Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Vol6 Section08

Cargado por

Syifa Alfiah Andini PutriTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Vol6 Section08

Cargado por

Syifa Alfiah Andini PutriCopyright:

Formatos disponibles

Section 8 - Execution of Welds

E, F, G

8-1

Section 8

Execution of Welds

A.

General

such applications shall be complied with.

1.

Scope, supplementary provisions

4.3

Welding consumables and auxiliary materials may

only be used with the electrode diameters covered by the

tests and for the approved welding positions. The

manufacturer's instructions and recommendations for use

(e.g. the type of current and polarity used) shall be complied

with.

1.1

This section contains universal rules applicable to

the performance of welding work, extending from the weld

preparation to the completion of the welded joints including

any finishing operations. For heat treatment see Section 9;

for testing of the welded joints, Sections 10 and 11.

1.2

The performance of the welding work is additionally

governed by the application-specific requirements stated

in the various Sections 12 to 16. The relevant provisions

of the respective Rules for Hull, Volume II, shall also be

complied with.

2.

Welding shop requirements

2.1

All workshops wishing to carry out welding work

shall comply with the welding shop requirements stipulated

in Sections 2 (Approval), 3 (Welder's Qualification Tests)

and 4 (Welding Procedure Tests), and where necessary,

Section 10 (Non-destructive Testing of Welds).

2.2

Workshops shall maintain up-to-date records of this

compliance and shall submit them to the Surveyor at his

request. If necessary (e.g. in the case of a prolonged

interruption to the work, cf. Section 2, A.4.2 and Section.3,

E.), the Society may reinspect the workshop.

3.

Materials, marking

3.1

Welding may only be performed on materials whose

identity and weldability under the given fabricating

conditions can be unequivocally established by reference

to markings, certificates, etc.

4.4

If necessary, welding consumables and auxiliary

materials are to be baked, prior to use, in accordance with

the manufacturer's instructions (keeping to the specified

maximum baking time) and are to be kept dry at the place

of work (in heated containers or similar).

5.

Overweldable shop primers

5.1

Overweldable shop primers which are applied to

plates, sections, etc. prior to welding and are not removed

must be tested and approved in accordance with Section.6.

5.2

Welding shops shall ensure by suitable checks

(especially on the thickness of the coating) and production

tests carried out at random during the course of normal

fabrication that the quality of the welded joints is not

impaired to an unacceptable degree.

6.

Manufacturing documents, company standards

6.1

Welds shall be executed in accordance with approved

drawings, welding schedules or company standards

recognized by the Society. Exceptions to this rule are subject

to the Society's consent in each individual case.

6.2

Compliance with the manufacturing documents is

the responsibility of the welding shop.

3.2

In case of doubt, the identity and weldability of the

materials shall be verified before welding commences.

4.

B.

Weld Preparation, Assembly

1.

Weld preparation

Welding consumables and auxiliary materials

4.1

Only welding consumables and auxiliary materials

tested in accordance with Section 5, approved by the Society

and of a quality grade appropriate to the base material to

be welded may be used. The various quality grades

corresponding to the different hull structural steels shall

be as shown in Table 12.1 in Section 12.

4.2

Welding consumables and auxiliary materials for

particular materials and those intended for special welding

processes which have been approved on the basis of a

(preliminary) welding procedure test may be used only for

the range of application specified in the relevant approval

certificate. Any special conditions or rules associated with

1.1

Weld preparation may be carried out by thermal

cutting or machining. Seam edges (groove faces) prepared

by thermal cutting shall be finished by machining (e.g.

grinding) if a detrimental effect on the welded joint as a

result of the cutting operation cannot be ruled out. Welding

edges of steel castings and forgings shall always be ground

as a minimum requirement; roll scale or casting skin is to

be removed.

1.2

Groove faces must be free from impurities and defects

liable to impair the quality of the welded joint, e.g. laps,

coarse grooves made by the cutting torch and slag. Prior

8-2

Section 8 - Execution of Welds

to welding, the welding edges shall be inspected for defects,

e.g. cracks, inclusions, blowholes or pores, using

non-destructive testing methods if necessary.

2.

2.2

The root opening shall not exceed twice the specified

gap. If the size of the gap permitted by this rule is exceeded

locally over a limited area, the gap may be reduced by

build-up welding of the side walls, subject to the consent

of the Surveyor. With fillet welds, the "a" dimension shall

be increased accordingly, or a single- or double-bevel weld

shall be made if the air gap is large. Inserts and wires may

not be used as fillers.

Alignment of components

3.1

Components which are to be united by butt welding

are to be aligned as accurately as possible. Sections welded

to plating shall be left unwelded at the ends for this purpose.

Special attention shall be paid to the alignment of (abutting)

girders which are interrupted by transverse members. If

necessary, such alignment shall be facilitated by drilling

check holes in the transverse member which are

subsequently closed by welding.

3.2

The permissible edge alignment error depends on

the nature, importance and loading of the component

concerned and is dealt with in the various section of Sections

12 to 16. Where special loading conditions or other

requirements relevant to the application necessitate a

limitation of the edge alignment error, the allowable error

shall be stated in the manufacturing documents.

4.

Tack welds and preparations for welding

4.1

Tack welds should be used as sparingly as possible

and should be made by trained personnel. Where their

quality does not meet the requirements applicable to the

welded joint, they are to be carefully removed before the

permanent weld is made.

4.2

Clamping plates, temporary ties and aligning pins

shall be made from the same material as the base material

or from a material of similar composition and should not

be used more than necessary. Any damage caused during

their removal shall be competently repaired.

4.3

With mechanized welding processes or when arc

striking and end crater defects in butt welds have to be

avoided, run-in and run-off plates shall be provided in

continuation of the line of the weld.

4.4

the welds. Any scale, rust, cutting slag, grease, paint (except

for approved overweldable shop primers), moisture or dirt

shall be carefully removed before welding.

Weld shapes, root openings (air gaps)

2.1

When preparing and assembling components, care

shall be taken to ensure compliance with the weld shapes

and root openings (air gaps) specified in the manufacturing

documents. With single- and double-bevel butt welds in

particular, care shall be taken to make an adequate root

opening to achieve sufficient root penetration.

3.

E, F, G

Components must be clean and dry in the area of

C.

Weather Protection, Preheating

1.

The areas to be welded shall be adequately protected

against climatic influences such as wind, damp and cold

and shall be preheated where necessary.

2.

The need for and degree of preheating is determined

by various factors, such as chemical composition, plate

thickness, two- or three-dimensional heat dissipation,

ambient and workpiece temperatures, or heat input during

welding (energy applied per unit length of weld). Details

are given in Section 9 and various section of Sections 12

to 16.

3.

Preheating shall be applied uniformly throughout

the thickness of the plate or component over a width of four

times the plate thickness, but not less than 100 mm.

Preheating may be as necessary for tack and auxiliary welds

as for fabricating welds.

D.

Welding Positions, Welding Sequence

1.

Welding should be performed in the optimum welding

position; positional welding is to be limited to the

indispensable minimum. The welders employed on positional

welding must be qualified for the welding positions

concerned. With regard to welding in the vertical-down

position, see Section 12, H.6.

2.

The welding sequence shall be chosen to allow

shrinkage to take place as freely as possible. Butt joints

in areas of plating shall invariably be fully welded prior

to attaching girders and stiffeners. The Society may require

an assembly procedure or welding sequence schedule to

be drawn up in special cases.

E.

Performance of Welding

1.

The welding shop shall ensure that the specified

welding parameters are adhered to and that the welding

work is expertly performed.

2.

Components shall not be subjected to any appreciable

movements or vibration during welding. Parts to be

assembled while suspended from cranes or floating shall

be clamped prior to tack-welding of the joints in such a way

that no relative movement of the parts is possible.

Components which have not been fully welded and which

are to be handled or turned must have welded joints of

adequate strength.

Section 8 - Execution of Welds

3.

Cracked tack welds may not be welded over, but

are to be machined out. In multi-pass welding, the slag of

the previous run shall be completely removed before the

next pass is laid down. Pores, visible slag inclusions and

other welding defects and cracks may not be welded over,

but are to be machined out and repaired.

4.

Welds must have sufficient penetration and must

display a clean, regular surface with "gentle" transitions

to the base material. Excessive weld reinforcements and

undercuts or notches affecting the edges of plates and cutouts

are to be avoided.

5.

Butt-welded joints must display full fusion over the

entire cross-section, unless otherwise specified in a particular

case. For this purpose, the root shall normally be grooved

and capped. Following a successful welding procedure test

confirmed by the Society, single-side welds, e.g. using

ceramic backings, may be regarded as equivalent to butt

welds executed from both sides. Other joints welded on

one side only, e.g. using permanent backings, are subject

to the Society's approval when scrutinizing the relevant

drawings.

6.

Single- and double-bevel butt welds are to be made

according to the design specification either with grooved

roots as full penetration welded joints or with a permitted

incomplete penetration at the root or defined, unwelded

root face subject to the appropriate reduction factors (cf.

Section 12, G.10.2). The type of weld is to be specified

in the drawings in each case and must have received the

Society's approval when scrutinizing the drawings.

7.

With fillet welds, particular attention shall be paid

to good root penetration. The penetration must extend to

at least the immediate vicinity of the theoretical root point.

The ideal fillet weld section is that of an equal-sided

flat-faced weld with smooth transitions to the base material.

At the ends of web plates, at cutouts and at welding

apertures, the fillet welds shall be formed round the web

to form a seal.

8.

Major cases of faulty workmanship or defects in

the material may only be repaired with the Surveyor's

agreement. Minor surface defects shall be removed by

shallow grinding. Defects which penetrate more deeply

into the material (e.g. cracks, or damage caused by the

removal of auxiliary erection equipment) shall be cleanly

machined out and where necessary repair-welded with an

adequate heat input.

9.

Repair (so-called production welds) on steel castings

and forgings shall only be made with the consent of the

E, F, G

8-3

Surveyor. If their volume is considerable, sketches and

descriptions of the repair work shall be submitted to the

Society's Head Office for approval, together with details

of the analysis of the base material, the welding process

and the welding consumables and auxiliary materials. The

Society may require stress relief heat treatment or, in special

cases, further heat treatment of the components after

welding.

10.

When working and welding higher-strength hull

structural steels, high-strength (quenched and tempered)

fine-grained structural steels, austenitic stainless steels and

aluminium alloys, attention should be paid to the relevant

information and instructions in the various section of

Sections 12 to 16. For this work, the Society may require

an appropriate welding specification to be submitted.

F.

Straightening, Tolerances

1.

Straightening operations (whether thermal or

mechanical) shall not impair the quality of the materials

and welded joints. The Society may require verification

of the suitability of the straightening method (e.g. by

means of a welding procedure test). This especially applies

to high-strength (quenched and tempered) fine grain

structural steels.

2.

Unless specific tolerances are stated in the various

section of Sections 12 to 16 or in the manufacturing

documents, the dimensional tolerances for welded structures

shall be as specified in the standards, e.g. EN ISO 13920

and for welded joints conforming to EN 25817/ISO 5817

or EN 30042/ISO 10042, (see Appendixes 6 and 7). The

degree of fineness and the evaluation category shall be

stipulated in the manufacturing documents. The Society

may specify other (tighter) tolerances where this is necessary

for reasons of strength and/or operational safety.

G.

Post-Weld Treatment of Welds

1.

If it is intended to carry out post-weld treatment of

the welds, e.g. to improve the surface finish in the case of

dynamic loading, such treatment shall not impair the

characteristics (mechanical properties) of the welded joints.

The Society may demand documentary proof thereof.

2.

For post-weld heat treatment, see Section 9; for the

post-treatment of surfaces for non-destructive testing, see

Section 10, F.1.

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Adhesives and SealantsDocumento8 páginasAdhesives and SealantsJosephus GallardoAún no hay calificaciones

- Attachment 5 - Valve Design Table PDFDocumento8 páginasAttachment 5 - Valve Design Table PDFbisworupmAún no hay calificaciones

- Fab Plans CatDocumento25 páginasFab Plans CatSyifa Alfiah Andini PutriAún no hay calificaciones

- 3MDyneon FKM Compounding Guide 98050413248RevCDocumento28 páginas3MDyneon FKM Compounding Guide 98050413248RevCDyaniAún no hay calificaciones

- A General Review of The Causes and Acceptance of Shape ImperfectionsDocumento6 páginasA General Review of The Causes and Acceptance of Shape ImperfectionsAnonymous vU7CuPAún no hay calificaciones

- Plant Curriculum Instructor Unit 1Documento46 páginasPlant Curriculum Instructor Unit 1ericleiva66Aún no hay calificaciones

- GRP - GRE - GRV Pipes and FittingDocumento11 páginasGRP - GRE - GRV Pipes and FittingPankajAún no hay calificaciones

- Sohar Oman CompaniesDocumento160 páginasSohar Oman CompaniesMinal Parapannawar67% (3)

- Corrosion HDBK S2Documento296 páginasCorrosion HDBK S2Aleksandra AleksicAún no hay calificaciones

- General: Hybrid PropulsionDocumento1 páginaGeneral: Hybrid PropulsionSyifa Alfiah Andini PutriAún no hay calificaciones

- NG 84Documento109 páginasNG 84Syifa Alfiah Andini PutriAún no hay calificaciones

- ANSYS15 Installation PDFDocumento9 páginasANSYS15 Installation PDFSyifa Alfiah Andini PutriAún no hay calificaciones

- AC and Refrigeration PlantsDocumento23 páginasAC and Refrigeration PlantsSyifa Alfiah Andini PutriAún no hay calificaciones

- Section 1 Principles Covering The Manufacture and Testing of MaterialsDocumento5 páginasSection 1 Principles Covering The Manufacture and Testing of MaterialsSyifa Alfiah Andini PutriAún no hay calificaciones

- Section 14 Welding of Pressure Vessels: Preliminary RemarkDocumento12 páginasSection 14 Welding of Pressure Vessels: Preliminary RemarkSyifa Alfiah Andini PutriAún no hay calificaciones

- Foreword Content Articles of The International Convention For The Safety of Life at Sea, 1974Documento12 páginasForeword Content Articles of The International Convention For The Safety of Life at Sea, 1974Syifa Alfiah Andini PutriAún no hay calificaciones

- Section 6 Overweldable Shop Primers: A. General 1. 1.2Documento3 páginasSection 6 Overweldable Shop Primers: A. General 1. 1.2Syifa Alfiah Andini PutriAún no hay calificaciones

- PC750-7 S/N 20001-UP (Overseas Version)Documento2 páginasPC750-7 S/N 20001-UP (Overseas Version)АлександрAún no hay calificaciones

- 2010 Masterformat Sample JobCost Codes + NotesDocumento11 páginas2010 Masterformat Sample JobCost Codes + NotesYay B. GicoAún no hay calificaciones

- BS 729 1971 Hot Ip Galvanized Coatings On Iron and Steel ArticlespdfDocumento15 páginasBS 729 1971 Hot Ip Galvanized Coatings On Iron and Steel ArticlespdfAvinash LalAún no hay calificaciones

- Is 2062 2011Documento17 páginasIs 2062 2011navneet SharmaAún no hay calificaciones

- Fire Resistance Ratings - ANSI/UL 263: Design No. U311Documento3 páginasFire Resistance Ratings - ANSI/UL 263: Design No. U311DavidAún no hay calificaciones

- E - Crosby Chain Grade 80 AlloyDocumento1 páginaE - Crosby Chain Grade 80 Alloyrony 2222Aún no hay calificaciones

- Nobel 2022 - CabinetDocumento10 páginasNobel 2022 - CabinetLynn ChiaAún no hay calificaciones

- Materials and Processes For Agricultural and Biosystems EngineeringDocumento11 páginasMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioAún no hay calificaciones

- ITB-KEOH-2016-009 - Section V - Annex D (Ii) - Electrical Works DrawingsDocumento29 páginasITB-KEOH-2016-009 - Section V - Annex D (Ii) - Electrical Works DrawingsSefaAún no hay calificaciones

- Comparative Analysis Between Lime and Cement Mortar in Traditional BuildingsDocumento44 páginasComparative Analysis Between Lime and Cement Mortar in Traditional BuildingsGAURAV mISHRAAún no hay calificaciones

- Effect of Aggregate Properties On Asphalt Concrete MixesDocumento18 páginasEffect of Aggregate Properties On Asphalt Concrete MixesNgabirano B. JuliusAún no hay calificaciones

- Masoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesDocumento9 páginasMasoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesisctomaslopezAún no hay calificaciones

- Infogramm: Remanium StarDocumento2 páginasInfogramm: Remanium StarPiAún no hay calificaciones

- SCI C Vitaulic Snap-Let Outlet Snap 11.04Documento2 páginasSCI C Vitaulic Snap-Let Outlet Snap 11.04jplutodAún no hay calificaciones

- Technical Instruction Manual: Meva Formset MfsDocumento20 páginasTechnical Instruction Manual: Meva Formset MfspablopelaAún no hay calificaciones

- Plumbing 4 ADocumento2 páginasPlumbing 4 AIvy Rafanan PascuaAún no hay calificaciones

- REO Range CatalogueDocumento8 páginasREO Range CatalogueSURAJ PratapAún no hay calificaciones

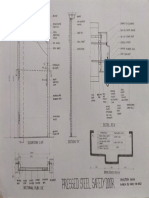

- Pressed Steel Safety DoorDocumento1 páginaPressed Steel Safety DoorAshutosh SinghAún no hay calificaciones

- Weight Room 51420 PDFDocumento6 páginasWeight Room 51420 PDFKeith HuckabayAún no hay calificaciones

- Decalit OtelDocumento2 páginasDecalit OtelCiprian MaiorAún no hay calificaciones

- Roof TestDocumento7 páginasRoof TestJoel BeyerAún no hay calificaciones

- Mod Mto 3Documento2 páginasMod Mto 3Alberto LazoAún no hay calificaciones