Documentos de Académico

Documentos de Profesional

Documentos de Cultura

B003u35 PDF

Cargado por

เปลี่ยนชื่อ ยังไงDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

B003u35 PDF

Cargado por

เปลี่ยนชื่อ ยังไงCopyright:

Formatos disponibles

SNAP-IN

Instruction Bulletin

Replaceable Parts List

Purgemaster

Series 10A6100

D184B003U35

Rev. 01 / 03.2001

You have purchased a high quality, modern instrument

from ABB Automation Products. We thank you for your purchase

and the confidence you have shown in us.

This Instruction Bulletin contains the instructions relating to the assembly and

installation of the instrument and the specifications for this design.

ABB Automation Products reserves the right to make hardware and

software refinements without prior notice.

Any questions which may arise that are not specifically answered by

these instructions should be referred to our main plant in

Gttingen, Germany or to one of our Technical Sales Bureaus.

Copyright by ABB Automation Products. All Rights Reserved

Introductory Safety Notes

Please read this Instruction Bulletin before attempting the installation of the flowmeter!

Ground the flowmeter system, if the indicator housing includes electrical components (see Instrument Tag

and Interconnection Diagram).

Personnel contact protection is negated when the housing cover has been removed and the power is

turned on!

Please observe the warning notes with this symbol:

Hazardous Material Regulations

In view of the Disposal Law of 27.08.86 (AbfG. 11 Special Wastes) the possessor of special wastes is

responsible for their disposal and at the same time an employer has the responsibility, according to the

Hazardous Material Law of 01.10.86 (GefStoffV, 17 General Responsibilities) to protect his employees,

we must make note that

a) all flowmeter primaries and/or converters returned to ABB Automation Products for repair are to be free

of all hazardous materials (acids, bases, solutions, etc.).

b) the flowmeter primaries must be flushed so that the hazardous materials are neutralized.

There are cavities in the flowmeter primaries between the metering tube and the housing. Therefore

after metering hazardous materials these cavities are to be neutralized (see Hazardous Material Law

GefStoffV, Appendix I). This requires that the metering tube, float and float stops be removed from the

flowmeter housing

c) for service and repair, written confirmation is required that the measures described in a) and b) have

been carried out

d) any costs incurred to remove and dispose of the hazardous materials during the repair will be billed to

the owner of the instrument.

Contents

Page

1.

Installation Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

Installation and Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.

Purgemaster with Differential

Pressure Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purgemaster with Alarm Transmitter Model 55AN3000 with Switch Amplifier

WE77/Ex1-Bi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.

Ordering Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.

Interconnection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.

Replaceable Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

15.

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.

Purgemaster SNAP-IN Series 10A6100

1.

Installation Recommendations

See also VDI/VDE-Guideline 3513 Sheet 3, Selection and

Installation Recommendations for Variable Area Flowmeters.

Shut Off Valve

Bypass Valve

Shut Off Valve

Inlet

Fig. 1

Outlet

Flowmeter

To prevent these auto-generated compression oscillations the

following recommendations should be applied:

Flowmeter Installation

Select a flowmeter with a minimum pressure drop.

Install with the up- and downstream distances to the next

throttling location as short as possible.

Increase the operating pressure taking into account the

resultant flowrate value changes due to the variation in the

operating density of the gas

Pressure Shock

Especially when metering gases and liquids containing gas

bubbles, fast opening of magnetic valves in combination with

unthrottled pipeline sections can result in pressure shocks or

oscillations. This can cause the float, due to the sudden change

in the pressure, to violently impact the output float stop. In

certain circumstances this can result in destruction of the

flowmeter.

Solids Contained in the Fluid

Variable Area Flowmeters are suitable for metering fluids

containing a limited quantity of solids. The wear on the flowmeter parts is a function of the concentration, particle size and

the type of solids. Furthermore, solids can leave deposits on the

float which could change its weight and shape. These effects

can lead to errors in the flowrate measurements.

Generally in such case the installation of a suitable filter is to be

recommended.

The Variable Area Flowmeter 10A6100 is installed vertically in

the pipeline. Pipeline vibrations and strong magnetic fields are

to kept at a distance from the flowmeter.

The pipeline size should correspond to the connection size of

the flowmeter. In- and outlet straight sections are not required.

Accuracy and Operating Conditions

The floats and metering tubes are selected for a specific set of

fluid operating conditions. For liquids and gases these are the

pressure and temperature dependent density and viscosity

values at the operating conditions. For gases this requires a

specific operating pressure and a specific operating temperature. The specified accuracy of the flowmeter is always based

on the operation conditions defined in the Specification Sheet..

Pressure Drop

The operating pressure at the flowmeter must be greater than

the pressure drop listed in the flowmeter Specification Sheet.

The pipeline and fitting losses downstream of the flowmeter

must also be considered.

Damping and Compression Oscillations for

Gas Flowmetering

When a certain critical volume up- and downstream to the next

throttling location is exceeded at low operating pressures,

compression oscillations (also called float bounce) may occur.

Purgemaster SNAP-IN Series 10A6100

2.

Specifications

Flow Ranges

See Flow Capacity Tables in the Specification Sheet

RM

Measurement Range

1:10

Accuracy Classes

70 mm scale length

Glass metering tube

Trogamid metering tube

100/130 mm scale length

38 mm scale length

RM = Reading mark for a ball float

4

10

6/1.6

6

Max. allow. Operating Conditions

Max. allow. operating pressure

for borosilicate glass metering tube:18 bar

for Trogamid metering tube:

16 bar**

**

16 bar at 20 C (the max. allow. operating pressure is

reduced by 2.5 bar/10 C temperature increase)

Maintenance

The float and the metering must be kept clean to assure proper

readability and flowmeter operation. The backcheck should

also be inspected for cleanliness and functionality. When

required, damaged parts are to be replaced.

The flowmeter is disassembled as follows:

Lightly squeeze the sides of the protection shield and pull

it out from flowmeter housing.

2.

Warning:

For models without a valve or with a valve at the inlet,

lightly press the metering tube upward against the spring

(approx. 6 to 7 mm). Remove the lower end of the metering tube towards the front of the flowmeter and pull the

metering tube away from the outlet fitting. (See Fig. 2)

Only operate flowmeters with a protection shield or

protection tube over the glass metering tube. It is

essential that the maximum allowable operating

conditions be observed. (See Instruction Bulletin for

installation and start-up information).

For models with a valve in the outlet the metering tube is

pressed downward against the spring in the inlet fitting

(approx. 6 to 7 mm). Remove the upper end of the metering tube towards the front of the flowmeter and pull the

metering tube away from the inlet fitting.

3.

The metering tube can be cleaned with alcohol or a similar

cleaning agent. Trogamid metering tubes must be

cleaned with conventional cleaning agents (e.g. soapy

water). The flowmeter is reassembled in the reverse order. Special attention must be given to the proper seating

of the O-ring seals. It is advisable to lubricate any O-rings

which have dried out to facilitate their assembly. O-rings

for flowmeters used to meter Oxygen may not be lubricated with grease under any circumstances. Instead the use

of Voltalef 90* (BAM tested) is recommended. Damaged

O-rings should always be replaced.1).

1)

When selecting the O-ring material, the corrosion resistance of the O-ring for the fluid being metered must be

considered.

May be obtained from :

Lehmann & Voss & Co, Alsterufer 19, 20354 Hamburg,

Germany

Installation and Start-Up

The Purgemaster flowmeter is to be installed vertically in the

pipeline with the highest scale values at the top. Dependent on

the design ordered, the flowmeter is supplied for front or rear

panel or wall mounting as well as for pipeline installation. The

threaded connections on the rear side are R 1/4 or 1/4 NPT.

Two holes or two adapter plates in the housing are provided for

wall or panel mounting (see Panel Drilling). When the two holes

are utilized for mounting the flowmeter, the procedure is as

follows: remove protection shield, metering tube and contrast

strip. Slotted, flat head, countersink screws (M5 per DIN 963)

are to be used for mounting the flowmeter. When using the

adapter plates the length of the M4-screw is to be selected

based on the panel thickness. A special wall mount bracket is

provided for mounting the differential pressure regulator when

one is included.

The flowmeter is started up in steps by slowly opening the

separately installed shut off valve. The valve installed in the

flowmeter is designed as a control valve and not as a shut off

valve.

4.

1.

Max. allow. operating temperature

0 to 120 C for Buna N O-rings

0 to 150 C for Viton A O-rings

0 to 60 C for Trogamid metering tube

3.

The diameter of the ball float is also its reading mark

(see Figure).

Purgemaster SNAP-IN Series 10A6100

5.

Disassembly

5.1

To clean the needle valve, backcheck or the O-rings, or

to replace the metering tube holders it is necessary to

first dissemble the flowmeter. Remove the protection

shield, metering tube, float as described in Section 4.

5.2

The complete valve can be removed from the fitting by

unscrewing the valve nut. Loosen cover and knob so

that the valve stem can be removed. Check all parts for

damage and if required, replace.

WARNING: The PTFE-ring is cut and serves only to

stabilize the valve stem.

6.

Purgemaster with Differential

Pressure Regulator

The flowrate can be maintained at the constant value set using

the flow control valve when a differential pressure regulator is

combined with the Purgemaster. While the flowrate of liquids

remains constant regardless of the up- or downstream pressure

variations the regulator is only suitable for gases when the

downstream pressure remains constant and only the upstream

pressure varies. Under these restrictions the normal volume or

mass flowrate of a gas will remain constant at the value set with

the needle valve. Additional details may be found in the Instruction Bulletin for the Differential Pressure Regulator (53R2110).

7.

Purgemaster with Alarm Transmitter

Model 55AN3000 with Switch Amplifier

WE77/Ex1-Bi

Interconnection Diagram, see Fig. 3.

A description of its operation may be found in the Specification

Sheet D184S032U03.

8.

Ordering Replaceable Parts

When ordering replaceable parts please include the flowmeter

Serial Number. The Serial Number may be found on the

Instrument Tag on the flowmeter housing. The replaceable

parts lists are located at the end of this Instruction Bulletin.

Fig. 2

Removal of the Metering Tube

5.3

To clean the backcheck the outlet metering tube holder

must be removed from the fitting.

5.4

If a fitting is to be removed from the housing the fitting

retaining clip (Item 18) located on the rear side must first

be removed.

5.5

Reassemble in the reverse order.

Removal of the In- and Outlet Fittings

Remove the metering tube as described in Chap. 4

The retainer ring (Item 16) can be removed using a pointed

object. If the retainer ring is lost, the flowmeter may be

reassembled without it.

Purgemaster SNAP-IN Series 10A6100

9.

Interconnection Diagram

Control Circuit

Max.

Control Circuit

WE77/Ex1-Bi

WE77/Ex1-Bi

9 10 11 12

9 10 11 12

Min.

Line

Line

Terminal Designations

10

11

Line

Fig. 3

12

Control Circuit

Closed Circuit

Current

Open Circuit

Current

Interconnection Diagram Alarm Transmitter 55AN3000 with Switching Amplifier WE 77/Ex1-Bi

Contact Circuit

Purgemaster SNAP-IN Series 10A6100

10. Dimensions

Pipeline Installation

Dimensions

D

Scale

Length

Model No.

G 1/4

1/4 NPT

338

80

238

264

10A6132-53R_2110

G 1/4

1/4 NPT

225

108

125

151

10A6131-53R_2110

G 1/4

1/4 NPT

194

108

94

120

1 1/2

10A6134-43R_2110

All Dims in mm

Fig. 4

ISO Projection Method E

Wall Mount Installation with Differential Pressure Regulator

Purgemaster SNAP-IN Series 10A6100

Dimensions

Front View

Valve in Inlet

Panel Drilling

Warning!

For side by side installations with ring initiator

alarms the following dimensions apply:

Centerline spacing

with RJ-10 Bi-Y20593 = 32 mm

with RJ-15 Bi-Y20594 = 42 mm

*

Without Valve

These holes are required for front panel

installations with an adapter plate.

Dimensions:

D

Valve in Outlet

G 1/4

1/4 NPT

36,5

165

181

238

264

Scale Length Model No.

5

10A6132/42

G 1/4

1/4 NPT

27,2

71

68

125

151

10A6131/41

G 1/4

1/4 NPT

27,2

40

37

94

120

1 1/2

10A6134/44

G 1/4

1/4 NPT

27,2

71

68

125

151

10A6135/45

All Dims in mm

Fig. 5

Pipeline and Front Panel Installation

ISO Projection Method E

Purgemaster SNAP-IN Series 10A6100

Dimensions

Without Valve

Dimensions:

D

Valve in Outlet

G 1/4

1/4 NPT

270

238

265

Scale Length Model No.

G 1/4

1/4 NPT

157

125

152

10A6131/41

G 1/4

1/4 NPT

126

94

121

1 1/2

10A6134/44

G 1/4

1/4 NPT

157

125

152

10A6135/45

All Dims in mm

Fig. 6

10A6132/42

ISO Projection Method E

Rear Panel Installation without Differential Pressure Regulator

Purgemaster SNAP-IN Series 10A6100

Dimensions

Dimensions:

D

G 1/4

1/4 NPT

121

238

270

Scale Length Model No.

10A6132/42

G 1/4

1/4 NPT

149

125

157

10A6131/41

G 1/4

1/4 NPT

149

94

126

1 1/2

10A6134/44

G 1/4

1/4 NPT

149

125

157

10A6135/45

All Dims in mm

Fig. 7

Rear Panel Installation with Differential Pressure Regulator

ISO Projection Method E

Purgemaster SNAP-IN Series 10A6100

Dimensions

Scale Length 5 (127 mm)

Scale Length 3 (70 mm)

Scale Length 1 1/2 (38 mm)

All Dims in mm

Fig. 8

ISO Projection Method E

Panel Cutout for Rear Panel Installation

Purgemaster SNAP-IN Series 10A6100

11.

Replaceable Parts Lists

Design w/ Valve in Inlet

15

18

17

12

16

11

12

3

10

5

7

4

8

12

16

11

12

Design w/Valve in Outlet & Alarm Transmitter

15

17

18

12

Opening for Max.

Alarm Cable

16

11

6

12

10

7

4

Alarm Transmitter

9

12

11

12

1

Fig. 9

10

8

6

16

Opening for Min.

Alarm Cable

Purgemaster SNAP-IN Series 10A6100

Replaceable Parts Lists

Design w/ Valve in Outlet

1

18

12

16

12

11

10

7

4

8

11

9

12

16

12

15

2

Design w/o Needle Valve

13

Fig. 10

11

Purgemaster SNAP-IN Series 10A6100

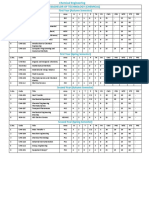

Replaceable Parts List

Item

Description

Qty.

Materials

316 Ti No. 1.4571

Brass

Fitting

Fitting

R 1/4

1/4 NPT

1

1

D301A105U02

D301A104U02

D301A105U01

D301A104U01

Fitting

R 1/4

1/4 NPT

1

1

D301A109U02

D301A108U02

D301A109U01

D301A108U01

Housing

1 1/2

3

5

1

1

1

D355A023U02

D355A023U03

D355A023U04

D355A023U02

D355A023U03

D355A023U04

Housing

1 1/2 w/ Alarm

3

5

1

1

D609A665U02

D455A065U03

D609A665U02

D355A065U03

1 1/2

3

5

1

1

D351C041U02

D351C041U03

D351C041U04

D351C041U02

D351C041U03

D351C041U04

1 1/2 w/ Alarm

3

5

D351C066U03

D351C066U04

D351C066U03

D351C066U04

Protection Shield

Protection Shield

Cover strip

1 1/2

3

5

D331C001U01

D331C001U02

D331C001U03

D331C001U01

D331C001U02

D331C001U03

Cover strip

3 mit Alarm

5

D331C002U02

D331C002U03

D331C002U02

D331C002U03

Metering tube

holder

1/16

1/8

1/4

D376C063U01

D376C064U01

D376C065U01

D376C063U04

D376C064U04

D376C065U04

7*

Metering tube

see SP D184S032U03

8*

Float

see SP D184S032U03

9*

Inlet float stop

1/16

1/8

1/4

Only for metering tube FP 1/4-25-G-5

1

1

1

1

1D304B1032U01

1D304B1023U01

1D304B1021U01

1D304B1022U01

1D304B1032U01

1D304B1023U01

1D304B1021U01

1D304B1022U01

10*

Outlet float stop

1/16

1/8

1/4

Only for metering tube FP 1/4-25-G-5

Only for metering tube FP 1/4-40-G-6

1

1

1

1

1

1D304B1001U01

1D304B1002U01

1D304B1004U01

1D304B1003U01

D304B008U01

1D304B1001U01

1D304B1002U01

1D304B1004U01

1D304B1003U01

D304B008U01

11*

Washer

2

2

2

D333C043U01

D333C044U01

D333C045U01

D333C043U01

D333C044U01

D333C045U01

12*

O-ring Kit

1/16 + 1/8

(w/o valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U01

D605A007U02

D605A007U03

D605A007U01

D605A007U02

D605A007U03

1/16 + 1/8

(w/ valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U04

D605A007U05

D605A007U06

D605A007U04

D605A007U05

D605A007U06

1/4

(w/o valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U13

D605A007U14

D605A007U15

D605A007U13

D605A007U14

D605A007U15

1

1

1

D605A007U16

D605A007U17

D605A007U18

D605A007U16

D605A007U17

D605A007U18

O-ring Kit

O-ring Kit

1/16

1/8

1/4

1/4

(w/ valve)

Buna N

Viton

Ethylene Propylene

* Recommended replacement parts

2

2

2

for scale length 1 1/2

for scale length 1 1/2

for scale length 1 1/2

O-ring Kit

12

Comments

for scale length 1 1/2

Purgemaster SNAP-IN Series 10A6100

Replaceable Parts List

Item

12*

Description

O-ring Kit

O-ring Kit

O-ring Kit

O-ring Kit

O-ring Kit

O-ring Kit

O-ring Kit

O-ring Kit

O-ring Kit

O-ring Kit

Qty.

Materials

316 Ti No. 1.4571

Brass

1/8

(w/o valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U01

D605A007U02

D605A007U03

D605A007U01

D605A007U02

D605A007U03

1/8

(w/ valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U04

D605A007U05

D605A007U06

D605A007U04

D605A007U05

D605A007U06

1/4

(w/o valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U13

D605A007U14

D605A007U15

D605A007U13

D605A007U14

D605A007U15

1/4

(w/ valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U16

D605A007U17

D605A007U18

D605A007U16

D605A007U17

D605A007U18

1/8

(w/o valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U01

D605A007U02

D605A007U03

D605A007U01

D605A007U02

D605A007U03

1/8

(w/ valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U04

D605A007U05

D605A007U06

D605A007U04

D605A007U05

D605A007U06

1/16

(w/o valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U07

D605A007U08

D605A007U09

D605A007U07

D605A007U08

D605A007U09

1/16

(w/ valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U10

D605A007U11

D605A007U12

D605A007U10

D605A007U11

D605A007U12

1/4

(w/o valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U13

D605A007U14

D605A007U15

D605A007U13

D605A007U14

D605A007U15

1/4

(w/ valve)

Buna N

Viton

Ethylene Propylene

1

1

1

D605A007U16

D605A007U17

D605A007U18

D605A007U16

D605A007U17

D605A007U18

D301C002U01

for scale length 3

for scale length 3

for scale length 3

for scale length 3

for scale length 5

for scale length 5

for scale length 5

for scale length 5

for scale length 5

for scale length 5

13

Intermediate ring

D301C002U01

15*

Spring

D424A015U01

D424A015U01

16

Retaining ring

D376H003U01

D376H003U01

17*

Ball

1D103A1001

1D103A1001

18

Fitting clip

1D390C1002

1D390C1002

19

Text label (not shown)

1D338C1104

1D338C1104

1D338B1009

1D338B1009

20

Company Tag (not shown)

* Recommended replacement parts

Comments

13

Purgemaster SNAP-IN Series 10A6100

Replaceable Parts List

Valve Fitting Comp. Standard

DVGW-Valve

Fig. 11

Item

Qty.

Materials

316 Ti No. 1.4571

Brass

Comments

Fitting, complete

R 1/4

1/4 NPT

1

1

D601B065U05

D601B066U05

D601B065U01

D601B066U01

for larger flow capacities

Fitting, complete

R 1/4

1/4 NPT

1

1

D601B067U05

D601B068U05

D601B067U01

D601B068U01

for smaller flow capacities

Fitting, complete

R 1/4

1/4 NPT

1

1

D601B069U05

D601B070U05

D601B069U01

D601B070U01

DVGW-Design,

large flow capacities

Fitting, complete

R 1/4

1/4 NPT

1

1

D601B071U05

D601B072U05

D601B071U01

D601B072U01

DVGW-Design,

small flow capacities

Valve stem

D668B003U02

D668B003U02

small flow capacities

Valve stem

D668B003U06

D668B003U06

large flow capacities

Valve nut

D433B003U01

D433B003U01

Valve nut

Protection Shield

D433B004U01

D433B004U01

Rotation ball

D124A004U06

D124A004U06

Cover

D124A004U07

D124A004U07

O-ring

101A711

101A711

O-ring

1

1

1

101V701

101A701

101F701

101V701

101A701

101F701

O-ring

101C701

101C701

Flat gasket

D377A011U01

D377A011U01

9

10

14

Description

Viton

Buna N

Ethylene Propylene

DVGW-Design

DVGW-Design

DVGW-Design

Purgemaster SNAP-IN Series 10A6100

12. Accessories

10

9

Panel

4/5

Fig. 12

Item

Description

Qty.

Model 10A6100

1 1/2

Model 10A6100

3

Model 10A6100

5

1

1

Front plate

Front plate (for flowmeter w/o valve)

1

1

D351C054U01

D351C054U02

D351C055U01

D351C055U02

D351C056U01

D351C056U02

Mounting bracket

D353F057U01

D353F058U01

D353F059U01

Screw M4x6 DIN 85

D003G106AU20

D003G106AU20

D003G106AU20

Spring washer A4.3 DIN 6797

D085F021AU32

D085F021AU32

D085F021AU32

Phillips phillister head screw M4x12 DIN 7985

D004G109AU20

D004G109AU20

D004G109AU20

Special nut M4

D092K003U01

D092K003U01

D092K003U01

Adapter plate

D355A040U01

D355A040U01

D355A040U01

Slotted flat head csk screw

D005G106AU20

D005G106AU20

D005G106AU20

10

15

Purgemaster SNAP-IN Series 10A6100

16

Purgemaster SNAP-IN Series 10A6100

17

ABB Automation Products GmbH

Dransfelder Str. 2, D-37079 Goettingen

Tel.: +49 (0) 5 51 9 05 - 0

Fax: +49 (0) 5 51 9 05 - 777

http://www.abb.com/automation

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Derry Beir Bua May 2010Documento2 páginasDerry Beir Bua May 2010Derry ThirtytwoAún no hay calificaciones

- Armour Pro ManualDocumento7 páginasArmour Pro ManualadiAún no hay calificaciones

- IIT Roorkee Programme Structure CHeDocumento4 páginasIIT Roorkee Programme Structure CHeabcAún no hay calificaciones

- Rules For Classification: Inland Navigation VesselsDocumento42 páginasRules For Classification: Inland Navigation VesselsDmitrii PustoshkinAún no hay calificaciones

- Finger Painting (Therapeutic Skills)Documento12 páginasFinger Painting (Therapeutic Skills)Ellyn GraceAún no hay calificaciones

- Excessive Workload and Ung IsaDocumento4 páginasExcessive Workload and Ung IsaElyssa Mae ChuaAún no hay calificaciones

- MemsDocumento3 páginasMemssteve johnsAún no hay calificaciones

- 2016, Yamasaki Et Al, Auditory Perceptual Evaluation of Normal and Dysphonic Voices Using The Voice Deviation Scale J VoiceDocumento5 páginas2016, Yamasaki Et Al, Auditory Perceptual Evaluation of Normal and Dysphonic Voices Using The Voice Deviation Scale J VoiceCarol PaesAún no hay calificaciones

- Provision List: No Item Description Qty Unit Price (IDR) Total PriceDocumento2 páginasProvision List: No Item Description Qty Unit Price (IDR) Total PriceSUSANTIAún no hay calificaciones

- Tools and Materials Needed For Manicure and PedicureDocumento43 páginasTools and Materials Needed For Manicure and PedicureJoan Patrice Mondarez MangalileAún no hay calificaciones

- Gazi Abdur Rakib BiodataDocumento2 páginasGazi Abdur Rakib Biodataগাজী আব্দুর রাকিবAún no hay calificaciones

- (PDF) Pass Through Panic: Freeing Yourself From Anxiety and FearDocumento1 página(PDF) Pass Through Panic: Freeing Yourself From Anxiety and FearmilonAún no hay calificaciones

- Stanley 25 Amp Automatic Battery Charger BC25BS ManualDocumento12 páginasStanley 25 Amp Automatic Battery Charger BC25BS ManualJoe ZhaoAún no hay calificaciones

- Proposal Letter New1Documento2 páginasProposal Letter New1api-242445476Aún no hay calificaciones

- Meaning and Scope of Supply Under GSTDocumento5 páginasMeaning and Scope of Supply Under GSTRohit BajpaiAún no hay calificaciones

- New Form 12BBDocumento2 páginasNew Form 12BBramanAún no hay calificaciones

- Rubrica - Speaking U3 6thDocumento1 páginaRubrica - Speaking U3 6thmireiaAún no hay calificaciones

- Enhancement of Rock Slope Engineering Practice Based On Findings of Landslide StudiesDocumento8 páginasEnhancement of Rock Slope Engineering Practice Based On Findings of Landslide StudiesHuy Le QuangAún no hay calificaciones

- St. Luke's Medical Center Employees Association-AFW v. National Labor Relations Commission, G.R. No. 162053, 7 March 2007Documento4 páginasSt. Luke's Medical Center Employees Association-AFW v. National Labor Relations Commission, G.R. No. 162053, 7 March 2007Ashley Kate PatalinjugAún no hay calificaciones

- Ead 230005-00-0106Documento14 páginasEad 230005-00-0106Ana Luísa EvaristoAún no hay calificaciones

- Barangay Development PlanDocumento14 páginasBarangay Development PlanKeith Clarence Bunagan100% (1)

- Conery MFG Inc Product Catalog 2010Documento28 páginasConery MFG Inc Product Catalog 2010jchandler3Aún no hay calificaciones

- Vampire Cortex Prime Conversion V.1Documento38 páginasVampire Cortex Prime Conversion V.1Jeferson MoreiraAún no hay calificaciones

- Distilled Spirit: Introduction (CAP 1)Documento9 páginasDistilled Spirit: Introduction (CAP 1)ned_nickAún no hay calificaciones

- MFMC 6000W-20000W Multi Module CW Fiber LaserDocumento2 páginasMFMC 6000W-20000W Multi Module CW Fiber Laser태환오Aún no hay calificaciones

- Method of Statement For 54 MT Tower Rev 02Documento10 páginasMethod of Statement For 54 MT Tower Rev 02zia uddinAún no hay calificaciones

- Hubungan Pola Makan Dan Kebiasaan Olah Raga Dengan Kadar Gula Darah Penderita Diabetes Melitus Tipe Ii Di Rs Pku Muhammadiyah SurakartaDocumento15 páginasHubungan Pola Makan Dan Kebiasaan Olah Raga Dengan Kadar Gula Darah Penderita Diabetes Melitus Tipe Ii Di Rs Pku Muhammadiyah SurakartaNova SanggelAún no hay calificaciones

- Perfil de Inteligencia Emocional - Construcción, Validez y ConfiabilidadDocumento12 páginasPerfil de Inteligencia Emocional - Construcción, Validez y ConfiabilidadGregorio Ramos OrtegaAún no hay calificaciones

- Pharmaceutical Analysis (Proposed) Syllabus - Effective From The Session 2017-18Documento22 páginasPharmaceutical Analysis (Proposed) Syllabus - Effective From The Session 2017-18neeraj dasAún no hay calificaciones

- WestvirginiaDocumento6 páginasWestvirginiaapi-280868990Aún no hay calificaciones