Documentos de Académico

Documentos de Profesional

Documentos de Cultura

FL Smidth PDF

Cargado por

Tanmay MajhiTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

FL Smidth PDF

Cargado por

Tanmay MajhiCopyright:

Formatos disponibles

1712_M_FLS_BarringDevice

18/12/01

8:49

Side 1

Barring device

Allows stopping the mill in any position

Facilitates mill servicing

Turns the mill at about 2% of normal speed

Saves starting and stopping the main motor

1712_M_FLS_BarringDevice

18/12/01

8:49

Side 2

BARRING DEVICE

Main features

Allows stopping the

mill in any position

Facilitates mill

servicing

Turns the mill at

about 2% of

normal speed

Saves starting and

stopping the main

motor during

maintenance

Application

Sometimes it is necessary to rotate the mill

slowly and position it precisely. This may be

the case when recharging the mill, replacing

grinding media, inspecting the mill, fitting

new parts, etc. With this in mind, F.L.Smidth

has developed a special barring device that

is installed between the driving motor and

the Symetro gear unit.

The barring device turns the mill at about

2% of normal speed and the mill can be

stopped in any position. The barring device

operates quite independently of the main

driving motor and needs no extra space.

The F.L.Smidth barring device is available

not only for new installations, but also for

existing facilities which use a membrane

coupling.

Operating principle

The barring device is coupled to the

Symetro gear drive with a hand-operated

clutch. Electric interlocking of the clutch

engagement mechanism and the main circuit breaker ensures that the main motor

will not start as long as the barring device is

engaged.

The barring device consists of an electric

motor and a three-stage speed reducer of

unorthodox design. The first reduction

stage is a spiral bevel gear assembly, while

the second and third stages have helical

and spur gearing, respectively.

The high standard of design and construction that characterises the Symetro gear

unit also applies to the barring device. Gearwheels, shafts, pinions and gear rims are

made of a special high-quality alloy steel.

The barring device has a hollow output

shaft which encloses the high-speed membrane coupling of the Symetro gear unit.

During normal mill operation the power

from the main motor is transmitted via the

coupling shaft.

To ensure precise positioning of the mill

when using the barring device, a doubleblock safety brake with electro-hydraulic

thrustor is fitted between the barring gearbox and the barring motor.

The input shaft and the two intermediate

shafts are mounted in self-aligning heavy

duty roller bearings, while the hollow output shaft with the third-stage gearwheel

runs in special sleeve bearings. Gearwheels

and bearings are enclosed within a cast

gearbox in three sections that is bolted to

rails embedded in the foundation. Gearwheels and bearings are dip-lubricated.

1712_M_FLS_BarringDevice

18/12/01

8:49

Side 3

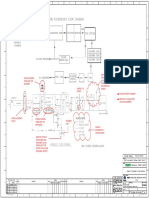

Type selection key

1.

2.

3.

4.

5.

Example

A mill with a power consumption of 2200

kW running at 16.5 rpm is to be provided

with a barring device.

Gear shaft

Motor shaft

Coupling with brake

Reversible barring motor

Handwheel for clutch

engagement mechanism

3

4

C) Space between shaft

end and coupling hub

The speed of the main motor n1 = 500 rpm.

The ratio of the Symetro gear unit is:

n1/n2 = 500/16.5 = 30.3

The speed of the barring motor is selected

at 960 rpm

The capacity factor of the main motor is:

P1/n1 = 2200/500 = 4.4 = P2/n4

The barring device selected is Type TTVF

1250 T with a max. capacity factor of 4.9

and a reciprocal ratio of the gearing = 99

The low-speed shaft of the barring gearbox

runs at 960/99 = 9.7 rpm

Accordingly, the low speed of the mill

operated by the barring gear is:

9.7/30.3 = 0.32 rpm corresponding to 2%

of the normal speed of 16.5 rpm.

Specifications

Machine

Power

transmitted

RPM

Capacity

factor

Main motor

P1

n1

P1/n1

Symetro gear unit

P1

n2

P1/n2

Barring device motor

P2

n3

P2/n3

Barring device

P2

n4

P2/n4

Barring device, Type TTVF

Type

Capacity factor

Reciprocal ratio of gearing

P2/n4

1000T

2.2

1110T

3.4

1250T

4.9

1430T

7.5

1700T

12.7

n3/n4

76

88

99

127

120

Built-in length 1)

B mm

565

625

650

700

800

Built-in length 2)

B mm

500

500

500

tonnes

2.5

3.6

4.7

6.7

11.1

Weight, calculated

1) For new installations 2) For existing installations

1712_M_FLS_BarringDevice

18/12/01

8:49

Side 4

Barring device with

reversible motor

Barring device,

disengaged

Clutch engagement

mechanism

MAAG Gear A/S production of high-quality gear units is certified to DS/EN ISO 9001.

www.flsmidth.com

Up-to-date addresses of worldwide

subsidiaries and sales offices are

available from our website

USA

INDIA

DENMARK

F.L.Smidth Inc.

2040 Avenue C

Bethlehem, PA 18017-2188

Tel: +1 610-264-6011

Tel: +1 800-523-9482

Fax: +1 610-264-6170

E-mail: info@flsmidth.com

Fuller India Limited

Capital Towers

180, Kodambakkam High Road

Nungambakkam

Chennai 600 034

Tel: +91 44-827-6030/8228623

Fax: +91 44-827-9393

E-mail: fil@fullerindia.co.in

F.L.Smidth A/S

Vigerslev All 77

DK-2500 Valby

Copenhagen

Tel: +45 36 18 10 00

Fax: +45 36 30 18 20

E-mail: info@flsmidth.com

12-01-285 Gramstrup Design ApS

Data in this brochure is intended for preliminary project planning only. Manufacturer reserves the right to modify equipment details and/or specifications without notice.

También podría gustarte

- GD755 5R - Cen00449 02 PDFDocumento16 páginasGD755 5R - Cen00449 02 PDFlesantiago100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAún no hay calificaciones

- Downhole Mud Motors - Directional Drilling ClubDocumento15 páginasDownhole Mud Motors - Directional Drilling ClubJames KaranjaAún no hay calificaciones

- Bomag BW 170 - 180Documento193 páginasBomag BW 170 - 180Anonymous yjK3peI7100% (4)

- Compact yet Powerful: Introducing the Hitachi ZAXIS-2 Mini ExcavatorsDocumento16 páginasCompact yet Powerful: Introducing the Hitachi ZAXIS-2 Mini ExcavatorsWillington Augusto Ariza100% (1)

- RT Drive Device User ManualDocumento13 páginasRT Drive Device User ManualJohn SimancaAún no hay calificaciones

- Design of Rolling Bearing Mountings in Motors and MachineryDocumento34 páginasDesign of Rolling Bearing Mountings in Motors and MachineryankitsarvaiyaAún no hay calificaciones

- Fabia Mechanics - Steering Brakes TyresDocumento10 páginasFabia Mechanics - Steering Brakes TyresbuerebistaAún no hay calificaciones

- ZF 6HP26X LR Description and OperationDocumento47 páginasZF 6HP26X LR Description and Operationcoral4him100% (4)

- Komatsu WA470-5 Wheel Loader Productivity & ReliabilityDocumento7 páginasKomatsu WA470-5 Wheel Loader Productivity & ReliabilityPhilip Chandra100% (2)

- AN Ngineering: Turning Gear and Component Selection GuidelinesDocumento2 páginasAN Ngineering: Turning Gear and Component Selection GuidelinesJose Lorenzo ToralAún no hay calificaciones

- Drive Technology: Rope Winches and GearboxesDocumento20 páginasDrive Technology: Rope Winches and GearboxesAnonymous ODKk6IgUJNAún no hay calificaciones

- Bearing LayoutDocumento30 páginasBearing LayoutmayasfaresAún no hay calificaciones

- Twin Spindle Auto Drilling Machine Increases ProductivityDocumento10 páginasTwin Spindle Auto Drilling Machine Increases ProductivitySan SuryaAún no hay calificaciones

- A30 Trailer Mounted Pump Parts ManualDocumento100 páginasA30 Trailer Mounted Pump Parts ManualPaul GuillaumeAún no hay calificaciones

- Technical Specification For Rollling Mill-20200922Documento15 páginasTechnical Specification For Rollling Mill-20200922Nilton Bruno Salazar MartinezAún no hay calificaciones

- D65e P-12Documento10 páginasD65e P-12Raphael Ruiz Ramos100% (1)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorDe EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorAún no hay calificaciones

- Filter MaintenanceDocumento6 páginasFilter MaintenanceTanmay MajhiAún no hay calificaciones

- Brochure Enduron High Pressure Grinding Rolls PDFDocumento8 páginasBrochure Enduron High Pressure Grinding Rolls PDFArturAún no hay calificaciones

- 6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDDocumento58 páginas6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDSANTOSH TIWARIAún no hay calificaciones

- U35000 PDFDocumento16 páginasU35000 PDFsujit5584Aún no hay calificaciones

- Omc 64-86Documento572 páginasOmc 64-86jeff83% (6)

- Iso2531 PDFDocumento16 páginasIso2531 PDFTanmay MajhiAún no hay calificaciones

- Bhs PDF en RDVDocumento10 páginasBhs PDF en RDVolgiertAún no hay calificaciones

- STP550Documento22 páginasSTP550waleedyehia0% (1)

- GCNS Pipe Friction Chart for Engineering CoursesDocumento1 páginaGCNS Pipe Friction Chart for Engineering Coursesshilton1989100% (2)

- Turning Gear For Gas TurbinesDocumento4 páginasTurning Gear For Gas TurbinesCharles3iAún no hay calificaciones

- Shimpo Circulute 3000 CatalogDocumento36 páginasShimpo Circulute 3000 CatalogElectromateAún no hay calificaciones

- Teikoku Pump BrochureDocumento16 páginasTeikoku Pump BrochureAndrew MaverickAún no hay calificaciones

- 4 - Chapter 1 Product Presentation DR3-DR10Documento33 páginas4 - Chapter 1 Product Presentation DR3-DR10rochim_putech_126885Aún no hay calificaciones

- EcoStruxure Hybrid DCS GPL Process Templates Reference Manual - Eng - EIO0000004043.00Documento1270 páginasEcoStruxure Hybrid DCS GPL Process Templates Reference Manual - Eng - EIO0000004043.00João Carlos AlmeidaAún no hay calificaciones

- Double Roll CrusherDocumento9 páginasDouble Roll CrusherVăn Quang Ngô100% (2)

- Psi Max2000 AgitatorsDocumento167 páginasPsi Max2000 Agitatorssaipem880% (1)

- MQ Ball Mill LMM GroupDocumento31 páginasMQ Ball Mill LMM Grouprmm99rmm99Aún no hay calificaciones

- Komatsu Gd555-5 eDocumento8 páginasKomatsu Gd555-5 eRobert Lowe100% (2)

- C Tower SpreadsheetDocumento17 páginasC Tower SpreadsheetJulio Cisneros GrandaAún no hay calificaciones

- FRP Fabrication ManualDocumento26 páginasFRP Fabrication ManualTanmay Majhi100% (1)

- F 15 F 35 Roving Frame Brochure 1904-V2 en Original 16514Documento12 páginasF 15 F 35 Roving Frame Brochure 1904-V2 en Original 16514Farah SaadAún no hay calificaciones

- Vertical Roller Mills KTM enDocumento6 páginasVertical Roller Mills KTM enJoko Dewoto100% (1)

- Amber Kinetics 125kW Flywheel System Generic Drawing SetDocumento7 páginasAmber Kinetics 125kW Flywheel System Generic Drawing SetFrancis SalongaAún no hay calificaciones

- FL SmidthDocumento4 páginasFL SmidthTanmay MajhiAún no hay calificaciones

- 1756 ControlLogix Controllers Specifications PDFDocumento24 páginas1756 ControlLogix Controllers Specifications PDFPatrick LiuAún no hay calificaciones

- 002005ea 2Documento34 páginas002005ea 2AliArababadiAún no hay calificaciones

- Catalogue: Lifting and Installation of MachineDocumento24 páginasCatalogue: Lifting and Installation of MachineGocha KakhniashviliAún no hay calificaciones

- Instruction Manual Garrard 401Documento21 páginasInstruction Manual Garrard 401CGWSPAMAún no hay calificaciones

- WL 00200 5 T2-8 de enDocumento34 páginasWL 00200 5 T2-8 de enrwva20100% (1)

- Garrard Model 401 Turntable ManualDocumento21 páginasGarrard Model 401 Turntable ManualDimitrios KonstantopoulosAún no hay calificaciones

- EY15-3 Service ManualDocumento62 páginasEY15-3 Service ManualFredirik Atienza BarucAún no hay calificaciones

- RMD Motor TypesDocumento19 páginasRMD Motor TypesMuhammed AyyubAún no hay calificaciones

- Hypo NicDocumento198 páginasHypo NiclptorreAún no hay calificaciones

- Fast, Precise Torque Adjustment! Precision Tork™ Clutches and BrakesDocumento8 páginasFast, Precise Torque Adjustment! Precision Tork™ Clutches and BrakesFrancisco A. GarcíaAún no hay calificaciones

- Sumitomo Gearbox BenefitsDocumento4 páginasSumitomo Gearbox BenefitsnordgearmotorsAún no hay calificaciones

- Siemens Brake MotorDocumento6 páginasSiemens Brake MotorAnonymous 95dlTK1McAún no hay calificaciones

- 译文 - 摆线针轮减速机Cycloidal pin wheel reducerDocumento10 páginas译文 - 摆线针轮减速机Cycloidal pin wheel reducerVocal SamirAún no hay calificaciones

- Wheel Dozer 844Documento20 páginasWheel Dozer 844Christian Kari100% (1)

- Report FinalDocumento36 páginasReport FinalRishabAún no hay calificaciones

- Motor Grader Terex DimensionDocumento16 páginasMotor Grader Terex DimensionMaulana Fajriansyah100% (2)

- Blain MD - GBDocumento4 páginasBlain MD - GBSylvester SullivanAún no hay calificaciones

- 3 WL 00200-5 Ex. 23-41Documento30 páginas3 WL 00200-5 Ex. 23-41NuM NaAún no hay calificaciones

- Buw Rollg enDocumento20 páginasBuw Rollg ensaranAún no hay calificaciones

- Large Wheel Loader Millyard Arrangements: Engine - 988H Engine - 990HDocumento16 páginasLarge Wheel Loader Millyard Arrangements: Engine - 988H Engine - 990HLin CarlosAún no hay calificaciones

- 002005ea 6Documento39 páginas002005ea 6AliArababadiAún no hay calificaciones

- BPM-DOWNHOLE MOTOR USER'S MANUALDocumento80 páginasBPM-DOWNHOLE MOTOR USER'S MANUALXueying LiAún no hay calificaciones

- Shimpo Circulute 3000 CatalogDocumento35 páginasShimpo Circulute 3000 CatalogElectromateAún no hay calificaciones

- GB C50R-3CDocumento8 páginasGB C50R-3CTomy Abad AbadAún no hay calificaciones

- Cargador Frontal Cat 914GDocumento28 páginasCargador Frontal Cat 914GHuayta Apaza Jacinto100% (1)

- Motorcycle, Solo (Harley-Davidson Model WLA)De EverandMotorcycle, Solo (Harley-Davidson Model WLA)Aún no hay calificaciones

- Flow Diagram 00Documento1 páginaFlow Diagram 00Tanmay MajhiAún no hay calificaciones

- HL249 PMHGN DD 001 2Documento1 páginaHL249 PMHGN DD 001 2Tanmay MajhiAún no hay calificaciones

- Turbine TestDocumento43 páginasTurbine TestNiraj WanjariAún no hay calificaciones

- Flow Diagram 00Documento1 páginaFlow Diagram 00Tanmay MajhiAún no hay calificaciones

- Flow Diagram - 00 PDFDocumento1 páginaFlow Diagram - 00 PDFTanmay MajhiAún no hay calificaciones

- G52 001en03Documento2 páginasG52 001en03Tanmay MajhiAún no hay calificaciones

- Effect of MLSS on Start-Up of Submerged Membrane BioreactorDocumento8 páginasEffect of MLSS on Start-Up of Submerged Membrane BioreactorTanmay MajhiAún no hay calificaciones

- Annexure 1Documento1 páginaAnnexure 1Tanmay MajhiAún no hay calificaciones

- Turbine & Generator Installation in Rajasthan Power PlantDocumento1 páginaTurbine & Generator Installation in Rajasthan Power PlantTanmay MajhiAún no hay calificaciones

- Field Quality Plan - Hot PipingDocumento1 páginaField Quality Plan - Hot PipingTanmay MajhiAún no hay calificaciones

- Hydrogen Optimization Systems: DistributedDocumento8 páginasHydrogen Optimization Systems: DistributedTanmay MajhiAún no hay calificaciones

- Proton Hydrogen GenerDocumento2 páginasProton Hydrogen GenerTanmay MajhiAún no hay calificaciones

- RCM Complete BrochureDocumento14 páginasRCM Complete BrochureTanmay MajhiAún no hay calificaciones

- Travel StopDocumento5 páginasTravel StopTanmay MajhiAún no hay calificaciones

- D Fog PDFDocumento8 páginasD Fog PDFTanmay MajhiAún no hay calificaciones

- Field Quality Plan - Hot PipingDocumento1 páginaField Quality Plan - Hot PipingTanmay MajhiAún no hay calificaciones

- HTTP WWW - Teledynees.com IndexDocumento2 páginasHTTP WWW - Teledynees.com IndexTanmay MajhiAún no hay calificaciones

- Install Under GroundDocumento8 páginasInstall Under GroundTanmay MajhiAún no hay calificaciones

- 6.ISCA RJEngS 2012 104 PDFDocumento8 páginas6.ISCA RJEngS 2012 104 PDFTanmay MajhiAún no hay calificaciones

- STD 118Documento36 páginasSTD 118Vikash TiwariAún no hay calificaciones

- Manitowoc 4600 4 SpecDocumento14 páginasManitowoc 4600 4 SpecTanmay MajhiAún no hay calificaciones

- ST Lube Oil Flushing 157.551SM (B) - 8Documento33 páginasST Lube Oil Flushing 157.551SM (B) - 8Tanmay MajhiAún no hay calificaciones

- Seal Oil System TG Part HALDIADocumento4 páginasSeal Oil System TG Part HALDIATanmay MajhiAún no hay calificaciones

- Turbine TestDocumento43 páginasTurbine TestNiraj WanjariAún no hay calificaciones

- Parking Brake System: SectionDocumento10 páginasParking Brake System: SectionPiyapong SaerimAún no hay calificaciones

- Tower Crane Load ChartDocumento1 páginaTower Crane Load ChartDahanTowerCraneAún no hay calificaciones

- Sensor de Flujo Referencia System Sensor A05-0180Documento2 páginasSensor de Flujo Referencia System Sensor A05-0180mono2072Aún no hay calificaciones

- Aviation Service ManualDocumento28 páginasAviation Service ManualArmo MoralesAún no hay calificaciones

- Casar Special Wire RopesDocumento48 páginasCasar Special Wire RopesmarketakisioannisAún no hay calificaciones

- (DOL) Motor Starter: Instructions For Direct-On-LineDocumento3 páginas(DOL) Motor Starter: Instructions For Direct-On-LineVenkata Suresh MandavaAún no hay calificaciones

- AMSOIL Diesel Injector Clean (ADF) PDFDocumento2 páginasAMSOIL Diesel Injector Clean (ADF) PDFamsoildealerAún no hay calificaciones

- IMG - 0036 PSME Code 2008 25Documento1 páginaIMG - 0036 PSME Code 2008 25Hnqr584hAún no hay calificaciones

- GuidesDocumento7 páginasGuidesALCHY IGNAún no hay calificaciones

- Peugeot 307 Vehicle Component ListingDocumento3 páginasPeugeot 307 Vehicle Component ListingStar MotorsAún no hay calificaciones

- Wave SpringsDocumento8 páginasWave SpringsHenrique SouzaAún no hay calificaciones

- Hydrolic Power PlantDocumento21 páginasHydrolic Power PlantRoy SwaidanAún no hay calificaciones

- 10” Osborn Gy-Roll Crusher GuideDocumento7 páginas10” Osborn Gy-Roll Crusher GuideCarl RichterAún no hay calificaciones

- Restore valves to like-new condition with ASCO/JOUCOMATIC spare parts kitsDocumento4 páginasRestore valves to like-new condition with ASCO/JOUCOMATIC spare parts kitsJohn MaguireAún no hay calificaciones

- Jat 810 - Air SavingDocumento2 páginasJat 810 - Air SavinghirenAún no hay calificaciones

- STC800Documento9 páginasSTC800Amit SinghAún no hay calificaciones

- Spacecraft Propulsion SystemsDocumento2 páginasSpacecraft Propulsion SystemsStephen LutzAún no hay calificaciones

- 3W 157xi B2 TS Engine DataDocumento4 páginas3W 157xi B2 TS Engine DataGigih WiraAún no hay calificaciones

- Pakistan Council of ScientificDocumento61 páginasPakistan Council of Scientificsufianabrar522Aún no hay calificaciones

- OpGL Product Instruction ManualDocumento16 páginasOpGL Product Instruction ManualRicardo NapitupuluAún no hay calificaciones

- Parker Jet-Pipe Servovalves: Care and Handling GuideDocumento9 páginasParker Jet-Pipe Servovalves: Care and Handling Guidebbkkss2Aún no hay calificaciones

- Lesson Plan ECEDocumento3 páginasLesson Plan ECEVenkatesan SwamyAún no hay calificaciones

- 14M R9J Schematic PDFDocumento8 páginas14M R9J Schematic PDFJhun HunkAún no hay calificaciones

- Barcol Product ProfileDocumento7 páginasBarcol Product ProfileMGENAún no hay calificaciones

- VG824 Cut-Grooving ToolDocumento4 páginasVG824 Cut-Grooving ToolMarcos FuentesAún no hay calificaciones

- Diagram 1 Camshaft Position S..Documento1 páginaDiagram 1 Camshaft Position S..Joycee Lázaro ReyesAún no hay calificaciones