Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Shipyard Risk Assessment & JH143 Survey Evaluation

Cargado por

Mohamed FouadTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Shipyard Risk Assessment & JH143 Survey Evaluation

Cargado por

Mohamed FouadCopyright:

Formatos disponibles

LIU Technical Bulletin

Shipyard Risk Assessment &

JH143 Surveys

LIU Technical Bulletin

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Shipyard Risk Assessment &

JH143 Surveys

LIU Technical Bulletins help our clients manage business and operational risks. The Bulletin is written for Shipyard

and Owner management teams and focuses on the various component areas of the JH143 survey, and the way this

information is evaluated by our risk engineers and underwriters.

In the first decade of the 21st Century, the shipbuilding industry underwent a boom which continued well past the

beginning of the global financial crisis. Changes in the world economy played a part not just in determining the number

and type of ships to be built, but where they were to be built.

Nowhere has the shift in global manufacturing been more pronounced than in shipbuilding. Where once most of the

worlds merchant tonnage was constructed in Europe and the United States, the center of world shipbuilding began

shifting to Japan in the 1960s, moving into Korea in the following decade, and finally to China, which has become the

worlds leading shipbuilder.

Aerial View of a Major Building and Repair Yard

Newbuild Vessel on Slipway Prior to Launch

As all of these changes were taking place, the complexity and value of the ships that builders risk underwriters were

insuring was also increasing. All of these circumstances came together when the market was hit by a series of

significant builders risk losses, mostly due to fire.

The information in this document is presented by Liberty International Underwriters Pte Limited (UEN. 201538069C).The information

contained herein should not be considered loss control or prevention advice. This information is intended to provide general

information only. You should not act on the basis of information contained within this communication without first obtaining specific

professional advice. Insurance coverage is subject to the terms and conditions of the policies as issued. Whether or to what extent a

particular loss is covered depends on the facts and circumstances of the loss and the terms and conditions of the policy as issued and

the risks involved. This information is current as at July 2012.

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

At one point, underwriters had been exposed to losses totalling approximately US$ 740 million against premiums of

approximately US$ 140 million. This state of affairs was unsustainable, and the problem was discussed and

addressed by the Joint Hull Committee of Lloyds in 2003.

The committee identified a number of areas that could contribute to the occurrence and magnitude of a loss, and

developed a survey warranty which required that a risk assessment survey be carried out of a given yard either prior to

the binding of a policy or as a condition. In line with Joint Hull committee practice, these surveys became known as

JH143 surveys.

A JH143 survey is intended to provide underwriters with a thorough understanding of the nature of the risk they are

insuring, and to provide meaningful risk management and reduction guidance to the yards. JH143 surveys evaluate a

yard in terms of the following areas:

Environmental and Geographical Risks

Site Safety

Theft & Personnel

Fire-Fighting Systems

Atmospheric Monitoring and Control of

Industrial Gases

Processes and Procedures

Management of subcontractors

General Site Conditions & Housekeeping

Yard equipment

Emergency Response Plans

Permit to Work Systems

Launching and Sea Trials

Quality Assurance/ Quality Control

Casualty History

In each area, the attending surveyor meets with the yard and owner project teams and gathers information. A through

physical survey of the site is then conducted to evaluate the effectiveness of production and safety systems. A letter

grade is then assigned to each subject area, which are then combined into a single average letter grade for the whole

yard.

The letter grade enables an underwriter to determine with a reasonable degree of certainty the existing level of risk

and the specific actions needed to keep their exposure within reasonable boundaries. (Builders Risk policies do not

respond to construction delays, which are normally addressed contractually.)

A shipyards risk exposure can be broadly divided into two categories:

Those to which the yard is exposed; and

Those to which the vessel under construction is exposed.

The JH143 survey examines these areas, management systems and prior history when developing the risk profile and

final grade for the yard.

Yard Risks

Environmental and Geographical Exposures

The location of a yard is driven by a number of factors, including the cost of land, proximity to the coast and trade

routes, ease of access and distance from industrial support and supply infrastructure. While it may be beneficial to site

a yard far up a river, a difficult transit will deter shipowners. In any event, yards located along major rivers can be

vulnerable to flooding or storm surges.

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Some regions are vulnerable to earthquakes, volcanic activity, tropical storms or tsunamis and these also need to be

considered. Recent examples of losses resulting from this type of risk include yards damaged during the March, 2011

tsunami in Japan.

General Site Conditions and Housekeeping

When infrastructure is properly maintained, materials are stored in an orderly manner, and waste is regularly and

properly disposed of, a safe and healthy work environment results. This in turn leads to a more productive, quality

oriented workforce. A key indicator of good housekeeping is the storage and handling of hazardous materials and

waste.

An Example of Poor Waste Management

An Orderly Storage Area

Well organized waste reception and disposal facilities are

essential to shipyard safety

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Site Safety

This component of the JH143 is closely related to the previous section. A successful enterprise needs to develop and

nurture a safety culture throughout the organization. Workers need to be provided with personal protective equipment,

such as safety glasses, safety boots, hardhats and safety harnesses. But it is not enough to merely provide

equipment. Training in proper use must also be provided.

A safety culture has a number of advantages; a safe workforce is more likely to produce a quality product, with less

time being devoted to work slowdowns and lost time injuries (LTI). Unsafe conditions also lead to poor morale and

resentment, which in turn cause poor quality and increase the likelihood of claims.

When injuries do occur, facilities should be provided for rapid response and treatment, such as on-site clinics and

ambulances. The nature of the industrial injuries which can occur in a shipyard should be discussed with local

hospitals, and contingency plans put in place to manage them.

Worker Safety Signage

Regular Inspection and Certification of Scaffolding is

Essential for Worker Safety

Yard Equipment

For any project, whether or not the yard owns, or can obtain the equipment necessary to complete it successfully is a

key consideration. The type and amount of equipment available is important, and so is the maintenance.

Colour Coded Rigging is Regularly Inspected

Shipyards Utilise many different types of Lifting Gear

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Welding Machines

Mobile Crane

A surveyor carrying out a JH143 survey will review the yards equipment list, and assess the material condition of the

equipment. Key points will include a review of preventive maintenance systems, and a check of the inspection and

certification program for lifting gear and rigging equipment.

Theft and Personnel

The loss of key materials and equipment in a shipbuilding project can cause serious delays. If special tools are

needed to complete a job, the impact of their non-availability can extend far beyond the actual job itself.

Finally, the key to any successful project is personnel. A stable, well-trained and motivated work force is one of the

best loss prevention measures available.

Vessel Risks

Heavy industrial installations such as shipyards are always exposed to potential losses due to the very nature of their

work. By far the greatest threat to a yard and the vessels inside it is fire. Two of the key areas addressed by a JH143

survey are emergency response plans and fire fighting.

Emergency Response Systems

Effective risk engineering requires the appreciation of the risks at hand and the development of coordinated response

systems to address them. These risks can vary from location to location, notably in the case of environmental risks.

An example of a common environmental risk in Asia is typhoon preparedness. Others, such as fire, are common to all

shipyards.

A key aspect of the JH143 survey is the review and evaluation of these plans. Actions of the yard staff must be

identified, and also a thoughtful consideration of the point at which outside assistance must be summoned. Welldesigned plans address coordination with outside sources and provide up to date points of contact. Regular review

and exercises can identify shortcomings, and offer the opportunity for revision.

While emergency response systems will not always eliminate the consequences of a casualty, those consequences

can often be significantly reduced.

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Fire Fighting Systems

Fire represents the greatest threat to any vessel under construction and the yard where it is being built. The faster a

fire can be identified and fought, the less damage will result.

Ideally, fire fighting systems should have more than one water source; in normal circumstances, water can be provided

from a municipal or city water main. However, in the event of a power failure or natural disaster, the city fire main may

be disrupted or cut off. For this reason, an independent supply (such as from the sea or adjacent river) should be

provided, along with independent pumps powered either by Diesel engines or emergency generators.

Some shipyards have their own fire stations, complete with fire trucks and trained personnel. Ideally, the fire trucks

should have the capability of taking an independent suction from the sea.

Fire mains have hydrants placed at intervals along their length. The hydrants can either be used to feed hoses for use

against fires ashore or in workshops, or can be used to supply manifolds on board a ship. Maintaining pressurized fire

hoses with ample water supplies on board the vessel enables the workforce to respond to a fire rapidly.

Fire extinguishers alone are not sufficient to fight an industrial fire, though they can provide prompt response to small,

localized fires. When welding or burning operations (hot work) are carried out, a firewatch should be posted in the

immediate vicinity. Their only task is to remove flammable materials from the hot work area, monitor the environment,

and take immediate action should a fire break out.

Permit to Work Systems

Certain activities, such as hot work, confined space entry, erecting and working on scaffolding, and electrical work are

inherently more dangerous than others. Managing the risk they pose requires careful implementation and monitoring

of safe working procedures.

Permits to work require workers and supervisors to review all hazardous tasks in accordance with established

procedures and to take action to minimize the hazard. The system also provides a means of documenting and

tracking the actions taken, and communicating the activities to others working on the vessel in a systematic manner.

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Atmospheric Monitoring and Control of Industrial Gases

Shipbuilding (and repair) involve creating and working in enclosed spaces. Where natural ventilation is limited or nonexistent, forced ventilation must be provided to ensure that spaces are safe for men and for hot work when it is

required. The determination of whether or not a space is safe is not based on guesswork; there are standards which

must be applied to make this determination.

The accumulation of flammable or toxic gases in a space can lead to asphyxiated workers or, in the presence of an

ignition source, an explosion. Regular monitoring in accordance with established procedures can prevent such losses.

Flashback Arrestor fitted to an Acetylene Line

Gas Cylinder Pressure Regulator

Safety Caps are essential to the safe handling of Gas Cylinders

Industrial gases are used in yards to supply cutting and welding torches and are also used in testing and

commissioning regimes. Ensuring that these gases are used when and where they are needed requires careful

management. Poorly maintained equipment or lack of safety fittings (such as flashback arrestors) can result in

damage or injury.

The hoses used to supply gases used in welding and cutting operations need to be manufactured for that purpose.

Substitution of hoses not designed for welding gases can lead to failures, leaks and fire. It is also important that hoses

are properly colour coded and fitted with correct fittings to ensure that oxygen hoses are fitted to oxygen tanks and gas

hoses to gas tanks.

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Launching and Sea Trials

Launching is a key event in the life of any ship. There are a number of different launching methods, including

sideways launching, slipway launching, floating out from drydocks, and using air bags. Each method has its own

particular risks that must be adequately addressed by the yards launching procedures.

For example, slipway launches use gravity to carry the ship into the water; but the vessels momentum must be

checked and controlled so that the vessel can be taken in hand by tugs rather than running aground on the opposite

bank. This method also requires a ship design that can withstand the stresses imposed by the transition from the slip

to the water.

Float out from a graving dock

Slipway Launch

The builder must prove that the new ship can meet its contractual performance requirements at sea during sea trials.

During this period, all propulsion, steering and navigation equipment are proven in real world operations.

Air Bag Launch

Side Launch

The JH143 survey process includes a review of how the shipyard manages both the launching procedures and the

standards for sea trials.

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Management System

Processes and Procedures

For a number of activities that a yard carries out, an evaluation of the way they conduct them out is necessary.

Examples include many of the functional areas outlined above, including safety, equipment maintenance, and work

processes. The evaluation of these processes and procedures provides an underwriter with a better understanding of

his exposures in a given yard.

An underwriter cannot evaluate a complex industrial activity such as shipbuilding without looking at systems and

observing first-hand how they function in the field. The JH 143 process not only provides underwriters with insight into

their risks, but the recommendations that come out of the survey can help a shipyard improve their entire operation,

leading to greater customer satisfaction and with it, a good reputation in a highly competitive marketplace.

Quality Assurance and Quality Control

These two closely related terms are often confused. Quality Assurance is a set of activities designed to ensure that a

given process will meet its objectives. Quality Control is a set of activities designed to evaluate a developed work

product. Rather than relying on a workers subjective experience, these formal procedures ensure that a consistent

product which meets customer and regulatory standards are met every time.

QA/QC Systems ensure blocks fit together and welds are strong

Quality Vessels are the result of good quality management

LIU Technical Bulletin

Shipyard Risk Assessment & JH143 Surveys

Certification of QA/QC processes by a third party to an ISO standard is an indicator of a yards commitment to quality,

but it is by no means the only indicator. A key part of the JH 143 process is an evaluation of the yards QA/QC

processes, not only by reviewing documentation, but also by first-hand observation of a yards work in the field, and by

conversations with owners teams and regulatory bodies.

Subcontractor Management

Few shipyards rely solely on their own workforce to complete a project. Maintaining a fully staffed shipyard at all times

is prohibitively expensive, so most rely on subcontractors in a variety of crafts to meet their commitments.

Effective subcontractor management requires rigorous vetting and close supervision by the yards core staff.

Attending surveyors review the engagement procedures, with an eye to how consistently they are applied. An

examination of the ratio of shipyard employees to subcontractors can provide a useful indicator of how likely the yard

is to maintain control over the work and produce a quality product.

Casualty History

The fact that a yard may have a history of casualties does not necessarily deter an underwriter from providing

coverage. The JH143 process provides a yard with the opportunity to demonstrate their response to a casualty to

candidate underwriters.

If, in the wake of a casualty, the yard investigates the causes, and then implements solutions to prevent a reoccurrence, this can have a positive effect on the evaluation of the yards systems and give the underwriters

confidence in the risk.

At Liberty International Underwriters we seek to provide our clients with engineered risk services, which utilizes the

best background information and experience to provide solutions which meet their needs. When it comes to Builders

Risk insurance, LIU is determined to be a global market leader.

For further information, please contact our Marine Risk Engineering team:

Singapore

Houston

Toronto

Alex Gordon

alex.gordon@libertyiu.com

Steve Weiss

steve.weiss@libertyiu.com

Ron de Bakker

ron.debakker@libertyiu.com

Scot Burford

scot.burford@libertyiu.com

También podría gustarte

- Shipyard Risk Assessment & JH143 Survey GuideDocumento11 páginasShipyard Risk Assessment & JH143 Survey GuideCak Nyum-nyumAún no hay calificaciones

- JH143 - Shipyard Risk AssesmentDocumento5 páginasJH143 - Shipyard Risk AssesmentjgmjackAún no hay calificaciones

- Oman DrydocksDocumento66 páginasOman DrydocksarvindkaushikAún no hay calificaciones

- Global Shipping Risk Management MethodsDocumento27 páginasGlobal Shipping Risk Management MethodsGopalakrishnan100% (1)

- OSHA Shipyard Industry StandardsDocumento275 páginasOSHA Shipyard Industry Standardsovantovalle80% (5)

- Shipyard Services SOWDocumento60 páginasShipyard Services SOWtoyuedoxx100% (1)

- Safety of Ships in YardDocumento63 páginasSafety of Ships in YardPetar Aleksandrov100% (1)

- Ship Repair Yard Organization ChartDocumento1 páginaShip Repair Yard Organization ChartVinayakKrishnanAún no hay calificaciones

- An Estimate of Operating Costs For Bulk, Ro-Ro and Container ShipsDocumento50 páginasAn Estimate of Operating Costs For Bulk, Ro-Ro and Container ShipsJoseoAún no hay calificaciones

- International Safety Management Code: MikepwleeDocumento62 páginasInternational Safety Management Code: Mikepwleeamina2amina-2Aún no hay calificaciones

- Oman Drydock IntroductionDocumento19 páginasOman Drydock IntroductionCostaDinos Papadopoulos100% (1)

- Dry Docking SafetyDocumento3 páginasDry Docking SafetyAnil Kumar100% (1)

- Planning & Managing Ship RepairDocumento26 páginasPlanning & Managing Ship RepairLukman Tarigan Sumatra100% (1)

- BHC Towage Risk Assessment Ed1 2018 PDFDocumento42 páginasBHC Towage Risk Assessment Ed1 2018 PDFAndy BayuAún no hay calificaciones

- Oviq3 7109 v1002 Feb19 PDFDocumento119 páginasOviq3 7109 v1002 Feb19 PDFfirdausfpsoAún no hay calificaciones

- Ship RepairDocumento5 páginasShip Repairycgoyal100% (1)

- L1 - 2 - Shipyard Productivity PDFDocumento33 páginasL1 - 2 - Shipyard Productivity PDFattiori fabriceAún no hay calificaciones

- Ship Maintenance and RepairDocumento25 páginasShip Maintenance and RepairNnamdi Celestine NnamdiAún no hay calificaciones

- Marine Safety Management SystemDocumento43 páginasMarine Safety Management Systemfilipi_vc100% (1)

- Shipyard Safety PDFDocumento174 páginasShipyard Safety PDFequalizer12345100% (1)

- Survey DrydockDocumento20 páginasSurvey DrydockHarshad Tallur100% (3)

- Section 9 - Hse Plan 2Documento49 páginasSection 9 - Hse Plan 2benAún no hay calificaciones

- Fmea Air Diving System SDS 8 System AmaniagaDocumento83 páginasFmea Air Diving System SDS 8 System AmaniagaKarikalan Jay100% (2)

- Drydocking RepairDocumento95 páginasDrydocking RepairAung Paing OoAún no hay calificaciones

- Mooring Buoy Maintenance Within Komodo National Park: 2009 ReportDocumento20 páginasMooring Buoy Maintenance Within Komodo National Park: 2009 ReportAndrew HarveyAún no hay calificaciones

- OVVP OffshoreVesselVettingProcess Tcm14-41400Documento52 páginasOVVP OffshoreVesselVettingProcess Tcm14-41400vdeviv100% (1)

- A Guide To Ship Repair Estimates in Man-Hours-2nd Edition-2012 PDFDocumento125 páginasA Guide To Ship Repair Estimates in Man-Hours-2nd Edition-2012 PDFJuan Camaney XngonAún no hay calificaciones

- Planned Maintenance System Manual: Integrated Management System (Ims)Documento63 páginasPlanned Maintenance System Manual: Integrated Management System (Ims)Jym GensonAún no hay calificaciones

- Scope of Work (Dry Docking List)Documento16 páginasScope of Work (Dry Docking List)boen jayme100% (2)

- Berth OperatorDocumento8 páginasBerth Operatorabang-abangAún no hay calificaciones

- Safety Investigation into Lifeboat Accident on Cruise Ship Saga SapphireDocumento66 páginasSafety Investigation into Lifeboat Accident on Cruise Ship Saga SapphireJeongheeseokAún no hay calificaciones

- Ship Shore Safety Check ListDocumento6 páginasShip Shore Safety Check ListMaktrukAún no hay calificaciones

- Speck Dock Is MT Kasim (After Aanwijzing)Documento127 páginasSpeck Dock Is MT Kasim (After Aanwijzing)nugroho sulistiyadiAún no hay calificaciones

- Small Boat Zodiac Operation RADocumento10 páginasSmall Boat Zodiac Operation RAAnonymous i3lI9MAún no hay calificaciones

- AP0523-RE-marine-shipyard-risk-assessments d-JH143-surveys-FinalDocumento8 páginasAP0523-RE-marine-shipyard-risk-assessments d-JH143-surveys-FinalAmin ThabetAún no hay calificaciones

- Ship Repair Most Common VocabularyDocumento20 páginasShip Repair Most Common VocabularyAnonymous IXswcnW100% (1)

- Towing Vessel Pre-Sailing ChecklistDocumento2 páginasTowing Vessel Pre-Sailing ChecklistJohannes KrisWiratmo WarnodihardjoAún no hay calificaciones

- Standard Operating Procedures for Towing BargesDocumento11 páginasStandard Operating Procedures for Towing BargesAnonymous UCveMQ100% (1)

- Marine Oil Spill ResponseDocumento54 páginasMarine Oil Spill ResponseMOHAMEDAún no hay calificaciones

- Vessel Safety GuideDocumento26 páginasVessel Safety GuidePasquale CutriAún no hay calificaciones

- Guidelines For The Safe Management and Operation of Offshore Support VesselsDocumento101 páginasGuidelines For The Safe Management and Operation of Offshore Support VesselsPaul Bd100% (4)

- Sample Vessel Condition ReportDocumento15 páginasSample Vessel Condition ReportredchaozAún no hay calificaciones

- Shipbuilding and Ship Repair PM Awareness - 2nd EditionDocumento58 páginasShipbuilding and Ship Repair PM Awareness - 2nd EditionFernando RemolinaAún no hay calificaciones

- PB 119 Drydocking and Repair Technical SpecificationsDocumento11 páginasPB 119 Drydocking and Repair Technical SpecificationsRem Larazi50% (2)

- 3358deck Barge SafetyDocumento36 páginas3358deck Barge SafetyRaphetgloireAún no hay calificaciones

- Dockmaster or Project Manager or Ship Manager or Paint InspectorDocumento2 páginasDockmaster or Project Manager or Ship Manager or Paint Inspectorapi-77458008Aún no hay calificaciones

- PCSB Fuel Bunkering GuidelineDocumento35 páginasPCSB Fuel Bunkering Guidelinefaizulilham100% (5)

- IALA Maintenance of BuoysDocumento19 páginasIALA Maintenance of BuoysCarlos Fuentes100% (1)

- 500 MTR Zone Checklist - IsMSBDocumento4 páginas500 MTR Zone Checklist - IsMSBRamli DisaAún no hay calificaciones

- Marine ProcedureDocumento31 páginasMarine ProcedureAbdullah Anar100% (2)

- Notes Shipyard ManagementDocumento90 páginasNotes Shipyard ManagementHaziqMajid100% (1)

- NAP Risk Analysis Volume I Ports and TerminalsDocumento94 páginasNAP Risk Analysis Volume I Ports and TerminalsJuno PajelAún no hay calificaciones

- Ship Safety and SecurityDocumento127 páginasShip Safety and SecurityPratham Kamboj50% (2)

- 01525-3 Health, and Environment Plan (HSE)Documento36 páginas01525-3 Health, and Environment Plan (HSE)omidziaAún no hay calificaciones

- Construction Safety HandbookDocumento189 páginasConstruction Safety HandbooktatonyAún no hay calificaciones

- Emergency Response Book PrintDocumento40 páginasEmergency Response Book Printtazzy007Aún no hay calificaciones

- Blowout Technical RefrenceDocumento89 páginasBlowout Technical Refrenceparsa2400Aún no hay calificaciones

- Safety and The EnvironmentDocumento10 páginasSafety and The EnvironmentYong Kai MingAún no hay calificaciones

- Well Control Emergency Response PlanDocumento40 páginasWell Control Emergency Response PlanMatt Smith100% (1)

- Formal Safety Assessment and Risk Analysis of Offshore StructuresDocumento25 páginasFormal Safety Assessment and Risk Analysis of Offshore StructuresDrAbdoz EngineeroAún no hay calificaciones

- 9-Valves Rating9Documento29 páginas9-Valves Rating9Mohamed FouadAún no hay calificaciones

- Kind of ValvesDocumento2 páginasKind of ValvesMohamed FouadAún no hay calificaciones

- Diaphragm Valves: Prof. DR: Nazih BayomiDocumento68 páginasDiaphragm Valves: Prof. DR: Nazih BayomiMohamed FouadAún no hay calificaciones

- Pump CalcDocumento8 páginasPump CalcMohamed FouadAún no hay calificaciones

- Pump Design WorksheetDocumento3 páginasPump Design Worksheetejzuppelli8036100% (8)

- Kind of ValvesDocumento2 páginasKind of ValvesMohamed FouadAún no hay calificaciones

- Design of Pumping Machinery for Water Supply ProjectDocumento1 páginaDesign of Pumping Machinery for Water Supply ProjectSn SatyanarayanaAún no hay calificaciones

- Cont RoundDocumento1 páginaCont RoundMohamed FouadAún no hay calificaciones

- Amirikiann A.analysis and Design .1957.TRANSDocumento55 páginasAmirikiann A.analysis and Design .1957.TRANSMohamed FouadAún no hay calificaciones

- Brochure Marine ServicesDocumento12 páginasBrochure Marine ServicesMohamed FouadAún no hay calificaciones

- Detail - MTU OnlineDocumento1 páginaDetail - MTU OnlineMohamed FouadAún no hay calificaciones

- Bollard Pull CalculationDocumento1 páginaBollard Pull CalculationMark Samsel Rohan100% (2)

- Hydraulically Driven Deck MachineryDocumento2 páginasHydraulically Driven Deck MachineryMohamed FouadAún no hay calificaciones

- Propeller Performance and Weight Predictions Appended To The Navy/NASADocumento40 páginasPropeller Performance and Weight Predictions Appended To The Navy/NASAMohamed FouadAún no hay calificaciones

- Pre-Feasibility Study: S H I P B R E A K I N GDocumento46 páginasPre-Feasibility Study: S H I P B R E A K I N GMohamed FouadAún no hay calificaciones

- 40ft shallowWaterWorkBarge1Documento1 página40ft shallowWaterWorkBarge1Mohamed FouadAún no hay calificaciones

- 20m Ga Drawings1Documento1 página20m Ga Drawings1Mohamed FouadAún no hay calificaciones

- 40ft shallowWaterWorkBarge4 2Documento1 página40ft shallowWaterWorkBarge4 2Mohamed FouadAún no hay calificaciones

- V53 2 p95 p102 PDFDocumento8 páginasV53 2 p95 p102 PDFMohamed FouadAún no hay calificaciones

- 40ft shallowWaterWorkBarge5Documento1 página40ft shallowWaterWorkBarge5Mohamed FouadAún no hay calificaciones

- 40ft shallowWaterWorkBarge3Documento1 página40ft shallowWaterWorkBarge3Mohamed FouadAún no hay calificaciones

- Optimizacion Ship DesignDocumento13 páginasOptimizacion Ship Designlucas polo100% (1)

- ForanTribon Into 3D Naval Architect Jan12Documento2 páginasForanTribon Into 3D Naval Architect Jan12Mohamed FouadAún no hay calificaciones

- 40ft shallowWaterWorkBarge2Documento1 página40ft shallowWaterWorkBarge2Mohamed FouadAún no hay calificaciones

- Full Text 01Documento61 páginasFull Text 01Imam BaihaqiAún no hay calificaciones

- Shipbuilding Quality Standard GuideDocumento59 páginasShipbuilding Quality Standard Guidenyaungzin100% (2)

- Modularization Analysis Presentation Revised PDFDocumento38 páginasModularization Analysis Presentation Revised PDFshiva1978in@gmail.comAún no hay calificaciones

- 1211 1365 PDFDocumento14 páginas1211 1365 PDFMohamed FouadAún no hay calificaciones

- Wang DDocumento4 páginasWang DMohamed FouadAún no hay calificaciones

- 04 2 PDFDocumento11 páginas04 2 PDFMohamed FouadAún no hay calificaciones

- Anacapa Light - CP DescriptionDocumento1 páginaAnacapa Light - CP DescriptionEmran khanAún no hay calificaciones

- NAME 449: L-4ff-2/NAME Date: 01104/2019Documento18 páginasNAME 449: L-4ff-2/NAME Date: 01104/2019rtgersergtgr trghgrwthtrtehAún no hay calificaciones

- Maritime Academy SEO-optimized titleDocumento10 páginasMaritime Academy SEO-optimized titleIvan SimonAún no hay calificaciones

- WARTSILA Offshore DesignDocumento4 páginasWARTSILA Offshore DesignFadhil NurrohmanAún no hay calificaciones

- The Guideline For Container Loading in Bulk CarrierDocumento12 páginasThe Guideline For Container Loading in Bulk CarrierBill KelsoAún no hay calificaciones

- Scna Jan 2023Documento2 páginasScna Jan 2023Sid ACHARYAAún no hay calificaciones

- GustoMSC moves ahead with new integrated companyDocumento13 páginasGustoMSC moves ahead with new integrated companyJ T Mendonça SantosAún no hay calificaciones

- Bad WX, PoopingDocumento6 páginasBad WX, PoopingAbu NawshadAún no hay calificaciones

- Watertight Doors On Ships: Types, Maintenance & SOLAS RegulationsDocumento16 páginasWatertight Doors On Ships: Types, Maintenance & SOLAS Regulationsgeorgesaguna100% (1)

- UntitledDocumento9 páginasUntitledYUSAKAún no hay calificaciones

- Green Field Shipyard in IndiaDocumento20 páginasGreen Field Shipyard in Indiagetnarayanaprakash100% (2)

- Ship TypesDocumento20 páginasShip TypesCatalin Apetre100% (4)

- Problem Set No 1Documento3 páginasProblem Set No 1Fatima Therese ManaloAún no hay calificaciones

- 2 Plane Area of A Vessel Will Increase in Reality. The Small Angle Formula For GZ Should Only Be Used For Angles of Heel Up To About 5° or 6°Documento3 páginas2 Plane Area of A Vessel Will Increase in Reality. The Small Angle Formula For GZ Should Only Be Used For Angles of Heel Up To About 5° or 6°marvin santocildesAún no hay calificaciones

- Thomas Andrews, Shipbuilder of The TitanicDocumento100 páginasThomas Andrews, Shipbuilder of The TitanicDouglas WestfallAún no hay calificaciones

- Significant Ships 2005Documento128 páginasSignificant Ships 2005Marcel SchmalAún no hay calificaciones

- Steerable Propulsion Units Hydrodynamic Issues andDocumento16 páginasSteerable Propulsion Units Hydrodynamic Issues andMaciej ReichelAún no hay calificaciones

- L-7 Electrical Survey Requirements U7Documento10 páginasL-7 Electrical Survey Requirements U7MaryAún no hay calificaciones

- Part 7 Ships of Special ServiceDocumento451 páginasPart 7 Ships of Special ServiceWojciechAún no hay calificaciones

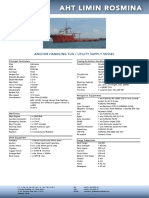

- Aht Limin Rosmina (4400 HP - 58 Tons BP - 280m2 Deck)Documento3 páginasAht Limin Rosmina (4400 HP - 58 Tons BP - 280m2 Deck)Andzar Muhammad FauziAún no hay calificaciones

- ALE Company Presentation PDFDocumento28 páginasALE Company Presentation PDFMíchel Van GarcíaAún no hay calificaciones

- Ship Handling ModifiedDocumento61 páginasShip Handling ModifiedNuman Kooliyat Ismeth100% (1)

- Rules For The Classification of Ships, Pt. 1, Ch.1, 2014Documento29 páginasRules For The Classification of Ships, Pt. 1, Ch.1, 2014Suseprianus PatumbaAún no hay calificaciones

- 1B. Mv. Stellar Rhapsody - Draught Survey - KorindoDocumento4 páginas1B. Mv. Stellar Rhapsody - Draught Survey - KorindoDanangAjiAún no hay calificaciones

- Sample Template: Written On Company Letterhead PaperDocumento2 páginasSample Template: Written On Company Letterhead PaperClyleo Eddard YoupaAún no hay calificaciones

- 6-Msc.1-Circ.1343 - Guidelines For The Information To Be Included in A Ship Construction FileDocumento9 páginas6-Msc.1-Circ.1343 - Guidelines For The Information To Be Included in A Ship Construction FileLinglong XiongAún no hay calificaciones

- CDM Flexplorer 146 Maverick EngDocumento9 páginasCDM Flexplorer 146 Maverick EngSteven RuiterAún no hay calificaciones

- Q88 PropontisDocumento6 páginasQ88 PropontisPadilaAún no hay calificaciones

- HVPQ5 v1 1 09Documento90 páginasHVPQ5 v1 1 09Pavel ViktorAún no hay calificaciones

- Calculation of Stability For Ships Carrying Bulk GrainDocumento11 páginasCalculation of Stability For Ships Carrying Bulk GrainЕкатерина РожковаAún no hay calificaciones