Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Poor Nodularity in Ductile Iron

Cargado por

arnaldorcr8646Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Poor Nodularity in Ductile Iron

Cargado por

arnaldorcr8646Copyright:

Formatos disponibles

Technical Information 25

Poor Nodularity in Ductile Iron

This sheet summarises some important considerations affecting nodularity in ductile iron

production. Factors causing different types of poor nodularity are described, and important

criteria distinguishing between the different types of poor nodularity given.

Compacted graphite:

• Low residual magnesium and/or rare

earth’s from poor nodularising practice,

high temperature or long holding times.

• Excess sulphur in the base iron not

balanced by sufficient magnesium.

• Excess titanium in iron from

compacted graphite iron returns.

Exploded graphite:

• Excess rare earth additions,

particularly when high purity charges

are used. Normally found in thick

section castings or at higher carbon

equivalents.

• Sudden drop in base iron sulphur

content from change of raw material

lots (steel scrap, pig iron, recarburiser).

Chunky graphite:

• Excess rare earth additions when high

purity charges are used.

• Low Sulphur to RE ratio.

• Promoted by poor inoculation

(pronounced segregation effects).

• Similar causes as exploded graphite.

Elkem ASA, Foundry Products © Copyright Elkem ASA

Postal address Office address Telephone Web Revision

P.O.Box 5211 Majorstuen Hoffsveien 65B +47 22 45 01 00 www.foundry.elkem.com No. 2.1

NO-0302 Oslo Oslo Telefax Org. no. 20.03.2004

Norway Norway +47 22 45 01 52 NO 911 382 008 MVA

Technical Information 25 2

Spiky graphite:

• Very small amounts of lead (Pb),

bismuth (Bi), or antimony (Sb) that

have not been neutralized by rare

earth’s. This has a catastrophic effect

on mechanical properties.

• Insufficient addition of rare earth’s to a

contaminated charge.

Irregular graphite shape:

• Poor inoculation or excessive fading of

inoculation. Often combined with low

nodule counts.

• High holding temperatures or long

holding times resulting in “dead” irons.

• Excessive addition of nodulariser.

• Can be improved by late addition of a

powerful specialty inoculant.

Nodule alignment:

• Low carbon equivalent.

• Poor inoculation causing hypo-eutectic

solidification and coarse dendrite

structures. Nodule alignment at

dendrite arms.

• High pouring temperatures.

Flake graphite surface:

• Excess sulphur built-up in moulding

sand. Reversion to flakes as

magnesium in the iron reacts with

sulphur.

• Can be overcome by using higher

magnesium or rare earth’s in

nodulariser, or a cerium containing

inoculant.

• Mould coating may also be useful.

También podría gustarte

- Effects of Minor and Trace Elements in Cast IronDocumento2 páginasEffects of Minor and Trace Elements in Cast Ironarnaldorcr864667% (3)

- Selection of NodularizersDocumento2 páginasSelection of Nodularizersarnaldorcr8646100% (2)

- Selection of Inoculants For Ductile Cast IronDocumento1 páginaSelection of Inoculants For Ductile Cast Ironarnaldorcr8646100% (1)

- Slag Defects in Grey IronDocumento1 páginaSlag Defects in Grey Ironarnaldorcr8646100% (1)

- Magnesium Slag Defects in Ductile IronDocumento1 páginaMagnesium Slag Defects in Ductile Ironarnaldorcr8646100% (1)

- Common Metallurgical Defects in Ductile IronDocumento1 páginaCommon Metallurgical Defects in Ductile IronMehdi Koneshlou100% (1)

- Nitrogen FissuresDocumento1 páginaNitrogen Fissuresarnaldorcr8646100% (1)

- Common Metallurgical Defects in Grey Cast Irons 2Documento1 páginaCommon Metallurgical Defects in Grey Cast Irons 2Rasool MohammadiAún no hay calificaciones

- Chunky GraphiteDocumento16 páginasChunky GraphitesachinguptachdAún no hay calificaciones

- Common Metallurgical Defects in Grey Iron: Hydrogen Blowhole Nitrogen Fissure Compaction of Graphite Flakes ShrinkageDocumento1 páginaCommon Metallurgical Defects in Grey Iron: Hydrogen Blowhole Nitrogen Fissure Compaction of Graphite Flakes ShrinkageJoao LuisAún no hay calificaciones

- Inoculation of Heavy Section CastingsDocumento2 páginasInoculation of Heavy Section Castingsarnaldorcr8646100% (1)

- SG Iron ProductionDocumento20 páginasSG Iron ProductionShreyashri Nayak100% (1)

- Common Metallurgical Defects in Ductile Cast IronDocumento10 páginasCommon Metallurgical Defects in Ductile Cast IronsateeshkoriAún no hay calificaciones

- Fading of Nodularity in Ductile IronDocumento2 páginasFading of Nodularity in Ductile Ironarnaldorcr8646100% (4)

- Shrinkage in Ductile IronDocumento5 páginasShrinkage in Ductile Ironkarthikkanda100% (1)

- Nitrogen in Cast IronDocumento4 páginasNitrogen in Cast IronFaizan TahirAún no hay calificaciones

- Magnesium Contents in Ductile IronDocumento2 páginasMagnesium Contents in Ductile Ironarnaldorcr8646Aún no hay calificaciones

- Composition of Grey Cast IronDocumento2 páginasComposition of Grey Cast IronPranil GhatageAún no hay calificaciones

- Ductile Dross Formation MonitoringDocumento27 páginasDuctile Dross Formation MonitoringsachinguptachdAún no hay calificaciones

- Fading of InoculationDocumento2 páginasFading of Inoculationarnaldorcr8646Aún no hay calificaciones

- Technical InformationDocumento78 páginasTechnical InformationCarlos Barrachina Martínez100% (2)

- Effect of Minor and Trace Elements in Cast IronDocumento2 páginasEffect of Minor and Trace Elements in Cast IronsachinguptachdAún no hay calificaciones

- Common Metallurgical Defects in Grey Iron English (1Documento1 páginaCommon Metallurgical Defects in Grey Iron English (1sateeshkori100% (2)

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocumento2 páginasPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646Aún no hay calificaciones

- Elkem 07 Magnesiun Contents in Ductile IronDocumento2 páginasElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123Aún no hay calificaciones

- Steel Pouring TimesDocumento2 páginasSteel Pouring Timesvasanthi100% (1)

- Analyzing Casting Defects in Foundry TechnologyDocumento12 páginasAnalyzing Casting Defects in Foundry TechnologyVirendra Gupta100% (1)

- Late Metal Stream InoculationDocumento2 páginasLate Metal Stream Inoculationarnaldorcr8646Aún no hay calificaciones

- Effects of Alloying Elements On The Micro Structures and Mechanical On Ductile Cast IronsDocumento5 páginasEffects of Alloying Elements On The Micro Structures and Mechanical On Ductile Cast IronsCharlie Chong100% (6)

- Selection of Inoculants For Grey Cast IronDocumento2 páginasSelection of Inoculants For Grey Cast Ironarnaldorcr8646Aún no hay calificaciones

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFDocumento23 páginas1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- S.G. Iron : MouldingDocumento11 páginasS.G. Iron : MouldingsureshbabuamalaAún no hay calificaciones

- SG Iron CompositionDocumento5 páginasSG Iron CompositionamirgukharAún no hay calificaciones

- Sampling of Liquid Cast IronDocumento2 páginasSampling of Liquid Cast Ironarnaldorcr8646Aún no hay calificaciones

- Effect of Bismuth in Ductile IronDocumento4 páginasEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Effect of Minor and Trace Elements in Cast IronDocumento2 páginasEffect of Minor and Trace Elements in Cast IronsachinguptachdAún no hay calificaciones

- Carbon Monoxide Blowholes in Grey IronDocumento1 páginaCarbon Monoxide Blowholes in Grey Ironarnaldorcr8646Aún no hay calificaciones

- Defects in Ductile IronDocumento12 páginasDefects in Ductile IronSerdar çevikAún no hay calificaciones

- 16 ScabbingDocumento4 páginas16 Scabbingvivek13120% (1)

- Cerium in Ductile IronDocumento2 páginasCerium in Ductile Ironvivek1312100% (2)

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocumento8 páginasRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazAún no hay calificaciones

- 26-ELKEM - Poster-Graphite Structures in Cast IronsDocumento1 página26-ELKEM - Poster-Graphite Structures in Cast IronsSalvador Rocha100% (2)

- Grey Cast IronDocumento43 páginasGrey Cast IronVasanth PrasadAún no hay calificaciones

- Elkem - Alloying Elements and Their EffectsDocumento8 páginasElkem - Alloying Elements and Their EffectsDeep Shikha Gupta100% (8)

- Recommended Target Analysis For Ductile IronDocumento2 páginasRecommended Target Analysis For Ductile Ironarnaldorcr8646100% (2)

- Guide Lines For Producing Quality S.G. Iron PDFDocumento28 páginasGuide Lines For Producing Quality S.G. Iron PDFsachinguptachd100% (1)

- S.G IronDocumento6 páginasS.G IronQasim BarkatAún no hay calificaciones

- Directional Solidification of Steel CastingsDe EverandDirectional Solidification of Steel CastingsCalificación: 5 de 5 estrellas5/5 (3)

- Applied Science in the Casting of MetalsDe EverandApplied Science in the Casting of MetalsK. StraussAún no hay calificaciones

- Engineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeDe EverandEngineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeAún no hay calificaciones

- The Structures of Alloys of Iron: An Elementary IntroductionDe EverandThe Structures of Alloys of Iron: An Elementary IntroductionAún no hay calificaciones

- Modern Metallography: The Commonwealth and International Library: Metallurgy DivisionDe EverandModern Metallography: The Commonwealth and International Library: Metallurgy DivisionCalificación: 5 de 5 estrellas5/5 (1)

- Cast Iron: Physical and Engineering PropertiesDe EverandCast Iron: Physical and Engineering PropertiesCalificación: 5 de 5 estrellas5/5 (1)

- The Foseco Foundryman's Handbook: Facts, Figures and FormulaeDe EverandThe Foseco Foundryman's Handbook: Facts, Figures and FormulaeT.A. BurnsCalificación: 3 de 5 estrellas3/5 (2)

- Common Metallurgical Defects in Ductile Cast IronDocumento10 páginasCommon Metallurgical Defects in Ductile Cast IronsateeshkoriAún no hay calificaciones

- Inoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesDocumento12 páginasInoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesZody YtuAún no hay calificaciones

- Common Metallurgical Defects in Ductile Cast IronDocumento10 páginasCommon Metallurgical Defects in Ductile Cast IronsateeshkoriAún no hay calificaciones

- Nitrogen FissuresDocumento1 páginaNitrogen Fissuresarnaldorcr8646100% (1)

- In The Mould Nodular Is IngDocumento2 páginasIn The Mould Nodular Is Ingarnaldorcr8646Aún no hay calificaciones

- Heat Conservation in Liquid Iron, 2005-07-10Documento5 páginasHeat Conservation in Liquid Iron, 2005-07-10arnaldorcr8646100% (1)

- Compacted Iron ElkemDocumento20 páginasCompacted Iron ElkemAmol ThakurAún no hay calificaciones

- Determining The Optimum Level of Inoculant Addition by Thermal Analysis - A Case Study, Ductile Iron News, Dec 2004Documento8 páginasDetermining The Optimum Level of Inoculant Addition by Thermal Analysis - A Case Study, Ductile Iron News, Dec 2004arnaldorcr8646Aún no hay calificaciones

- Common Metallurgical Defects in Ductile Cast IronDocumento10 páginasCommon Metallurgical Defects in Ductile Cast IronsateeshkoriAún no hay calificaciones

- Magnesium Versus Sulphur in Ductile IronDocumento2 páginasMagnesium Versus Sulphur in Ductile Ironarnaldorcr8646100% (2)

- Late Metal Stream InoculationDocumento2 páginasLate Metal Stream Inoculationarnaldorcr8646Aún no hay calificaciones

- Hydrogen PinholesDocumento1 páginaHydrogen Pinholesarnaldorcr8646Aún no hay calificaciones

- Internal Shrinkage PorosityDocumento1 páginaInternal Shrinkage Porosityarnaldorcr8646100% (2)

- Selection of Inoculants For Grey Cast IronDocumento2 páginasSelection of Inoculants For Grey Cast Ironarnaldorcr8646Aún no hay calificaciones

- Inoculation of Heavy Section CastingsDocumento2 páginasInoculation of Heavy Section Castingsarnaldorcr8646100% (1)

- Carbon Monoxide Blowholes in Grey IronDocumento1 páginaCarbon Monoxide Blowholes in Grey Ironarnaldorcr8646Aún no hay calificaciones

- Elkem 19 Aluminum in Cast IronDocumento2 páginasElkem 19 Aluminum in Cast Ironmarcotulio123Aún no hay calificaciones

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocumento2 páginasPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646Aún no hay calificaciones

- Heat Conservation in Liquid IronDocumento2 páginasHeat Conservation in Liquid Ironarnaldorcr8646Aún no hay calificaciones

- Factors Influencing The Recovery and Addition of MagnesiumDocumento4 páginasFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Aún no hay calificaciones

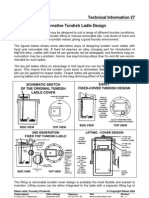

- Alternative Tundish Ladle DesignDocumento2 páginasAlternative Tundish Ladle Designarnaldorcr8646Aún no hay calificaciones

- Fading of Nodularity in Ductile IronDocumento2 páginasFading of Nodularity in Ductile Ironarnaldorcr8646100% (4)

- The "Sandwich Pocket Process"Documento2 páginasThe "Sandwich Pocket Process"arnaldorcr8646Aún no hay calificaciones

- Factors Influencing The Recovery and Addition of MagnesiumDocumento4 páginasFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Aún no hay calificaciones

- Recommended Target Analysis For Grey IronDocumento2 páginasRecommended Target Analysis For Grey Ironarnaldorcr8646Aún no hay calificaciones

- Application of Buffer in Water TreatmentDocumento2 páginasApplication of Buffer in Water TreatmentAshrul NasirAún no hay calificaciones

- STPM 2009Documento19 páginasSTPM 2009one kilometer100% (2)

- Coordination CPPDocumento8 páginasCoordination CPPSri KrishnaAún no hay calificaciones

- B600Documento3 páginasB600gfgugf100% (1)

- Periodic TableDocumento44 páginasPeriodic TableKithminiAún no hay calificaciones

- Shapes of Molecules & Ions: Name . . FormDocumento2 páginasShapes of Molecules & Ions: Name . . FormjnfjngsdjAún no hay calificaciones

- Code of Practice: Normalisation Renault Automobiles Service 65810 Section Normes Et Cahiers Des ChargesDocumento42 páginasCode of Practice: Normalisation Renault Automobiles Service 65810 Section Normes Et Cahiers Des ChargesLica EmilAún no hay calificaciones

- Reference Assortment Kits for Non-Destructive Metal TestingDocumento1 páginaReference Assortment Kits for Non-Destructive Metal TestingAntonioCarlosSilvaAún no hay calificaciones

- "Cyanide Complexes of The Transition Metals" In: Encyclopedia of Inorganic and Bioinorganic ChemistryDocumento11 páginas"Cyanide Complexes of The Transition Metals" In: Encyclopedia of Inorganic and Bioinorganic ChemistryPaulo HenriqueAún no hay calificaciones

- Identifying Elements: ProblemDocumento6 páginasIdentifying Elements: ProblemAdamari Andrade OrtizAún no hay calificaciones

- HydridesDocumento2 páginasHydridesLeyre GonzálezAún no hay calificaciones

- Thermal, Density & Mechanical Properties of Common MaterialsDocumento6 páginasThermal, Density & Mechanical Properties of Common MaterialsHassanAún no hay calificaciones

- Boron and Refractory CompoundsDocumento666 páginasBoron and Refractory Compoundscraz3xAún no hay calificaciones

- Cambridge IGCSE Chemistry Study and Revision GuideDocumento342 páginasCambridge IGCSE Chemistry Study and Revision GuideMayank Maddula33% (3)

- Percentage Yield & Atom Economy: Name . . FormDocumento2 páginasPercentage Yield & Atom Economy: Name . . FormMeeran HassanAún no hay calificaciones

- Oxidaciones CrO3Documento16 páginasOxidaciones CrO3COMPAQSR14Aún no hay calificaciones

- Modul Banding Alkana Dan AlkenaDocumento7 páginasModul Banding Alkana Dan Alkenarudi_zAún no hay calificaciones

- ScP019 Chemical Equations 1Documento2 páginasScP019 Chemical Equations 1ORBeducationAún no hay calificaciones

- Inorganic Spectoscopy-UV-VisDocumento100 páginasInorganic Spectoscopy-UV-VisUsama El-Ayaan100% (5)

- Workbk 10Documento177 páginasWorkbk 10Manushree NayakAún no hay calificaciones

- Cfy-21-25 - PT-6 - X Lot-Science (Cbse Type)Documento5 páginasCfy-21-25 - PT-6 - X Lot-Science (Cbse Type)Himansu MookherjeeAún no hay calificaciones

- Notes Organic Chemistry and AlkanesDocumento17 páginasNotes Organic Chemistry and Alkanessrk78Aún no hay calificaciones

- A Level Chemistry Unit 3B Revision: Reagent TestsDocumento1 páginaA Level Chemistry Unit 3B Revision: Reagent TestsKaruvarakkalAún no hay calificaciones

- Jee 2014 Booklet7 HWT Oxygen Containing Organic Compounds IIDocumento10 páginasJee 2014 Booklet7 HWT Oxygen Containing Organic Compounds IIvarunkohliinAún no hay calificaciones

- Lesson 1.3 Mass Relationships in Chemical ReactionsDocumento70 páginasLesson 1.3 Mass Relationships in Chemical ReactionsLance Adrian BengalanAún no hay calificaciones

- Stoichiometry: Previous Eamcet BitsDocumento7 páginasStoichiometry: Previous Eamcet BitswdwdwdwdwAún no hay calificaciones

- 04 Lecture PPT NewDocumento37 páginas04 Lecture PPT Newapi-201447595Aún no hay calificaciones

- Cambridge Lower Secondary Progression Test: Science Paper 1Documento16 páginasCambridge Lower Secondary Progression Test: Science Paper 1mahdi hassan100% (4)

- CH 13 Nuclear Physics and RadioactivityDocumento14 páginasCH 13 Nuclear Physics and RadioactivityAkash KoulAún no hay calificaciones

- Chemistry Past 10 Year Papers 2002-2013Documento106 páginasChemistry Past 10 Year Papers 2002-2013siddharth199650% (2)