remediation of Contaminated SoilsAdelina96Aún no hay calificaciones

- 99ebook Com Msg00388 PDFDocumento15 páginas99ebook Com Msg00388 PDFM Sarmad KhanAún no hay calificaciones

- Work WsDocumento5 páginasWork Wsapi-261954479Aún no hay calificaciones

- Bisection - Method For One Equation2 - ENDocumento4 páginasBisection - Method For One Equation2 - ENsegorin2Aún no hay calificaciones

- Gases AnswersDocumento8 páginasGases AnswersSayAún no hay calificaciones

- Indion 850 Resin Engg Data SheetDocumento6 páginasIndion 850 Resin Engg Data SheetsoumitrabanAún no hay calificaciones