Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Design of Bed Block PDF

Cargado por

ChManikumarTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Design of Bed Block PDF

Cargado por

ChManikumarCopyright:

Formatos disponibles

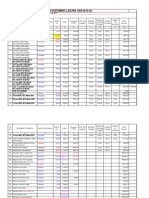

Name of the Work:- Construction of High Level Bridge on Local Vage at Km 3/0 to 3/2 on the Road from

Kalavalla (V) to Viswanadhapuram (V) Via V.R.Kota of Lingasamudram Mandal of Prakasam District.

I)

Design of Backing wall

Deck thickness

RCL

Bed block top level

Thickness of bed block

Width of abutment bed block

Length of abutment

Thickness of backing wall

Diameter of main bars

Diameter of distribution bars

Height of backing wall

A)

+

+

+

=

=

=

=

=

=

0.700

101.050

100.250

0.300

0.750

8.748

0.300

12

10

M

M

M

M

M

M

M

MM

MM

101.050

0.1 -

100.25 =

30 o

1.8 t/cum

Ka =

0.279

Moment due to earth pressure

From Coulomb's formula,

for Phi

Unit weight of earth,

Y

=

=

Active earth pressure, Pa

Lever arm =

0.42 H

Moment due to earth pressure,M1

at the base of backing wall

=

=

Bending moment due to fluid pressure

(480 kg/cum)

0.279 x

2

0.42 x

0.123 x

WH3 =

6

1.8

0.7 =

0.294 =

0.48 x

0.7

0.700 M

0.294 M

0.036 tm

0.7

6

<

B)

C)

Moment due to live load surcharge

Live load surcharge

=

Intensity of LL surcharge, Pa(ll)

=

Ka.Y.H =

Total earth pressure due to LL surcharge =

Moment due to LL surcharge at M2

=

1.2

0.279

0.603

0.422

M

x

x

x

Moment due to braking force

Maximum axle load is 20 t for class 70 R wheeled

Braking force

=

20%

Dispersion width at the top of bed block

( distances of wheel loads as per Cl. IRC 6)

=

0.3 +

0.3 +

0.3 +

=

3.9 M

Intensity of wheel load / RM

Lever arm

Moment due to braking force, M3

Total Moment, M1+M2+M3

=

=

=

Adopt M20 grade concrete

C

=

67 kg/sqcm

t=

m=

10 k=

d eff

=

30 4.00 dreqd

sqrt( M/Qb)

0.7 +

4.00

3.9

1.2

1.03

0.036

1.8 x

0.7 =

0.7 x

1.2 =

0.422 t/m

0.5 =

20 =

4t

0.3 +

0.3 +

1.03 t

+

x

+

0.7 =

1.9 =

0.148 +

2000 kg/sqcm

0.251 j=

0.916

1.20 =

25.40

2

sqrt(

2.133

7.7

Q=

cm

x

x

0.123 t/sqm

0.027

tm

0.036 tm

0.603 t/sqm

0.148 tm

0.3 +

2x

acts at 1.20 M above RCL

1.9 M

1.949 tm

1.949 =

2.133 tm

7.7

100000 )=

100

<

16.640 cms

25.400 cms d available

0.7

Ast =

2.133 x

100000

=

4.583 sqcm

2000 x

0.916 x

25.4

Min. steel =

0.15% x

25.40 x

100 =

3.81 sqcm

Hence provide Ast

=

4.583 sqcm

Use

10 mm dia bars

Spacing =

0.785 x

100 =

17.130 cms

>

4.583

Provide mm dia.

10 mm

barsbars

@ 150

@mm c/c150

on both

mm sides

c/c in in

thethe

form of stirrups

Distribution steel

0.15 % of C/s area =

Use

10 mm dia bars

Spacing

0.785 x

4.500

Provide

10 mm dia @

II)

0.15% x

100 =

100 =

4.5 sqcm

17.440 cms

170 MM c/c

Design of bed block reinforcement

(As per IRC 78-1983 Cl. 716.2.1)

Steel to be provided

=

1% x

75 x

30 =

22.5 sqcm

Long bars at top and bottom

=

22.5 =

5.625 sqcm

Use

12 mm dia

4

Spacing

5.625

=

4.978 Nos

or say

5 Nos

1.13

Hence provide 12 mm dia. 5 Nos each at top and bottom equally spaced

Steel in transverse direction

Ast

=

22.5 =

2

Volume of steel, t/m

=

Use

10 mm dia

Length of each stirrup

=

Volume of each stirrup

No. of stirrups

11.250 sqcm

11.25 x

2 x(

=

1125 =

153.86

Spacing of stirrups

=

100 =

8

Provide

10 MM dia. stirrups at

III)

=

30.000

15 cms

Design of Pier bed block reinforcement

Steel to be provided

=

1% x

Long bars at top & bottom =

Provide

12 MM dia bars

100 =

1125 cucm

67 +

196 x

22 ) +

0.785 =

7.312 No or say

18 x

1.00 =

153.86 cucm

8.000 Nos.

12.500 cms

120 MM c/c

86 x

25.8 =

4

=

6.450 sqcm

25.8 =

2

12.9 x

12.900 sqcm

30 =

25.800 sqcm

6.450 =

5.708 Nos. or say

1.13

Hence provide 12 mm dia. 6 Nos at top and bottom equally spacing

Steel in transverse direction

Area of steel

=

Volume of steel, t/m

Use 10 mm dia. Bar

Length of each stirrup

Volume of each stirrup

No. of stirrups

=

=

=

=

2 x(

242 x

1290 =

189.97

Spacing of stirrups

100 =

8

Provide

10 MM dia. stirrups at

196 cms

100 =

1290 cucm

87 +

25 )+

18 x

0.785 =

189.97 cucm

6.791 Nos. or say

8.000 Nos

12.500 cms

120 MM c/c

6.000 Nos

1=

242 cms

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- Naruto Vol 4Documento171 páginasNaruto Vol 4Andrew WongAún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Fisiologia de KatzDocumento663 páginasFisiologia de KatzOscar Gascon100% (1)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- RCC Design Based in Indian CodesDocumento43 páginasRCC Design Based in Indian Codeschaos_atulAún no hay calificaciones

- Calculation For 1.4m X 1.5m RCC Box CulvertDocumento8 páginasCalculation For 1.4m X 1.5m RCC Box CulvertChManikumarAún no hay calificaciones

- Calculation For 1.4m X 1.5m RCC Box CulvertDocumento8 páginasCalculation For 1.4m X 1.5m RCC Box CulvertChManikumarAún no hay calificaciones

- Vox Latina The Pronunciation of Classical LatinDocumento145 páginasVox Latina The Pronunciation of Classical Latinyanmaes100% (4)

- Vital StatisticsDocumento35 páginasVital StatisticsRadha100% (1)

- Pile Foundation DesignDocumento82 páginasPile Foundation Designcuongnguyen89% (28)

- 30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingDocumento21 páginas30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingkilioAún no hay calificaciones

- Cold mix vs hot mix cost comparisonDocumento8 páginasCold mix vs hot mix cost comparisonChManikumarAún no hay calificaciones

- Organic Evolution (Evolutionary Biology) Revised Updated Ed by Veer Bala RastogiDocumento1212 páginasOrganic Evolution (Evolutionary Biology) Revised Updated Ed by Veer Bala RastogiTATHAGATA OJHA83% (6)

- Design of Aspects of CC Roads PDFDocumento12 páginasDesign of Aspects of CC Roads PDFviharikapavuluri1290100% (1)

- Design of Aspects of CC Roads PDFDocumento12 páginasDesign of Aspects of CC Roads PDFviharikapavuluri1290100% (1)

- Pathophysiology of Cardiogenic Pulmonary EdemaDocumento8 páginasPathophysiology of Cardiogenic Pulmonary EdemaLili Fiorela CRAún no hay calificaciones

- Design of Pier PDFDocumento4 páginasDesign of Pier PDFChManikumarAún no hay calificaciones

- Design of Pier PDFDocumento4 páginasDesign of Pier PDFChManikumarAún no hay calificaciones

- Design of Pier PDFDocumento4 páginasDesign of Pier PDFChManikumarAún no hay calificaciones

- Design of Abutment PDFDocumento4 páginasDesign of Abutment PDFChManikumarAún no hay calificaciones

- PACL Lodha Commette Final NOTICE of SALE With Property DetailsDocumento4 páginasPACL Lodha Commette Final NOTICE of SALE With Property DetailsVivek Agrawal100% (2)

- BR Det and AbstractDocumento24 páginasBR Det and AbstractChManikumarAún no hay calificaciones

- ASTRA Data InputDocumento20 páginasASTRA Data InputChManikumarAún no hay calificaciones

- Reatining WAll With SLOPING Bach FillDocumento28 páginasReatining WAll With SLOPING Bach Fillp_ignatiusAún no hay calificaciones

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Documento37 páginasSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarAún no hay calificaciones

- NABARD XXII Tranche Proposed Works List Prakasam DistrictDocumento2 páginasNABARD XXII Tranche Proposed Works List Prakasam DistrictChManikumarAún no hay calificaciones

- Design of SlabsDocumento2 páginasDesign of SlabsHaychikkina Bull RockersAún no hay calificaciones

- DPR Estimate Oduru RoadDocumento42 páginasDPR Estimate Oduru RoadChManikumarAún no hay calificaciones

- Design of SlabsDocumento2 páginasDesign of SlabsHaychikkina Bull RockersAún no hay calificaciones

- Kothapatnam Shelter Type B - 10TDocumento2 páginasKothapatnam Shelter Type B - 10TChManikumarAún no hay calificaciones

- PrakasamDocumento4 páginasPrakasamChManikumarAún no hay calificaciones

- Reatining WAll With SLOPING Bach FillDocumento28 páginasReatining WAll With SLOPING Bach Fillp_ignatiusAún no hay calificaciones

- Score SheetDocumento1 páginaScore SheetChManikumarAún no hay calificaciones

- PrakasamDocumento4 páginasPrakasamChManikumarAún no hay calificaciones

- Hydraulics VR Kota KandukurDocumento6 páginasHydraulics VR Kota KandukurChManikumarAún no hay calificaciones

- Model PMGSY Road Datas 2013-14-SSRDocumento91 páginasModel PMGSY Road Datas 2013-14-SSRChManikumarAún no hay calificaciones

- PrakasamDocumento4 páginasPrakasamChManikumarAún no hay calificaciones

- Score SheetDocumento1 páginaScore SheetChManikumarAún no hay calificaciones

- Score SheetDocumento1 páginaScore SheetChManikumarAún no hay calificaciones

- Key Personnel'S Affidavit of Commitment To Work On The ContractDocumento14 páginasKey Personnel'S Affidavit of Commitment To Work On The ContractMica BisaresAún no hay calificaciones

- Compliance Risks and Controls: Speaker: Dott. Fabio AccardiDocumento14 páginasCompliance Risks and Controls: Speaker: Dott. Fabio AccardiJefferson WidodoAún no hay calificaciones

- Ferain Et Al, 2016 - The Fatty Acid Profile of Rainbow Trout Liver Cells Modulates Their Tolerance To Methylmercury and CadmiumDocumento12 páginasFerain Et Al, 2016 - The Fatty Acid Profile of Rainbow Trout Liver Cells Modulates Their Tolerance To Methylmercury and Cadmiumarthur5927Aún no hay calificaciones

- Ecma L1221BR3 PD02 05172016Documento2 páginasEcma L1221BR3 PD02 05172016Anil JindalAún no hay calificaciones

- Blink CodesDocumento3 páginasBlink CodesNightin VargheseAún no hay calificaciones

- Viviana Rodriguez: Education The University of Texas at El Paso (UTEP)Documento1 páginaViviana Rodriguez: Education The University of Texas at El Paso (UTEP)api-340240168Aún no hay calificaciones

- Duet Embedded Memories and Logic Libraries For TSMC 28HP: HighlightsDocumento5 páginasDuet Embedded Memories and Logic Libraries For TSMC 28HP: HighlightsmanojkumarAún no hay calificaciones

- Job Interview CV TipsDocumento2 páginasJob Interview CV TipsCarlos Moraga Copier100% (1)

- Sles-55605 C071D4C1Documento3 páginasSles-55605 C071D4C1rgyasuylmhwkhqckrzAún no hay calificaciones

- Crio - Copy Business Operations - Case Study AssignmentDocumento3 páginasCrio - Copy Business Operations - Case Study Assignmentvaishnawnikhil3Aún no hay calificaciones

- Cases 39 45 PDFDocumento11 páginasCases 39 45 PDFYvette Marie VillaverAún no hay calificaciones

- Admission Notice 2023-24Documento2 páginasAdmission Notice 2023-24Galav PareekAún no hay calificaciones

- Schedule For Semester III, Class of 2021Documento7 páginasSchedule For Semester III, Class of 2021Jay PatelAún no hay calificaciones

- Lab 1 Boys CalorimeterDocumento11 páginasLab 1 Boys CalorimeterHafizszul Feyzul100% (1)

- List of OperationsDocumento3 páginasList of OperationsGibs_9122100% (3)

- CEA-2010 by ManishDocumento10 páginasCEA-2010 by ManishShishpal Singh NegiAún no hay calificaciones

- DRUG LISTDocumento45 páginasDRUG LISTAmitKumarAún no hay calificaciones

- The Meaning of Solar CookerDocumento4 páginasThe Meaning of Solar CookerJaridah Mat YakobAún no hay calificaciones

- Chapter - 2 Fish MongeryDocumento10 páginasChapter - 2 Fish MongeryKrishna ChaudharyAún no hay calificaciones

- Going to the cinema listening practiceDocumento2 páginasGoing to the cinema listening practiceMichael DÍligo Libre100% (1)

- CSIR AnalysisDocumento1 páginaCSIR Analysisசெபா செல்வாAún no hay calificaciones

- Case NoDocumento13 páginasCase NoLaurente JessicaAún no hay calificaciones