Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Nfpa 1917

Cargado por

guilloteapolo0 calificaciones0% encontró este documento útil (0 votos)

15 vistas17 páginasnfp

Título original

nfpa1917

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentonfp

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

15 vistas17 páginasNfpa 1917

Cargado por

guilloteapolonfp

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 17

1917-8

2.3.40 Other Publications, Memian-Witsiers Collegiate Dietio-

nary, 1th edition, Mertiam-Webstes, Inc., Springficld, MA,

2003.

24 References for Extracts in Sections.

NFPA 70", National Eletical Cod, 2014 edition.

NFPA M1, Standard fr a Fire and Emergency Service While

Operations Training Progms, 2013 edition.

NFPA 1901, Standard for Automat Fire Apparatus, 2016 edi-

tion,

‘Chapier Definitions

3.1 General. The definitions contained in thic chapter shall

apply to the terms used in thie standard. Where terms are not

defined in this chapter or within another chapter, they shall

be defined using ther ordinarily accepted meanings within

the contextin which they are uscd. Merrign-Witser’s Collegiate

Dictionary, th edition, sball be the source for the ordinarily

accepted meaning.

3.2 NEPA O fficial Definitions.

3.21° Approved. Acceptable to the authority having juriscice

tion,

3.2.2° Authority Having Jurisdiction (AH). An organization,

office, or individual responsible for enforcing the requi

ments of a code or standard, or for approving equipment

‘material, an installation, ora procedure

3.23 Labeled. Equipment or materials tw which has been

attached a label, symbol, or other identifying mark of an orgs

nization that is acceptable to the authority having juriedici on

and concemed with product evaluation, that maintains peri

‘odic inspection of production of labeled cquipment or mate-

rials, and by whose labeling the manufacturer indicates com-

pliance with appropriate standards or performance in a

specified manner.

3.24° Listed. Equipment, materials, or services included ina

list published by an organization that is acceptable to the au-

thority having jurisdiction and concemed with evaluation of

products or services, that maintains periodic impecion of

Production of listed equipment or matcrialsor periodic evalu-

ation of services, and whose listing states that either the eq uip-

‘ment, material, or service meets appropriate designated stan-

darck or kus been tested and found suitable for a specified

purpose,

3.25 Shall, Indicates mandatory requirement.

3.2.6 Should. Indicates 2 recommendation or that which is

achised but not required.

3.27 Sndard. An NFPA Standard, the main text of whit

contains only mandatory provisions using the word “shall” wo

indicate requiremems and that is in a form generally suitable

for mandatory reference by another standard -or code or for

adoption into law Nonmandatory provisions are not to be

considered a pant of the requirements of a standard and shall

be located in an appendix, annex, footnote, informational

note, oF other means as permitted in the NFPA Manuals of

Style When used in a generic sense, such as in Uke phrase

“sundards development process” or “standards development

activities,” the term “stanelards” includes all NEPA Standards,

including Codes, Sundards, Recommended Practices, and

Guides.

Deore ston

AUTOMOTIVE AMBULANCES,

3.3 General Definitions.

AI Acceptmce, An agrcement bemcen the purchasing

authority and the contractor that the terms and conditions of

the contract have been met [1901, 2016]

3.3.2 Acceptance Test. Tests performed on behalf of or by

the purchaser at the time of delivery to determine compliance

‘with the specifications or the ambulance.

333 Ambulance. Avehicle used for outofhospital medical

‘care and patient transport that provides a driver's compart-

ment, a patient compartment to accommodate an emergency

medical services provider (EMSP) and atleast one patient lo

‘cateel on the primary cot positioned so that the primary pa

tient can be given emergency care during transit; equipment

and supplies for emergency careat the scene as well as during.

‘anspor: safety, comio i, and avoidance of aggravation of the

paticnt’s injury or illness; two-way radio communication; and

audible and visual traffic warning devices

3331 Substantially Similar Ambulance, An ambulance in

‘which the relevant area ar component that is being com-

pared or considered is comparable. Applicable to the test

being considered foran ambulance in Which like arcassare

comparce

3332 Type / Ambulance. An ambulance with 2 10,001 Ib,

(4536 kg) to- 14,000 Ib (6350 kg) grossvehicle weight ening

(GVWR) constructed on 2 cab chassis with a modular am

bbulance bod

3333 Type FAD (Additional Duty) Ambulance. An ambu-

lance with 2 14,001 Ib (6351 kg) or more GVWR com

structed on a.cab chassis with a modular ambulance body.

3334 Type Ambulance. An ambulance constructed on

B35. Type I Ambulance. An ambulance with 3 10,001 1b.

10 14,000 Ib GVWR comtructed on a cutaway van chassis

‘with integrated modular ambulance bod.

3336 Type HEAD (Additional Duly) Ambulance. An armbu-

lance with 2 14,001 Ib or more GVWR constructed on

cutaway van chassis with integrated modular body.

BA Ange.

3341 Ample of Approach. The smallest angle made be

ween the road surface and a line drawn from the front

point of ground comact of the front tire to any projection

‘ofthe ambulance in front of the front axle.

342 Angle of Departure. The smallest angle made be

tween the road surfice and a line drawn from the rear

point of ground contact of the rear tire to any projection of |

theambulance behind the rear axle.

3343 Ramp Breahover Angie. The angle measured be

twcen two lines tangent to the front and rear tire static

loaded radius, and intersecting ata pointon the underside

Lofthe vehicle that defines the largest rump over which the

sehicle can roll, [1901, 2016]

3.25 Automatic Electrical Load ManagementSystem. Advice

that continuously monitors the dectrical sytem village and

automatically sheds predetermined loads in 2 selected! order

tw prevent exerdice harging of the ambulance’s batteries

33.6 Bonded (Bonding). Connected to establish electrical

‘continuityand conductivity. 11901, 2016]

DEFINITIONS

i970

3.47 Bulkhead. The partition dividing the driver compan-

‘ment from the patient compartment.

3.3.8 Center of Gravity. The point atwhich the entire weight

of the ambulance is considered to be concentrated so that, if

supported at this point, the ambulance would res equi-

librium in any position.

33.9 Chasis, ‘The basic operating motor vehide, including,

the engine, frame, and other esential structural and meckani-

cal puns, but exclusive of the body and all appurtenanees for

the accommodation of driver, property, passengers, appli-

ances, or equipment related to fumetions other than control

3.3.10° Common and Critical Equipment and Supplies. Equip-

ment and/or supply items that are frequently used for or are

essential to providing patient care.

3.311 Compartment.

3.311 Enclosed Compartment. A weatherresistant area

designed to protect stored items from environmental dam-

age that is confined on six sides and equipped with an ac-

cess opening(s) that can be closed and latched.

3.3.1.2 Patient Compartment. The postion of the ambu-

lance behind the cab.

3.3AL21 Type I Patient Compartment. The modular body

area added on behind the cab.

33.A1.22 Type I Patient jaut. ‘The body area be-

ginning immediately behind the forware bulkhead.

331123 Type Ml Patiewt Compartment, The modular

body area added on behind the cab.

3.3.12 Conductor

33.121 Grounding Comludor. A vomcurrenteanying

conductor used 10 conneet equipment or the ground cr

stant load for an indefinitely long time. [1901, 2016]

3.8.14 Contractor: The person or company responsible for

fulliling an agreed upon contract. (1901, 2016]

3.3.5 Defect. Adiscontinuity in a part or a failure to fine

‘ion that interferes with the service or reliability for which the

‘part wasimtendedi, (1901, 2016]

3.3.16 Documentation, Any data or information supplied by

‘the manufacturer or contractor relative to the ambulance, in

‘duding information om its operation, service, and mainte

3.3.17 Electrical Appliance. An clectrical device or instru

‘ment designed to perform a specific funetion, such as scene

lights, batiery charger, medical equipment, and so forth,

3.3.18 Hlectronic Siren. An audible waming device that pro-

‘duces sound electronically through the usc of amplifiers and

‘electromagnetic speakers, (1901, 2016]

3.3.19 Exterior Anonshelicred location exposed tothe envi-

Tonment either continuously or intermittently. (1901, 2016]

3.520 Federal Mowr Vehicle Standards (FMVSS).

Regulations promulgated by the National Highway: Traffic

Safety Administration (NHTSA) of the United States under

Public Law 89.563 that are mandatory and must be complicd

with when motor tehicles or items of motor vehicle efip-

ment arc manufactured and ccrified thercta,

3.521 Fiwed Power Source. Any line voltage power source

cexcepta portable generior

3.8.22 Fully Latched Posidon. The lst or filly closed position

fon the striter of 2 49 CFR 571, FMVSS 206 compliant door

hatch

3.5.25 Gallon. United States gallon. (1901, 2016]

3.3.24 Gauge. Avvisual device that indicates a measurement.

(1901, 2016]

3.3.25 GAWR. Scc3.5.701, Gross Axle Weight Rating,

$5.26 Generator clectromechanical device fr the pro-

duction of electricity. [1901, 2016]

$527 Gels A nessremontof the angle wed nso de-

Sige andexpreced se percentage of clceston change ote?

distance. (1901, 2016)

5.3.28 Grand Cearance. The learance under weise st

Siiocatoneesecptthe sian devas concctone Ie

Sie orhcmsdelgned seiner

55.29 GHWR. Sce 553.705, Grow Vehicle Weight ting

(GVWR).

5.350 High Speed Con. conta oF sehr

that proness ere toner th engi operating speed

fron tc contin o's higher rea operating ped

{1901, 2016]

5.554 Lael, Avni indication ether pictorial or word

(ormauthat provides forthe ienteation of x conte, itch,

indistor: of gge othe spoof ilrmation nec oe

‘operator [1901, 2016]

$5.5 neh A mechanical device med t poo the door

imsclowed pesto mv tothe a Framer with Bron

‘fon frecontlled sles or operon

5.3.56 Line Vtage Gis Equipment or Siem. nae de

‘kari creuitcqipment omer whee he volage to

Grounds tomline eines cyclo reterthan alt

fm ac), i vltepesk (x) oF 0 ole

3.3.37 Load Distribution Man. A drawing or spreadsheet of

eee cabinets riparientrceherse age

‘hs maximern of Next rhe ech loco

$5.58 Loow Eppes Eqsipment other than the os

pane andthe cot tha iene be or onthe a

tee

nie ection

191710.

3.3.39 Low Vokage Grcuit, Equipment, or System. Anclectri-

cal circuit, equipment, or system where the voltage does not

exceed 30 volis ms (ac), 4224 volts peak (ac), or 60 volts dc

ustnilly 12volts de in an ambulance.

3.340 Manufacturer. The person or persons, company, finm,

corporation, parmership, or other omganization responsible

for turning raw matesials or components imto a finished prod-

uct.

3.3411 Optical Center. The point specified by the optical wam-

ing device manufacturer ofhighest intensity when measuring the

output of an optical waming device. (1901, 2016]

3342 Optical Power. A unit of measure designaicd as

candela-seconds/minute that combines the flash energy and

flash rate of an optical source into one power measurement

representing the truc visual efleetiveness of the emitted light

(1901, 2016),

3.3.43° Optical Source. Any single, independently mounted,

lightemiuing componentin alighting system. [1901, 2016]

3.344 Optical Waming Device. A manufactured ascmbly of

‘one oF more optical sources. [1901, 2016]

3.345 Panelboard. A single panel or group of panel

designed for assembly in the form of a single panel, including

buses and automatic overcurrent devices, and equipped with

or without switches for the control of light, heat, or passer

Gireuits designed to be placed in a cabinet or cutout box

placed in or against a wall, partition, of other support; and

accessible only from the front. [70:100]

3.346 Patient Cot. An clevating paticmt conveyance device

upon which the primary patient is transported, which is also

known as a transporter, gumcy, and cartier.

3347 Power Source. A device that produces line voltage

electricity. [1901, 29016]

sembly that is parly comprised

grounding conductor, and line voltage conductors connected

from the oulput terminals of the power source to the Grst

main overcurrent protection device. (1901, 2016]

3.5.49 Primary Patient Care Seat. The seating position desig-

nated by the AH] from which the EMSP is expected to provide

primary patient care,

3.3.50 Proper(ly). In accordance with the manufacusrer’s

specifications or as recommended by the manufacturer,

[1901, 2016)

3.3.51 pei. Pounck per square inch.

3.5.52 PTO. Power takeoff.

3.3.53 Purchase The authority having responsi

specification and acceptance of the ambulance.

3.3.54 Purchasing Authority. The agency thathas the sole re

sponsibility and authority for negotiating. placing. and, where

necessary, modifying cach and every solicitation, purchase or

der, or other award issued bya governing body. [1901, 2016]

3.3.55 Qualified Person, A person who, by possession of a

recognized degree, certificate, professional standing, or skill,

and who, by knowledge, training, and experience, has demon-

strated the ability to deal with problems related wo the subject

matter, the work, or the project. (1451, 2013]

yy for the

D ceis eaten

AUTOMOTIVE AMBULANCES

33.56 Readily Accesible. Able to be located, reached, ser-

iced. or removed without removing other components or

parts of the ambulance and without the need to use special

tools to open enclosures.

3.3.57 Reserve Capacity. The ability of a banery to sustain a

minimum electrical load im the event of a charging system

jure or a prolonged charging system deficit. [1901, 2016]

BR58 Seat.

SR5R.1 Child Retruint Seat. Ascat capable of transporting

achild 661b (30 kg) or lessin accordance with 49 CFR 571,

FMVSS 213 and mounted in accorekance with the seat manu:

facurer’s recommendation.

SS.58.2 fifa! Restraint Sent. A scat capable of transport:

ing an infant ® Ib (10 kg) or less in accordance with

48 CFR 571, FMVSS 213 and mounted in accordance with

the seat manufacturer's recommendation,

3.3.59 Side Entry Door. The bodly door on the side of the

ambulance body that prosides entry into the patient compart-

ment and through which patients can be loaded and un-

loaded.

33.60 Sign. A visual indication whetherin pictorial or word

format that provides 2 warning to the operator or other per-

sons near the ambulance.

3361 Stretcher A transportation device ako known asa cot,

liter, or flat, designed to transporta supine patient.

3.3.62 Substantially Similar Ambulance. One or more compo-

nents or systems that are the same and that perform the same

functions in whicles or equipment sold or offered for sale in

the United States, regardless of whether the partnumbersare

identical,

3363 Swiker Amechanical device with which thelatch en-

F3gc on the opposing member of the body framework.

S:K6E Switch, Any set of contacts that interrupts or controls

‘current flow through an electrical circuit. (1901, 2016]

33.65 Total Continuous Flectrical Load. The total current re-

‘quired to operaicall of the devices permanently connected (0

the ambulance that can be simultaneously energized exclude

ing intermitenteype loads.

3.3.65 Tuming Clearance Radius. One-half the larger of the

left or right full cirde wall-to-wall turning dismeter. [1901, 2016]

R67" Type Centificate. A document that is isewed to certify

the compliance of an ambulance design or component to a

specific tes.

33.68 Unable Payload. The weight of the loose equipment,

‘occupants, and cot that can be carried in the ambulance with-

‘out exrceding the GVWR.

33.69 Weight.

3369.1° Curb Weight. The total weight of the complete

ambulance less the payload.

SA 70 Weight Rating.

3370.1 Gross Aule Weight Rating (GAHR). The firal-stage

manufacturer's specified maximum load-carrying capacity

of an axle system, at measured at the tire-ground inter

faces.

GENERAL REQUIREMENTS

1917-11

3.3.70.2 Gross Combination Weight Rating (GCWR). The

final-stage manufacturer's specificd maximum loaded

weight for a combination (articulaicd) vehicle consisting

of a tow vehicle and one or more towed units.

3.3.70.3° Gross Vehick Weight Rating (GVWR). The final-

stage manufacturer's specified maximum load-carrying ca-

pacity of'a single vehicle.

3.3.71 Wet Location (Related to Ambulances). A location on a

nonecaclosed exterior surface of an ambulance body or driver

and crew compariment or a nonshelicred location inside a

compartment with a door or cover that, while open, exposes

the enclosure or panclboard to the environment.

Chapter 4 General Requirements

4.1 General. All ambulances shall comply with Chapters |

through 9.

42° Responsibility of the Purchaser.

42.1 Itshall be the responsibility of the purchaser to. con-

sider the amount of equipment and the number of personnd

that will be cuuried on the ambulance and to specify a mini-

mum usable payload that will accommodate this weight once

the ambulance is placed in service.

422 It shall be the responsibility of the purchaser to specify

any details of the ambulance that would exceed the minimum

specifications of this standard.

4.3. Responsibility of the Contractor.

43.1 The contractor shall provide a detailed description of

the ambulance, a list of equipment to be furnished, and other

construction and performance details to which theambulance

4.5 Legal Requirements. The ambulance shall comply with

the following:

(1) Applicable federal regulatiot

(2) State regulations as specified by the purchaser

4.6 Third-Party Certification of Test Results. Where this stan-

dard requires the witnessing or performing of tests by an inde-

pendent third-party organization, that organization shall meet

the requirements of this section.

4.6.1 Testing shall be witnessed or performed by an organiza

tion that is accredited for inspection of ambulances in accor

dance with ISO/IEC 17020, Gener Criteria for the Operation of

Various Types of Bodies Performing Inspection, or accredited for

testing ambulances to this stamdard in accordance with

ISO/IEC 17023, General Requirements for the Competence of Tasting

and Calibration Laboratories

4.6.2 The certification organization shall not be owned or

controlled by the final-stage ambulance manufacturer.

4.6.3 The certification ization shall witness all tests and

shall refuse to certify any test results for a system if.all compo-

nents of that system requiring testing do not pass the testing

required by this stamdard_

4.64 Conditional, temporary, or partial certification of test

results shall mot be permitted.

4.6.5 Formsor data shects shall be provided and used during

the testing. [1901:1.7.6]

4.6.6 Programsshall be in place for taining, proficiency test-

ing, and performance verification of any stalf involed with

certification. [1901:47.7]

4.6.7 Appeal Process.

4.6.7.1 The certification organization's operating proce-

dures shall provide a mechanism for the manuficturer to ap-

(16) Authorized signature

4.7 Manufacturer Certification of Test Results. Where this

standard requires the results of tests or the performance of

‘component to be centified by the manufacuier, the manufac

turershall meet the requirements of this section. [190121.8]

4.7.1 The ambulance manufacturer shall test each ambu-

lance in accordance with the following:

(1) AMD 005, Low Voltage Electsical System Test

(2) AMD 010, Waser Leak Test

(3) AMD 015, Ambulaner Main Medical Gas System Test

(A) AMD 021, Aspiraor Sytem Test

(5) AMD 025, Orrupant Head Cleerance Zones Tit

(6) AMD 027, Line Vinge Betrcal Syems Tat

4.7.2 Avepresennative of the manufacturer shall witness all

tests and shall refwse to certify any test results for a system

unlessall components of that stem requiring testing pass the

testing required by this standard, [1901:48.1]

4.7.3. Conditional, temporary, or partial cenification of test

reaults shall not be permitted.

474 The manufacturer shall have the facilities andl oquip-

‘ment necessary to conduct the required testing. 2 program for

the calibration of all instruments, and procedures to ensure

the proper control of ll testing. (1901:4.83]

4:7.5 Forms or data sheets shall be provided and used during

the testing. [1901:1.84]

47.6 Programs shall be in place for waining, proficiency tst-

ing, and performance verilication of any personnel involved

with centification. [1901285]

4.22.7 An ollicial of the company that manufacturesor installs

the product shall designate in writing who is qualified to wit

ness testsand cenify results, [1901:4.8.6]

47.8 Ceviification documcatation shall be delivered with the

ambulance, including results of the cenification tests,

4.7.9 Certification tests performed on 2 substantially similar

ambulance shall be valid for up to 7 years or until such time 2s

the production product changesare so-significant that they no

Jonger meet the definition of a substantially similar ambu-

lance.

48 Personnel Protection.

4.8.1* Guards, shiclds, or other protection shall be provided

where necessity in order to prevent injury of personnel by

‘hot, moving, or rotating pans during nonmaintenance opera:

tions. [1901:4.9.1]

D ere eaten

49 Controls and Instructions.

49.1 Mlumination shall be provided for controls, switches,

sgiuges, and instruments necessary for the operation of the

ambulance and the equipment on it.

4.9.2" All required signs, instruction plates, and labelsshall be

permanent in nature, securely attached, and meet the require

ments of 4.9.9.1 and ANSI/UL 969, Standard for Making and

Labding Systems.

49.21 Thesigns, instruction plates, and labels shall be resis

tant to damage from the following:

(2) Fluids to which they will nomally be exposed

(2) Tempcramres benveen ~30"°F (-35°C) and 176°F (80°C)

(3) Ulwaviolet radiation

49.22 The exteriormounted labels relating tosafety or crit

cal operational instructions shall be reflective or illuminated,

49.23 Controls and Switches.

4.9.2.3.1* Controls and switches that arc expected to be oper

ated by the belted driver while the ambulance is in motion

shall be sisible and within reach,

49232 Controls and switches that are expected to be oper-

ated by the belted emergency medical service provider

(EMSP) while the ambulance is in motion shall be visible and

within reach of the designated primary patient care position.

49.24 Lever controls, equipment, items, anddevicesshall be

installed, located, and stowed for the convenience of the pur

pose intended and stall not interfere with the EMSP’s or the

pationt's ingress into or egress from compartments,

49.25 Marking of switches, indicators, and control devices

stall be percepuively and permanently identified with at least

12-point letters for the noun or fincion and &point lettcrs

for the remainder of the legend

49.26 The idemifications shall be contrasting colors etched

or engraved in plastic or metal or printed and laminated trans

lucent plastic, grouped according to function, and mounted

in illuminated or backlit panel(s) or the console.

4.10 Component Protection.

4.10.1 Hydraulic hose lines, air 9stem tubing, control cor

and clectrical hamesses shall be mechanically attached to the

frame or body structure of theambulance.

410.2 The wpes of equipment described in 4.10.1 shall be

furnished with protective looms, grommets, or other devices

at cach point where they pass through body panels or struc

tural members or whereverthey lie against a sharp metal edge

4103 A through-theframe connector shall be permitted 10

be used in place of protective looms or grommets

4,11 Ambulance Performance.

4.111% Where temperature requirements are mot otherwise

specified, the ambulance shall be designed to function in am-

bient temperature conditions between O'F (-18°C) te 10°F

43°C).

4.11.1.1 All imcrior stems, components, andl permanenly

attached equipment shall function satisfactorily over a tem-

perature range of 32°F 10 95°F (0°C 10 35°)

4,111.14 Compliance of the equipment function shall be

validated by testing a substantially similar ambulance in accor-

dance with AMD O11, Equipsment Temperature Test

411.112 The ambulance andall ystems, components and

equipment shall be capable of being aoredatan ambient tem-

perature bemeen 32°F and 95°F (0°C to 35°C) without damm

age oF deterioration,

4.11.2 The ambulance shall be capable of being driven for at

least 250 rmi (402 km) without refuel ng

4,113. The vehicle shall be capable of thrce fo

water entering patient and equipment compartments while

being driven through 2 minimum of Sin. (208 mm) of water,

at specds of 3 mph (8 kin/br), fora distance of at least 100 ft

(80m)

4.12 Road Performance.

4.121 When loaded w its grow whide weight rating

(GVWR), the ambulance shall be capable of meeting the fol-

lowing performance criteria om dry, paved roads that are in

00d condition:

(1) From a standing start, the ambulance shall be able to at

tain nape of hemp (0 m/e} within 9 ccm on

(2) The ambulance shall be able to maintain 2 speed of at

least 5 mph (Skm/br) on any grade up w % percent

{s) Operiung mstrucions tor ihe chasas and any major

‘components

(9) Inetmuctions regarding the frequency and procedure for

‘recommended maintenance

(10) Overall ambulance operating instructions

(UL) Safety considerations

(19) Limitations of use

(13) Inspection procedures

(14) Recommended service procedures

(15) Troubleshooting guide

(16) Ambulance bod chassis, and other component mami

Tacuirer’s warranties

(17) Special data required by this standard

(18) Safety data sheet (SDS) for any fluid that is specified for

‘use on the ambulance module

4.16.3 Certification and Payload Signage.

4.16.3.1° All ambulances shall have a centfication and pay-

load label as shown in Figure 4163.1

Figure 4.1631 was revised by 2 tentative interim

amendment (TIA). See page 1

4.16.32 The label shall be mounted on the body (module)

interior in a conspicuous location

4.16.33 The calculation of the usable payload listed om the

label shall also be provided with the ambulance.

4.17 Statement of Exceptions. The cntty esponsible for final

assembly of the ambulance shall diver wih the ambulance a

certification that the ambulance complieswith the

requirements of this standard or, when exceptions to thisstan-

dard are required by the purchaser, a statement of exceptions

bbased on any exceptions to this standard that are required 1

‘meet the specifications of the purchaser shall be listed and

tached to the owner's manual

4.17.1. The statement of exceptions shall contain for cach

‘exception at the time of delivery a scparaic isting of the sec-

tion(s) of the applicable standard for which an exception has

occurred.

4.13.4 These components shall not be welded oF otherwise

permanently secured in place.

4.14 Teason Delivery.

4.14.1 [acceptance teas are conducted at the point of deli

‘en; they shall mot be performed in a manner that requires the

ambulance or a component to operate outside its designed

‘operating range.

4.14.2 Certification from OEM and individual equipment

‘man ufscurers are acceptable, provided they are not altered.

4.15* Documentation.

4.15.1 Any documentation delivered with the ambulance

shall be permitted to be in printed format, electronic format,

audiovisual format, or a combination thereof.

4.15.2° The ambulance manufacturer shall calculate the load

distribution plan for the ambulance and deliver that load die

tribution plan with the ambulance.

4.16 Data Required of Contractor.

4.16.1 Ambulance Documentation, The contractor shall de-

liver with the ambulance at least one copy of the following

documents:

(1) The mamaficturer’s record of ambulance constuction

ale including the following information

{@) Owner’smame nd address

(b) Ambulance manufacturer, model, and serial number

(0) Chasis make, model, nd vebicl identification num

ber VIN)

(a) GAWRof front and rearaxlesand GUWR

{e) Front resin and wal ted capacity pounds (ki

logams)

(0) Rear resize and total rated capacityin pounds (klo-

sms)

emapter > Cnassts

5.1 Caring Capacigy.

SLL The manufacturer shall design the ambulance so that

the completed ambulance, when loaded to its required gross

schicle weight rating (GVWR) with all loose equipment die.

Uwibuted to its intended inservice configuration, does not ex:

‘ced the GUWR oF gross asle weight rating (GAWR) of the

‘chassis using the method and values specified in Table 5.1.1

‘Table 5.1 Required GVWR Calculation

Gusis

‘Ambulance body complete

Automotive aids

Pomancatly mounted equipment

Looe equipment

(Cee one of these alues unless

the required loose equipment is

specified by the purchaser.)

Type! 750

TypeLaD 150

‘Typell 500

Type 750

TypeHFAD 150

Belted occupant cating positions (No.seats) x 171

Cor patient m1

Gor ‘Standardeot 100

Power cot 0

Spare capacity 0

Minimum GVWR required

ForSt nis, 11D= 045k

ausas

1917-15

5A.2 The manufacturer shall establish the required GVWR

during the design of the ambulance using the method and

values specified in Table 5.1.1

5.1.3 Label.

5.1.3.1 The ambulanec manufacturer shall prenide a bigh=

Visibility label ina location visible to the driver while seated.

5.1.3.2 The label shall show the heightof the completed am-

bulance in fect and inches (meters) and the GVWR in tone

and pounds (metric tons and kilograms)

5.2° Weight Distribution.

5.2.1 Longitudinal Weight Distribution.

5.2.1.1 When the ambulance is loaded wo its GYWR the

frontie-rear weight distribution and vertical center of gravity

shall be within the limite set bythe chasis manufacturer,

5.1.2 The front GAWR shall be not less than 90 percent of

the GVWR.

5.213 The rear GAWR shall be not less than 50 percent of

the GVWR.

5.2.2* Lateral Weight Distribution. The vchicle, when loaded

10 its GVWR, shall havea side-to-side tire load variation of no

more than 5 percent of the total tircload for that axle,

5.23. The front axle loads shall notbe les than the minimum

axle loads specified by the chassis manufacturer under full

load and all other loading conditions.

5.24. \ehide and component ratings shall be the manufac-

‘urer’s published ratings and shall not be modified

written authorization from the OEM

5.2.5 The manufacturer shall design the ambulance to com-

plywith the GAWR, the overall GVWR, and the chassis manu-

Facturer’s load balance guidelines.

5.3 Engine and Engine System Design.

5.31 Cold Start Performance Requirements.

3.1 The chassis engine shall stan.and run for 5 minutes

without stalling at O°F (-18°C) without the use of extemal

power or starting Muids and without the aid of engine block

prebeating devices (except glow plugs or combustion air pre-

heater).

5.3.2. Indicators shall be provided to alent the driver wo high

engine temperature or low oil pressure conditions.

533. Ancngine hour meter shall be provided.

5A Engine Speed Auxiliary Control Device.

5.4.1* An engine speed auxiliary control device (highidle

switch, throtie, or automatic voltage monitor) shall be in-

stalled to allow an increase in the engine speed to no more

than 1600 revolutions per minute when the ambulance is

parked.

54.2 An interlock shall prevent the operation of the engine

speed auniliary control device unless the parking brake isen-

gaged and the transmission is in neutral or park or the park-

ing brake is engaged and the engine is ¢isengaged from the

drive wheels.

5.5 Cooling System.

5.5.1 The engine's cooling system shall maintain a tempers:

ture at orbelow the engine manufieturer’s maximum coolant

temperature.

5.6 Exhaust System.

5.6.1 The exhaust piping and discarge outlet shall be lo

‘cated or shielded so as not to expose any portion of the ambu-

lance or equipment to excessive heating.

5.6.2 Where parts of the exhaust qystem are exposed so that

they are likely to cause injury to operating personnel, protec

tive guards shall be provided.

5.6.3 The tailpipe outlet shall not terminate within 12 in.

(300 mm) of the vertical axis of the fuel fill opening, medical

fas storage, oF patient entry doors where these features are

located on the same side of the vehicle

5.7 Braking System.

5.7.1 All brakes shall be accessible for inspection,

5.7.2 Where airactunted braking gstems are provided, they

shall include the following:

(2) Am automatic moisture Gector

(2) Anair dryer

(3) Apressure protection valve to preventall airoperated ac-

‘cesorics from drawing air from the air brakesystem when

the air system's pressure dropsbelow a pressure setting 10

lower than 80 psi (550 kPa)

5.7.3* Any time a eecondary braking device such as wansmic-

sion retaders or exhaust restriction devices are used, they

shall have a switch to um them off during adverse road con-

5.8 Suspension.

5.8.1° With the exeeption of the OEM's furnished and installed

‘components, the ambulance ssall prenide mot less than the fol

lowing dearance, measured in accordance with SAE. J689, Cusi-

sane Cearanee, Aphwach, Departue, and Ramp Barakaoe ages

(1) Approach angle of 10 degrees

(2) Ramp breakoxer of 10 degrees

(3) Departure angle of 10 degrees

5.8.2° A traction control feature shall be provided.

5.8.3 Shock absorbers shall be fummished on the front and

rearasles.

584 Any ambulance with am airride suspemion shall in-

dude an air dryer and automatic heated moisture «jection

device to ensure that the air system is provided with dy air to

Protect the suspension control components,

5.9 Wheels and Tires.

5.9.1 Hub caps or whed covers shall be removable without

looscning the lug nutsso that wheels can be observed for daily

inspection.

5.9.2 Tiresshall be matched to vehicle performance in terms

of wacion, loadcarying ability, rolling diameter, and specd

rating.

re eaton

1917-16

AUTOMOTIVE AMBULANCES

5.9.3 Mud Flaps.

5.93.1 Mud flaps, at least.as wie as the tre(s), shall be pro-

Vided behind the front and rear wheels and shall be win-

forced at the point of attachment to the whide.

5.93.2 Mud flaps shall be permitted to be incorporated into

the running beards.

5.94. Bodies designed with wheel openings shall have the rear

‘wheels centered, within 29in. (259 mm) of those openings

5.9.50 Each tire shall be equipped with a visual indicator o

‘monitoring system that indicates tire pressure.

5.10 Vehicle Stability. Ifthe ambulance is equipped with =

ability control system, the system shall have a stecring wheel

position sensor, a vehicle yaw sensor, a lateral accelerometer,

and individual wheel brake controls.

5.1 Bumpers.

S.IL.L* A front bumper shall be furnished in the front of the

chassis that is atleast the equivalent ofthe chasds manufactur

en's OFM bumper,

BAL The rear of the ambulance shall be furnished with =

bumper that extends to within 6 im, (152 mm) of each side of

theambulanee,

SALA The rear bumper shall be secured to the vehicle's

chassis frame.

SAL22 The rearbumper of Typel and Type Hl whicles shall

be provided with an integrated step.

5.AL23. The step shall be designed to prevent the accurmul

tion of mud, ice, orsnow and shall be mate of antiskid open

grating material

SALZ4_ The step shall not be located or exposed to the inte

rior ofthe ambulance when the door (s) is losed.

5AL25 The sicp shall be at least the width of the door open-

ing for which itis provided.

5.112.6. The stepping surface shall have aminimum depth of

3 in. (197 mm) and a maximum depth of 10 in, (254 mm).

$12.7 Mthe step protnides more than 7in, (178 mm) from

the rear of the wehicle, 2 fold-up step shall be furnished.

5.1L2.8* Stepping Surface.

S.IL281 Therear stepping surface shall withstand aload of

0b (227 kg) with no more than 1.0 in, (23.4 mm) of delec-

tion oF 035 in, (6 mm} of permanent deformation

5.1282 Compliance of the rear step surface shall be vali-

dated by testing a substantially similarambulance or bumper

and step structure in accordance with Scetion AMD O18, fear

Steping Surface Load Tes

5.1283 Thedistance from the rad surface to the wop su

face ofthe first step shall not exceed 39 in. (559 mm) with the

vehicle loaded to its CMWR and/or the sspension in the

Kneding condiion.

$11,284. Steps hall be provided in the door openings

$285 Sep wells shall beilluminated.

5.286 Step surfaces shall be constructed with anti-tip m=

terial

DD core canon

BALQR7° All steps shall have a minimum arca of 35 in”

(2.580 mm*) and shall be of such a shape that 2 5 in

(125 mm) diameter disk does mot overlap any side when

placed on the step.

AZ Cab Seal.

SAZA If the eaband the patient compartment are separate

‘enclosures, the cab shall be provided with a sealing device

SAZZ_ The seal shall be fabricated from a material resistant to

‘ozone, sunlight, oil, and fungus.

S23. The seal shall remain flexible im temperatures be

meen -20°F and 110°F (-20'Cand 43°C),

RAZA The seal shallbe designed for proper fitand finish and

be able to absorb Lateral, vertical, and torsional displacement

due to body /cab movement.

KAS PromtSeats.

SASL Front cab seating for the driver and at least one pat-

senger shall be provided.

IS2 The driver's seat shall have the OEM's full, unob-

stuctedseat track travel range of longitudinal adj usumentand

a minimum of 30 percent of the range of inclination, but not

less than the angle furnished om 's standard nonre

clininghigh back seat

514° Mirrors.

MLL Dual side view mirrors having a combination flat and

‘convex mirror system shall be furnished.

S142 All primary side view mirrors used by the driver shall

be adjustable from the drixer’s position.

13 Hardware and mirror heads shall have a corrasion

resistant exterior finish.

5.15 Cab Integrity. Cabs on ambulances with a GVWR greater

than 26,000 Ib (11,800 kg) shall meet the requirements of SAE

P420, COE Frontal Siength Evaluation — Dynamic Loading

‘Heavy Trucks, and SAE |9499, Cab Roof Siength Evahvation —

Quasi Stic Loating Hey Trucks

Chapter 6 Patient Compartment

61 Patient Compartment Configuration. The paticnt com

partment shall provide a minimum of 275 f° (7.7 m') of

‘space, less volume for cabinets, while complying with 6.1-2and

a3.

GLI Selfcontained breathing apparatus (SCBA) mounts

shall not be located in the patient compartment.

G12 A minimum of 10 in. (254 mm) shall be provided from

the nearest cdge of the cot mattress to the loading do.or(s).

6.3" The companment shall provide a clear aisle walkway on

at leastane side of the patient cot.

G2 Mounting. If the bodyis of modular construction, itshall

be mounted per the allowed and /or recommended methods

‘of the chassis manufacturer.

6.3 Structural Integrity — Roof Loading.

G31 Any Type I or Type LAD ambulance body shall with-

‘stand a force equal to- 2.5 times the curb weight of the vehicle

applied to the roof of thevehicle's body structure, validated by

PATIENT COMPARTMENT

1917-17

testing a substantially similar ambulance in accomlance with

AMD O01, Ambulance Body Structure Text

63.2 Any Type Il ambulance body shall withstand a force

cequalto 15 times the curb weight of the vehicle applied to the

roof ofthe vehicle's body structure, validated by testing a sub-

standally similar ambulance in accordance with AMD 001, Ase

lance Body Structuse Test.

63.3. Any Type Ill or Type HILAD ambulance body shall with-

standa force equal to 2.5 times the curb weight of the vehicle

applied tothe roof of the vehide’s body structure, validated by

testing a substantially similar ambulance in accordance with

AMD O01, Ambulance Body Structure Test

63.4 The downward vertical movement at any point on the

roof application plate chall not exceed 5.12 in. (130 mm).

6.3.5 Each exterior egress door of the whicle shall be

capable of opening and closing during the full application of

the force and alter release of the force.

63.6. Nostructural damageto any load bearing or supporting

members (c.g, tom or broken material, broken welds,

popped or sheared body rivets, bolts, and /or fasteners) shall

bbe evident during the application of the force and after the

release of the force.

6.4 Body Structural Integrity — Side Loading.

64.1 Any Type Lor Type FAD ambulance body shall with-

standa force equal to 2.5 times the curb weight of the vehicle

applied to cither the driver or passenger side of the wchicle’s

body structure, validated by testing a substantially similar am-

bulance in accordance with AMD O01, Ambulance Body Structure

Test,

64.2 Any Type Ill or Type HI-AD ambulance body shall with-

stand a force equal to 9.5 times the curb weight of the vehicle

applied to cither the driver or passenger side of the wchicle’s

body strucure, validated by testing a substantially similar am-

Ibulance in accordance with AMD OO1, Ambulance Body Structure

Test,

643. Fach exterior egress door of the vehicle shall be ca

ppable of being opened and closed during the full application

of the fore and after release of the force.

6.5 Body Sealing.

6.5.1 Sealing Out Water.

6.5.1.1 There shall be no water leakage into the cab, any

exicrior comparunent, or the patient compartment

6.5.1.2 Compliance of the body sealing out water shall be

Validated by the manufsewrer by testing each finished ambu-

lance in accordance with AMD 010, Water Leak Test

6.5.2 Sealing Out Exhaust Gas.

6.5.2.1 The body shall be sealed and vented so that the inte

rior carbon monoxide level docs not exceed 13 ppm of carbon

monoxide (CO)

6.52.2 The paticnt compartment shall include a listed OO

detector in accordance with ANSI/UL 20H, Standard fr Safes

Singfeand Multiple Station Carbon Monacide Alarms.

6.6 Wheel Housings.

6.6.1 Wheel housingsof mod ular bodies shall inclu splash

shields between the body wheel housing and the wheels, ex

tending over the top of the tires tothe bottom of the body side

skirting.

66.2 Wheel housing openings shallallow for tire chain usage

and easy tire removal and serice and conform to SAE J685,

Tire Chain Clearance — Trucks, Buses (Exrept Suburi, Intercity,

‘and Transit Buses), and Combinations of Vehicles.

6.6.3 The OFM’s standard wheel housings on Type Il ambu-

lances shall be acceptable.

6.7 Patient Compartment to Cab Partition.

67.1 Abulihead partition shall be provided between the cab

and the paticnt compartment,

6.7.2 The pantition(s) shall be located behind the driver's

seal and the cab pasenger seat when in the rearmost position

and the seat back is eclined a minimum of L5 degrees

67.3. The panttion shall extend from the floor tothe ceiling:

6.7.4 The partition shall be wide enough to cover the width

of cach cab seat excluding arm rests.

6.7.58 The cab and body bulkheads shall have an aligned wine

dow opening of atleast 150 in # (06,780 mm?) or other means

of viual and hands-free audio communication

6.7.6 Ifso equipped, a window in the eab or body shall be of

the sliding type, aligned, and connected with the modular

body window opening.

6.2.7 The window shall be a transparent, shatterproof panel,

which is laichable from the cab side.

6.8 Access Handrails or Handholds.

6.8.1° Imerior or exterior access handrails or handholds shall

be provided at cach entrance toa driing or crew compart

ment and at each position where steps or Ladders for climbing.

are located.

68.2 An overhead handrail shall be provided on the ceiling

‘ofthe patient compartment -

683 Exterior acces: handrails shall be between | in. and

sin. (25 mmand 42 mm) indiameter and have a minimum

dlearance between the handrails and any surface of at least

2in. 30mm),

6840 All exterior and interior access handrails shall be de-

signedand mounted to reduce the pessibility of handslippage

and to avoid smagging of equipment or clothing.

685 Acces: handrails applied by the chassis manufacturer

‘oma commercial chassis shall he permitted to be used to meet

the requirements ofthis section.

6.56 Handkail Testing.

6.86.1 Handrails shall withstand a force of 300 Ib (136 kg)

applied in any direction without detaching, loosening, oF per

rmncntly deforming.

686.2 Compliance of the handrail shall be validated by text

ing a substantially similar ambulance oF body structure in ac-

cordance with AMD 008, Handi Static Load Test.

6.9 Patient Compartment Entry Doors.

69.1 The paticnt compartment shall be equipped with at

least one primary access door opening with minimum dimen-

sions of 44 in_ (1117 mm) wide by 46 in. (1168 mm) high

are caice

191718

AUTOMOTIVE AMBULANCES

6.9.2 Door handles shall be designed and installed to prowect

againstaccidental or inadvertent opening.

6.9.3 Entry doors and door openings shall be designed w

‘minimize inadvertent snagging of apparel

6.9.4 Door latches, hinges, and hardware furnished by OEMs

and finalstage ambulance manufacturers (FSAMSs) shall meet

the performance requirements of 49 CFR 571, FMVSS 206,

6.9.5 When doors arc open, the hinges and latches shall not

prowude into the access area.

6.96 Doors shall be equipped with a boldopen device.

6.9.7 One externally operated lock for each door opening

shall be provided.

6.9.8° Aninternal lock on cach paticnt compartment primary

entry door shall be prenided.

6.9.9 All patient companment entry door locks shall be iden-

tically keyed

6.9.10 Patient loading doors shall be equipped with not less

than 250 in? (161,300 mm") af safety glass area per door.

6.9.11 Doors shall be designed to prevent leakage of exhaust

fumes, dust, water, and airinte the patient compartment,

6.10 Means of Egress.

6.10.1 Any interior area to be occupied by personnel shall

have a minimum of two means of egress,

6.10.2 Pach means ofegress opening shall be a minimum of

30 in, (752 mm) by 46 in. (1168 mm)

6.10.8 Secondary egres doors shall not be blocked by patient

compartment structures that would prevent the unloading of

a patient om a backboard,

6.104 The egress doors shall have a secondary emergency

release mechanism,

G1L822 The four reading in cach direction shall be ayer.

aged and reportedasthe slip resistance for the materialin that

‘orientation.

G12 Exterior Storage.

612.1 Alleuicriorcompartment doorsshall have latches with

locks that hold the door in 2 closed position.

612.2 All hinged doors wider than I in, (356 mm) and ex-

luding battery compartments shall have positive holdopen

devices that permit one-hand dosure.

6123 Hardware shall be rust resistant

6124 All primary exterior compartment doors shall have

Latches with locks.

6.125. The interior ofall exerior comparuments greater than

4f¢° (0.11 m’) shall be automatically illuminated when a door

is opened and meet the requirements of 7.11.7.1.

6.12.6 Al surfaces shall be nonabsorbent.

6.13 Floor

13.1% The patient compartment floor shall be flat, except

where the area near the rear entrance door is sloped for a

lower emicring height.

613.2 With the exception of cot retention hardware, the

floor shall be free of obstructions in the door(s) access and

workarea.

6133. The floor shall be designed to eliminate voids or pock-

ats where water or moisture can become tripped.

&134. The sublloor construction shall cover the full lengih

and width of the patient compartment.

15.5 If plywood isused in the subfloor, itshall be marine or

‘exterior grade.

6.11 Exterior Stepping Surfaces and Interior Ste 6.13.6 _If the ambulance has 2 modular body, the subfloor

6.11.1 All materials used for exterior surfaces designated as

stepping, sunding, and walking areas and all imenor steps

shall havea minimum slip resistance in amy orien tation of 0.68

when tested wet using the English XL tester in accordance

with the manufacturer's instructions oF 0.52 when tested wet

using the Brungraber Mark Il tester in accordance with the

manuficuree’s instructions.

6.11.2 Astandard Neolite® test sensor shall be used with both

the English XL tester and the Brungraber Mark HI tester.

6.11.3 Sampling Strategy.

6.1.3.1 For uniformly patterned materials, at Least 16 read

ings-shall be taken on cach sample.

6.11L.3.1.1 Each reading shall be taken 0 degrees dockwise

from the previous orientation, resulting in at least four reac

ings in each orientation,

6.13.12. The readings shall be averaged and reponed 2s the

slip resistance for the material

6.1132 For directionally pawemed muerials, at least 32

readings shall be taken on each sample.

6.11324 Bach reading shall be when 45 degrees dlockwise

from the previous orientation, resulting in at least four read

ings in each orientation,

DD aore eaten

‘hall be designed to prevent water penetration,

6.13.7 Body Floor Structural Integrity.

6137.1 If the subfloor is constructed of plywood, the ply-

‘wood shall have am American Plywood Asociation (APA) floor

rating of 16 in. (405 mm) on center or better.

6.15.7.2. Ifthe subfloor isconstructed of other than plywood,

ia shall betested using a | in, (25 mum) disk and have a mani-

mum of 0.135 in. (3 mm) deflection at 200 Tb (91 kg) force

and 2 minimum wlimate load of 400 Ib (181 kg) for 2 16 in,

(406 mm) on center load.

6137.21 The maximum floor structure spacing shall be

used for testing.

6137.22 Compliance of the floor strucuiral integrity shall

bbe validated by testing the midpoint of the longest unsup-

ported section of a substantially similar ambulance or floor

‘Structure in accordance with the concentrated static Loud test

procedure im ASTM E661, Sendard Test Method for Performance

of Wout and Wind-Based Foor and Roof Sheathing Under Concen-

tried Static and Impact Loads.

6187.2.2.1 If panel joints occur at the maximum span loce

tion, they shall be present in the test sample as a worst-case

PATIENT COMPARTMENT

1917-19

6.13.73 Adravingof the floor structure and fastening sched-

ule of the subfloor material to the structure shall be required

im the certification report.

6.14 Floor Covering.

6.14.1 Floor covering shall be nonpermeable and seamless.

6.14.2 The floor covering shall cover the entire length and

width of the compartment s exposed floor.

6.143. Joints where the floor covering meets the sidewalls

shall be sealed and bordered with cormosion-resistant cove

molding, or the floor covering shall exicnd at Ieast 3 in

(36 mm) up the sidewalls.

6.15 Insulation.

6.15.1 Where the patient compariment is insulated, it shall

be insulated with a nonseuling type, verminproof, mildew-

proof, nontoxic, and nonby ‘material that mects the

Tequirements of 41 CFR 571, FMVSS 302

6.15.2 If fiberglass insulation is used, it shall be protecied

from exposure to water

6.16* Interior Storage.

6.16.1 The interior of the paticnt compartment shall provide

enclosed storage space.

6.16.2 Companment(s) under the floor that have opening

panel(s) inside the patient comparunent shall not be accept

able.

6.16.3. Where furnished, top-opening squad bench lids shall

be fitted with an automatic holdopen device and 2 quick-

release slam-type latching device when closed.

6.164 Sorage compartment door handles, where provided,

shall not protrude more than | in. (25 mm) iflocated 14 in

(356 mm) or higher above the floor and shall not protrude

more than Yin, (51 mm) iflocated lower than Hin. (356mm)

‘or higherabove the floox

6.16.5 Dooreshall be designed to remain coved during trans

por.

6.16.6 Storage compartments shall be fastened to the body

strucwre,

6.16.7 The securing mechanicm of those interior storage

cabinets and drawers, if provided, shall be capable of being

accessed under the same Teach condition,

6.168 Each patient comparment cabinet shall be perma

rnontly labeled with its maximum load capacity

6.169 Fach enclosed compartment shall be capable of con-

taining the coments when a 10 g force is applied in the longi-

tudinal, lateral, or vertical axis of the vehicle.

6.17 Interior Surfaces.

6.17.4 The interior of the body shall be frce of all sharp pro-

jections and sharp comers,

6.17:2° The finish of the entire patient compartment and ex-

terior storage, including interiors of storage cabinets, shall be

as follows,

(2) Impervious to soap, water, body fluids, and disinfectants,

(2) Mildew resistant

(3) Fire resistant in compliance with £ CFR 571, FMYSS 32

(4) Able tw be cleaned and disinfected

6.173 Countertop borizontal surface shall be scamless and

impervious to-contaminants.

I7A All edges that meet vertical cabinets shall be scaled.

17.5 Countertop horizontal surfaces shall be surrounded

bya lipof not less than 4% in. (12 mm) in height.

18 Equipment Mounting.

18.1 Medical Supplies and Equipment Storage Mounting.

Supplies, devices, tools, and other equipment shall be stored

in enelosed compartments oF fastened to secure them during,

‘vehicle motion.

6.18.2 Equipment weighing 1b (1.36 kg) or more stored in a

driving or patient companment shall be mounted or con-

tained in an enclosed compartment.

18.2.1 Equipment mounts or retention devices shall meet

the performance requirementsof SAF J3043, Ambulance Eui pe

ment Mounts

18.3 Built-in communication deviecs installed im the pa-

tient compartment shall be within reach of EMSPs while

‘seated and rearained in the designated primary patient care

‘seat

6.19 Waste and Sharps Disposal. A receptacle for general

‘waste and an OSHA-compliant container for sharps disposal

shall be provided in the patient compartment.

6.19.1 Containers for contaminated sharps shall be within

reach of EMSPs while remaining seated and restrained in the

designated primary patient care seat

6.20 Holder for Intravenous Fluid Containers.

6.20.1 Onc mounted derice specifically designed for holding

and securing an IV Quid container against arcidental release

‘during normal transport activity shall be provided.

6.20.2 The device shall mot protrude more than 1.0 in.

(25 mm) in the closed pasition.

6.21 Patient Compartment Seats.

6.21.1 Seat Integrity. Any seat mounted in a patient compan

ment shall meet the performance requirements specified in

SAE J3026, Ambulenee Patient Compartment Seating Iniqgrity and

‘Occupant Restraint

6.21.2 All scating in the patient compartment shall conform

toall applicable 49 CFR 571, FMVSS requirements.

6.21.3° Occupant Crash Protection.

6.213.1¢ Fach designated seating position shall be provided

with occupant crash protection.

6.2132 Inthe occupant crash protection isa seat belt system,

the seat belt shall comply with 621.3.3.1 and 621.3.3.12.

6.2133 Ambulances abowe 19,500 1b (8845 kg) GVWR shall

provide scat belis in accordance with 6213.31 and

62133.12intheeab.

6.2133.1 Theelfective ceat belt web length for a Type 1 lap

belt for pelvic restraint shall be a minimum of 60 in.

(1525 mm) with the seat adjusted all the way back and down

when measured using the following procedure:

(1) Locate am imaginary line where the plane of the center of

the seatback surface intersects the plane of the center of |

the seateushion surface (line 1in Figure 6.21 3.3.1).

core eaten BD

1917-20

AUTOMOTIVE AMBULANCES

(2) Locate poimt Aon line 1 at the outside of the seat on the

retractor side of the seat

(3) Locate point Gon line | at the outside of the seat on the

bucHle side of the seat.

(4) Locate point D at the tip of the buckle.

(5) Pullthe seat belt web bing entirely out of the retractor and

measure along the webbing bemscen point A and the seat

belt latch plate (tongue). Record this length 2c AD.

(6) Measure from point Co point D, and record this length

asCD.

(7) The effective seat belt web length equals AD + €D.

pr Unes

Uees

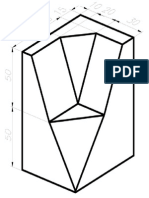

FIGURE 6.21.33.1 Dimension Lines for Measuring Seat Belt

Effective Length.

6.21.33.1.1 Elfective seat belt web length fora single reac

tor Type 2 seat belt shall be measured accondiiig to the follow.

ing procedure:

(1) Locate an imaginary line where the plane of the center of

the scat back surfice intersects the plane of the center of

the seat cushion surface (line I in Figure 6.21.33.1),

(2) Locate animaginary ine parallel with ine | and lying on

the center of the seat back surface 20 in, (74) mm) rom

line 1 (line 2in Figure 6213.81)

(3) Locate point A.on Tine 1 at the outside of the scat on the

retractor side of the seat

(4) Locate point B on line 2 at the shoulder strap edge of the

seatback,

(5) Locate point Gon line 1 at the outside of the seat om the

buckle side of the seat.

(6) Locate point Dat the tip of the buckle.

(7) Pull the seat belt webbing entirely out of the retractor,

and measure along the webbing between points A and B.

Record this length as AB.

(8) Measure from point C to point D, and record this length

asCD.

(9) The effective lap belt web length oquals AB + 2CD.

621.3312 Effective seat bet weblengih for adual rewactor

‘Type 2 scat belt shall be measured acconding to the following

procedure:

D cots caren

(0) Locate an imaginary Tine where the plane of the center

‘ofthescat back surface! mersecs the plancof the conler

‘ofthe scat cushion surface (ar line {in Figum 6,21.3.3.1.

(2) Locate pesntA om line 1 atthe outide ofthe scaton the

retractor side of the seat

(8) Locate point Coa line I at the outside of theseat on the

receiver side of the

(4) Eee point D atthe tip ofthe buckle.

(5) Pall ahe lap bk webbing ere cut ofthe lap bel setae

tor, and manure slong the webbing betwecm point A and

the seat belt ach plate (tongue). Record this lengua AD.

(6) Ubeaeantinagngy int poll wine Land ng on

thecenter af the seat back surface 29 in (TAO mon} from

line I (ine? in Figure 6:21:33.)

(7) Locate point Bonline2at the shoulder strap edge of the

scat back.

(8) Pall the shoulder beh webbing entirely out of theshoul

der belt retractor, and measure along the webbing be

tween point B and the wat belt latch plate (Longue)

Record thislengih 2: BD

(9) Mesure from point CtopointD, and record thislength

a.

(10) The eifectve ap eh web length equals AD + CD.

U1) The cifecive shoulder beltweb Leng eqns BD + CD.

G235.2 A Type 2 cat bl shall have either single reuse

tor or dial retrcions

258.21 Asingle minicior Type 2 pelvic and upper torso

restraintaiyle seat belt sembly shall ave a minimum eee

lve ceat belt web length of 110 in. (2800 mm) with the seat

aipstedal the way backand down and.as measured in accor

dence wih621331.1

6235.22 Adual reuactor Type 2 pelvic and upper torso

restaiataigle seat belt scemblychall have a minimum elec:

fire shoulder belt web Length of 50m. (1270 mm and tink

tum elfocive lap bel web length of 60 in. (1550 tan) with

the scat all the vay back and down and ax measured in

s213312

621.3583" In the case ofa Type? seat belt, the distance from

the buctle anchgraey (coin E in, Frure 6213.8.) to the

tuclletip (pointD in Figure 6.213.53) shall benomorcthan

‘in, (108 en) longer than the perpendlcilar distance fom

the buckle anchorage lteral ans through the H-pointof the

Ain imax)

FIGURE 6.21333 Dimension Lines for Measuring Buckle

Length. (1901:Figure 141.3.23]

PATIENT COMPARTMENT

1917-21

seat (line $in Figure 6.21.3.33) when the seat is adjusted to its

lowest and most rearward position.

6.21.34 Signs that read “Occupants Must Be Seated and

Belted When Ambulance Is in Motion” shall be visible from

cach seaied position.

6.21.4 Seated Head Clearance.

6.21.4.1 The minimum scattocciling dimension from the

top surface of the seat bottom cushion to the nearest overhead

obstruction for each designated seating position shall be 8 in.

(1092 mm).

6.21.42 The measurement shall be in accordance with

AMD (85, Occupant Head Clearance Zones Test.

6.21.5 Seat Adjustment. Where independent horizontal seat

adjustment is provided, it shall be fully adjustable within

10 seconds.

6.21.6 Seating Position Width. Each designated seating space

shall have a minimum width of 24 in. (610 mm) measured

from the seat surface to 43 in. (1092 mm) above the seating

surface.

6.21.7 Seat Size.

6.21.7.1 The seat bottom cushion bright shall bea maximum

of 21in. (533 mm) measured from the floor.

6.21.7.2. Scat bottom cushions shall be a

(460 mm) in width.

6.21.7.3* Scat bottom cushions shall be between 15 in,

(380mm) and 19in. (483mm) from the front of the cushion

to the face of the seat back.

6.21.7.4* Each seat shall provide back and head suppon.

6.21.7.5 For amy scat not covered by #) CFR 571, FMVSS 202,

the top of the seat back or head rest shall be 2 minimum of

10 in. (254 mm) in width.

6.21.8 Access to Patient.

um of 18 in

6.221.8.1 [the primary patient care scat is at the patient torso

position, it shall be capable of being adjusted such that the

seat bottom cushion is within 6 in. (152 mm) of the patient

cob

6.1.8.2 If the primary patient care position is at the patient

torso position, the forcali position of the scat shall bc capable

of lining up within 6 in. (152 mm) of the midpoint between

the head end of the cot and the backrest hinge.

6.21.83 the primary patient care seatis at the patient head

pasition, it shall be capable of being adjusted such that the

nearest edge of the seat bowom cushion is within 6 in

(152mm) of the nearest edge of the patient cot.

6.21.84. Ifthe designated primary patiemt care seat is at the

patient head position, the longitudinal centerline of the scat

shall line up within 11 in, (280 mm) of the longitudinal cen-

terline of the cot.

6.21.9 Child Seating Restraints.

6219.1 Any seat with a built-in system for wansporting a

child or an infant shall be designed for operation in a forward-

facing or rear-facing direction during transport.

6.21.9.2 If the ambulance isdesigned to wanspon infants in a

seat, the ambulance shall indude an infant resraint seat or

‘have provisions to accommodate an infant car seat.

6.21.9.3 Ifthe ambulance is designed to wanspor childrenin

a seat, it shall include a child restraint seat or have provisions

to. accommodate a child car seat.

6.21.10 Seatbelt Waring System.

62 An occupant restraint warning system shall be pro-

vided for cach designated seating position in the patient com-

partment.

6.21.10.2. The warming system shall indicate if'an occupant in

the patient compartments not belted or restrained

6.21.10.3 The warning system shall consist of an audible and

visual warning device that can be heard and seen by the driver

and seen by the occupants of the patient compartment.

6.21.10.3.1 The audible portion of the warning system shall

comply at a minimum with 49 CFR.571, FMVSS 208,

621.104 The waming shall be activated when the parking

brake is released and the transmission is not in neutral or

park.

6.21.10.5 The warning system shall not show an affirmative

indication unless it has determined that the scat was occupied

before the seat belt or restraint was buckled.

6.22 Patient Cot Retention.

6.22.1 Patient cots shall meet the performance requirements

‘of SAE J3027, Ambulance Litter Integrity, Retention, and Patient

Restraint.

6.22.2 The installed cot fastener device(s) for wheeled cats

shall meet the performance requirements af SAE [3027, Ambu-

lance Litter Intagrity, Retention, and Patient Restraint

6.223 A cot fstencr assembly with a quick-release latch shall

be furnished.

6.22.4 The cot fastencr shall be installed according to the cot

fastener manufacturer's directions.

6.22.5 The floor substructure shall be tested in accordance

AMD 004, Litter Retention System Tesi.

6.22.6 Cot and infant wansporters shall only be used with the

required fastener assembly and occupant restraint systems as

prescribed by the litter/ transporter manufacturer.

6.23* HVAC. Connecting hoses for the heating and air

conditioning system stall be supported by rubberinsulated

metal clamping devices at least every 18 in. (457 mm)

6.23.1 Heating.

6.23.11 A heating system shall be provided that is capable of

raising the interior temperature from 32°F to 68°F (0°C to

20°C) within 30 minutes,

6.23.12 Compliance of the heating system shall be validated

by testing a substantially similar ambulance in accordance

with AMD O12, Inderior Climate Control Test

6.23.2 Air Conditioning.

6.23.2.1 An airconditioning system shall be pravided thatis

capable of lowering the interior temperature from 95°F i

TSF (35°C w 95°C) at a minimum of 40 percent relative hu-

midity within 30 minutes.

6.23.2.2 Compliance of the airconditioning system shall be

validated by testing a substantially similar ambulance in accor-

dance with AMD 012, /nterior Climate Control Test

wie eaten

1917-22

AUTOMOTIVE AMBULANCES

6.233 Ventilation.

6.28.3.1 A patient care compartmentair exhaust fan shall be

provided,

6233.2. Ventilation shall be separately controlled within the

caband the patient compariment.

6.2333 Fresh air intakes shall be provided and shall not be

located near the engine exhaust outlet.

6.24 Interior Noise.

6.24.1 The interior sound level in the patient compartment

shall not exceed 80 decibels.

6.242 Compliance of the patient companment interior

sound level stall be validated by testing a substandally similar

ambulance in acconlance with AMD 006, Patient Compartment

Sound Level Test.

6.25° Reflective Suiping.

6.25.12 A revorcfleciive stripe, 2 combination of reuroreflee-

tive stripes, or Battenburg markings shall be allixed to the

ambulance in the following proportions:

(1) % percent of the length off cach of the cab side surfaces

when approached from cach side

(2) 7% percent of the patient comparument side surfaces

when approached from cach side

6.252 The stripe or combination of stipes shall bea mini

‘mum of 6 in. (159 mm) in worl vertical widdh.

6.253 TheGin. (159 mm) wide suipe or combination of axipes

shall be permied wo be iniemuptedby objets (eq. receptacles,

cracks between dts in rollup doors), prenided Use fal spe i

conspicuous asthe ambulance is approached.

6.254. Arcuorcflectve graphic design shall be permitted wo

replace al or part of the required striping material om the

front and sides of the vebicle if the design or combination

thereof covers at least the sume surface arca as required by

625.1

6.25.5 Any vertically hinged door shall have at least 60

(38,710 mm!) of reworelective material affixed to the inside

othe door.

6.25.6° Atleast 50 percentof the rear-facing venical surfaces

other than glass and lenses, visble when facing from the ear

ofthe ambulance, shall be equipped with retoreflective mate

al

6.5.6.1 Where chevronsare used, each stripe in the chevron

shall be a single color alternating betwoen two high-contrast

colors.

6.5.6.2. Fach stripe shall be 6 im. (152 mmm) in width,

6.25.63 Where Battenburg markings are used, cach box in

the Battenburg markings shall be 144 in.* (92,903 mm)

6.25.7 Allreworeflecve material shall eonform w the require.

‘ments of ASTM D1956, Standanl Specficatio for Retmflectoe het.

ing for Tac Cont Section 6.1.1, for Type I Sheeting.

6.25.8 All etroreflective materials thatare colors not listed

in ASTM D4956, Standard Specification for Retroreective Sheet-

ing for Traffic Control, Section 6.1.1, shall have 2 minimum

cocflicient of retroreflection of 10 with an observation

angle of 0.2 degrees and an entrance angle of 4 degrees.

D are ea10n

6.25.9. Any printed orprocessed retrorcflective film construc:

tion shall conform to the standards required of an integral

colored film as specified in ASTM D4956, Standard Specification

for Retrarefetive Shectng far Traffic Contnl, Section 6.1.1

6.25 Metal Finish. Where dissimilar metals that pose a gal

‘sanic corrosion or reactive threat are to be mounted togetier,

the mounting base matcrial shall have an isolation barrier

prior to assembly to prevent dissimilar metal reaction.

6.27 Painting,

6.27.1 All exposed ferrous metal surfaces that are not plated

‘oF stainless stcel shall be cleaned, prepared, and painted or

coud.

G22 The paint or coating, including any primer, shall be

applicd in accordance with the paint oF coating manuficusr

cr's recommendation.

6.28 Medical Gas — Main Supply and Installation,

628.1 Theambulance shall have a piped medical gas system

‘capable of supplying a minimum of 793 gal (300 L) of medi-

alga,

622 Ma compressed gas cylinder is used, 2 cylinder.

‘changing wrench shall be sccured within the medical gas stor-

age compartment.

6.28.3" All medical gas system controls shall be accessible

from inside the vehicle.

6284 A medical gae-capacity indicator shall be visible from

the designated primary pationt care seating position,

62.5. The medical gas outlet shall be accesible from the

designated primary patient care seating pexition,

6.23.6 The purchaser shall specify the quantity and location

of medical gas outlets

6.28.7 Medical gas system shall include the following:

(2) Apresure regular

(2) Low pressure, dectrically conductive hose and finingsap-

proved for medical gas

(8) Medical gas piping that is concealed and not exposed 10

the elements, securely supported to prevent damage, and

be readily accessible for inspection and replacement

(4) Medical gas that is piped wo a se-scaling medical gas out.

letwith2 minimums flow rte of 964 gpm (1001/min) at

the outlet

©) Ouilet(s) that is marked and identified and does not in-

terfere with the suction outlet

628.8 Medical gas and suction ports shall be within reach of

EMSPs while remaining seated and restrained in the desig-

sated primary patient care position,

628.9 Medical Gas Pressure Regulator.

6289.1 The medical gus presure reducing and regulating

salve sjstem shall be provided with the following features

(1) An inlet filter at the tinder

(2) Aline relief valve set 2t 200 pai (1380KPa) maximum

) Agauge or digital monitor with a minimum range of Opsi

10 2500 pai (0 kPa to 17,237 KPs) graduated in not more

than 100 pi (690 kPs) increments

(® Alocking adjustment preset at 50 psi = 2 psi (345 KPa

= M4 KPa) line pressure

LOW VOLTAGE ELECTRICAL SYSTEMS AND WARNING DEVICES

6.28.9.2 ‘The regulator shall meet the performance required

‘by 6.29.3 at an inlet pressure range from 150 pri to 2500 pri

(1054 kPa wo 17,257 KPa)

6.28.93 With the regulator set at 30 psi =2 pai (345 kPa

2 14 kPa), 2.96.4 gpm (100 L/min) minimum Dow rate shall

bbe available at all medical gas outlets,

6.28.10 Medical Gas Tank Storage.

628.101 Storage forthe main medical gas cylinder shall be

accesible for replacement from an outside postion.

628.102 The medical gas compartment shall be provided

with atleast 9 in.* (580 mm) of open vent to dissipate or went

leaking medical gas to the outside of the ambulance.

6.238.103 Medical gascylinder compartment shall not be uti-

lized for storge of any other equipment and shall be labeled

*Medlical Gas Storage Only

6.28.11 Medical Gas Tank Retention.

6.28.11.1 Medical gas cjlinder(s) shall be mounted with 2 re-

straining device 6) that meets the requirements of SA J3043,

‘Ambulance Equipment Mounts

628.112 Compliance of the medical gas tank retention de~

vice shall be validated by testing a sample retention dev

using a substantially similar ambulance or body structure in