Documentos de Académico

Documentos de Profesional

Documentos de Cultura

WPQT Format

Cargado por

RafiqKuDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

WPQT Format

Cargado por

RafiqKuCopyright:

Formatos disponibles

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

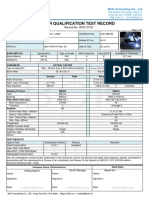

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

SYED MOHD MUKHTAR

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1127)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 24/07/2014

no.:

Welder no.:

910206-11-5501

EM-88

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

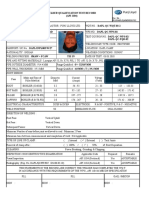

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

AHMAD YUSRI B.MOHD GHANI

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1127)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 24/07/2014

no.:

Welder no.:

880610-11-5525

EM-87

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

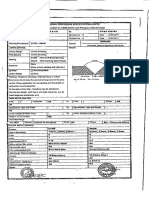

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

OSMAN B.MOHAMAD

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1126)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 24/07/2014

no.:

Welder no.:

900101-11-5709

EM-86

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

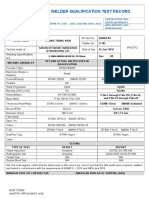

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD AZLI B.ALI

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1126)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 24/07/2014

no.:

Welder no.:

760904-11-5401

EM-85

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD AMRIEE B.UMAR

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1126)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 24/07/2014

no.:

Welder no.:

880715-06-5659

EM-84

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

KHAIRUL ANUAR B.ABU BAKAR

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1126)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 24/07/2014

no.:

Welder no.:

811022-11-5263

EM-83

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

AZIZULRAHMAN B.MOIDIN

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1119)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 23/07/2014

no.:

Welder no.:

910407-11-5145

EM-82

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

WAN FADHLI B.WAN HARUN

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1119)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 23/07/2014

no.:

Welder no.:

840426-11-5449

EM-81

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD NASIR B.ABDULLAH

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1119)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 23/07/2014

no.:

Welder no.:

690102-11-7471

EM-80

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD PADILAH B.EMBONG

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No (QW-452.1(b))

3mm / 10.97 mm

7.97mm/10.97mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-1119)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Name/Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 23/07/2014

no.:

Welder no.:

611124-11-5057

EM-79

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

A5.18/5.1

7018

ER70S-G/E7018

6/4

N/A

N/A

7 mm

97mm

6mm / 21.94 mm

15.94mm/21.94mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD SHAMIZAM BIN ZAKARIA

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18/5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G/E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

3 layers minimum (

) Yes (

) No (QW-452.1(b))

3mm / 10.97 mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

M.ZARAWI

ACCEPTED (WCTSB/EMSB/PPT/RT-)

Length and percent of defects

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

MOHD ZAIDI

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 23/07/2014

no.:

Welder no.:

860428-46-5889

EM-63

( X ) Test coupon (

) Production weld

Thickness :

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar chemical composition

7018

6/4

N/A

N/A

7 mm

6mm / 21.94 mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCENDCEP

EP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

or

UT

efects

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

DI

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

NAJIB RAZAK

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

E(M)SB/WPS/010

SA 335

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW

Welding Process (es)

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.4 to P-No.4

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A 5.28

Filler metal or electrode specification(s) (SFA) (info. only)

ER80S-G

6

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

3 layers minimum (

) Yes (

) No (QW-452.1(b))

7.11 mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

TGS-1 CM

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

ACCEPTED (WCTSB/EMSB/GPSRT/0115/023)

Length and percent of defects

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

AZMAN YUSOF

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

NAZIR MUDA

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 20/01/2015

no.:

Welder no.:

BUKAN WARGANEGARA

EM-00

( X ) Test coupon ( ) Production weld

Thickness :

SA 335 Gr. P11

7.11 mm

on Limits

Values

Range Qualified

GTAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.4

metals of similar chemical composition

G

6

N/A

N/A

14.22 mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCEN

TGS-1 CM or EQUIVALENT

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

)

efects

or

UT

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

AMJ COATING SDN. BHD.

Laboratory test no.

DA

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD AMRIEE BIN UMAR

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18 / 5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G / E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum (

) Yes ( x ) No

(QW-452.1(b))

3mm

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No

(QW-452.1(b))

7.97 mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

Current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

ACCEPTED (WCTSB/EMSB/WQT/RT/0215/004)

Length and percent of defects

M.ZARAWI

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

M.AMIN SYAH

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 18/02/2015

C no.:

Welder no.:

880715-06-5659

EM-84

( X ) Test coupon (

) Production weld

Thickness

:

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar mechanical properties

and chemical composition

.1

E7018

ER70S-G / E7018

6/4

N/A

N/A

6mm

15.94 mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCEN/DCEP

CEP

NA

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

4)

efects

or

UT

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

AH

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD FAIZAL BIN ABDULLAH

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18 / 5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G / E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum (

) Yes ( x ) No

(QW-452.1(b))

3mm

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No

(QW-452.1(b))

7.97 mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

Current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

ACCEPTED (WCTSB/EMSB/WQT/RT/0215/009)

Length and percent of defects

M.ZARAWI

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

M.AMIN SYAH

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 18/02/2015

C no.:

Welder no.:

730412-11-5109

EM-97

( X ) Test coupon (

) Production weld

Thickness

:

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar mechanical properties

and chemical composition

.1

E7018

ER70S-G / E7018

6/4

N/A

N/A

6mm

15.94 mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCEN/DCEP

CEP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

9)

efects

or

UT

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

AH

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MUHAMAD FAHMI BIN HASSAN

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/002

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW + SMAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 6'' ) 168.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18 / 5.1

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G / E7018

6/4

N/A

N/A

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum (

) Yes ( x ) No

(QW-452.1(b))

3mm

Process 2 :

SMAW

3 layers minimum (

) Yes ( x ) No

(QW-452.1(b))

7.97 mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN/DCEP

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

Current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

ACCEPTED (WCTSB/EMSB/WQT/RT/0215/010)

Length and percent of defects

M.ZARAWI

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

M.AMIN SYAH

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 18/02/2015

C no.:

Welder no.:

890729-11-5281

EM-98

( X ) Test coupon (

) Production weld

Thickness

:

SA 106 GR. B

10.97 mm

on Limits

Values

Range Qualified

MAW

GTAW + SMAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 73mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar mechanical properties

and chemical composition

.1

E7018

ER70S-G / E7018

6/4

N/A

N/A

6mm

15.94 mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCEN/DCEP

CEP

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

0)

efects

or

UT

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

AH

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD SYAHDARWIN BIN YAHYA

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/001

SA 106

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 2'' ) 60.3mm OD

P-No.1 to P-No.1

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.18

Filler metal or electrode specification(s) (SFA) (info. only)

ER70S-G

6

N/A

SOLID

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

Process 2 :

GTAW

-

3 layers minimum (

3 layers minimum (

) Yes ( x ) No

) Yes ( x ) No

5.54 mm

-

(QW-452.1(b))

(QW-452.1(b))

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

N/A

N/A

DCEN

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

ACCEPTED (WCTSB/EMSB/WQT/RT/0215/002)

Length and percent of defects

M.ZARAWI

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

M.AMIN SYAH

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 18/02/2015

C no.:

Welder no.:

890425-11-5645

EM-96

( X ) Test coupon (

) Production weld

Thickness

:

SA 106 GR. B

5.54 mm

on Limits

Values

Range Qualified

GTAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 25 mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.1

metals of similar mechanical properties

and chemical composition

G

6

N/A

SOLID

11.08

-

mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

N/A

N/A

DCEN

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

2)

efects

or

UT

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

AH

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,

Terengganu Darul Iman.

Tel No : 09-827 2777 Fax No : 09-827 4336

WELDER PERFORMANCE QUALIFICATION TES

SECTION IX, ASME BOILER AND PRESSURE VESSEL

Welder's name

I/C no.:

MOHD AMRIEE BIN UMAR

Test Description

Identification of WPS followed

:

Specification and type/grade or UNS Number of base metal(s):

ESB/WPS/003

A312 T

Testing Variables and Qualification Limits

Actual Values

Welding Variables (QW-350)

GTAW

Welding Process (es)

MANUAL

Type (i.e; manual, semi automatic) used

NO

( 2'' ) 60.3mm OD

P-No.8 to P-No.8

Backing (with/without) (QW-402.4)

(

) Plate ( / ) Pipe (enter diameter if pipe or tube) (QW-403.16)

Base Metal P-Number to P-Number (QW-403.18)

A5.9

Filler metal or electrode specification(s) (SFA) (info. only)

ER316L

6

N/A

SOLID

Filler metal or electrode specification(s) (info. only) (QW-404.14)

Filler metal F-Number(s) (QW-404.15)

Consumable Insert (GTAW or PAW) (QW-404.22)

Filler type (solid/metal or flux cored/powder)(GTAW or PAW) (QW-404.23)

Deposit thickness for each process (QW-404.30)

Process 1 :

GTAW

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

Process 2 :

3 layers minimum ( ) Yes ( x ) No

(QW-452.1(b))

5.54 mm

6G

Position qualified (2G, 6G, 3F, etc.) (QW-405.1)

Uphill

N/A

ARGON (99.9%)

N/A

DCEN

Vertical progression (uphill or downhill) (QW-405.3)

Type of fuel gas (OFW) (QW-408.8)

Inert gas backing (GTAW,PAW,GMAW) (QW-408.8)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN) (QW-404.4)

N/A

* Note: Filler brand name

RESULTS

Visual examination of completed weld (QW-302.4)

-

Satisfactory

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-4

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate spec

Type

Result

Type

Result

Alternative Volumetric Examination Result (QW-191)

Fillet weld-fracture test (QW-181.2)

- Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184)

Other tests

Film or specimens evaluated by

ACCEPTED (WCTSB/EMSB/WQT/RT/0215/005)

Length and percent of defects

M.ZARAWI

- Fillet weld in pipe [QW-462.4(c)]

Fillet size (mm)

Company

Mechanical test conducted by

Welding supervised by

M.AMIN SYAH

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in acco

of Section IX of the ASME CODE.

CERTIFIED BY:

Quality Control

REVIEW BY :

Name / Signature

DN BHD

ar,

7 4336

ON TEST RECORD

VESSEL CODE

TEST DATE : 18/02/2015

C no.:

Welder no.:

880715-06-5659

EM-84

( X ) Test coupon (

) Production weld

Thickness

:

A312 TP 316L

5.54 mm

on Limits

Values

Range Qualified

GTAW

MANUAL

W/WITHOUT BACKING (GTAW)

PLATE AND PIPE 25 mm OD

P-No.1 thru' P-No.15F, P-No.34, and

P-No.41 thru' P-No.49 and unassigned

m OD

-No.8

metals of similar mechanical properties

and chemical composition

L

6

N/A

SOLID

11.08

-

mm

Plate&Pipe > 610mm OD: ALL

Pipe 73mm to 610mm OD: ALL

Plate & Pipe fillet : ALL

Uphill

N/A

W/WITHOUT BACKING

N/A

DCEN

9.9%)

N/A

ends [QW-462.3(b)]

Side bends (QW-462.2)

W-462.5(c)]

QW-462.5(d)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Result

Type

Result

RT

5)

efects

or

UT

(check one)

-

2.4(c)]

x

Concavity/convexity (mm)

WELDCHECK TECHNOLOGIES SDN. BHD.

Laboratory test no.

AH

ted in accordance with the requirements

APPROVED BY:

Name / Signature

ENPROSERVE (M) SDN B

ENPROSERVE

Lot-7731, Kaw. Perindustrian Chacar,

23100 Paka, Dungun,