Documentos de Académico

Documentos de Profesional

Documentos de Cultura

AB Wool Glasswool

Cargado por

Catur Oka NurfansyahDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

AB Wool Glasswool

Cargado por

Catur Oka NurfansyahCopyright:

Formatos disponibles

Glasswool

FEATURES

AB Wool Insulation glasswool are lightweight, flexible and resilient, they provide excellent

thermal insulation for flat or low-picthed roof using metal decking or asbestoscement

roofing sheet. In places where condensation exists.

AB Wool Insulation glasswool must be faced with a reflective alumunium foil vapour barrier.

PRODUCT APPLICATION

AB Wool Insulation glasswool are used for external lagging air condition ducts and thermal

Insulation of roofs, etc.

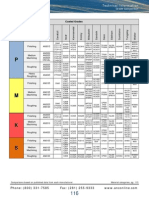

PHYSICAL CHARACTERISTICS

Type

Blanket

3

16

Nominal Density (kg/m )

Sheet

24

32

48

Nominal Thickness (mm)

25

50

25

50

25

50

25

50

Standard Width (m)

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

30

15

30

15

30

15

2.3

2.3

0.40

0.80

0.60

1.20

1.80

1.60

1.20

2.40

Standard Length (m)

2

Mass Perunit Area (kg/m )

THERMAL CONDUCTIVITY (K-Value)

- Density 16 kg/m3 (0.037 W/mk) at 20oC mean temperature

(0.257 BTU-in/hr.ft2oF at 68oF mean temperature.)

Thermal conductivity (K), W/mk

Deformation Of nominal thickness, %

Ductwrap 16

- Density 24 kg/m3 (0.035 W/mk) at 20oC mean temperature

(0,243 BTU-in/hr.ft2oF at 68oF mean temperature.)

125

- Density 32 kg/m3 (0,034 W/mk) at 20oC mean temperature

(0,236 BTU-in/hr.ft2oF at 68oF mean temperature.)

100

80

60

40

5

10

15 20

25

2

Compressive loading, kN/m

0.10

Type

0.06

20 40 60 80 100 120 140 160

Mean Temperature C

Deformation Of nominal thickness, %

Nominal Thickness (mm)

Thermal Conductivity

(K)

Thermal Conductance

125

(C)

100

Thermal Resistance

80

(R)

60

0

5

10

15 20

25

2

Compressive loading, kN/m

0.10

0.08

0.06

0.04

0.02

16

Nominal Density (kg./m )

40

Blanket

3

0.04

0.02

At mean temperatur 20 C (metric value) and 68 C (imperial value)

0.08

Ductwrap 24

Thermal conductivity (K), W/mk

- Density 48 kg/m3 (0,033 W/mk) at 20oC mean temperature

(0,229 BTU-in/hr.ft2oF at 68oF mean temperature.)

* Mean temperature = (T1+T2)/2

Where T1 = Temperature of hot side of insulation

T2 = Temperature of cool side of insulation

20 40 60 80 100 120 140 160

o

Mean Temperature C

25

Sheet

24

50

25

48

32

50

25

50

25

50

0.037 0.037 0.035 0.035 0.034 0.034 0.033 0.033

W/mK

2 o

BTU in/hr.ft . F

2

W/m K

2 o

BTU in/hr.ft . F

0.257 0.257 0.243 0.243 0.236 0.236 0.229 0.229

1.48

0.74

1.40

0.70

1.36

0.68

1.32

0.66

0.26

0.13

0.24

0.12

0.24

0.12

0.23

0.11

0.67

1.35

0.71

1.43

0.74

1.47

0.76

1.52

2 o

3.89

7.78

4.12

8.23

4.24

8.47

4.37

8.73

m K/W

hr.ft . F/BTU

Thermal conductivity (K), W/mk

Deformation Of nominal thickness, %

Ductwrap 32

Glasswool

100

80

60

40

MOISTURE ABSORPTION

20

0

5 10 15 20 25 30 35 40

2

Compressive loading, kN/m

AKALINITY

0.09

0.08

0.07

0.06

0.05

0.04

0.03

0.02

When tested in accordance with British Standard 3958 AB Wool Insulation glasswool is

slightly alkaline pH9.

MAXIMUM SERVICE TEMPERATURE

o

20 40 60 80 100 120 140 160180 200

o

Mean Temperature C

Deformation Of nominal thickness, %

Ductwrap 48

Thermal conductivity (K), W/mk

When tested in an atmosphere of 65% relative humidity at 20oC (in accordance with

British Standard 2972-1975), the moisture content of AB Wool Insulation glasswool

is 0,1% by volume.

The maximum service temperature for AB Wool Insulation glasswool is 340 C.

Where facing are applied, the temperature tolerances of the facing adhesive limit the

o

surface temperature to be 70 C. (The appropriate insulation thickness can be used to

o

limit surface temperature to 70 C.)

SOUND ABSORPTION C0-EFFICIENT

AB Wool Insulation glasswool has the following sound absorption coefficient when tested in

accordance with AS 1045 - 1971 by th Reverberation Room Method.

Tests were carried out with no air space behind the samples, and results are based on test

reports from C.S.I.R.O. or other N.A.T.a Registered laboratories.

100

80

60

40

20

0

5 10 15 20 25 30 35 40

2

Compressive loading, kN/m

0.09

0.08

0.07

0.06

0.05

0.04

0.03

0.02

20 40 60 80 100 120 140 160180 200

o

Mean Temperature C

Sond Absorption Coefficient (reverberation)

Nominal Density Nominal Thickness

Frequency - Hz

3

(kg./m )

(Mm)

125 250 500 1000 2000 NRC

16

25

0.28 0.30 0.37 0.61 0.78 0.52

16

50

0.25 0.47 0.74 0.79 0.81 0.70

24

25

0.16 0.27 0.57 0.79 0.90 0.63

24

50

0.26 0.55 0.92 1.05 1.04 0.89

32

25

0.15 0.33 0.64 0.77 0.88 0.65

32

50

0.26 0.59 0.98 1.04 1.03 0.90

48

25

0.08 0.25 0.64 0.90 1.05 0.71

48

50

0.27 0.79 1.11 1.18 1.10 1.05

Result tested in accordance with AS 1045 - 1976 By the Reverberation Room Method

Ducting Insulation: Outside

AB Foil

AB Wool

AB Coat

Lokfom

Galvanize

Ducting Insulation: Inside

AB Coat

Lokfom

Galvanize

Tilement

Spindle Pin

FIRE PERFORMANCE

AB Wool Insulation glasswool products are non-combustible. When it is exposed to the

conditions of the test specified in British Standard 476: Part 4: 1970 Fire Test on Building

Materials and Structures - Non-combustibility Test for Materials.

RESULTS:

Description

Specimen 1

Specimen 2

Specimen 3

Requirements

Time of continuous flaming (sec.)

<10

Temperature rise of furnace (C)

28

21

19

<50

Temperature rise of sample (C)

Classification

AB Wool

<50

NonCombustion

NonCombustion

NonCombustion

AB Cloth

PRODUCT BENEFIT

Wire Mesh

- Energy Conservation - Noise Reduction

- Personnel Protection

- Temperature Control - Condensation Control - Etc

AUTHORIZED DISTRIBUTOR

INSULATION, BUILDING, AIRCON & INDUSTRIAL INSTALLATION MATERIALS

Jl. Pangeran Jayakarta 131 - A / 11, Jakarta 10730 - INDONESIA

Telp. (021) 6257888 (H), 6397888 (H) Fax. (021) 6258836 - 6393079

website : www.adimasisolasitama.com

E-mail : adimas@adimasisolasitama.com

También podría gustarte

- Glasswool Spec PDFDocumento3 páginasGlasswool Spec PDFabhishek198327Aún no hay calificaciones

- SMP Multi Rifled TubesDocumento12 páginasSMP Multi Rifled TubesDiego Martínez FernándezAún no hay calificaciones

- Kalpraxis Cement Plants PDFDocumento14 páginasKalpraxis Cement Plants PDFalbertbunguriAún no hay calificaciones

- Thep Nhat-Han For DesignDocumento10 páginasThep Nhat-Han For DesignNhuVan NguyenAún no hay calificaciones

- Spring SteelDocumento2 páginasSpring Steelvaishu1502Aún no hay calificaciones

- Nanotech PaintingDocumento16 páginasNanotech Paintingkr_abhijeet72356587Aún no hay calificaciones

- Vautid 100Documento4 páginasVautid 100emad sabriAún no hay calificaciones

- European Steel and Alloy Grades: S235JRG2 (1.0038)Documento2 páginasEuropean Steel and Alloy Grades: S235JRG2 (1.0038)farshid KarpasandAún no hay calificaciones

- SUS 316 Material Properties PDFDocumento1 páginaSUS 316 Material Properties PDFYudo ArdianAún no hay calificaciones

- GB 3087Documento14 páginasGB 3087QUYEN TRANAún no hay calificaciones

- Hangzhou Shanli Purify Equipment Spare Parts Quotation Less Than $8,100Documento1 páginaHangzhou Shanli Purify Equipment Spare Parts Quotation Less Than $8,100Syed Muhammad AfzalAún no hay calificaciones

- Hydac FilterDocumento6 páginasHydac FilterAlexander Ruiz IbagueAún no hay calificaciones

- Sealing DIN 3670 - 5Documento2 páginasSealing DIN 3670 - 5Tobajasz HermaniuszAún no hay calificaciones

- Multi-Rifled Boiler Tubes Improve Heat Transfer EfficiencyDocumento8 páginasMulti-Rifled Boiler Tubes Improve Heat Transfer EfficiencyböhmitAún no hay calificaciones

- PGE Tech GPT PDFDocumento2 páginasPGE Tech GPT PDFAnonymous 1ykzuaxWgYAún no hay calificaciones

- Hardox 500 Sheet: General Product DescriptionDocumento2 páginasHardox 500 Sheet: General Product DescriptionDylkanWingsAún no hay calificaciones

- Aisi 9254 - Spring SteelDocumento2 páginasAisi 9254 - Spring SteelSergio100% (1)

- Sandvik PipeDocumento4 páginasSandvik PipeMarcelene Justine DionisioAún no hay calificaciones

- Hydac Filter ElementsDocumento30 páginasHydac Filter Elementsatorresh090675Aún no hay calificaciones

- Jis - 5k & 16k - Globe Valve - CatalogDocumento53 páginasJis - 5k & 16k - Globe Valve - CatalogRajesh ChoudharyAún no hay calificaciones

- Kalmetall W Kalpraxis GBDocumento12 páginasKalmetall W Kalpraxis GBkaniappan sakthivelAún no hay calificaciones

- Shell-Morlina-S2-BL-10 (TDS) PDFDocumento2 páginasShell-Morlina-S2-BL-10 (TDS) PDFOtjpag NizarAún no hay calificaciones

- Materials Comparison: Steel Grades in JIS, Foreign, and European StandardsDocumento1 páginaMaterials Comparison: Steel Grades in JIS, Foreign, and European Standardswulfgang66Aún no hay calificaciones

- Evaporative Condenser in Stainless SteelDocumento11 páginasEvaporative Condenser in Stainless Steeljose luisAún no hay calificaciones

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocumento2 páginasAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987Aún no hay calificaciones

- STAUFF Catalogue 9 STAUFF Filtration Technology English PDFDocumento216 páginasSTAUFF Catalogue 9 STAUFF Filtration Technology English PDFHernan MartAún no hay calificaciones

- Schunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFDocumento2 páginasSchunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFMUHAMMAD ASYRAAF BIN ANUARAún no hay calificaciones

- 1.9.1.2-ALCRO - Arc Sprayed Iron-Chrome-Aluminum WireDocumento4 páginas1.9.1.2-ALCRO - Arc Sprayed Iron-Chrome-Aluminum WirechonubobbyAún no hay calificaciones

- As 2660-1991 Hose and Hose Assemblies - Air Water - For Underground Coal MinesDocumento5 páginasAs 2660-1991 Hose and Hose Assemblies - Air Water - For Underground Coal MinesSAI Global - APACAún no hay calificaciones

- Jis G4051 PDFDocumento13 páginasJis G4051 PDFParthi NatarajAún no hay calificaciones

- Krautkramer Thickness Gauge Probes and Accessories Price ListDocumento7 páginasKrautkramer Thickness Gauge Probes and Accessories Price List7043578600Aún no hay calificaciones

- Stainless Steel Alloys Comparsion ChartDocumento3 páginasStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- Manufacturing Process of Rolling Element Bearing NewDocumento26 páginasManufacturing Process of Rolling Element Bearing NewRamakanth P JoshiAún no hay calificaciones

- BS2L99 Alloy DetailDocumento2 páginasBS2L99 Alloy Detailcharles_boyle_3Aún no hay calificaciones

- WA SeriesDocumento24 páginasWA SeriesNoushad P Hamsa100% (1)

- Kunlun Ki25x TdsDocumento2 páginasKunlun Ki25x TdsTriWijaya PurnamaAún no hay calificaciones

- Technical Information: Grade Comparison ChartDocumento2 páginasTechnical Information: Grade Comparison ChartsansagithAún no hay calificaciones

- Gs Hydro CatalogDocumento186 páginasGs Hydro CatalogjcAún no hay calificaciones

- B467Documento8 páginasB467odqm_25Aún no hay calificaciones

- Everything You Need to Know About Q235 SteelDocumento5 páginasEverything You Need to Know About Q235 SteelpierocarnelociAún no hay calificaciones

- JIS G4801 SUP10 Steel GuideDocumento2 páginasJIS G4801 SUP10 Steel GuideĐình Sỹ TTPAún no hay calificaciones

- KVC Ball ValvesDocumento8 páginasKVC Ball ValvesDenstar Ricardo SilalahiAún no hay calificaciones

- MSS11 R2.0Documento2164 páginasMSS11 R2.0tammy_garnerAún no hay calificaciones

- Zeus Catalog 11Documento76 páginasZeus Catalog 11a100acomAún no hay calificaciones

- Carbon Arc Cutting PDFDocumento44 páginasCarbon Arc Cutting PDFMark InnesAún no hay calificaciones

- Survey Steel Grades MarkenübersichtDocumento12 páginasSurvey Steel Grades MarkenübersichtLeandro AlmeidaAún no hay calificaciones

- 304 Stainless Steel Data Sheet Explains Properties & UsesDocumento4 páginas304 Stainless Steel Data Sheet Explains Properties & UsesMani KannaAún no hay calificaciones

- SN757 2005-05 eDocumento4 páginasSN757 2005-05 ehasan_676489616Aún no hay calificaciones

- Hydraulics 2015 Product CatalogDocumento442 páginasHydraulics 2015 Product CatalogAlex Maceira GraterolAún no hay calificaciones

- JIS C 3406 (1971) - Auto CablesDocumento1 páginaJIS C 3406 (1971) - Auto CablesBrandon BroAún no hay calificaciones

- NMJT 2 LatestDocumento19 páginasNMJT 2 LatestAnonymous pSozzNFcAún no hay calificaciones

- S235jr Carbon SteelDocumento2 páginasS235jr Carbon Steelcheligp1981Aún no hay calificaciones

- LDP Series Actuator - DEMBLADocumento4 páginasLDP Series Actuator - DEMBLAKamitkumar PatelAún no hay calificaciones

- Brosur Glass WoolDocumento3 páginasBrosur Glass WoolHarry NovfriandiAún no hay calificaciones

- LIGHTWEIGHT, NON-SAGGING BUILDING INSULATIONDocumento8 páginasLIGHTWEIGHT, NON-SAGGING BUILDING INSULATIONPhan LongAún no hay calificaciones

- Power MVDocumento39 páginasPower MVFani Dwi PutraAún no hay calificaciones

- 11kV 3 Core PILC SWA BS6480 Cable SpecificationDocumento3 páginas11kV 3 Core PILC SWA BS6480 Cable SpecificationMuhammad TaufiqAún no hay calificaciones

- Glasswool Insulation PropertiesDocumento2 páginasGlasswool Insulation PropertiesDerahamaniAún no hay calificaciones

- SET Ingenieros Technical Specification for 2XS(FL)H-GC-WTC 1x500RM/180 40/69 (72.5)kV CableDocumento3 páginasSET Ingenieros Technical Specification for 2XS(FL)H-GC-WTC 1x500RM/180 40/69 (72.5)kV CableedwinljbAún no hay calificaciones

- CRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaDocumento4 páginasCRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaKarthikeyan VkAún no hay calificaciones

- AC Splite (Andi)Documento5 páginasAC Splite (Andi)Catur Oka NurfansyahAún no hay calificaciones

- Kios Monitoring Schedule and Completion SequenceDocumento69 páginasKios Monitoring Schedule and Completion SequenceCatur Oka NurfansyahAún no hay calificaciones

- Appendix E - Piping Material SpecsDocumento6 páginasAppendix E - Piping Material Specssanjayt0100% (1)

- A - Piping Joint HandbookDocumento161 páginasA - Piping Joint HandbookCharles Tauk100% (30)

- Dialogue KelDocumento1 páginaDialogue KelCatur Oka NurfansyahAún no hay calificaciones

- Ashrae Standard Designation and Safety Classification of RefrigerantsDocumento12 páginasAshrae Standard Designation and Safety Classification of RefrigerantsArul SankaranAún no hay calificaciones

- Caesar Book MaterialDocumento148 páginasCaesar Book MaterialCatur Oka Nurfansyah100% (11)

- Dfent ReadmeDocumento2 páginasDfent ReadmeCatur Oka NurfansyahAún no hay calificaciones

- 2011 Bolts, Nuts & WashersDocumento6 páginas2011 Bolts, Nuts & WashersCatur Oka NurfansyahAún no hay calificaciones

- MRC Bearing CatalogDocumento404 páginasMRC Bearing CatalogRajagopal100% (3)

- Brake SystemDocumento12 páginasBrake SystemCatur Oka NurfansyahAún no hay calificaciones

- HandphoneDocumento1 páginaHandphoneCatur Oka NurfansyahAún no hay calificaciones

- Doc1 PDFDocumento1 páginaDoc1 PDFCatur Oka NurfansyahAún no hay calificaciones

- Center of Gravity CalculatorDocumento2 páginasCenter of Gravity CalculatorAalekh PrajapatiAún no hay calificaciones

- Basic Pipe Stress Analysis TutorianyrnyrnlDocumento26 páginasBasic Pipe Stress Analysis TutorianyrnyrnlCatur Oka Nurfansyah100% (1)

- Diagram Moody 3Documento1 páginaDiagram Moody 3Catur Oka NurfansyahAún no hay calificaciones

- Spesification AE865tv5v5tv5v5v5Documento2 páginasSpesification AE865tv5v5tv5v5v5Catur Oka NurfansyahAún no hay calificaciones

- Doc1 PDFDocumento1 páginaDoc1 PDFCatur Oka NurfansyahAún no hay calificaciones

- 2008 ASHRAE Handbook License Agreement: I Agree Idonot AgreeDocumento1 página2008 ASHRAE Handbook License Agreement: I Agree Idonot AgreeCatur Oka NurfansyahAún no hay calificaciones

- 2n3055 (NPN), Mj2955 (PNP)Documento4 páginas2n3055 (NPN), Mj2955 (PNP)chikulenkaAún no hay calificaciones

- Garrison: Oceanography An Invitation To Marine Science, 8e FinalDocumento22 páginasGarrison: Oceanography An Invitation To Marine Science, 8e FinalBagas IndiantoAún no hay calificaciones

- B62 0030 (Rev. B 2003.05) EN - THERMOPLASTIC, THERMOSETTING MATERIALS AND THERMOPLASTIC ELASTOMERS SPECIFICATIONS - SYMBOLSDocumento10 páginasB62 0030 (Rev. B 2003.05) EN - THERMOPLASTIC, THERMOSETTING MATERIALS AND THERMOPLASTIC ELASTOMERS SPECIFICATIONS - SYMBOLSDiego CamargoAún no hay calificaciones

- M 236 ContentDocumento103 páginasM 236 ContentgeetanandnAún no hay calificaciones

- Propagation of Surface Waves in Thermoelastic Materials with VoidsDocumento10 páginasPropagation of Surface Waves in Thermoelastic Materials with VoidsSOUMIK DASAún no hay calificaciones

- Hardness Testing Comparison Table enDocumento1 páginaHardness Testing Comparison Table ennedim cılız100% (1)

- Ranpelen PP Random Copolymer: DescriptionDocumento2 páginasRanpelen PP Random Copolymer: DescriptionVu Thanh ThuongAún no hay calificaciones

- Solar Cell Lecture-2Documento33 páginasSolar Cell Lecture-2SUNIABHIAún no hay calificaciones

- PP, PE, PVC, POM, PET, PA6G material characteristicsDocumento1 páginaPP, PE, PVC, POM, PET, PA6G material characteristicsandytuorAún no hay calificaciones

- 310 Spec SheetDocumento2 páginas310 Spec Sheetsandry CANELONESAún no hay calificaciones

- DPP - Structure of Atom - Chemistry - Victory PDFDocumento5 páginasDPP - Structure of Atom - Chemistry - Victory PDFAnshul VermaAún no hay calificaciones

- Heat Exchanger Thermal Calculation by Rey FiedacanDocumento5 páginasHeat Exchanger Thermal Calculation by Rey FiedacanRajdeepsinhAún no hay calificaciones

- Guidelines For Stress Analysis of Hdpe LinesDocumento5 páginasGuidelines For Stress Analysis of Hdpe Lineszahoor100% (1)

- Pressure and Buoyancy Calculations from Physics ProblemsDocumento5 páginasPressure and Buoyancy Calculations from Physics ProblemsRichard EngAún no hay calificaciones

- Earth Gravity and Satellite Orbits CalculationsDocumento9 páginasEarth Gravity and Satellite Orbits CalculationsYoobsan Asaffaa FufaaAún no hay calificaciones

- Chapter13 - Acids and BasesDocumento44 páginasChapter13 - Acids and BasesXiaohan TangAún no hay calificaciones

- Beam CalculationsDocumento17 páginasBeam CalculationsFellaa Supazaein100% (1)

- Pipingchevronoffshore 2Documento56 páginasPipingchevronoffshore 2Velpandian ManiAún no hay calificaciones

- Desiccant Dehumidifier MDC 18000: Forget Humidity For Ever!Documento4 páginasDesiccant Dehumidifier MDC 18000: Forget Humidity For Ever!Mourad AhmadAún no hay calificaciones

- JEE Adv. - Growth - Sample Paper-2 - StudentDocumento15 páginasJEE Adv. - Growth - Sample Paper-2 - Studentanurag jaiswalAún no hay calificaciones

- Deep Beam-1Documento14 páginasDeep Beam-1mohammed04149778Aún no hay calificaciones

- Asme Sec Viii Div-2Documento31 páginasAsme Sec Viii Div-2Yash Rami100% (3)

- Lab Report Fiber OpticsDocumento5 páginasLab Report Fiber OpticsArvinBautista100% (1)

- Fiorentini Series C Rotary Meter Offers High Accuracy and RangeabilityDocumento8 páginasFiorentini Series C Rotary Meter Offers High Accuracy and RangeabilityuceskaAún no hay calificaciones

- Validation of ENVI-met PMV Values by In-Situ Measuremen TsDocumento6 páginasValidation of ENVI-met PMV Values by In-Situ Measuremen TsHendra CesmamulyaAún no hay calificaciones

- NTN Ball and Roller Bearing CatalogDocumento399 páginasNTN Ball and Roller Bearing Catalogdaniarsalan100% (2)

- Ex3 - Fire Under Concrete Slab - Compos PDFDocumento64 páginasEx3 - Fire Under Concrete Slab - Compos PDFEmra MerdićAún no hay calificaciones

- Lab Report 1 (EXP1-Draft)Documento17 páginasLab Report 1 (EXP1-Draft)Jamiel CatapangAún no hay calificaciones

- LiteratureDocumento22 páginasLiteratureSHRADDHA KADAMAún no hay calificaciones

- Vectors - Practice Sheet - Arjuna Neet 2024Documento4 páginasVectors - Practice Sheet - Arjuna Neet 2024kumar ashvikAún no hay calificaciones

- CHH LVL Portal Frame Design Example - Sept 2008Documento92 páginasCHH LVL Portal Frame Design Example - Sept 2008podderickAún no hay calificaciones