Documentos de Académico

Documentos de Profesional

Documentos de Cultura

8.T-ProofCrete 709 13-03-28

Cargado por

Shamsul IslamDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

8.T-ProofCrete 709 13-03-28

Cargado por

Shamsul IslamCopyright:

Formatos disponibles

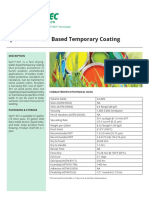

ProofCrete 709

Two-Component Cementitious

Waterproofing Coating

DESCRIPTION ProofCrete 709 is a superior

cement-based waterproofing system for concrete

and masonry surface. It is a two component system,

liquid modified acrylic dispersion (Part B) and

special blend (Part A) of cement, fillers and other

active chemicals.

ProofCrete 709 is a permanently flexible membrane

that allows moisture vapor from the substrate or

building interior to escape through the membrane

while remaining impervious to water penetration

from the exterior.

USES ProofCrete 709 was specifically developed

to waterproof concrete and masonry building

exteriors and interiors. It is recommended for

exterior facades, walls, floors, swimming pools,

internal lining of water tanks, wet areas such as

kitchens and bathrooms, and flat and corrugated

roofs. ProofCrete 709 has been tested for toxicity

and deemed suitable for potable water tanks

intended for human consumption.

ADVANTAGES

Excellent waterproofing and damp-proofing of

substrate.

Easy to mix and apply by brush.

Non-toxic for potable water reservoirs or

foodstuffs.

Prevents cracks from telegraphing.

Does not promote fungus growth.

Tough with high impact resistance.

Forms a membrane that is water and chemical

resistant.

Creates a flexible membrane that bridges any

structural movement or drying shrinkage cracks.

Low VOC.

LIMITATIONS Never apply to new concrete

surfaces before they have been allowed to cure for

a minimum of 28 days. Intended only as a coating do not use to fill cracks or holes in the surface.

Do not apply when the ambient temperature is

below 13C. Do not apply when the relative humidity

is in excess of 95%. Do not apply if weather

conditions will not permit complete cure before rain

or freezing temperatures occur.

PHYSICAL PROPERTIES

Tensile Strength (ASTM D41202)

Compressive Strength (ASTM C

109)

Flexural Strength (ASTM C 348)

T-PC709-13-03

3.2 N/mm

8.2 N/mm

7.1 N/mm

Adhesion

D4541)

Strength

(ASTM

Mix Density

Elongation (ASTM D412)

Water Penetration (ASTM D57095, 24 hour immersion)

Water Vapor Transmission

(ASTM E96)

Permeability [on Concrete]

(Positive Hydrostatic) DIN 1048

Toxicity (BS 6920 Part 2)

Odor

Color Change (max. 1%)

Flavor

Turbidity (max. 5)

Dissolved O2

Heavy Metals

Chemical Analysis

Volatile Organic Compounds

(EPA 24)

2.1 N/mm

1.7 0.1 kg/ltr

62%

Nil

7.8 perms.

No Signs of

Discoloration

None discernable

<1%

None discernable

<1

Pass

Pass

Pass

nil

COVERAGE Actual coverage will depend on

surface porosity and level, application method, and

job conditions. A coverage rate of 15-17 sq

meters/kit at 1 mm WFT is dominant.

SURFACE PREPARATION New and unpainted

surfaces must be structurally sound, clean, dry, fully

cured, and free from dust, curing agents, form

release agents, efflorescence, scale, and other

foreign materials.

All cracks larger than hairline shall be considered as

moving and must be repaired with PatchCrete 102

Crack Filler. All delaminated and splashed areas of

concrete shall be repaired prior to application of

ProofCrete 709 with PatchCrete 101 Multi-Use

Repair Mortar. Remove all unsound concrete.

Patches shall be flush with the surrounding surface

and shall match the texture of existing surfaces.

Previously painted surfaces shall be sandblasted

or water blasted to remove all paint and bring it to

bare a sound surface.

MIXING ProofCrete 709 is supplied in

proportioned units ready for mixing. In a clean

container add 20 kg of ProofCrete 709 (Part A) to

approximately 5 liters of ProofCrete 709 (Part B). If

necessary, ProofCrete 709 (Part B) may be diluted

with a small quantity of water to aid mixing. Use a

" drill with a mixing paddle at low speed

(approximately 300 RPM). Mix components for 3-5

minutes, allow to slake, then mix for a further 2-3

minutes until a uniform consistency is reached. Do

www.tex-crete.com

1/2

TECHNICAL DATA SHEET

Creative Concrete Concepts

ProofCrete 709 Two-Component Cementitious Waterproofing Coating

not over mix as this could entrap air. Pot life is

approximately 30-90 minutes.

APPLICATION ProofCrete 709 may be applied by

brush or hopper spray gun. It is essential that the

first coat be thoroughly worked into the substrate to

completely fill and cover all voids, holes, and

nonmoving cracks.

Always apply in two coats in order to avoid pinholes.

Subsequent coats must be applied in a direction

perpendicular to the previous one in order to insure

thorough coverage of the surface. Allow 24 hours

drying time between coats. The second coat shall

be applied in a direction perpendicular to the first

coat after it has dried.

STORAGE & SHELF LIFE Product should be

stored at 25C in dry conditions away from direct

sun light. Shelf life is approximately 12 months from

date of purchase in original unopened container at

specified storage temperature.

SAFETY PRECAUTIONS KEEP OUT OF REACH

OF CHIDREN. DO NOT TAKE INTERNALLY. Use

goggles, protective clothing and vinyl gloves when

handling. FIRST AID: Eyes Do not rub eyes,

immediately flush with fresh water. Skin Wash with

soap and water. Ingestion Seek immediate

medical attention.

PACKAGING 20 kg paper bag (Part A), 5 liter

Container (Part B).

Surfaces subject to continuous splashes or

permanent contact with water storage tanks must be

left to dry for at least 4 days before they are filled

with water.

CLEANING Tools and equipment may be cleaned

with fresh water.

Creative Concrete Concepts

PO Box 925794, Amman 1110, Jordan; Tel +962-6-487-4078, Fax +962-6-488-9133 PO Box 91234, City of Industry, CA 91715-1234,

USA; Tel +1-909-266-0709, Fax +1-909-266-0711 PO Box 31017, Sharjah, UAE; Tel +971-6-532-1119, Fax +971-6-532-8833

T-PC709-13-03

www.tex-crete.com

2/2

También podría gustarte

- AI Hempel's Galvosil 15700 EnglishDocumento7 páginasAI Hempel's Galvosil 15700 EnglishvitharvanAún no hay calificaciones

- Corrosion Failures: Theory, Case Studies, and SolutionsDe EverandCorrosion Failures: Theory, Case Studies, and SolutionsAún no hay calificaciones

- Evaluation of Corrosion Protection Properties of Additives For Waterborne Epoxy Coatings On SteelDocumento9 páginasEvaluation of Corrosion Protection Properties of Additives For Waterborne Epoxy Coatings On SteelJhon jairo100% (1)

- Jammu and Kashmir PPT by Vritti 4 DDocumento10 páginasJammu and Kashmir PPT by Vritti 4 Dvritti gandotraAún no hay calificaciones

- Chemical Resistance GuideDocumento11 páginasChemical Resistance GuideMohamed NouzerAún no hay calificaciones

- Tanks and Hold Corrosion Prevention DNVDocumento9 páginasTanks and Hold Corrosion Prevention DNVblakasAún no hay calificaciones

- Interspec: Tangguh Expansion ProjectDocumento43 páginasInterspec: Tangguh Expansion ProjectZamri Rahmat SikumbangAún no hay calificaciones

- Effect of Coatings on Corrosion of SteelDocumento6 páginasEffect of Coatings on Corrosion of SteelLuthfi Ady100% (1)

- Cte Ongc SpecDocumento21 páginasCte Ongc SpecMohamed HushainAún no hay calificaciones

- Zinga Vs ZRCDocumento1 páginaZinga Vs ZRCMarco Antonio Moncerrate100% (1)

- Chemtech GM Clear - English (Uk) - Issued.06.12.2007Documento3 páginasChemtech GM Clear - English (Uk) - Issued.06.12.2007Mohamed Farag50% (2)

- Chartek 1709 BrochureDocumento2 páginasChartek 1709 BrochureNedu Nedu100% (1)

- Internal Launch Presentation Version 01 - SingaporeDocumento100 páginasInternal Launch Presentation Version 01 - SingaporeEnrico Savira100% (1)

- Project To Estimate The New Shot Blasting & Painting Facility For New ProjectDocumento24 páginasProject To Estimate The New Shot Blasting & Painting Facility For New ProjectHarshad_SAún no hay calificaciones

- Fouling-Resistant Coating for Heat ExchangersDocumento3 páginasFouling-Resistant Coating for Heat Exchangersزيد عدنان عبد الحسين100% (1)

- Corrosion Performance TestsDocumento252 páginasCorrosion Performance TestsChatchai Manathamsombat100% (1)

- Challenging The Organic "Zinc Rich" Primer StandardDocumento9 páginasChallenging The Organic "Zinc Rich" Primer Standardaliabdulhamid100% (2)

- 6 Sigma PaintDocumento38 páginas6 Sigma PaintAnonymous fvO1W3Aún no hay calificaciones

- Executive Summary:: International Maritime OrganizationDocumento6 páginasExecutive Summary:: International Maritime Organizationtudormoraru100% (1)

- Salt ContaminationDocumento8 páginasSalt Contaminationabdayub100% (1)

- Ballast TK HempelsDocumento15 páginasBallast TK HempelsGeorgios PapakostasAún no hay calificaciones

- Từ Điển Công Nghệ Thực Phẩm Anh Việt Và Việt Anh - Cung Kim Tiến PDFDocumento296 páginasTừ Điển Công Nghệ Thực Phẩm Anh Việt Và Việt Anh - Cung Kim Tiến PDFTiên NguyenAún no hay calificaciones

- Corrosion Protection Evaluation of Some Organic Coatings Incorrosion Protection EvaluationDocumento61 páginasCorrosion Protection Evaluation of Some Organic Coatings Incorrosion Protection EvaluationUsama Awad100% (1)

- Water Proofing Solutions PDFDocumento24 páginasWater Proofing Solutions PDFRay PascuaAún no hay calificaciones

- Cortec ProductDocumento20 páginasCortec ProductLiu YangtzeAún no hay calificaciones

- How Vci WorkDocumento21 páginasHow Vci Work同道文档中心100% (1)

- Sheet Pile Wall: A Presentation OnDocumento22 páginasSheet Pile Wall: A Presentation OnRajaAún no hay calificaciones

- Polyaspartic Webinar Protective and MarineDocumento47 páginasPolyaspartic Webinar Protective and MarinequimizaAún no hay calificaciones

- Non Skid AreasDocumento2 páginasNon Skid AreasHossain AnwarAún no hay calificaciones

- 2018Documento16 páginas2018asfaruk2556Aún no hay calificaciones

- Angels and Demons in The Realm of Protective CoatingsDocumento26 páginasAngels and Demons in The Realm of Protective Coatingsaliabdulhamid100% (1)

- Long-lasting tank coatingsDocumento6 páginasLong-lasting tank coatingsjinyuan74Aún no hay calificaciones

- C Tape Datasheet PDFDocumento2 páginasC Tape Datasheet PDFIftikhar Ahmed KhalidAún no hay calificaciones

- Jotun Penguard Midcoat MIO Application GuideDocumento8 páginasJotun Penguard Midcoat MIO Application GuideSANKARAN.KAún no hay calificaciones

- Amine Blush+Bloom Explained - Dow BulletinDocumento5 páginasAmine Blush+Bloom Explained - Dow BulletinPhilip La Trobe100% (2)

- Corrosion AuditDocumento4 páginasCorrosion AuditGopal RamalingamAún no hay calificaciones

- Plasite 4500 S Pds 10-14 - MarineDocumento3 páginasPlasite 4500 S Pds 10-14 - MarineAchraf BoudayaAún no hay calificaciones

- Thermal Spray Coating Preparation MethodsDocumento6 páginasThermal Spray Coating Preparation MethodsIqbalAbdulloh100% (1)

- The Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantDocumento5 páginasThe Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantSergio Daniel Barea Nuñez100% (1)

- Icorr Certification Scheme: Icorr Training Courses (Itc)Documento5 páginasIcorr Certification Scheme: Icorr Training Courses (Itc)sheikbbaAún no hay calificaciones

- eBroc-FRP Custom Cooling Towers, YWCTDocumento28 páginaseBroc-FRP Custom Cooling Towers, YWCTJurizal Julian Luthan100% (1)

- Report - Epo-Chem RA 500M - MarineDocumento38 páginasReport - Epo-Chem RA 500M - MarineMullah FassudinAún no hay calificaciones

- ABRASIVE BLASTING SM PRESENTATION 2017.ppsxDocumento18 páginasABRASIVE BLASTING SM PRESENTATION 2017.ppsxIsaac SamuelAún no hay calificaciones

- PROTECT STEEL WITH MOST USED PAINTSDocumento12 páginasPROTECT STEEL WITH MOST USED PAINTSsmartcharlinAún no hay calificaciones

- BrederoShaw TP TropicEnvironment PDFDocumento8 páginasBrederoShaw TP TropicEnvironment PDFMakrame BattazAún no hay calificaciones

- Soot in Combustion Systems: and Its Toxic PropertiesDocumento428 páginasSoot in Combustion Systems: and Its Toxic PropertiesMiguel AranaAún no hay calificaciones

- 7.3 Calculation of PFP ThicknessDocumento10 páginas7.3 Calculation of PFP ThicknessmaheshbandhamAún no hay calificaciones

- Surfacepreparation StandardDocumento11 páginasSurfacepreparation StandardAri SupramonoAún no hay calificaciones

- Critical Review of Concrete Scaling CausesDocumento41 páginasCritical Review of Concrete Scaling CausessatpalAún no hay calificaciones

- AkzoNobel TB ArmohibfinalDocumento13 páginasAkzoNobel TB ArmohibfinalMuhammad NaeemAún no hay calificaciones

- Jota Armour Brochure 2007Documento6 páginasJota Armour Brochure 2007yudiar2008Aún no hay calificaciones

- Coating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryDocumento43 páginasCoating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryLarasanto Larasanto100% (1)

- Corrosion ProtectionDocumento95 páginasCorrosion ProtectionNestor Mijares100% (1)

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingDocumento4 páginasSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaAún no hay calificaciones

- TDS Weberdry 360 PUDocumento3 páginasTDS Weberdry 360 PUMahmoudFarhatAún no hay calificaciones

- Ambigard - 2K Waterproof Coating For ConcreteDocumento4 páginasAmbigard - 2K Waterproof Coating For ConcreterudrabirAún no hay calificaciones

- iKOTE AC 40 (DEC-2023) V1.3Documento2 páginasiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhAún no hay calificaciones

- Waterproof acrylic cement coating protects concreteDocumento2 páginasWaterproof acrylic cement coating protects concreteFourier MakambioAún no hay calificaciones

- Material Rate PWD 2014...........Documento70 páginasMaterial Rate PWD 2014...........Shamsul IslamAún no hay calificaciones

- Seismic HazardDocumento20 páginasSeismic HazardShamsul IslamAún no hay calificaciones

- Annual Report 2017-2018-00Documento167 páginasAnnual Report 2017-2018-00Shamsul IslamAún no hay calificaciones

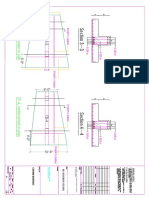

- CF3 DetailDocumento1 páginaCF3 DetailShamsul IslamAún no hay calificaciones

- The Accord InspectionDocumento7 páginasThe Accord InspectionShamsul IslamAún no hay calificaciones

- Green 2008Documento95 páginasGreen 2008Shamsul IslamAún no hay calificaciones

- Offer Steel Building FormatDocumento16 páginasOffer Steel Building FormatShamsul IslamAún no hay calificaciones

- Angle Capacity v1Documento25 páginasAngle Capacity v1Shamsul IslamAún no hay calificaciones

- CV Jobdatul ArefinDocumento3 páginasCV Jobdatul ArefinShamsul IslamAún no hay calificaciones

- Cladding Dsign For Earthquake and WindDocumento32 páginasCladding Dsign For Earthquake and WindShamsul IslamAún no hay calificaciones

- Camber GuidelineDocumento1 páginaCamber GuidelineShamsul IslamAún no hay calificaciones

- Know BangladeshDocumento12 páginasKnow BangladeshShamsul IslamAún no hay calificaciones

- The Design Report Format: General RequirementsDocumento3 páginasThe Design Report Format: General RequirementsShamsul IslamAún no hay calificaciones

- Preparation of Papers - Paper Title: First A. Author, Second B. Author, JR., Third C. AuthorDocumento1 páginaPreparation of Papers - Paper Title: First A. Author, Second B. Author, JR., Third C. AuthorRalph CastinoAún no hay calificaciones

- Energy Method For EQ DesignDocumento1 páginaEnergy Method For EQ DesignShamsul IslamAún no hay calificaciones

- Questionnaire To 2013-2014 E-Course Participants #2: X X X X X X X X X X X X X X X X X X XDocumento2 páginasQuestionnaire To 2013-2014 E-Course Participants #2: X X X X X X X X X X X X X X X X X X XShamsul IslamAún no hay calificaciones

- Calculate liquefaction potential and safety factor FLDocumento4 páginasCalculate liquefaction potential and safety factor FLShamsul IslamAún no hay calificaciones

- 13 Time Predictable Fault Modeling of BDDocumento91 páginas13 Time Predictable Fault Modeling of BDShamsul IslamAún no hay calificaciones

- NewBNBC - Part 6-Chap 2Documento133 páginasNewBNBC - Part 6-Chap 2Shamsul IslamAún no hay calificaciones

- Class EvaluationDocumento6 páginasClass EvaluationShamsul IslamAún no hay calificaciones

- Bangladesh EarthquakeDocumento31 páginasBangladesh EarthquakeShamsul IslamAún no hay calificaciones

- '13 IiseeDocumento31 páginas'13 IiseeShamsul IslamAún no hay calificaciones

- StudyTrip - Tohuku AreaDocumento8 páginasStudyTrip - Tohuku AreaShamsul IslamAún no hay calificaciones

- Settlement Analysis of FoundationDocumento1 páginaSettlement Analysis of FoundationShamsul IslamAún no hay calificaciones

- NewBNBC - Part 6-Chap 2Documento133 páginasNewBNBC - Part 6-Chap 2Shamsul IslamAún no hay calificaciones

- BRI LecsfsftureDocumento1 páginaBRI LecsfsftureShamsul IslamAún no hay calificaciones

- Settlement Analysis of FoundationDocumento1 páginaSettlement Analysis of FoundationShamsul IslamAún no hay calificaciones

- New Microsoft Office Word DocumentDocumento21 páginasNew Microsoft Office Word DocumentShamsul IslamAún no hay calificaciones

- Tech Bulletin 2Documento7 páginasTech Bulletin 2Shamsul IslamAún no hay calificaciones

- CVX7640 28Documento18 páginasCVX7640 28malingauomAún no hay calificaciones

- Recycling of Waste Glasses Into Partially Crystallized Glass FoamsDocumento7 páginasRecycling of Waste Glasses Into Partially Crystallized Glass Foamsmohamadi42Aún no hay calificaciones

- Practice Test For MasonryDocumento2 páginasPractice Test For MasonrySilver Martinez100% (1)

- Road Note 29: A Guide To The Structural Design of Pavements For New RoadsDocumento43 páginasRoad Note 29: A Guide To The Structural Design of Pavements For New Roads7d5b3373100% (7)

- Foundations GlossaryDocumento518 páginasFoundations GlossaryanaivmAún no hay calificaciones

- Qts 102 1st NotesDocumento9 páginasQts 102 1st NotesALIYUAún no hay calificaciones

- 3 Cells Box Culvert EstimateDocumento105 páginas3 Cells Box Culvert Estimatesaikumar yellankiAún no hay calificaciones

- Building Failure - Causes and Case StudiesDocumento14 páginasBuilding Failure - Causes and Case Studiesresha bhatiaAún no hay calificaciones

- Carck WidthDocumento21 páginasCarck WidthPiyush VidyarthiAún no hay calificaciones

- Bridge Cost SummaryDocumento19 páginasBridge Cost SummaryShashank SrivastavaAún no hay calificaciones

- 20-03-19 Far - West Blood Bank, Dhangadi Nepal, QA Daily Report No 125.Documento7 páginas20-03-19 Far - West Blood Bank, Dhangadi Nepal, QA Daily Report No 125.roan sthaAún no hay calificaciones

- Sika JointDocumento16 páginasSika JointnasrulaminzubainiAún no hay calificaciones

- Design of Formwork for Concrete StructuresDocumento30 páginasDesign of Formwork for Concrete StructuresSantosoAún no hay calificaciones

- Review of Related LiteratureDocumento12 páginasReview of Related LiteratureangelofsteelAún no hay calificaciones

- MS 2282 4 2011 PDocumento5 páginasMS 2282 4 2011 PSYED FADZIL SYED MOHAMED0% (2)

- Direct Tension in Anchor Bars PDFDocumento13 páginasDirect Tension in Anchor Bars PDFvsballaAún no hay calificaciones

- Damage Mechanics Modeling of Nonlinear Seismic Behavior Concrete StructuresDocumento10 páginasDamage Mechanics Modeling of Nonlinear Seismic Behavior Concrete StructuresDaniele Dominic ColluraAún no hay calificaciones

- Constructions Material - AmetheusDocumento34 páginasConstructions Material - AmetheusAmetheus // GKSahaAún no hay calificaciones

- Structural Walls Experimental Data on Strength and DeformationDocumento55 páginasStructural Walls Experimental Data on Strength and DeformationNasarKhanAún no hay calificaciones

- CONCRESIVE 2200 - v1Documento2 páginasCONCRESIVE 2200 - v1VaishamAún no hay calificaciones

- Silo DesigDocumento32 páginasSilo DesigJaganraj SesurajAún no hay calificaciones

- Types of Construction Materials in Civil EngineeringDocumento2 páginasTypes of Construction Materials in Civil EngineeringAssyifa FitrianiAún no hay calificaciones

- Quality Certificate PCC June 2017Documento1 páginaQuality Certificate PCC June 2017Tri NardiAún no hay calificaciones

- MasterSeal 599 TDSDocumento3 páginasMasterSeal 599 TDSStephen OgaloAún no hay calificaciones

- Alvin Ipo Elopre Bom For Batangas ProjDocumento7 páginasAlvin Ipo Elopre Bom For Batangas ProjADONIS PLATINOAún no hay calificaciones

- MS For Chamber ConstructionDocumento17 páginasMS For Chamber ConstructionWilliam C. Pasamonte100% (1)

- Thumb Rule For Site EngineersDocumento2 páginasThumb Rule For Site EngineersWei LeeAún no hay calificaciones

- Underwater Repairs: 18.1 GeneralDocumento11 páginasUnderwater Repairs: 18.1 GeneralmigescuAún no hay calificaciones

- Qualidade Da ÁguaDocumento16 páginasQualidade Da ÁguaJanaina LeitinhoAún no hay calificaciones

- Cesmm 3Documento114 páginasCesmm 3gskodikara2000100% (5)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsDe EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsCalificación: 4.5 de 5 estrellas4.5/5 (6)

- Produced Water Treatment Field ManualDe EverandProduced Water Treatment Field ManualCalificación: 4.5 de 5 estrellas4.5/5 (5)

- A Place of My Own: The Architecture of DaydreamsDe EverandA Place of My Own: The Architecture of DaydreamsCalificación: 4 de 5 estrellas4/5 (241)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe EverandNuclear Energy in the 21st Century: World Nuclear University PressCalificación: 4.5 de 5 estrellas4.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDe EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseCalificación: 5 de 5 estrellas5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDe EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAún no hay calificaciones

- An Architect's Guide to Construction: Tales from the Trenches Book 1De EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Aún no hay calificaciones

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialAún no hay calificaciones

- Building Construction Technology: A Useful Guide - Part 1De EverandBuilding Construction Technology: A Useful Guide - Part 1Calificación: 4 de 5 estrellas4/5 (3)

- Advanced Process Control: Beyond Single Loop ControlDe EverandAdvanced Process Control: Beyond Single Loop ControlAún no hay calificaciones

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDe EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationCalificación: 4 de 5 estrellas4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedCalificación: 5 de 5 estrellas5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionCalificación: 4.5 de 5 estrellas4.5/5 (2)

- Chemical Process Safety: Learning from Case HistoriesDe EverandChemical Process Safety: Learning from Case HistoriesCalificación: 4 de 5 estrellas4/5 (14)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsDe EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsAún no hay calificaciones

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDe EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksCalificación: 5 de 5 estrellas5/5 (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDe EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentAún no hay calificaciones

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationDe EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationAún no hay calificaciones

- Building Construction Technology: A Useful Guide - Part 2De EverandBuilding Construction Technology: A Useful Guide - Part 2Calificación: 5 de 5 estrellas5/5 (1)

- Civil Engineer's Handbook of Professional PracticeDe EverandCivil Engineer's Handbook of Professional PracticeCalificación: 4.5 de 5 estrellas4.5/5 (2)

- Field Guide for Construction Management: Management by Walking AroundDe EverandField Guide for Construction Management: Management by Walking AroundCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Markup & Profit: A Contractor's Guide, RevisitedDe EverandMarkup & Profit: A Contractor's Guide, RevisitedCalificación: 5 de 5 estrellas5/5 (11)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItDe EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItCalificación: 4 de 5 estrellas4/5 (16)

- Guidelines for Siting and Layout of FacilitiesDe EverandGuidelines for Siting and Layout of FacilitiesAún no hay calificaciones