Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Safe Work Method Statement - Plumbing

Cargado por

John KurongTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Safe Work Method Statement - Plumbing

Cargado por

John KurongCopyright:

Formatos disponibles

the Safe Work

Safe Work Method Statement - Plumbing Complete

Method Statement BEFORE

Location/Department

:

Date

Developed:

Date of

Task/Activity:

Last

Review:

Legislation, Codes of Practice, Standards used in development of SWP (list below):

Approved

By:

work is started

Signature of Person

Authorising SWMS:

Required PPE to carry

out the activity

Helmet

Boots

Eye

Vest

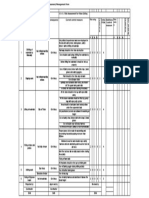

WORK ACTIVITY

HAZARDS PRESENT

(Steps in the activity/task)

(What could cause injury)

Moving vehicles

Other people staff and customers

Access

Client unaware of contractor on site

Falling objects, Hitting objects

Slips/trips/falls

Hazard substances

Noise

Biological factors

Arrival on site/ Site Inspection

Use of chemicals paints, glues, solvents,

adhesives, petrol, poisons

Manual handling activities

Hazardous substances

Manual handling/body stressing

Slips/trips

Exposure to inhalation, absorption

and ingestion

Spray drift (if spraying)

Back strain

Muscle strain

Impact injuries

Gloves

RISK

SCORE

Med

Med

Med

Hearing

Respirat

or

Harness

RISK CONTROL MEASURES

(What can be done to minimise the risk of injury)

High visibility clothing, appropriate PPE

Park in appropriate areas

Advise client of presence on site

Display identification

Sign into Visitors Log book and obtain site visitors Tag if

required

Ensure others on site are aware of your presence

Handle according l to manufacturers instructions

(including the label and MSDS)

PPE respirators, elbow length gloves, face shield,

overalls

Wear moisture resistant work boots with adequate grip

Mix on level ground, away from others

Replace lid on container

Always use backflow prevention device

Always have spill response kit available

Warm up briefly beforehand

Keep back straight, eyes fixed straight ahead; lift with

legs & not the back

Get help if load is too heavy or awkward

Dont twist

Wear safety boots and gloves if necessary

Use trolley or mechanical mean if possible

RESIDUAL RISK

SCORE

Low

Low

Low

WORK ACTIVITY

HAZARDS PRESENT

(Steps in the activity/task)

(What could cause injury)

Use of power tools

Safe use of ladders

Safe use of manual tools saws, hammers,

screwdrivers

Hot work electric or gas welding.

Soldering/Cutting

Electric shock

Burns

Skin irritations

Excessive noise

Cuts, abrasions, amputations

Eye injury

Falls, sprains and breaks

Back injury

Falling ladder if not secure

Injury from poorly maintained ladder

Cuts

Abrasions

Splinters

Eye damage due to flying debris

Burns

Welding flash

Fire

Falling oxy or acetylene

Oxy & acetylene flashback

RISK

SCORE

RISK CONTROL MEASURES

(What can be done to minimise the risk of injury)

RESIDUAL RISK

SCORE

Med

Test & tag regularly

Visually check before use to make sure all safety

features and guards are in place & there is no damage

Dont operate in wet conditions

Ensure earth leakage protections is in place and is at the

supply end of the extension lead

If device trips, dont reset and start again until cause is

found

Switch tool off if any faults or abnormal actions become

apparent

Ensure tool action is stopped before setting down

Wear appropriate PPE safety glasses, ear protection

Secure any loose hair and clothing

Low

Med

Inspect ladder prior to use make sure is in sound

condition, clean and undamaged

Use two person to carry if required

Secure ladder to structure before climbing onto steps

Have another person near the ladder supervising the

area to support the ladder

Wear appropriate footwear when climbing ladders

Have three limbs on the ladder at all times

Wear a tool pouch to carry tools

Low

Med

Watch what is being done dont be distracted by

others and activities within the work area

Wear appropriate PPE eye protection if sawing and

sanding; steel capped boots

Low

High

Transport in an open, well ventilated vehicles, If a

closed van is being used, ensure gas plugs and chains

are preventing leaks.

Wear appropriate PPE

Currently tagged in date fire extinguisher must be

available where hot work is to take place

Do not use cylinders which are standing in an enclosed

vehicle always move outside first

If there is a possibility of a leak, test with soap and

water

Ensure no flammable liquids or gases are anywhere in

vicinity

Bottles are to be chained when in upright position

Hoses re to be fitted with flash back arrestors and

regulators

After use ensure cylinder valves are tightly shut, outlet

gas plugs and valve protection caps installed .

Med

WORK ACTIVITY

HAZARDS PRESENT

(Steps in the activity/task)

(What could cause injury)

RISK

SCORE

Cutting hands

Hepatitis "B" & "C"

Uncontrolled cable coiling causing arm

strains

Electrocution

Med

Falls

Injuries to people below from falling

objects

Med

Working on sewers, drains and piping

1

0

Working at heights

11

Install new hot water unit unit.

Reconnect gas and water supply pipe-work

Manual handling-back strain

Gas leaks/Explosion from

oxy/Acetylene use

12

Locate gas leak

Head injuries

Asphyxiation (suffocation)

Explosion

High

13

Replace PC Items (basins, WC Pans etc)

Flooding causing Slips on wet floor

Scalding from hot water

Germs

High

High

RISK CONTROL MEASURES

(What can be done to minimise the risk of injury)

Wear leather gloves, clear safety glasses

Immunise workers for hepatitis "B"

Use disinfectant to wash hands to manufacturers

guidelines.

Use the foot pedal to turn the machine on & off.

Install earth leakage safety switch at all sources of

power

Test and tag 15 Amp leads every month

Elevate power leads 2m where vehicle access occurs or

potential trips are likely. Extension leads should not

exceed 35m.

When working at heights above 2 metres, ensure

appropriate fall protection is in place

Carry out risk assessment prior to starting work:

Locate power lines & stay at least 2 metres clean

Identify any other obstructions

Ensure ladders are placed on a level surface

Barricade area to remove any dangers to other people in

the area this will isolate hazards and control the risks

Use a trolley to remove the used hot water system.

Ensure work area is well ventilated

Test work area with a gas detector. Turn it on when

entering the work area.

Keep mobile phones, electrical and lighters away from

work area.

Isolate gas leads when not in use by turning off at the

bottle.

Wear appropriate PPE

Ventilate the work area by opening all doors and

windows

Ensure no flammable liquids or gases are anywhere in

vicinity

Ensure Gas cylinder valves are tight fixed.

Mop up slippery floor

Isolate hot water supply

Correct PPE Equipment

RESIDUAL RISK

SCORE

Low

Low

Low

Med

Low

This SWMS has been developed to reduce and manage the risks that are known to be on the above work site. All members of the team working on this site have read, understood and signed

this Safe Work Method Statement.

Signatures:

Risk Score Grid:

Name:

Signature:

Date:

Name:

Date:

Signature:

También podría gustarte

- Safe Work Method StatementDocumento7 páginasSafe Work Method StatementAjith NairAún no hay calificaciones

- (SWMS-01) Loading, Unloading and ShiftingDocumento5 páginas(SWMS-01) Loading, Unloading and ShiftingPRATEEK SINGH100% (2)

- SWPDocumento7 páginasSWPSamadarshi Sarkar100% (1)

- Concrete Formwork Suspended SlabDocumento5 páginasConcrete Formwork Suspended SlabKate HopleyAún no hay calificaciones

- Safe Work Procedure, Gem MaintenanceDocumento46 páginasSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- EPC-5 Project Incident RegisterDocumento6 páginasEPC-5 Project Incident RegisterAgung Tri SugihartoAún no hay calificaciones

- Biomechanics of Throwing ExplainedDocumento41 páginasBiomechanics of Throwing ExplainedApple Grace Zamora100% (1)

- Company Instrumentation Coring Works Risk AssessmentDocumento11 páginasCompany Instrumentation Coring Works Risk AssessmentJayson EscamillanAún no hay calificaciones

- 7-Block Work Risk Assessment ReportDocumento7 páginas7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- RISK ASESSMENT For SKYLIGHTDocumento23 páginasRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- Brazing (Oxygen and Acetylene)Documento6 páginasBrazing (Oxygen and Acetylene)My Zain100% (1)

- SWMSDocumento11 páginasSWMSSathika Godawatta100% (1)

- Skillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayingDocumento6 páginasSkillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayinguknandiAún no hay calificaciones

- SWMS Sandvik Asia Pvt Ltd Hot Work WeldingDocumento14 páginasSWMS Sandvik Asia Pvt Ltd Hot Work WeldingParasAún no hay calificaciones

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocumento1 páginaRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Documento9 páginasSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- Excavation Procedure & Permitting GuideDocumento4 páginasExcavation Procedure & Permitting GuideTengku & Wan ResourcesAún no hay calificaciones

- HSE Violation Fine FormDocumento1 páginaHSE Violation Fine FormGatot Edi SusantoAún no hay calificaciones

- Thohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFDocumento17 páginasThohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFbubele pamlaAún no hay calificaciones

- Head and Neck: Openings in The Base of The Skull and The Structures That Pass Through ThemDocumento11 páginasHead and Neck: Openings in The Base of The Skull and The Structures That Pass Through ThemcathdelosoAún no hay calificaciones

- SWMS Mobilisation of Blocks For MLT TEST RKDocumento14 páginasSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- Master Builders SA - Safe Work Method Statement - Roof Metal InstallationDocumento7 páginasMaster Builders SA - Safe Work Method Statement - Roof Metal InstallationvictorAún no hay calificaciones

- PARENTERAL MEDICATION Part 1Documento8 páginasPARENTERAL MEDICATION Part 1Marielle ChuaAún no hay calificaciones

- SWMS-HYD-VAYUCON-03 - Unloading and Shifting Material Through ForkliftDocumento7 páginasSWMS-HYD-VAYUCON-03 - Unloading and Shifting Material Through ForkliftBodakunta Ajay VarmaAún no hay calificaciones

- SWMS - PlumberDocumento7 páginasSWMS - PlumberSiddiqueShaikhAún no hay calificaciones

- Hazard Task Risk Control MeasuresDocumento5 páginasHazard Task Risk Control MeasuresIshan DankharaAún no hay calificaciones

- Safe Work Method StatementDocumento11 páginasSafe Work Method StatementJAún no hay calificaciones

- Rebar Job Hazard AnalysisDocumento1 páginaRebar Job Hazard Analysisjoker batmanAún no hay calificaciones

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocumento3 páginasRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanAún no hay calificaciones

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Documento18 páginasSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocumento12 páginasIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpAún no hay calificaciones

- RA - For Precast ChambersDocumento5 páginasRA - For Precast ChambersKallem RajashekarAún no hay calificaciones

- Metal Fabrication Guide SafetyDocumento46 páginasMetal Fabrication Guide SafetyRADHIKAAún no hay calificaciones

- Very Very Good Risk Assessment EnvironmentDocumento8 páginasVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- Project Safety Plan SummaryDocumento85 páginasProject Safety Plan SummaryJohn Kurong78% (9)

- Articular Fractures PrinciplesDocumento9 páginasArticular Fractures PrinciplesSylviany El NovitaAún no hay calificaciones

- Risk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Documento16 páginasRisk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Mohsin MohdAún no hay calificaciones

- HAZARD ID AND RISK ASSESSMENTDocumento17 páginasHAZARD ID AND RISK ASSESSMENTfaizan khanAún no hay calificaciones

- SWMS Scaffold FixedDocumento11 páginasSWMS Scaffold FixedEdha AliAún no hay calificaciones

- HSE guidance on safety devices for rapid roller doorsDocumento11 páginasHSE guidance on safety devices for rapid roller doorsmsc920138Aún no hay calificaciones

- TBT-Driving in FogDocumento2 páginasTBT-Driving in FogImran KhanAún no hay calificaciones

- Piling Safety PlanDocumento8 páginasPiling Safety PlanBalogun Isaac100% (1)

- Safe Work Method StatementDocumento19 páginasSafe Work Method StatementParas100% (2)

- 1b. MS 02 Installation of FencingDocumento17 páginas1b. MS 02 Installation of Fencinghamidsk100% (1)

- Ductile Iron Pipe Installation Guide 05 2015Documento134 páginasDuctile Iron Pipe Installation Guide 05 2015Anonymous R7EKGEDAún no hay calificaciones

- Excavation Safety ProceduresDocumento7 páginasExcavation Safety ProceduresHasanuddin HAMIDAún no hay calificaciones

- Forensic Medicine & Toxicology QBDocumento140 páginasForensic Medicine & Toxicology QBShaban YasserAún no hay calificaciones

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocumento13 páginasJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Plumber - Drainer SWMSDocumento12 páginasPlumber - Drainer SWMSallen2912100% (1)

- Safe Work Method StatementDocumento4 páginasSafe Work Method StatementShahed Facebook100% (1)

- Factory Acceptance Test Report - MixerDocumento1 páginaFactory Acceptance Test Report - MixerJohn KurongAún no hay calificaciones

- Safe Work Method Statement Template SampleDocumento5 páginasSafe Work Method Statement Template SampleTAHER AMMARAún no hay calificaciones

- Ladder Log Ladder Inspection ChecklistDocumento2 páginasLadder Log Ladder Inspection Checklistkhalis100% (1)

- SWMS - Glass PartitionDocumento11 páginasSWMS - Glass PartitionParasAún no hay calificaciones

- JSA FormDocumento6 páginasJSA FormAjeesh CochinAún no hay calificaciones

- Risk Assessment For Partition MarkingDocumento5 páginasRisk Assessment For Partition Markingkhalid14Aún no hay calificaciones

- Brick Masonry - EHS Risk AssessmentDocumento2 páginasBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocumento2 páginasSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherAún no hay calificaciones

- Giles Retention Exam Giles Retention ExamDocumento28 páginasGiles Retention Exam Giles Retention ExamAnne Serneo100% (1)

- Detailed Lesson Plan in Health (Final Demo)Documento4 páginasDetailed Lesson Plan in Health (Final Demo)Maria Gizella Valencia Paa80% (71)

- Safety Method StatementDocumento14 páginasSafety Method StatementnayakyaAún no hay calificaciones

- Cunninghams Manual of Practical Anatomy v3 1000902964Documento624 páginasCunninghams Manual of Practical Anatomy v3 1000902964adiseifAún no hay calificaciones

- Akk Jha Installation of Diesel TankDocumento3 páginasAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Suspended From Man-Rider (Vertical Rescue Plan)Documento1 páginaSuspended From Man-Rider (Vertical Rescue Plan)Paul100% (1)

- Method Statement For Installation of Temporary Plumbing, Drainage System and Electrical SupplyDocumento48 páginasMethod Statement For Installation of Temporary Plumbing, Drainage System and Electrical SupplyAnandu AshokanAún no hay calificaciones

- Method Statements 02 - Work at HeightDocumento10 páginasMethod Statements 02 - Work at HeightMathewAún no hay calificaciones

- JSO Cable Drum (02 Sept.'07)Documento2 páginasJSO Cable Drum (02 Sept.'07)Francis Enriquez TanAún no hay calificaciones

- HIRA No. 02-Use of Access Scaffolding SBDDocumento2 páginasHIRA No. 02-Use of Access Scaffolding SBDVenkadesh Periathambi25% (4)

- SMS - SF 4.4.6.6.1 Method Statement Glass Partition InstallationDocumento7 páginasSMS - SF 4.4.6.6.1 Method Statement Glass Partition InstallationAli SahibzadaAún no hay calificaciones

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocumento4 páginasJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradAún no hay calificaciones

- Risk Assessment Template For Combo Roof Waterproofing Work.Documento14 páginasRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaAún no hay calificaciones

- SWMS 1 Loading, Unloading & ShiftingDocumento8 páginasSWMS 1 Loading, Unloading & ShiftingJ.j.JijoAún no hay calificaciones

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyDocumento4 páginasJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqAún no hay calificaciones

- Example JSADocumento3 páginasExample JSAnattwa2010Aún no hay calificaciones

- Water Resources: Part 3: DisinfectionDocumento12 páginasWater Resources: Part 3: DisinfectionJohn KurongAún no hay calificaciones

- Southern Steel Supplies Complete Catalogue March 2019Documento43 páginasSouthern Steel Supplies Complete Catalogue March 2019John KurongAún no hay calificaciones

- Dimensional Analysis A A SoninDocumento57 páginasDimensional Analysis A A SoninJeff WebbAún no hay calificaciones

- Front Page Garaj TYTDocumento8 páginasFront Page Garaj TYTJohn KurongAún no hay calificaciones

- Price list for digital mall outlet IT productsDocumento2 páginasPrice list for digital mall outlet IT productsStefan Klaus MelitonAún no hay calificaciones

- Example Population EstimationDocumento2 páginasExample Population EstimationJohn KurongAún no hay calificaciones

- Aveva PlantDocumento6 páginasAveva PlantKhalil Ibrahim AhmedAún no hay calificaciones

- Work ProgramDocumento1 páginaWork ProgramJohn KurongAún no hay calificaciones

- Bar Construction PDFDocumento1 páginaBar Construction PDFJohn KurongAún no hay calificaciones

- PC Price 2017Documento2 páginasPC Price 2017John KurongAún no hay calificaciones

- Example Population EstimationDocumento2 páginasExample Population EstimationJohn KurongAún no hay calificaciones

- Bil AirDocumento6 páginasBil AirJohn KurongAún no hay calificaciones

- Construction Methodology Flow ChartDocumento1 páginaConstruction Methodology Flow ChartJohn KurongAún no hay calificaciones

- 1Documento2 páginas1John KurongAún no hay calificaciones

- NIOSH-PDD-CSAESPRDocumento3 páginasNIOSH-PDD-CSAESPRJohn KurongAún no hay calificaciones

- PR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionDocumento37 páginasPR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionsurnaikAún no hay calificaciones

- 772 - Wall Penstock - MIDocumento15 páginas772 - Wall Penstock - MIJohn KurongAún no hay calificaciones

- T-308 Admixture - Edition 2015Documento2 páginasT-308 Admixture - Edition 2015John Kurong100% (1)

- T 305 CatalogueDocumento2 páginasT 305 CatalogueJohn KurongAún no hay calificaciones

- Job Hazard Analysis Template SampleDocumento2 páginasJob Hazard Analysis Template SampleJohn KurongAún no hay calificaciones

- Pentens ProductDocumento17 páginasPentens ProductJohn KurongAún no hay calificaciones

- Risk Management Techniques HAZOP and HAZ PDFDocumento4 páginasRisk Management Techniques HAZOP and HAZ PDFJohn KurongAún no hay calificaciones

- Light Welding Operations: Safe Work PracticeDocumento2 páginasLight Welding Operations: Safe Work PracticeJohn KurongAún no hay calificaciones

- EMP Procedure in MalaysiaDocumento24 páginasEMP Procedure in Malaysialamkinpark3373Aún no hay calificaciones

- Kinematics of The Ankle and Foot.Documento31 páginasKinematics of The Ankle and Foot.Sneha ParveenAún no hay calificaciones

- Surgery by HamoudDocumento89 páginasSurgery by Hamoudelhamy magdyAún no hay calificaciones

- 2017 10 User Manual Laevo V2.5.0 ENDocumento23 páginas2017 10 User Manual Laevo V2.5.0 ENCarlosAún no hay calificaciones

- Cryotherapy For Acute Ankle Sprains - A Randomised Controlled Study of Two Different Icing ProtocolsDocumento7 páginasCryotherapy For Acute Ankle Sprains - A Randomised Controlled Study of Two Different Icing ProtocolsBlessing NyazikaAún no hay calificaciones

- IOACON 2021 Goa Conference DetailsDocumento16 páginasIOACON 2021 Goa Conference DetailsDr Jaspreet Singh0% (1)

- BonaireDocumento40 páginasBonaireKabya ShresthaAún no hay calificaciones

- Bandaging and Dressing Grade 9 HealthDocumento12 páginasBandaging and Dressing Grade 9 HealthkaekyokaAún no hay calificaciones

- Injection Techniques On Pathology of ShoulderDocumento51 páginasInjection Techniques On Pathology of ShoulderSafitri MuhlisaAún no hay calificaciones

- REFRIGERADOR - 316980H01 - Rev C - Thermo Scientific General Purpose and Chromatography Laboratory Refrigerators With Alarms - User ManualDocumento26 páginasREFRIGERADOR - 316980H01 - Rev C - Thermo Scientific General Purpose and Chromatography Laboratory Refrigerators With Alarms - User ManualJolukalel CamargoAún no hay calificaciones

- C VADocumento25 páginasC VAsudeepminz15Aún no hay calificaciones

- Course Format EmergencyDocumento5 páginasCourse Format Emergencyazizi ahmad nordinAún no hay calificaciones

- NURSING CARE PLAN - FractureDocumento2 páginasNURSING CARE PLAN - FractureAbdallah Alasal100% (1)

- Bruises, Blisters, Sprain, Dislocation First AidDocumento9 páginasBruises, Blisters, Sprain, Dislocation First AidGWYNETH REIN CARI�OAún no hay calificaciones

- Auerbachs Wilderness Medicine 2 Volume Set 7th EditionDocumento61 páginasAuerbachs Wilderness Medicine 2 Volume Set 7th Editionmatthew.grasso983100% (42)

- Human Anatomy Objectives WAPT 2022Documento5 páginasHuman Anatomy Objectives WAPT 2022ExcelAún no hay calificaciones

- Warm Up For TaekwondoDocumento8 páginasWarm Up For TaekwondoAki ZamiraAún no hay calificaciones

- Health Optimizing Physical Education 1: Jethro Leo P. Almaden Grade 11 - DuhatDocumento22 páginasHealth Optimizing Physical Education 1: Jethro Leo P. Almaden Grade 11 - DuhatJethro Leo AlmadenAún no hay calificaciones

- Necrotizing Soft Tissue Infections GuideDocumento21 páginasNecrotizing Soft Tissue Infections GuideHen RyAún no hay calificaciones

- Let Your Guard Down-INGLESDocumento28 páginasLet Your Guard Down-INGLESYESSYTAESAún no hay calificaciones

- A/w AvnDocumento7 páginasA/w Avnlaw0516Aún no hay calificaciones

- Clinical Neurology and NeurosurgeryDocumento4 páginasClinical Neurology and NeurosurgeryGissela AlvaradoAún no hay calificaciones