Documentos de Académico

Documentos de Profesional

Documentos de Cultura

1 PB

Cargado por

Rith MakaraTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

1 PB

Cargado por

Rith MakaraCopyright:

Formatos disponibles

Modern Applied Science; Vol. 8, No.

2; 2014

ISSN 1913-1844

E-ISSN 1913-1852

Published by Canadian Center of Science and Education

Fatigue Investigation of the Interface Shear Performance in Asphalt

Pavement

Cristina Tozzo1, Antonio D'Andrea1, Domingo Cozzani1 & Andrea Meo1

1

Sapienza University of Rome, Via Eudossiana 18, Roma, Italy

Correspondence: Cristina Tozzo, DICEA, Sapienza University of Rome, Via Eudossiana 18, 0018 Roma, Italy.

E-mail: cristina.tozzo@uniroma1.it

Received: September 10, 2013

Accepted: January 22, 2014

Online Published: February 17, 2014

doi:10.5539/mas.v8n2p1

URL: http://dx.doi.org/10.5539/mas.v8n2p1

Abstract

This paper shows the interlayer fatigue performance evaluated by the Sapienza shear testing machine. The tests

can be performed by placing double layer specimens in several inclinations, in order to reproduce a variety of

expected ratios between the normal and the shear stress. The machine manages loads with any kind of waveform

and is particularly able to simulate the stress trends expected in field in points located just outside the wheel path.

In this experimentation, the machine applies a triangular waveform load computed by a linear elastic multilayer

program at the depth of the first pavement interface. A fatigue law is estimated considering the number of

repetitions that causes the interface failure. A linear regression in the log-log graph suitably fits the experimental

results for the analyzed conditions of temperature and interface type.

Keywords: pavement durability, interface shear behavior, interlayer bonding fatigue, shear test

1. Introduction

The performance of the road structure is directly influenced by the bond conditions between pavement layers.

The impacts of bond failures are more evident where the vehicles turn, brake, go uphill or downhill, accelerate or

decelerate. Slippage cracking and permanent deformations are the most typical effects. The subsequent

modification of the stress distribution affects the service life with a significant reduction (Khweir & Fordyce,

2003).

Furthermore, the common assumptions of a completely full bond or full slip between the layers are both

incorrect. In fact, the interaction between the layers is not that strong to prevent a relative displacement. Even

when the failure occurs, a fully sliding is not possible because friction has to be taken in consideration.

The damage caused by bond failures is so important that the design methods of bituminous pavements should be

improved considering an interface fatigue performance criterion, besides the bottom-up and top-down tensile

fatigue, rutting and low temperature cracking. That will improve the accuracy of the predictions about pavement

lifetime.

The settlement process of this new criterion is at its first step. One of the biggest difficulties is the large variety

of stress conditions that the vehicles wheels generate in the different points of the interface in the real pavements.

Concerning this subject, a parametric study of the stress conditions at different depths was presented by

Xiaoyang et al. (2013). The test machines proposed so far are able to reproduce just few of those stress

conditions.

The most common type of testing modality is the direct shear test, where a shear load is applied at the interface

with the possibility to add also a normal force. The output of the test is a parameter named shear strength. It is

computed as the peak level of the unit shear resistance, opposed by the interface when one layer is pushed across

the other, until the failure. Several testing devices have been developed worldwide with different working

schemes. They are able to test cylindrical or prismatic specimens with different sizes (Sangiorgi et al., 2002;

Raab & Partl, 2004; Ferrotti et al., 2012) and have been used to evaluate and compare the influence on the

interface shear strength of several factors such as the tack coat efficiency (Mohammad et al., 2002), the surface

conditions (Mohammad, 2012) or the surface profile (DAndrea et al., 2013; Loprencipe & Cantisani, 2013).

Generally, these testing machines work in monotonic modalities thanks to the application of an established

displacement rate. Such a scheme has become the most popular within the researchers because of their installing

1

www.ccsenet.org/mas

Modern Applied Science

Vol. 8, No. 2; 2014

and setting simplicity. However, the prolonged application of high stress is not close to the interface loading

condition in the field. In fact, the vehicles apply on the pavement repetitive short loadings. Furthermore, just in

certain points those loadings are oriented in the same direction for all the time of the wheel passage; in other

points they assume opposite orientations during the loading cycle. Finally, very various loading conditions can

be experienced in different positions at the interface. That can happen also in the same point in different

moments, depending on the lateral wander of traffic, which should be studied by statistical analysis methods

(Cantisani & Loprencipe, 2013; Mauro & Brando, 2013).

The aim of the present research is to reproduce some of the stress trends which actually happen at the interface

during the wheel passage. Therefore the device used in this research is able to repetitively apply dynamic loading

cycles, in order to obtain information about the interface shear fatigue performance.

2. Bibliography

In the recent years, the interface shear behavior has been one of the most investigated research fields because of

the growing understanding of the interlayer bond importance in the pavement performance decay. Due to the

absence of a standard in the testing mode, several shear devices have been developed, but only few have been

designed to work in dynamic mode, because the installation and set are characterized by great complexity with

respect to the monotonic devices. Furthermore, the dynamic tests need long time to perform when the loading

levels are low, as happens in several locations into the pavement structure.

A comparison between the results of monotonic and dynamic tests was conducted by Crispino et al. (1997); they

developed a dynamic shear test and assessed that the dynamic shear reaction modulus is three times higher than

the monotonic one.

Carr et al. (2001) developed a direct shear box able to test slabs (320 by 200 mm) under repeated shear loads

combined with the application of a normal load. Kruntcheva et al. (2001) showed that the disadvantage of this

equipment is the non-uniform interface stress distribution that needs proper assumptions to interpret the results.

Romanoschi and Metcalf (2001) designed a shear fatigue device where the longitudinal axis of the specimen

forms an angle of 25.5 with the vertical in order to have the shear stress proportional to the normal one and

equal to half of its value. The loading conditions used to test the specimens consider a haversine load, applied

vertically by the loading machine, and assumes as comparative parameter of the interface fatigue properties the

number of cycles that leads to an increase of 1 mm in the permanent deformation.

Also, in the Mechanics and modeling of materials and structures in civil engineering Laboratory of the

University of Limoges, France, a modified compact shear test device was developed to study the shear fatigue

behavior of different asphalt mixtures and tack coat materials. The machine was used on prismatic specimens

(70x30x100 mm), formed by three parts, obtained by gluing back to back two samples of the same couple of

layers. With such a working scheme the shear load can be applied on the unrestricted middle layer of the double

specimen in monotonic or repeated mode until failure. Because of the low rigidity of the test frame, a new device

named new double-shear testing frame was developed by Diakhat et al. (2011) in order to test specimens at high

frequency and low temperature. In this case, the gluing of the specimen on the steel plates that apply the shear

load ensures the best alignment of the steel plates in relation to the double loading configuration and a perfect fit

of the specimen in the device. The experimental program was intended to carry out both fatigue and

oligocyclic tests under alternate sinusoidal force control, in order to span a number of loading cycles between

10 and several millions.

Among the shear tests devices are also included the two machines designed and developed by DAndrea and

Tozzo (2012, 2013) at the Sapienza University of Rome, both able to work in monotonic conditions under a

loading machine that applies a set displacement rate. In the devices, named SHST and SIST Machine, the shear

and the normal load act together on the specimen during the test, so to have a composite state of stress. In the

SHSTM the normal load is constant during the test while in the SISTM the two components proportionally vary.

These two machines were recently transformed to perform dynamic tests under the loading appliance used for

fatigue tests (DAndrea & Fiore, 2003).

3. Objective

The aim of this paper is to present the results of shear fatigue tests carried out with the dynamic shear test device

called SIST Machine. The device can be located under a dynamic loading machine. In this way, the shear fatigue

behavior of the interface can be analyzed considering loading conditions similar to some of the real ones as

occurs for the vehicles transit. For the particular working scheme of the device, the load is divided in dynamic

normal stress and shear stress at the interface.

2

www.ccsenet.org/mas

Modern Applied Science

Vol. 8, No. 2; 2014

The study will start with the analysis of the stress levels expected for the pavement structure when a moving

wheel load transits on the surface; these will be calculated with CIRCLY, a software for the mechanistic analysis

and design of road pavements. The trend through time of the stress at the first interface between binder and

wearing course will be inferred from a simply static analysis, by considering its output as an influence curve for

a fixed point. That curve will be imposed as waveform for the force applied by the loading machine on the

device.

Tests will be performed by reproducing the amplitude of the two stress components as evaluated by CIRCLY for

heavy axles. These test conditions are to try to simulate realistically the fatigue damage rise at the interface.

Moreover, tests with higher stresses combinations will be performed (oligocyclic fatigue test), in order to

contribute to a better definition of the fatigue line on the plane Stress vs. Number of Repetitions. A fatigue law

will be proposed, according to the experimental results.

4. Experimental Program

4.1 Specimens Preparation

The double layer specimens have been constructed to reproduce the first interface of a pavement, with binder

and wearing course. The two layers were manufactured with different contents of the same 60/70 bitumen and

different granulometric size distributions. For the binder course a mix of calcareous aggregates (20 mm

maximum size) and a bitumen content of 4,5% have been selected, while for the wearing course the mixture has

been composed of basalt and calcareous aggregates (10 mm maximum size) with a bitumen content of 5,5%.

Cylindrical moulds 130 mm high, with an interior diameter of 100 mm, have been used for the specimen

manufacturing under the Marshall Compactor. The blows have been applied only on the upper surface of each

layer as many times as the bulk density complied the most common acceptance requirements for the Italian

public work contracts: minimum 98% of the bulk density of the same mixture compacted in standard Marshall

mode (EN 12697). That purpose demanded 125 blows for the binder and 150 blows for the wearing course.

The lower layer, about 60 mm high, was left to cool at room temperature after the compaction. The interface was

treated to improve the adhesion with the application of a tack coat. The application rate selected for this study

has been 0.4 kg/m2 of residual bitumen, according to the Italian common prescription. Prior to perform the shear

test, all specimens were left to cool for more than 24 hours.

4.2 Apparatus

The Sapienza Inclined Shear Test Machine (SISTM), a prototype designed and developed at the Sapienza

University in the recent years, has been judged useful as test device for the evaluation of fatigue performance.

This is a direct shear machine similar to the device used by Romanoschi (Romanoschi & Metcalf, 2001); two

half moulds (100 mm interior diameter) hold the cylindrical double-sample and ensure the location of the

specimen under the loading machine in several inclinations. The SISTM brings the innovation of a joint, which

engages the top half of the equipment at the loading machine and avoids that this upper part of the device could

weight the specimen.

The gap between the two half moulds is fixed at 1 cm with the interface 5 mm apart. The device is equipped with

LVDT for the displacements measurements. A ball bearing plate allows the sliding of one part against the other.

For the cyclic working modality, a special attachment for the dynamic loading machine has been manufactured

as shown in Figure 1.

The relationships between the vertical load (F) applied by the loading machine and the load components

transmitted on the interface are the following:

T=Fsin

and

N=Fcos

(1)

where N is the normal load, T is the shear load and is the angle between the longitudinal axis of the specimen

and the vertical.

Once set the specimen angle, the ratio between the shear and normal stress is established and cannot be changed

during the test. In this study, the angle has been fixed at 60; then the shear stress is 3 times the normal one.

www.ccsennet.org/mas

Modernn Applied Sciencce

Vol. 8, No. 2; 2014

Figure 11. SISTM deviice

4.3 Loadinng Conditions

In order tto establish thhe level of F which has to be applied, iit is importantt to estimate the level of stress

s

commonlyy acted within real pavementt structures whhen a wheel looad passes alonng the surface using a nume

erical

modellingg as practice in pavement design (Boniin et al., 20077; Villani et aal., 2010). Foor this purposee, the

software C

CIRCLY was selected.

s

The input data shoown in Table 1 were considdered for the ssimulation of three

typical roaad pavements: a semi-rigid aand two flexibble pavements, one light andd one heavy, w

when a single wheel

w

or a dual w

wheel axle is moving.

m

www.ccsennet.org/mas

Modernn Applied Sciencce

Vol. 8, No. 2; 2014

Table 1. Innput data for thhe CIRCLY sim

mulation

Layer

CASE 1)

Thickness [mm

m]

E [MPaa]

Wearing course

40

7000

0.35

Binder

60

6000

0.35

Base

120

5000

0.35

Cement S

Stabilized

130

2000

0.2

Sub-basee

175

150

0.40

Subgradee

50

0.40

Layer

CASE 2)

Thickness [m

mm]

E [MP

Pa]

Wearing course

40

70000

0.355

Binder

60

60000

0.355

Base

200

50000

0.355

Sub-basee

225

1500

0.400

Subgradee

50

0.400

Thickness [m

mm]

E [MP

Pa]

Wearing course

30

70000

0.355

Binder

40

60000

0.355

Base

120

50000

0.355

Sub-basee

130

1500

0.400

Subgradee

50

0.400

Layer

CASE 3)

LOAD

ssingle wheel axle 120 kN

radius oof contact areaa

duaal wheel axle 120 kN

158 mm

radius of coontact area

115 mm

The layerss were consideered fully bonnd. The normaal and the tanggential stress aalong the drivving direction were

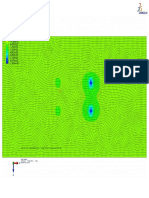

evaluated on the differennt alignments ddrawn in Figurre 2.

a))

b))

F

Figure

2. Alignnments for outpput extraction (single and duual wheel)

5

www.ccsennet.org/mas

Modernn Applied Sciencce

Vol. 8, No. 2; 2014

Some resuults are shown in Figure 3, fo

for the single w

wheel at the aliignments of x=

=0, x=80, x=160, x=190. Th

he zz

and the xzz are plotted, identifying

i

thee x axis as the perpendicularr direction to tthe vehicles m

motion. Very sim

milar

results were obtained foor dual wheel at similar disttance from thee external wheeel print edge, when the inflating

pressure is the same ass the single w

wheel. The grraphs of Figurre 3 can be vviewed not onnly as static stress

s

distributions in the spacce, but also as stress trends in the time, inn order to defi

fine the influennce curves. Fo

or the

purpose off this research,, the stress trennds were derivved at the depthh of the first innterface for a vvehicle speed of

o 15

km/h.

a)

b)

c)

d)

Figgure 3. Semiriggid pavement normal (left sside) and shearr (right side) sttress due to a ssingle wheel

alongg vertical planee on the alignm

ments at 0 (a); 80 (b); 160 (c)); 190 (d) mm

6

www.ccsennet.org/mas

Modernn Applied Sciencce

Vol. 8, No. 2; 2014

In Figure 4, the trends through time of the normall and shear strress are reportted for some of the investig

gated

positions. At the centrall position (x = 0), or in the other positionns under the w

wheel print (i.ee. x = 80), the

e two

trends are very differennt. On the conntrary, out of the vertical pprojection of the wheel priint there is a clear

proportionnality between shear and norrmal stress. In fact, for the aalignments bettween 170 andd 200 mm from

m the

center of tthe loading sinngle wheel arrea, the levels of and arre approximateely proportionnal each other. The

proportionnality rate is rooughly constannt for the wholee period of loaading.

The SIST Machine is able to reproduce these conditiions. The diagrams in Figuree 4 show that ffor the alignme

ent at

190 mm thhe ratio / is equal to that yyou can obtainn by setting thee longitudinal axis of the specimen at 60 with

the verticaal.

a)

b)

c)

d)

Figure 4.. Stress trends at the first inteerface for a sem

mi-rigid pavem

ment at the aliggnments of 0 (a), 80 (b), 160

0 (c)

and 190 (d) m

mm from the ceenter of the loaading single whheel area

The stresss trends are very similar inn the semirigidd and the stroong flexible pavements. Forr the light flexible

pavement, where the weearing course iis thinner and the global pavvement stiffneess is lower, a ratio / simillar to

that given by setting thee inclination at 60 is reachedd at 180 mm ffrom the centerr and the stress peak is highe

er, as

shown in F

Figure 5.

a)

b)

y, at

Figure 5. Stress trends at the first inteerface for a ligght flexible (a)) and semi-rigid (b) pavemennt, respectively

ments of 180 aand 190 mm from the center of the loadingg single wheel aarea

the alignm

7

www.ccsennet.org/mas

Modernn Applied Sciencce

Vol. 8, No. 2; 2014

Consequenntly, a triangullar waveform hhas been appliied by the loadding machine dduring the tests. It reproduce

es the

trends thatt the pavemennt structure reccords for the nnormal and shhear stress at thhe first interfaace just outside the

loading arrea. The trianggular impulse hhas been repeated always inn the same waay for all timee of the fatigue

e test

long. Thatt corresponds to

t the hypotheesis of a null ttrajectory scatttering of the vvehicles, as is the case of a strict

channeled bus lane.

The fatiguue behavior haas been analyzzed for differennt loading am

mplitudes. Channging the ampplitude, the loa

ading

time has been kept unmoodified.

4.4 Tests P

Plan

A summarry for the loadiing conditionss of the experim

mental program

m is shown inn Table 2, referrring to the peak of

the normall stress zz appplied in every ccycle. The low

wer stress levells (first two row

ws of the Tablle 2) are aroun

nd the

values estimated by CIR

RCLY for heaavy axles. Thee investigationn of lighter looad states, reppresentative off less

weighted aaxles, could be

b very useful to have a com

mplete experim

mental supporrt for fatigue llaw, but the te

esting

time wouldd become veryy long. Then thhey are missing in the presennt research. Vice versa, tests at high stress level

are not tim

me consuming (oligocyclic teests) and rapiddly supply usefful informationn to confirm thhe fatigue trend

d and

possibly too early estimatte the behaviorr of different taack alternativees (last rows off the Table 2).

The test teemperature hass been kept at 20 0.5 C foor all the experimentation, bby a room conttrol and monito

oring

system. Thhe standard cyycle provides tthat the rest tim

me equals the loading time. The total cyclle duration is 0.2

0 s.

At the streess level given by CIRCLY thhis duration is enough to com

mplete the recoovery of the ellastoviscous efffects.

On the othher hand, at higgher stresses tthe relaxation nneeds more tim

me for the recoovery. In thosee cases the pla

anned

load cyclee provides longger relaxation times (0.4 annd 0.9 s). As cconsequence, tthe total cyclee duration beco

omes

respectivelly 0.5 and 1 s.

Table 2. Exxperimental looading conditioons

zzz peak (MPa)

xz peak (MPa)

F (kN)

looading time (s)

relaxatiion time (s)

0.08

0.144

1.31

0.1

0.1

0.16

0.28

2.62

0.1

0.1

0.24

0.422

3.94

0.1

0.4

0.40

0.69

6.56

0.1

0.9

0.80

1.39

13.12

0.1

0.9

For all thee five conditioons, a preload of 0.3 kN hass to be appliedd for the loadinng machine seet up requirem

ments;

this preloaad can be negleected thanks too its low valuee in relation to the applied foorce (F). A typiical response curve

c

of the test is shown in Fiigure 6.

Figure 6. Typpical responsee curve of the iinterface displaacement VS N

Number of loadd cycles

www.ccsennet.org/mas

Modernn Applied Sciencce

Vol. 8, No. 2; 2014

Looking aat the evolutioon of the inteerface displaceement with thhe number of load applicatiions, the failu

ure is

conventionnally fixed att the point w

where the response curve records the m

maximum currvature before

e the

displacemeent indefinite increasing

i

(Nfaatigue).

5. Results

mens have beenn tested with a multiplicity oof 5 for all the iinvestigated looad conditions. The

The double layer specim

fatigue ressults are shownn in Figure 7.

Figuree 7. Results at 220 C with a teest angle of 600

t applied cyyclical load levvel, the numbeer of repetitionns that the intterface can sup

pport

With the iincreasing of the

decreases consistently. For the maxim

mum stress (ooligocyclic tessts), the speciimen bears a number of fa

atigue

repetitionss of a few tenss. For load am

mplitude similaar to those expperienced in thhe reality whenn braking o turrning

stresses are absent, the number

n

of suppported load appplications incrreases significaantly.

The averagge Nfatigue outcomes for the aanalyzed stresss values are suuitably fitted w

with a linear reggression. What it is

to notice tthe high R2 vallue gained forr the presentedd tests. Varyingg the inclinatioon of the devicce, the evolutio

on of

shear fatiggue damage in points locatedd at different diistances from tthat edge can bbe analyzed.

The fatiguue law shown in

i Figure 7 is vvalid just for 220 C and withh the studied m

materials and innterface condittions,

but it incittes to some rem

marks. At a disstance from thhe wheel print edge where thhe ratio / is ssimilar to that fixed

in the test machine with an angle of 600 (x=190 mm

m), the CIRCLY

Y simulation shows that the peak of the no

ormal

stress on tthe interface iss about 0.12 M

MPa for a tire iinflating presssure of 0.8 MP

Pa. This stress is reduced by

y half

for half innflating pressuure. The regresssion line is chharacterized bby an exponential trend withh approximatelly an

exponent oof 4 (see Figurre 7). If the reggression line ccan be considerred valid also for stress leveels lower than those

t

tested in llab, like 0.06 MPa, then it will be possibble to comparre the damage potential of tthese two diffferent

passages. IIn fact, at the alignment of 190 mm, abouut 30 mm from

m the wheel prrint edge, one ppassage of a wheel

w

inflated at e.g. 0.8 MPa generates a strress of 0.12 M

MPa and Nfailure about 90000, while a wheell inflated at e.g

g. 0.4

MPa generrates a stress of

o 0.06 MPa an

and Nfailure abouut 1400000. Thhat means thatt one passage of a wheel infflated

at 0.8 MPaa causes the saame shear dam

mage as about 116 passages of a wheel inflateed at 0.4 MPa..

6. Conclussions

The Sapieenza Inclined Shear Test M

Machine (SIST

TM), a prototyype designed and developeed at the Sapiienza

Universityy in the recent years, has beeen modified too be used in thhe evaluation oof fatigue perfformance of do

ouble

9

www.ccsenet.org/mas

Modern Applied Science

Vol. 8, No. 2; 2014

layer cylindrical specimens. Several inclinations can be easily set, in order to reproduce a large variety of

combinations between the normal and the shear stress.

The device is able to reproduce some of the stress combinations which occur during the wheel passage. In

particular it reproduces the conditions of points situated at the interface, next to the edge of the wheel path. In

those positions the shear stress is headed always in the same direction for the whole duration of the vehicle

passage. Also in the lab load cycle the shear stress is always applied in the same direction.

Setting the longitudinal axis of the specimen at 60 with the vertical corresponds to choose a position at about 30

mm from the edge of the wheel. Under this condition, the fatigue behavior has been analyzed and a fatigue law

has been achieved.

Even if the SIST Machine is able to reproduce some significant states of stress, they are just a few of those

experienced by the pavements, because that type of device obliges to set and maintain a fixed proportionality

between the normal and shear applied load. A more complete analysis of the interface stress conditions requires

the combination of different tests results performed with several machines, which are able to reproduce other

normal and shear stress ratios, as the pavement structure simulation indicates.

References

Bonin, G., Cantisani, G., Loprencipe, G., & Ranzo, A. (2007). Dynamic effects in concrete airport pavement

joints. Industria Italiana del Cemento, 77(834), 590-607.

Cantisani, G., & Loprencipe, G. (2013). A Statistics Based Approach for Defining Reference Trajectories on

Road Sections. Modern Applied Science, 7(9), 32-46. http://dx.doi.org/10.5539/mas.v7n9p32

Carr, A. G. (2001). The behavior of layered pavement structures: the dynamic shear box. Project Report, The

University of Nottingham, Nottingham, UK.

Crispino, M., Festa, B., Giannattasio, P., & Nicolosi, V. (1997). Evaluation of the interaction between the asphalt

concrete layers by a new dynamic test. Presented at the Eighth International Conference on Asphalt

Pavements.

DAndrea, A., & Fiore, N. (2003) Fatigue life of asphalt concrete with rubber grains. In A. Varvani-Farahani,

C.A. Brebbia. Fatigue Damage of Materials - Experiment and analysis. Advances in Damage Mechanics

(pp. 65-74). ISBN: 1-85312-979-8. WITpress, June 2003 (united kingdom).

DAndrea, A., & Tozzo, C. (2012). Interlayer Shear Failure Evolution with Different Test Equipments. Procedia

Social and Behavioral Sciences, 53, 556-567. http://dx.doi.org/10.1016/j.sbspro.2012.09.906

DAndrea, A., Russo, S., & Tozzo, C. (2013). Interlayer shear testing under combined state of stress. Advanced

Materials Research, 723, 381-388. http://dx.doi.org/10.4028/www.scientific.net/AMR.723.381

DAndrea, A., Tozzo, C., Boschetto A., & Bottini, L., (2013). Interface Roughness Parameters and Shear

Strength. Modern Applied Science, 7(10), 1-10. http://dx.doi.org/10.5539/mas.v7n10p1

Diakhat, M., Millien, A., Petit, C., Phelipot-Mardel, A., & Pouteau, B. (2011). Experimental investigation of

tack coat fatigue performance: Towards an improved lifetime assessment of pavement structure interfaces.

Construction and Building Materials, 25, 1123-113, http://dx.doi.org/10.1016/j.conbuildmat.2010.06.064

Ferrotti, G., Canestrari, F., Pasquini, E., & Virgili, A. (2012). Experimental evaluation of the influence of surface

coating on fiberglass geogrid performance in asphalt pavements. Geotextiles and Geomembranes, 34, 11-18.

http://dx.doi.org/10.1016/j.geotexmem.2012.02.011

Khweir, K., & Fordyce, D. (2003). Influence of layer bonding on the prediction of pavement life. ICE J.Trans.

156(TR2), 73-83. http://dx.doi.org/10.1680/tran.2003.156.2.73

Kruntcheva, M. R., Collop, A. C., & Thom, N. H. (2001). Shear box test: finite element modelling. Project

Report PGR01-05, NCPE, Nottingham, UK.

Loprencipe, G., & Cantisani, G. (2013). Unified Analysis of Road Pavement Profiles for Evaluation of Surface

Characteristics. Modern Applied Science, 7(8), 1-14. http://dx.doi.org/10.5539/mas.v7n8p1

Mauro, R., & Brando, F. (2013). Update on the Statistical Analysis of Traffic Counting on Two-Lane Rural

Highways. Modern Applied Science, 7(6), 67-80. http://dx.doi.org/10.5539/mas.v7n6p67

Mohammad, L. N., Raqib, M. A., & Huang, B. (2002). Influence of asphalt tack coat materials on interface shear

strength. Transportation Research Record: Journal of the Transportation Research Board, 1789(1), 56-65.

http://dx.doi.org/10.3141/1789-06

10

www.ccsenet.org/mas

Modern Applied Science

Vol. 8, No. 2; 2014

Mohammad, L. N. (2012). Optimization of Tack Coat for HMA Placement (Vol. 712). Transportation Research

Board. Project 09-40 ISSN 0077-5614 ISBN 978-0-309-21397-4. Library of Congress Control Number

2012934201.

Raab, C., & Partl, M. N. (2004). Interlayer shear performance: experience with different pavement structures.

Proceedings of the 3rd Eurasphalt & Eurobitume Congress, May 2004, vol. 1, pp. 535-545. Vienna.

Romanoschi, S., & Metcalf, J., (2001). Characterization of Asphalt Concrete Layer Interfaces. Transportation

Research

Records

Journal

Transportation

Research

Board,

1778,

132-139.

http://dx.doi.org/10.3141/1778-16

Sangiorgi, C., Collop, A. C., & Thom, N. H. (2002). Laboratory assessment of bond condition using the Leutner

shear test. Proceedings of the 3rd International Conference Bituminous Mixtures and Pavements,

Thessaloniki.

Villani, M. M., Liu, X., Scarpas, A., & DAndrea, A. (2010). Numerical modeling of the mechanical response of

recycled materials in embankments. Numerical Methods in Geotechnical Engineering-Proceedings of the

7th European Conference on Numerical Methods in Geotechnical Engineering (pp. 569-574).

Xiaoyang, J., Baoshan, H., & Lihan, L. (2013). A simplified approach for evaluating interlayer shear resistance

in asphalt pavement. Presented at the Transportation Research Board 92nd Annual Meeting.

Copyrights

Copyright for this article is retained by the author(s), with first publication rights granted to the journal.

This is an open-access article distributed under the terms and conditions of the Creative Commons Attribution

license (http://creativecommons.org/licenses/by/3.0/).

11

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Numerical Analysis of Cracking in Concrete Pavements Subjected To Wheel Load and Thermal Curling PDFDocumento327 páginasNumerical Analysis of Cracking in Concrete Pavements Subjected To Wheel Load and Thermal Curling PDFRith Makara100% (1)

- S33 Bottom of HMADocumento1 páginaS33 Bottom of HMARith MakaraAún no hay calificaciones

- Immigration InformationDocumento11 páginasImmigration InformationRith MakaraAún no hay calificaciones

- Mixture DesignDocumento2 páginasMixture DesignRith MakaraAún no hay calificaciones

- Abaqus Printed Document Aug 24 2015Documento1 páginaAbaqus Printed Document Aug 24 2015Rith MakaraAún no hay calificaciones

- Blending Aggregates for Asphalt ConcreteDocumento40 páginasBlending Aggregates for Asphalt ConcreteKashif Muhammad80% (5)

- A Rational Approach To The Prediction of Reflective Cracking in Bituminous Overlays For Concrete Pavements PDFDocumento226 páginasA Rational Approach To The Prediction of Reflective Cracking in Bituminous Overlays For Concrete Pavements PDFRith MakaraAún no hay calificaciones

- Lau1994 PDFDocumento15 páginasLau1994 PDFRith MakaraAún no hay calificaciones

- Paper 200703 Dynamic ModulusDocumento22 páginasPaper 200703 Dynamic ModulusRith MakaraAún no hay calificaciones

- Evaluating Weak Subgrade For Pavement Design and Performance Prediction - A Case Study of US550Documento13 páginasEvaluating Weak Subgrade For Pavement Design and Performance Prediction - A Case Study of US550Rith MakaraAún no hay calificaciones

- Determination of Prony Series CoefficientDocumento2 páginasDetermination of Prony Series CoefficientRith MakaraAún no hay calificaciones

- 2nd Figure and List of TableDocumento4 páginas2nd Figure and List of TableRith MakaraAún no hay calificaciones

- A Rational Approach To The Prediction of Reflective Cracking in Bituminous Overlays For Concrete Pavements PDFDocumento226 páginasA Rational Approach To The Prediction of Reflective Cracking in Bituminous Overlays For Concrete Pavements PDFRith MakaraAún no hay calificaciones

- Dynamic Modulus of Asphalt Material, E 2. Rigid Pavement Analysis (Comparing: KENSLAB, ISLAB2000, and Westergaard Method)Documento1 páginaDynamic Modulus of Asphalt Material, E 2. Rigid Pavement Analysis (Comparing: KENSLAB, ISLAB2000, and Westergaard Method)Rith MakaraAún no hay calificaciones

- Printed Using Abaqus/CAE On: Wed Aug 26 17:24:57 Korea Standard Time 2015Documento1 páginaPrinted Using Abaqus/CAE On: Wed Aug 26 17:24:57 Korea Standard Time 2015Rith MakaraAún no hay calificaciones

- Engineering Course of GWNUDocumento6 páginasEngineering Course of GWNURith MakaraAún no hay calificaciones

- 3 Stress and StrainDocumento28 páginas3 Stress and StrainRith MakaraAún no hay calificaciones

- MairePav8 ConferenceDocumento1 páginaMairePav8 ConferenceRith MakaraAún no hay calificaciones

- TP4Documento10 páginasTP4Rith MakaraAún no hay calificaciones

- Pavement - Homework#3Documento5 páginasPavement - Homework#3Rith MakaraAún no hay calificaciones

- Abaqus Printed Document Aug 24 2015Documento1 páginaAbaqus Printed Document Aug 24 2015Rith MakaraAún no hay calificaciones

- HM#6Documento14 páginasHM#6Rith MakaraAún no hay calificaciones

- Summary of Finite Element AnalysisDocumento4 páginasSummary of Finite Element AnalysisRith MakaraAún no hay calificaciones

- Wang J2001Documento139 páginasWang J2001rehabsalmaAún no hay calificaciones

- AADTDocumento8 páginasAADTOliverPranavAún no hay calificaciones

- Pra MetricDocumento17 páginasPra MetricRith MakaraAún no hay calificaciones

- Nº Allowable Load Repetition Developer: R, I Predicted at I Stress Level AllowableDocumento2 páginasNº Allowable Load Repetition Developer: R, I Predicted at I Stress Level AllowableRith MakaraAún no hay calificaciones

- Etabs Design of Tall Building Reinforcement DetailingDocumento54 páginasEtabs Design of Tall Building Reinforcement Detailingutoy032367100% (8)

- Timetable GWNUDocumento2 páginasTimetable GWNURith MakaraAún no hay calificaciones

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Love My LifeDocumento5 páginasLove My LifeLinda Veronica0% (1)

- Material Balance On A 2 Unit DistillationsDocumento6 páginasMaterial Balance On A 2 Unit Distillationsnhalieza1067Aún no hay calificaciones

- Design of Gain Compensator: DR Mirza Tariq HamayunDocumento19 páginasDesign of Gain Compensator: DR Mirza Tariq HamayunAsad RehanAún no hay calificaciones

- Latent Heat of Fusion VaporizationDocumento18 páginasLatent Heat of Fusion Vaporizationapi-449002661Aún no hay calificaciones

- OAT Bootcamp Physics Equation Sheet PDFDocumento11 páginasOAT Bootcamp Physics Equation Sheet PDFjon100% (2)

- Diaphragm Design PDFDocumento50 páginasDiaphragm Design PDFManoj JaiswalAún no hay calificaciones

- Harald J. W. Muller-Kirsten-Electromagnetic Field Theory-World Scientific Publishing Company (2004) PDFDocumento203 páginasHarald J. W. Muller-Kirsten-Electromagnetic Field Theory-World Scientific Publishing Company (2004) PDFMonã Hegel BenettiAún no hay calificaciones

- Numerical Solution of Seepage Problem of Groundwater FlowDocumento5 páginasNumerical Solution of Seepage Problem of Groundwater FlowIOSRjournalAún no hay calificaciones

- Vibration Case HistoriesDocumento56 páginasVibration Case HistoriesanuprajaAún no hay calificaciones

- Pseudocode for determining minimum launch angle to clear an obstacleDocumento8 páginasPseudocode for determining minimum launch angle to clear an obstacleChristian BatayenAún no hay calificaciones

- PMM WordDocumento3 páginasPMM WordShrey R DhanawadkarAún no hay calificaciones

- Lightweight SUV Frame Design DevelopmentDocumento50 páginasLightweight SUV Frame Design DevelopmentAltairEnlightenAún no hay calificaciones

- Analysis of Wood Bending PropertiesDocumento11 páginasAnalysis of Wood Bending Propertiesprasanna020391100% (1)

- D Mec Frac Fatigue Part IIDocumento38 páginasD Mec Frac Fatigue Part IIsure516vAún no hay calificaciones

- Molecular Partition Function ExplainedDocumento18 páginasMolecular Partition Function ExplainedAnimasahun Olamide HammedAún no hay calificaciones

- The role of root canal fillings in endodontic successDocumento9 páginasThe role of root canal fillings in endodontic successYassir MudharAún no hay calificaciones

- Archimedes Heat RayDocumento5 páginasArchimedes Heat RayElliah Jen BiluganAún no hay calificaciones

- Polar Moment of Inertia ExperimentDocumento17 páginasPolar Moment of Inertia Experimentsohail parachaAún no hay calificaciones

- Tuning Equation of State ModelsDocumento34 páginasTuning Equation of State Modelswelltest vspAún no hay calificaciones

- Working of Steam Turbines and Its AuxillariesDocumento48 páginasWorking of Steam Turbines and Its AuxillariesbalajigandhirajanAún no hay calificaciones

- Sample Lesson Plan in Science V Using Explicit InstructionDocumento6 páginasSample Lesson Plan in Science V Using Explicit InstructionKrimson Mike DolorzoAún no hay calificaciones

- Mijlocul Cerului in SinastrieDocumento2 páginasMijlocul Cerului in SinastrieKali KaliAún no hay calificaciones

- G.D.GOENKA PUBLIC SCHOOL CLASS 10 CHEMISTRY CHAPTER 2 ACIDS BASES SALTS ASSIGNMENTDocumento3 páginasG.D.GOENKA PUBLIC SCHOOL CLASS 10 CHEMISTRY CHAPTER 2 ACIDS BASES SALTS ASSIGNMENTvikas aggarwal100% (1)

- History of Contingency Theory: Reporter: Emiliana J. LozanoDocumento23 páginasHistory of Contingency Theory: Reporter: Emiliana J. Lozanoaireenclores100% (3)

- ASTM TablesDocumento185 páginasASTM Tableslahiru198367% (3)

- Soil Settlement ElasticityDocumento10 páginasSoil Settlement ElasticityAnonymous aZrC1EZAún no hay calificaciones

- PhoneticsDocumento5 páginasPhoneticsKarensita Totty' HerreraAún no hay calificaciones

- Synperonic EthoxylatesDocumento2 páginasSynperonic Ethoxylatesjacky ye100% (1)

- Reka Bentuk, Pembinaan Dan Pentadbiran UjianDocumento9 páginasReka Bentuk, Pembinaan Dan Pentadbiran UjianAiman HazimAún no hay calificaciones

- SKEM 3742 Electro Hydraulic LabsheetDocumento6 páginasSKEM 3742 Electro Hydraulic Labsheetcikgu_relaAún no hay calificaciones