Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Contech Systems FINALStrand

Cargado por

TuroyDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Contech Systems FINALStrand

Cargado por

TuroyCopyright:

Formatos disponibles

Strand Anchors

Strand Anchors

Strand Anchors

Contents:

CTS Strand Anchors:

Cover

Company Profile......................................

Strand Anchor Introduction.....................

Our Committment...................................

Corrosion Protection Tree.......................

Corrosion Protection Classification.... .....

Anchor Details.........................................

Technical Data.........................................

Technical Data.........................................

Anchor Head Technical Data...................

Hollow Ram Jacks...................................

Accessories.............................................

Accessories.............................................

Strand Anchor Off-Coilers.......................

Applications............................................

Back Cover: Contact Information

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Recognised as one of the strongest, most flexible and cost effective anchor systems in the industry, Strand Anchors

are in use throughout North America. Our unique encapsulation process ensures that the Strands bond length is

not contaminated with the grease from the free length. Strand Anchors are typically used for either permanent or

temporary tie down and tie back anchors in either rock or soil. Examples include hydroelectric dams, wind tower

foundations, slope stabilization and excavation shoring.

Advantages of CTS Strand Anchors:

The Dalles Dam, WA/OR

Cutting of length of anchors on job site possible to suit local ground conditions.

Installation of flexible anchor tendons under extremely tight space conditions.

Company Introduction:

on-Tech Systems Ltd. was

founded in 1985 and is a family

owned company. Since inception our primary focus in the

initial stages was manufacturing

post-tensioned Strand Anchors

for geo-technical construction.

Since that time, not only have

we remained close to our roots

with our innovative Strand products, but we have also developed and promoted many other

unique and innovative products

to allow our customers to complete many difficult projects.

Con-Tech has completed strand

projects as small as one anchor

to projects containing thousands

of anchors. We have completed

projects with anchors as small

as one strand, to ninety-two

strands; still the largest anchor

ever manufactured in the world.

With these wide selections of

products still available to our

customers today we are abe to

service not only large interna-

...page2

tional contractors but also small

owner operators. We have the

ability to produce anchors with

standard corrosion protection

systems and are also able to

adapt to special project corrosion requirements as needed.

Through our several production

plants and offices located across

Canada and the USA; from B.C.

to Ontario, from Washington

State, to North Carolina and

Florida, we are able to service

any of your project needs.

Transportation of anchor tendons on reels

coiled or looped. Therefore only small storage and assembly area are required.

Less danger of contact with overhead power lines, because anchors are not as rigid as

bars.

Pacific Coastal Highway

Retaining Wall, Gorda, CA

High yield point (1570 N/mm2 = 227 KSI)

and low E-modulus of 20000 N/mm2 =

29000 KSI indicates that the strain of strand

is greater than that for 150 KSI bars.

With our strand anchors more than one

tension element in each anchor guarantees

higher safety versus single bar anchors.

Our slim line strand coupler allows for easy

splicing of even multiple strand anchors.

The Dalles Dam, WA/OR

92 Strand Anchors, Seven Mile Dam. To date worlds largest anchors!

Greenwich Wind Farm, Ontario, Canada

...page3

Strand Anchors

Strand Anchors

Our Committment:

Corrosion Protection Tree:

Con-Tech Systems Ltd. is committed to providing our customers with the best quality products and service.

From the time an order is placed we have strict processes to ensure the customer gets not only what they need

but also what they want. We have highly trained, professional staff who ensure that our anchors conform to

the latest edition of the Post-Tensioning Institute Manual for Rock and Soil Anchors.

...page4

Service Life

Temporary

(less than 2 years)

Extended Temporary

(2 to 5 years)

Permanent

Aggressivity

Aggressivity

Class I Protection

Aggressive

Non-Aggressive

Class II Protection

No Protection

Aggressive

Class I Protection

Non-Aggressive

Class II Protection

...page5

Strand Anchors

Strand Anchors

Anchor Details:

Corrosion Protection Classification:

In the 2014 Recommendations for Prestressed Rock and Soil Anchors (this is the Fifth Edition and is endorsed

by the ADSC Anchored Earth Retention Committee) the Post-Tensioning Institute defines three classes of Corrosion Protection:

PTI Class I: Encapsulated Tendons

(often referred to as double corrosion protected, DCP)

PTI Class II: Grout Protected Tendons

(often referred to as single corrosion protected, SCP)

Temporary: Grout Protected

(often referred to as single corrosion protected, SCP)

PROTECTION REQUIREMENTS

Class

Anchorage

PTI Class I

Encapsulated

Tendon

PTI Class II

Temporary up to 24 months

PTI - ClassI

DoubleCorrosionProtection

Unbonded

Length

Trumpet

Grout or corrosion

inhibiting compound filled, cover

if exposed.

Trumpet

Grout or corrosion

inhibiting compound filled, cover

if exposed.

No trumpet.

Tendon Bond

Length

Corrosion inhibiting

compound filled sheath

encased in grout, or

Grout filled sheath, or

Grout encased epoxy-coated strand in a successfully

water-pressure tested drill

hole.

Corrosion inhibiting

compound filled sheath

encased in grout, or

Grout filled sheath, or

Grout encased fully or

partially bonded tendon in

sound rock or concrete.

Grease-filled sheath.

Unbonded

Length

Grout-filled encapsulation, or

Epoxy coated strand

tendon in a successfully

water-pressure tested drill

hole.

PTI-ClassII

SingleCorrosionProtection

Cover Cap

Cover Cap

Wedge

Wedge

Wedge

Wedge Plate

Wedge Plate

Wedge Plate

Bearing Plate

Bearing Plate

Bearing Plate

Greased &

Sheathed

Strand in

Unbonded

Length

Trumpet

Trumpet

Corrugated

Sheathing

Unbonded

Length

Greased &

Sheathed

Strand in

Unbonded

Length

Unbonded

Length

OptionalGreased &

Sheathed

Strand in

Unbonded

Length

Seal

Seal

Seal

Organizers

along Bond

Length

Organizers

along Bond

Length

Organizers

along Bond

Length

Bare Strand in

Bond Length

Bare Strand in

Bond Length

Internal

Grout Tube

Grout encasement.

Bare Strand in

Bond Length

No extra protection

required.

TemporaryAnchor

NoCorrosionProtection

Bond

Length

Bond

Length

Bond

Length

Centralizer

Centralizer

Centralizer

2-0 Shop

Grouted

Typical Applications:

PTI Class I

...page6

PTI Class II

End Cap

Temporary

...page7

Strand Anchors

Strand Anchors

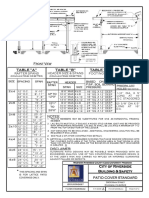

Strand Technical Data:

CTS Rock and Soil Anchors meet the ASTM A-416 or ASTM A-488 (epoxy coated strand) specifications for 0.6, 7 wire strand.

Ultimate stress (fpu)

270 ksi

1861.65 N/mm2

Weight per strand

0.74 lbc./lf

1.10 kg/m

They are in accordance to:

Recommendations for Prestressed Rock and Soil Anchors, Post Tensioning Institute (PTI), latest edition.

Ground Anchors and Anchored Systems, Geotechnical Engineering Circular No. 4, Federal Highway Administration, Washington DC, FHWA-IF-99-015, 1999

Strands

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

27

30

31

37

47

60

92

X-Section Area

(Aps)

inch

0.217

0.434

0.651

0.868

1.085

1.302

1.519

1.736

1.953

2.17

2.387

2.604

2.821

3.038

3.255

3.472

3.689

3.906

4.123

4.34

4.557

4.774

5.859

6.51

6.727

8.029

10.199

13.02

19.964

mm

140

280

420

560

700

840

980

1120

1260

1400

1540

1680

1820

1960

2100

2240

2380

2520

2660

2800

2940

3080

3780

4200

4340

5180

6580

8400

12880

Ulimate Load

(fpu x APS) = GUTS

kips

58.6

117.2

175.8

234.4

293.0

351.6

410.2

468.8

527.4

586.0

644.6

703.2

761.8

820.4

879.0

937.6

996.2

1054.8

1113.4

1172.0

1230.6

1289.2

1582.2

1758.0

1816.6

2168.2

2754.2

3516.0

5391.2

kN

260.7

521.3

782.0

1042.7

1303.3

1564.0

1824.7

2085.3

2346.0

2606.7

2867.3

3128.0

3388.7

3649.3

3910.0

4170.7

4431.3

4692.0

4952.7

5213.3

5474.0

5735.4

7038.9

7821.0

8081.7

9645.9

12251.3

15640.0

23981.3

Max Jacking Load

(80% of GUTS)

kips

46.9

93.8

140.6

187.5

234.4

281.3

328.2

375.0

421.9

468.8

515.7

562.6

609.4

656.3

703.2

750.1

797.0

843.8

890.7

937.6

984.5

1031.4

1265.8

1406.4

1453.3

1734.6

2203.4

2812.8

4313.0

kN

208.6

417.1

625.6

834.1

1042.7

1251.2

1459.7

1668.3

1876.8

2085.3

2293.9

2502.4

2710.9

2919.5

3128.0

3336.5

3545.1

3753.6

3962.1

4170.7

4379.2

4588.3

5631.1

6256.8

6465.4

7716.7

9801.0

12512.0

19185.0

Max Design Load

(60% of GUTS)

kips

35.2

70.4

105.6

140.8

176.0

211.2

246.4

281.6

316.8

352.0

387.2

422.4

457.6

492.8

528.0

563.2

598.4

633.6

668.8

703.2

738.4

773.5

949.3

1054.8

1090.0

1300.9

1654.4

2112.0

3238.4

kN

156.4

312.8

469.3

625.7

782.1

938.5

1094.9

1251.4

1407.8

1564.2

1720.6

1877.0

2033.5

2189.9

2346.3

2502.7

2659.1

2815.6

2972.0

3128.0

3284.4

3441.2

4223.3

4692.6

4849.0

5787.5

7351.7

9385.2

14390.6

HDPE Corrugated Sheathing

Nominal

Diameter

Outside Diameter

inch

inch

mm

2"

2.4

61

3"

3.6

91

4"

4.7

119

5"

5.7

145

6"

7.1

180

8"

9.5

241

10"

N/A

11.6

N/A

295

N/A

The drill hole size chosen should allow for a minimum grout cover over the corrugated sheath of 0.5 (12.7 mm).

If our post-grout pressure lines are used, allow for a minimum of 1 (25.4 mm) grout cover on the side where the grout pipe is assembled.

Our centralizers are made to allow for a minimum of 0.5 (12.7 mm) grout cover or to a specified size.

They are available as single wing parts (a minimum of 3 wings is required per location) or as multiple wing elements.

Our strand organizers are fabricated to provide the minimum strand spacing recommended in the PTI manual.

...page8

...page9

Strand Anchors

Strand Anchors

Anchor Head Technical Data:

Hollow Ram Jack Details:

Anchor Head Dimensions

Strands

Diameter

Thickness

4

7

9

12

15

5"

5-1/2"

6-1/4"

7-1/2"

8-1/2"

2"

2"

2-5/8"

2-3/4"

3-1/2"

Bearing Plate

Thru Hole

3-1/2"

4"

4-3/4"

5"

6"

Any variation of custom sizes or machining

such as external threading available upon request

Trumpet Size

Required (Min.)

3-1/2" SCH40

4" SCH40

5" SCH40

5" SCH40

6" SCH40

9 Strand Anchor Head

Or HSS Equivalent

Anchor Head Side View

Hollow Ram Jacks:

CTS offers a variety of Hollow-Ram Jacks for stressing Strand Anchors.

Sizes range from 100 Ton to 2200 Ton+.

Calibrated Kits for rent include Jacks, Hydraulic Power Packs, Guages and Hoses

Please call us and allow us to assist you with your specific requirements.

Monostrand Jack

500 Ton Hollow Ram Jack

Stressing Jacks table:

Model

Number

(No. of Strands)

CTS-CBJ-3

CTS-25-8

CTS-50

CTS-100

CTS-100

CTS-120

CTS-150

CTS-150

CTS-200

CTS-200

CTS-200

CTS-300

CTS-300

CTS-500

CTS-800

CTS-2200

1

1

Titan

4

4

5

6

6

7

7

9

12

12

15

27

92

Usage

Stroke

3.0 "

8.0 "

4.0 "

6.0 "

8.0 "

6.5 "

8.0 "

10.0 "

7.0 "

9.5 "

9.5 "

18.0 "

18.0 "

14.0 "

14.0 "

35.0 "

Ram Area

2

(inch )

5.0 "

5.0 "

10.3 "

21.0 "

21.0 "

24.3 "

30.0 "

29.5 "

40.0 "

40.0 "

40.0 "

60.0 "

60.0 "

110.0 "

160.0 "

440.0 "

Maximum

Load

@ 10,000 PSI

25 TONS

25 TONS

50 TONS

100 TONS

100 TONS

120 TONS

150 TONS

150 TONS

200 TONS

200 TONS

200 TONS

300 TONS

300 TONS

500 TONS

800 TONS

2,200 TONS

Center

Hole I.D.

Cylinder

O.D.

Height

Collapsed

Material

Weight

(lbs.)

0.70 "

0.70 "

2.12 "

2.00 "

3.50 "

3.50 "

3.50 "

3.50 "

3.50 "

3.50 "

4.50 "

5.25 "

5.25 "

8.00 "

9.50 "

16.00 "

4.25 "

4.50 "

7.50 "

7.00 "

10.00 "

9.50 "

10.00 "

12.00 "

11.00 "

12.00 "

11.50 "

14.00 "

14.00 "

20.00 "

26.50 "

38.50 "

8.00 "

13.00 "

9.50 "

12.50 "

16.00 "

14.00 "

15.00 "

19.00 "

17.00 "

19.00 "

21.00 "

27.50 "

34.00 "

27.50 "

32.50 "

55.00 "

ALUM

ALUM

ALUM

STEEL

ALUM

ALUM

ALUM

ALUM

STEEL

ALUM

STEEL

STEEL

STEEL

STEEL

STEEL

STEEL

10

20

40

90

120

80

125

225

335

200

450

875

1,350

1,830

3,600

13,000

2200 Ton Hollow Ram Jack

Carbon Fiber light weight Jack

...page10

...page11

Strand Anchors

Strand Anchors

Accessories:

Accessories:

Grippers - Designed to be used with standard .600 7

Cover Caps - Standard sizes stocked for 4, 7, 9, 12,

Post Grout Tubes - any required length can be

Centralizers - Various sizes and styles including

balloon, snap ring, banana peel style, and heavy duty.

Couplers - designed to be used with standard

0.600 diameter, 7 wire anchor tendon.

Bearing Plates - any size or configuration can be ac-

wire strand anchor tendon. Variety of sizes are available.

Adjustable Stressing Chairs - available in 4, 7,

9, 12 and 15 Strand sizes.

Anchor Heads - Many standard sizes available as

well as any custom anchor head if required.

accommodated thanks to our modular system.

Restrainer Plates - Standard restraining plates

are kept in stock in the 4, 7, 9, 12, and 15 strand sizes

however, any other size can be fabricated to match

the required anchor.

...page12

and 15 strand anchor heads. Custom sizes are available.

Organizers - Can be made to accommodate any

size of anchor.

commodated including addition of trumpets if needed.

...page13

Strand Anchors

Strand Anchors

Applications:

Strand Anchor Off-Coilers:

Con-Tech Systems Ltd. offers uncoiling equipment to facilitate the safe installation of our Strand Anchors.

Manual Horizontal and Motorized Vertical Off-Coilers are available for a variety of applications.

Dam Retrofits

Manually operated Horizontal Off-Coiler

Tom Miller Dam, Austin TX

Retaining Walls

US 27/SR 29 Hwy, Chatanooga, TN

Motorized Vertical Off-Coiler

Excavation Shoring The Cosmopolitan, Las Vegas NV

Foundations

Bridges

Landslide Mitigation

Greenwich Wind Farm, Ontario

Manually operated Horizontal Off-Coiler

...page14

...page14

Bixby Creek Bridge, CA

The Point, San Diego, CA

page15

...page...15

Seven Mile Dam, B.C.

Seismic upgrade of the hydro power dam.

CTS Tie Down Anchors with 92 Strands.

Magnolia Point, Seattle WA

Tie Back Anchors for mud slide repair. (In progress/completion)

Head Office:

Sales & Production:

8150 River Road,

Delta, B.C. Canada

V4G 1B5

Western Locations:

Toll Free: 1-888-818-4826

Email: ctswest@contechsystems.com

Tel: 604-946-5571

Toll Free: 1-888-818-4826

Email: con-tech@contechsystems.com

Partnerships:

Eastern Locations:

Production Plant:

Blaine, WA USA

Sales & Production:

Brockville, ON, Canada

Tel: 613-342-0041

Charlotte, NC, USA

Tel: 704-494-3989

Sales:

East Stroudsburg, PA, USA

Tel: 613-342-0041

New Port Richey, FL, USA

Tel: 727-842-5760

Email: ctseast@contechsystems.com

Memberships:

Website: www.contechsystems.com

Version: 2014

También podría gustarte

- Foundation Design Using Standard Penetration Test (SPT) N-ValueDocumento39 páginasFoundation Design Using Standard Penetration Test (SPT) N-Valueneilmark undagAún no hay calificaciones

- Common Problems With Coordinate System Configurations - Trimble GeospatialDocumento12 páginasCommon Problems With Coordinate System Configurations - Trimble GeospatialTuroyAún no hay calificaciones

- Biochemical Oxygen DemandDocumento4 páginasBiochemical Oxygen DemandHutapeaReynoldHamonanganChristoffelAún no hay calificaciones

- Mitek 12kN Pile FixingDocumento2 páginasMitek 12kN Pile FixingTuroyAún no hay calificaciones

- Considerations in Wind Design of Wood StructuresDocumento9 páginasConsiderations in Wind Design of Wood StructuresTuroyAún no hay calificaciones

- Soil Liquefaction - Presentation June 2009Documento27 páginasSoil Liquefaction - Presentation June 2009TuroyAún no hay calificaciones

- Triggering of Liquefaction Recurring Questions 10-BoulangerDocumento30 páginasTriggering of Liquefaction Recurring Questions 10-BoulangerTuroyAún no hay calificaciones

- BBSC 433 Jessica Bennett Wind Design GuideDocumento34 páginasBBSC 433 Jessica Bennett Wind Design GuideTuroyAún no hay calificaciones

- Bioremediated Ground ImprovementDocumento26 páginasBioremediated Ground ImprovementTuroyAún no hay calificaciones

- 038Documento8 páginas038Divya Dev C MAún no hay calificaciones

- Wind Design of Timber Panelised Roof Structures de-Panelized-Roof-WindDocumento40 páginasWind Design of Timber Panelised Roof Structures de-Panelized-Roof-WindTuroyAún no hay calificaciones

- Mitek 6kN Pile FixingDocumento2 páginasMitek 6kN Pile FixingTuroyAún no hay calificaciones

- Differences Between Autocad and Autocad LTDocumento2 páginasDifferences Between Autocad and Autocad LTTuroyAún no hay calificaciones

- Door and Window Standard Sizes WANZ Test Size Configurations - July 2007Documento1 páginaDoor and Window Standard Sizes WANZ Test Size Configurations - July 2007TuroyAún no hay calificaciones

- Design of Chinese steel TV towers: Analysis of wind and seismic loadsDocumento6 páginasDesign of Chinese steel TV towers: Analysis of wind and seismic loadsTuroyAún no hay calificaciones

- Dashcam Number of HrsDocumento9 páginasDashcam Number of HrsTuroyAún no hay calificaciones

- Grout Epcon c6Documento8 páginasGrout Epcon c6TuroyAún no hay calificaciones

- Reproducing The REal Pressure CoefficientsDocumento8 páginasReproducing The REal Pressure CoefficientsTuroyAún no hay calificaciones

- Engineers Briefing Invitation 20 May 2016Documento2 páginasEngineers Briefing Invitation 20 May 2016TuroyAún no hay calificaciones

- Australia:: What Makes A Home Relocatable?Documento2 páginasAustralia:: What Makes A Home Relocatable?TuroyAún no hay calificaciones

- Foundations On Expansive Clays and RocksDocumento6 páginasFoundations On Expansive Clays and RocksTuroyAún no hay calificaciones

- Options For A WInd Loading CodeDocumento10 páginasOptions For A WInd Loading CodeTuroyAún no hay calificaciones

- SLIDE Water ModellingDocumento10 páginasSLIDE Water ModellingTuroyAún no hay calificaciones

- Engineers Briefing Invitation 20 May 2016Documento2 páginasEngineers Briefing Invitation 20 May 2016TuroyAún no hay calificaciones

- Raft Technical ManualDocumento24 páginasRaft Technical ManualTuroy100% (1)

- Foundations On Expansive Soils Sudan Experience - XXDocumento13 páginasFoundations On Expansive Soils Sudan Experience - XXTuroyAún no hay calificaciones

- Discussion On Swelling SoilDocumento4 páginasDiscussion On Swelling SoilTuroyAún no hay calificaciones

- Computer Program For Simulation of Wall Construction SequenceDocumento90 páginasComputer Program For Simulation of Wall Construction SequenceTuroyAún no hay calificaciones

- Driven Piles in Central Texas Expansive SoilsDocumento10 páginasDriven Piles in Central Texas Expansive SoilsTuroyAún no hay calificaciones

- Patio Cover Standard DrawingDocumento2 páginasPatio Cover Standard DrawingTuroyAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Boiler BlowdownDocumento2 páginasBoiler BlowdownbaratheonAún no hay calificaciones

- Philippine STEM Module Explains Photoelectric EffectDocumento12 páginasPhilippine STEM Module Explains Photoelectric EffectJp menorAún no hay calificaciones

- AssignmentDocumento2 páginasAssignmenttayyabauzairAún no hay calificaciones

- Compact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetDocumento4 páginasCompact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetLê ĐạtAún no hay calificaciones

- CPRMSE GuidelinesDocumento2 páginasCPRMSE GuidelinesDeepak KumarAún no hay calificaciones

- TST-13 Aircraft Manual With 503 Engine LSA Rev.1Documento52 páginasTST-13 Aircraft Manual With 503 Engine LSA Rev.1smeassick100% (1)

- Aquatic Ecology and LimnologyDocumento96 páginasAquatic Ecology and LimnologySale AlebachewAún no hay calificaciones

- FOCAL DYSTONIA-A NEUROLOGICAL CONDITION-TREATED WITH CAUSTICUM - Karl Robinson MDDocumento2 páginasFOCAL DYSTONIA-A NEUROLOGICAL CONDITION-TREATED WITH CAUSTICUM - Karl Robinson MDFaker FockerAún no hay calificaciones

- Exp. 5 Test For Fats and ProteinsDocumento6 páginasExp. 5 Test For Fats and ProteinsEMELIE GRACE E CACHEROAún no hay calificaciones

- John Taylor Case Study ENP and EPPDocumento11 páginasJohn Taylor Case Study ENP and EPPAhata Sham NewazAún no hay calificaciones

- PreparationDocumento2 páginasPreparationmghaffarzadehAún no hay calificaciones

- SKC EPAM-5000 Instruction Manual PDFDocumento90 páginasSKC EPAM-5000 Instruction Manual PDFmegacobAún no hay calificaciones

- Piling Procedure - IoclDocumento8 páginasPiling Procedure - IocltpgggkAún no hay calificaciones

- 08-05-2021 JR - Super60 ActP (In Coming) Jee-Main WTM-01 Question PaperDocumento14 páginas08-05-2021 JR - Super60 ActP (In Coming) Jee-Main WTM-01 Question Paperpurandar puneetAún no hay calificaciones

- HemophiliaDocumento62 páginasHemophiliamuhirwa Samuel100% (1)

- Mr. Tieu Dat's English Academy Practice TestDocumento16 páginasMr. Tieu Dat's English Academy Practice TestĐỗ Nhật QuangAún no hay calificaciones

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocumento4 páginasWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashAún no hay calificaciones

- Thermax ION Exchange Resins SDS BrochureDocumento8 páginasThermax ION Exchange Resins SDS Brochureparthibanemails5779Aún no hay calificaciones

- Masagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningDocumento6 páginasMasagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningjhonaAún no hay calificaciones

- List of Employees with Start and End DatesDocumento394 páginasList of Employees with Start and End DatesMuhammad Faishal TazakkaAún no hay calificaciones

- Norris Claire White Paper Liftware PDFDocumento14 páginasNorris Claire White Paper Liftware PDFmeysam NaaAún no hay calificaciones

- Test Bank For Leadership and Management in Nursing 4th Edition Mary Ellen Grohar MurrayDocumento36 páginasTest Bank For Leadership and Management in Nursing 4th Edition Mary Ellen Grohar Murraywitchingmazybs7k7100% (39)

- PKL Geri RevDocumento3 páginasPKL Geri RevKurniati NiaAún no hay calificaciones

- Pastillas DelightDocumento12 páginasPastillas DelightBryan DutchaAún no hay calificaciones

- Red Velvet Cake RecipeDocumento6 páginasRed Velvet Cake RecipeRuminto SubektiAún no hay calificaciones

- Design and PlanningDocumento15 páginasDesign and PlanningZeljkoSipcicAún no hay calificaciones

- Crosbys Molasses and MoreDocumento37 páginasCrosbys Molasses and MoreShaikh MeenatullahAún no hay calificaciones

- PGDHM SyllabusDocumento34 páginasPGDHM SyllabusankushlmpAún no hay calificaciones

- Blessed Are Those Who MournDocumento7 páginasBlessed Are Those Who MournPatrick MabbaguAún no hay calificaciones

- Msae Msae2018-Arwm012 Full Dronespraying 2Documento4 páginasMsae Msae2018-Arwm012 Full Dronespraying 2Muhammad Huzaifah Mohd RoslimAún no hay calificaciones