Documentos de Académico

Documentos de Profesional

Documentos de Cultura

OHS&W Plant Specific Hazard Identification

Cargado por

Julio Best SetiyawanDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

OHS&W Plant Specific Hazard Identification

Cargado por

Julio Best SetiyawanCopyright:

Formatos disponibles

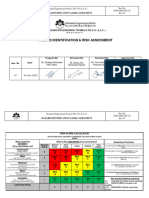

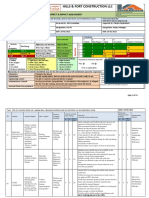

Plant Hazard Identification & Risk Assessment Form

Company:

Section/Area:

Risk Assessor (s):

Section 1.

Assessment Date:

Hazards: Potential Damaging Energies

Mechanical hazards

Machine parts or work pieces eg,

shape, relative location, mass and

stability

Radiation

Restoration of energy supply after Interuption

Low-frequency, radio frequency

radiation; microwaves

External influences on electrical equipment

Accumulation of energy inside

machinery eg elastic elements

(springs), liquids of gases under

pressure, the effect of vacuum

Infrared, visible and UV radiation

Other external influences (gravity, wind etc.)

Crushing hazard

X-rays and gamma rays

Errors in software

Shearing hazard

Cutting or severing hazard

Alpha and beta rays, electron beams

neutrons

Relating to travelling function

Entanglement hazards

Materials and Substances

Drawing in or trapping hazard

Contact with or inhalation of harmful

fluids, gases, mists, fumes and dusts

Impact hazard

Fire and explosion

Stabbing puncture

Friction or abrasion hazard

Ergonomics

High pressure

Unhealthy postures or excessive

effort

Electrical Hazards

Lasers

Biological or microbiological hazards

Errors made by operator (human/machine

mismatch)

Movement when starting Engine

Movement without driver at driving position

Movement without all parts in a safe position

Excessive speed of pedestrian-controlled

machinery

Excessive oscillations when moving

Insufficient ability of machinery to be slowed

down, stopped and immobilised

Inadequate consideration of handarm or foot-leg anatomy

From handling of the machine (lack of stability)

Contact of persons with live parts

(direct contact

Neglected use of PPE

Mechanical hazard and hazardous events

Contact of persons with Parts which

have become live under faulty

conditions (indirect contact)

Inadequate lighting

From load falls, collisions, machine tipping (lack of

stability)

Approach to live parts under high

voltage

Mental overload and underload,

stress

Uncontrolled loading-oveloading-overturning

moments exceeded

Electrostatic phenomena

Human error, human behaviour

Unexpected/unintended movement of loads

Thermal hazards

Inadequate design or location of

visual display units

Hazards from engine and the batteries

Burns, scalds and other injuries by

possible contact with objects or

materials (hot or cold)

Hazards from transmission of power between

machines

Damage to health by hot or cold

working environment

Use of hands held machines

Hazards from coupling and towing

Noise

Whole body vibration

Hearing Loss or other physiological

disorders

Unexpected startup, Unexpected

Overrun/OverSpeed

Interference with speech, acoustic

signals

Failure/Display of control system

Thermal radiation or other

phenomena such as projection of

molten particles and chemical

effects from short circuits, overloads

Inadequate design, location or

identification of manual controls

Vibration

Due to power source and to the transmission

of power

Page 1 of 3

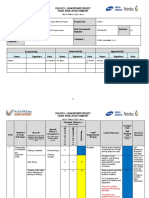

Section 2. - Summary of Identified Hazards

1.

Hazards:

Associated Risks:

2.

3.

Any specific circumstances:

Persons at Risks: (list)

Is the risk (Tick one)

Minimal risk exposure

Adequately controlled. No further action required

In adequately controlled. Further Action/Investigation Required. Proceed with Risk Assessment (Section 3)

Covered by Regulation/Standard/Code Specify:

Section 3. Risk Assessment

Existing Controls (if any)

Likelihood (tick one):

Consequence (tick one):

Very Likely

Likely

Unlikely

Highly Unlikely

Life Threatening

Detrimental

Harmful

Negligible

Risk Rating:

High

Medium

Section 4. Risk Controls

Low

Preferred Hierarchy of Controls

Possible Controls:

1. Elimination

2.Substitution

3. Engineering (Isolation, Guarding,

Redesign) AS 4024:2006

Preferred Controls:

4. Administrative (SOPs,Training)

5. Personal Protective Equipment

Section 5 Implementation Plan

Control Option

Associated activities

Resources

Person (s)

Responsible

Proposed

Implementation

date

Page 2 of 3

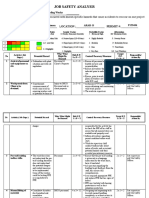

Section 6 Comments and Endorsements

Comments of Person carrying out the assessment:

Name:

Signature:

Date:

Signature:

Date:

Line manager to endorse the assessment:

Name:

Page 3 of 3

También podría gustarte

- Plant HazrdDocumento3 páginasPlant Hazrdayuzme123Aún no hay calificaciones

- k3 Bore Pile DenganBIMDocumento6 páginask3 Bore Pile DenganBIMrhoewiebAún no hay calificaciones

- Ws Job Safety Assessment 11Documento8 páginasWs Job Safety Assessment 11liveconnectionz282Aún no hay calificaciones

- Risk Assessment Green Dream - HIDD AL SAADIYAT VILLA - SP4 - 58 - V1Documento29 páginasRisk Assessment Green Dream - HIDD AL SAADIYAT VILLA - SP4 - 58 - V1طارق رضوانAún no hay calificaciones

- Risk Assessment CleaningDocumento7 páginasRisk Assessment Cleaningahmer09Aún no hay calificaciones

- DT-1 Cleaning PTWDocumento2 páginasDT-1 Cleaning PTWsubhashkpn86Aún no hay calificaciones

- Fiberglass Cloth SdsDocumento5 páginasFiberglass Cloth Sdslance boxAún no hay calificaciones

- HSE Guide for SupervisorsDocumento12 páginasHSE Guide for Supervisorsmilyandi322Aún no hay calificaciones

- Risk Assesment Fab - Rev-07Documento71 páginasRisk Assesment Fab - Rev-07Nikhil PuthiryAún no hay calificaciones

- Warehouse Risk Assessment Aldir II IWPPDocumento25 páginasWarehouse Risk Assessment Aldir II IWPPMadhu MohanAún no hay calificaciones

- 9C - MSDS FiberglassDocumento3 páginas9C - MSDS FiberglassSon TranAún no hay calificaciones

- Fire, Rev 0111Documento85 páginasFire, Rev 0111Suraj AmbekarAún no hay calificaciones

- Protect Yourself from Moving Machine PartsDocumento7 páginasProtect Yourself from Moving Machine PartsPedro ViegasAún no hay calificaciones

- BOMMI-PRD-03.0008-Rev.00 - Personal Protective EquipmentDocumento10 páginasBOMMI-PRD-03.0008-Rev.00 - Personal Protective Equipmentfundatia_gaudeamusAún no hay calificaciones

- 01 - Safety - Introduction and Fundamental ConceptsDocumento32 páginas01 - Safety - Introduction and Fundamental Conceptsayman aydanAún no hay calificaciones

- Job Safety Analysis Sheet: Manual ExcavationDocumento1 páginaJob Safety Analysis Sheet: Manual ExcavationSafety ProfessionalAún no hay calificaciones

- 006 Ins - Night Work SafetyDocumento1 página006 Ins - Night Work SafetyGökhan KOCAATAAún no hay calificaciones

- Unsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentDocumento5 páginasUnsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentTayyab Hasnain Saadat JanjuaAún no hay calificaciones

- Caramics LotoDocumento7 páginasCaramics LotoAhmad MensaAún no hay calificaciones

- Mie Hse Jha 004 Installation of TransformerDocumento5 páginasMie Hse Jha 004 Installation of TransformerMd Gulam SafiAún no hay calificaciones

- JHA Maintenance Tech HVACDocumento2 páginasJHA Maintenance Tech HVACMdavaAún no hay calificaciones

- JP Jo Interview QuestionsDocumento10 páginasJP Jo Interview QuestionsMuhammad MehboobAún no hay calificaciones

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocumento20 páginasQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106Aún no hay calificaciones

- Operating in Confined SpacesDocumento4 páginasOperating in Confined SpacesFaiqoh NahareyAún no hay calificaciones

- 010 - Scaffolding (Erection & Dismantling)Documento6 páginas010 - Scaffolding (Erection & Dismantling)Prem ChristianAún no hay calificaciones

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Documento5 páginasCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaAún no hay calificaciones

- Form Accident ReportDocumento4 páginasForm Accident ReportKarthik SAún no hay calificaciones

- TOPIC: Demolition SafetyDocumento1 páginaTOPIC: Demolition SafetyMohamed HamdallahAún no hay calificaciones

- Safe Work Method For Peb Work: Procedure Possible Hazards Control MeasuresDocumento35 páginasSafe Work Method For Peb Work: Procedure Possible Hazards Control Measuressandip patilAún no hay calificaciones

- Risk assessment for hanging doorsDocumento11 páginasRisk assessment for hanging doorsMitchRappAún no hay calificaciones

- TRA FOR FRT - Rev.S2-2 (Recovered)Documento31 páginasTRA FOR FRT - Rev.S2-2 (Recovered)rodman823Aún no hay calificaciones

- PTW/Hot Work 2/checklist 34 - Excavations and Work WithinDocumento2 páginasPTW/Hot Work 2/checklist 34 - Excavations and Work WithinAli Shaikh AbdulAún no hay calificaciones

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocumento168 páginasAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathAún no hay calificaciones

- Safety Alert - Danger of Infection - January 2010Documento1 páginaSafety Alert - Danger of Infection - January 2010Meklo1Aún no hay calificaciones

- Safety Alert Safety Alert: BackgroundDocumento1 páginaSafety Alert Safety Alert: BackgroundAnonymous h0yGTDQWZAún no hay calificaciones

- JOB SAFETY ANALYSIS FOR CONFINED SPACE ACTIVITIESDocumento4 páginasJOB SAFETY ANALYSIS FOR CONFINED SPACE ACTIVITIESMuhammad Umar GondalAún no hay calificaciones

- Confined Space Entry Safety AnalysisDocumento2 páginasConfined Space Entry Safety AnalysisDheeraj Kapoor /QOGIL/QuippoworldAún no hay calificaciones

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocumento3 páginasAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferAún no hay calificaciones

- Water Proofing JSADocumento9 páginasWater Proofing JSARamAún no hay calificaciones

- Unsafe ActDocumento1 páginaUnsafe ActAnuj SinghAún no hay calificaciones

- Hse-Swms-018-A - Traffic Signal Maintenance - NSWDocumento12 páginasHse-Swms-018-A - Traffic Signal Maintenance - NSWapi-326016071Aún no hay calificaciones

- JsaDocumento10 páginasJsaTanzeel LiaqatAún no hay calificaciones

- Incident ReportDocumento5 páginasIncident Reportrizal azizanAún no hay calificaciones

- Task Risk Assessment FormDocumento8 páginasTask Risk Assessment FormNurpadmi KusbiantoroAún no hay calificaciones

- Risk Assessment: CCTV Inspection - Al MerifDocumento9 páginasRisk Assessment: CCTV Inspection - Al MerifSaim AliAún no hay calificaciones

- Risk Assessment of Cable Tray InstallationDocumento10 páginasRisk Assessment of Cable Tray Installationfayaz fayazhotmail.comAún no hay calificaciones

- Technical Drilling SafetyDocumento4 páginasTechnical Drilling SafetyjihadspiritAún no hay calificaciones

- JSA ExcavationDocumento6 páginasJSA ExcavationidreisAún no hay calificaciones

- RA Excavation For Trial TrenchDocumento9 páginasRA Excavation For Trial TrenchSasi KumarAún no hay calificaciones

- Job Safety Analysis (Jsa) Sheet: Erection and Modification of ScaffoldingDocumento7 páginasJob Safety Analysis (Jsa) Sheet: Erection and Modification of ScaffoldingJobin FrancisAún no hay calificaciones

- Duke University - Facilities Management Department: Ergonomics ProgramDocumento4 páginasDuke University - Facilities Management Department: Ergonomics ProgramEdgard Bruno Soto LuqueAún no hay calificaciones

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocumento13 páginasEMP-TR347-HFC-MES-020 Tie in ConnectionsajinAún no hay calificaciones

- GC Risk Assessment 1Documento2 páginasGC Risk Assessment 1api-464221711Aún no hay calificaciones

- CL-07-02 Crane Lift Study ChecklistDocumento7 páginasCL-07-02 Crane Lift Study Checklisthanes0% (1)

- Machine Guarding Checklist: Questions Requirements For All SafeguardsDocumento2 páginasMachine Guarding Checklist: Questions Requirements For All SafeguardsAVENON MardocheeAún no hay calificaciones

- HIRARC 2 - Hazard Classification Hazard CategoryDocumento77 páginasHIRARC 2 - Hazard Classification Hazard CategorySASHI NAIR100% (1)

- Upgrade Wastewater Treatment Facilities Hazard ID PlanDocumento14 páginasUpgrade Wastewater Treatment Facilities Hazard ID PlanDarius DsouzaAún no hay calificaciones

- Acf-Mra-064 - SCDocumento1 páginaAcf-Mra-064 - SCFateh AliyaAún no hay calificaciones

- Hazard Identification and Risk Management GuideDocumento3 páginasHazard Identification and Risk Management Guiderajeev1711bAún no hay calificaciones

- MSDS AralditeDocumento5 páginasMSDS AralditeFaris Dien MuhammadAún no hay calificaciones

- Tide Simply - Updated 02-05-2014Documento5 páginasTide Simply - Updated 02-05-2014asimnaqvi2008Aún no hay calificaciones

- Advertisement SR Training Officer 2019Documento4 páginasAdvertisement SR Training Officer 2019Julio Best SetiyawanAún no hay calificaciones

- The Drinking PlaceDocumento1 páginaThe Drinking PlaceJulio Best SetiyawanAún no hay calificaciones

- Sexual Harassment PreventionDocumento15 páginasSexual Harassment PreventionNikita KarambelkarAún no hay calificaciones

- Tide Simply - Updated 02-05-2014Documento2 páginasTide Simply - Updated 02-05-2014Julio Best SetiyawanAún no hay calificaciones

- SCM 2.0 Business Partner Portal User Guide - SCAN V 2.0Documento17 páginasSCM 2.0 Business Partner Portal User Guide - SCAN V 2.0Julio Best SetiyawanAún no hay calificaciones

- Akreditasi PBI 2005-2011Documento5 páginasAkreditasi PBI 2005-2011Julio Best SetiyawanAún no hay calificaciones

- Tide Simply - Updated 02-05-2014Documento5 páginasTide Simply - Updated 02-05-2014asimnaqvi2008Aún no hay calificaciones

- PumaDocumento6 páginasPumaJulio Best SetiyawanAún no hay calificaciones

- Perilaku Hidup SehatDocumento2 páginasPerilaku Hidup SehatJulio Best SetiyawanAún no hay calificaciones

- SCM 2.0 Business Partner Portal User Guide - SCAN V 2.0Documento17 páginasSCM 2.0 Business Partner Portal User Guide - SCAN V 2.0Julio Best SetiyawanAún no hay calificaciones

- SCM 2.0 Business Partner Portal User Guide - SCAN V 2.0Documento17 páginasSCM 2.0 Business Partner Portal User Guide - SCAN V 2.0Julio Best SetiyawanAún no hay calificaciones

- The User Is Yulisetiyawan05 and Pasword Rinajaya - 2018Documento3 páginasThe User Is Yulisetiyawan05 and Pasword Rinajaya - 2018Julio Best SetiyawanAún no hay calificaciones

- ILO 2017-Report-v3.2-FINAL-EN PDFDocumento40 páginasILO 2017-Report-v3.2-FINAL-EN PDFEndahAún no hay calificaciones

- SIPP Minimum Requirements Detailed ExplanationDocumento11 páginasSIPP Minimum Requirements Detailed ExplanationJulio Best Setiyawan100% (2)

- TOEFL Test Grammar ExamplesDocumento48 páginasTOEFL Test Grammar ExamplesErik'swim Mirinda100% (1)

- BWI 6th Synthesis Report v3.2 FINAL enDocumento5 páginasBWI 6th Synthesis Report v3.2 FINAL enJulio Best Setiyawan100% (1)

- 2018 - SRTM Agenda (Id)Documento2 páginas2018 - SRTM Agenda (Id)Julio Best SetiyawanAún no hay calificaciones

- Aryani Widhiyastuti Laporan KhususDocumento1 páginaAryani Widhiyastuti Laporan KhususJulio Best SetiyawanAún no hay calificaciones

- ILO 2017-Report-v3.2-FINAL-EN PDFDocumento40 páginasILO 2017-Report-v3.2-FINAL-EN PDFEndahAún no hay calificaciones

- PT Ungaran Sari Garment 2015Documento2 páginasPT Ungaran Sari Garment 2015Julio Best SetiyawanAún no hay calificaciones

- Memorandum of Understanding Sample TemplateDocumento3 páginasMemorandum of Understanding Sample Templateamershareef337Aún no hay calificaciones

- Weekly Working Hours by EmployeeDocumento3 páginasWeekly Working Hours by EmployeeJulio Best SetiyawanAún no hay calificaciones

- ISBBDocumento8 páginasISBBmufid00Aún no hay calificaciones

- Aps Trailer & Truck MonitoringDocumento2 páginasAps Trailer & Truck MonitoringJulio Best SetiyawanAún no hay calificaciones

- Work CertificateECDocumento1 páginaWork CertificateECJulio Best SetiyawanAún no hay calificaciones

- Calmentor MOUDocumento7 páginasCalmentor MOUJulio Best SetiyawanAún no hay calificaciones

- TOEFL Test Muridmengajar 2786Documento5 páginasTOEFL Test Muridmengajar 2786Julio Best SetiyawanAún no hay calificaciones

- Projective Personality TestsDocumento16 páginasProjective Personality TestsJulio Best SetiyawanAún no hay calificaciones

- HIV Prevention: HSCI 225 BY Mutua Moses MuluDocumento23 páginasHIV Prevention: HSCI 225 BY Mutua Moses MuluJibril MohamudAún no hay calificaciones

- Sspc-Ab 2Documento3 páginasSspc-Ab 2HafidzManafAún no hay calificaciones

- The Holy Grail of Curing DPDRDocumento12 páginasThe Holy Grail of Curing DPDRDany Mojica100% (1)

- Vector and Pest Control in DisastersDocumento10 páginasVector and Pest Control in DisastersTaufik RizkiandiAún no hay calificaciones

- Atwwi "Virtual" Trading Room Reference Document November 2, 2020Documento4 páginasAtwwi "Virtual" Trading Room Reference Document November 2, 2020amisamiam2Aún no hay calificaciones

- Anand - 1994 - Fluorouracil CardiotoxicityDocumento5 páginasAnand - 1994 - Fluorouracil Cardiotoxicityaly alyAún no hay calificaciones

- Senior Counsel or Associate General Counsel or Assistant GeneralDocumento3 páginasSenior Counsel or Associate General Counsel or Assistant Generalapi-76922317Aún no hay calificaciones

- Collection of Blood From DonorsDocumento7 páginasCollection of Blood From DonorsBernardoHernandezAún no hay calificaciones

- Psychiatric Nursing 6th Edition Keltner Test BankDocumento35 páginasPsychiatric Nursing 6th Edition Keltner Test Bankfrustumslit.4jctkm100% (26)

- 03 Klasifikasi Penyakit Dan Keadaan Yang Mempengaruhi Jaringan PeriodontiumDocumento16 páginas03 Klasifikasi Penyakit Dan Keadaan Yang Mempengaruhi Jaringan PeriodontiumFloba Ika SianturiAún no hay calificaciones

- Referralsystem 161202080450Documento21 páginasReferralsystem 161202080450DRx Sonali Tarei100% (1)

- Low Back Pain Dr. Hardhi PRanataDocumento57 páginasLow Back Pain Dr. Hardhi PRanataPerwita ArumingtyasAún no hay calificaciones

- Safety Data Sheet SummaryDocumento8 páginasSafety Data Sheet SummaryReffi Allifyanto Rizki DharmawamAún no hay calificaciones

- School District of Philadelphia's Immigrant & Refugee ToolkitDocumento58 páginasSchool District of Philadelphia's Immigrant & Refugee ToolkitKristina KoppeserAún no hay calificaciones

- Tinea IncognitoDocumento1 páginaTinea IncognitoJana AtanasovaAún no hay calificaciones

- Emergent Care Clinic StudyDocumento5 páginasEmergent Care Clinic StudyAna Bienne0% (1)

- Charakam Sidhistanam: Vamana Virechana Vyapat SidhiDocumento45 páginasCharakam Sidhistanam: Vamana Virechana Vyapat Sidhinimisha lathiffAún no hay calificaciones

- Metaphor and MedicineDocumento9 páginasMetaphor and MedicineCrystal DuarteAún no hay calificaciones

- TOFPA: A Surgical Approach To Tetralogy of Fallot With Pulmonary AtresiaDocumento24 páginasTOFPA: A Surgical Approach To Tetralogy of Fallot With Pulmonary AtresiaRedmond P. Burke MD100% (1)

- The Nature of Feeding and Swallowing Difficulties in PDFDocumento118 páginasThe Nature of Feeding and Swallowing Difficulties in PDFLisa NurhasanahAún no hay calificaciones

- Work Authorization Permit.Documento1 páginaWork Authorization Permit.Gabriel TanAún no hay calificaciones

- 2.4 Maxillofacial Trauma (Sia) - Sales&TanDocumento11 páginas2.4 Maxillofacial Trauma (Sia) - Sales&Tanmr dojimamanAún no hay calificaciones

- The Regent's Park - Risk AssessmentDocumento3 páginasThe Regent's Park - Risk AssessmentEiman'E'RostamiAún no hay calificaciones

- 100 Workouts Vol1 by DarebeeDocumento207 páginas100 Workouts Vol1 by DarebeeKoulick100% (2)

- Sulphonamides: A Pharmaceutical ReviewDocumento3 páginasSulphonamides: A Pharmaceutical ReviewinventionjournalsAún no hay calificaciones

- HSE Manual PDFDocumento30 páginasHSE Manual PDFRanjan Kumar75% (4)

- New TNMDocumento157 páginasNew TNMShouvik ChowdhuryAún no hay calificaciones

- Malunggay Para sa PamilyaDocumento4 páginasMalunggay Para sa PamilyaJeffrey S. Saballo100% (1)

- Mumps Guide: Causes, Symptoms, Treatment & PreventionDocumento14 páginasMumps Guide: Causes, Symptoms, Treatment & PreventionChristian JonathanAún no hay calificaciones

- HRFuture Sept 2020 MJLKJDocumento59 páginasHRFuture Sept 2020 MJLKJGlecy KimAún no hay calificaciones

- A Brief History of Time: From the Big Bang to Black HolesDe EverandA Brief History of Time: From the Big Bang to Black HolesCalificación: 4 de 5 estrellas4/5 (2193)

- Summary and Interpretation of Reality TransurfingDe EverandSummary and Interpretation of Reality TransurfingCalificación: 5 de 5 estrellas5/5 (5)

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessDe EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessCalificación: 4 de 5 estrellas4/5 (6)

- The Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismDe EverandThe Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismCalificación: 4 de 5 estrellas4/5 (500)

- When the Earth Had Two Moons: Cannibal Planets, Icy Giants, Dirty Comets, Dreadful Orbits, and the Origins of the Night SkyDe EverandWhen the Earth Had Two Moons: Cannibal Planets, Icy Giants, Dirty Comets, Dreadful Orbits, and the Origins of the Night SkyCalificación: 3 de 5 estrellas3/5 (7)

- Strange Angel: The Otherworldly Life of Rocket Scientist John Whiteside ParsonsDe EverandStrange Angel: The Otherworldly Life of Rocket Scientist John Whiteside ParsonsCalificación: 4 de 5 estrellas4/5 (94)

- Midnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterDe EverandMidnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterCalificación: 4.5 de 5 estrellas4.5/5 (409)

- Too Big for a Single Mind: How the Greatest Generation of Physicists Uncovered the Quantum WorldDe EverandToo Big for a Single Mind: How the Greatest Generation of Physicists Uncovered the Quantum WorldCalificación: 4.5 de 5 estrellas4.5/5 (8)

- Infinite Powers: How Calculus Reveals the Secrets of the UniverseDe EverandInfinite Powers: How Calculus Reveals the Secrets of the UniverseCalificación: 4.5 de 5 estrellas4.5/5 (126)

- The Holographic Universe: The Revolutionary Theory of RealityDe EverandThe Holographic Universe: The Revolutionary Theory of RealityCalificación: 4.5 de 5 estrellas4.5/5 (75)

- Packing for Mars: The Curious Science of Life in the VoidDe EverandPacking for Mars: The Curious Science of Life in the VoidCalificación: 4 de 5 estrellas4/5 (1395)

- Machinery of the Mind (An Interview)De EverandMachinery of the Mind (An Interview)Calificación: 4.5 de 5 estrellas4.5/5 (28)

- Quantum Physics: What Everyone Needs to KnowDe EverandQuantum Physics: What Everyone Needs to KnowCalificación: 4.5 de 5 estrellas4.5/5 (48)

- What is Life?: With Mind and Matter and Autobiographical SketchesDe EverandWhat is Life?: With Mind and Matter and Autobiographical SketchesCalificación: 4 de 5 estrellas4/5 (139)

- Quantum Physics for Beginners Who Flunked Math And Science: Quantum Mechanics And Physics Made Easy Guide In Plain Simple EnglishDe EverandQuantum Physics for Beginners Who Flunked Math And Science: Quantum Mechanics And Physics Made Easy Guide In Plain Simple EnglishCalificación: 4.5 de 5 estrellas4.5/5 (18)

- The Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceDe EverandThe Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceCalificación: 4.5 de 5 estrellas4.5/5 (23)

- The Biggest Number in the World: A Journey to the Edge of MathematicsDe EverandThe Biggest Number in the World: A Journey to the Edge of MathematicsCalificación: 4.5 de 5 estrellas4.5/5 (5)

- The Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeDe EverandThe Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeAún no hay calificaciones

- Bedeviled: A Shadow History of Demons in ScienceDe EverandBedeviled: A Shadow History of Demons in ScienceCalificación: 5 de 5 estrellas5/5 (5)

- Lost in Math: How Beauty Leads Physics AstrayDe EverandLost in Math: How Beauty Leads Physics AstrayCalificación: 4.5 de 5 estrellas4.5/5 (125)

- The Beginning of Infinity: Explanations That Transform the WorldDe EverandThe Beginning of Infinity: Explanations That Transform the WorldCalificación: 5 de 5 estrellas5/5 (60)

- Chasing Heisenberg: The Race for the Atom BombDe EverandChasing Heisenberg: The Race for the Atom BombCalificación: 4.5 de 5 estrellas4.5/5 (8)

- Starry Messenger: Cosmic Perspectives on CivilizationDe EverandStarry Messenger: Cosmic Perspectives on CivilizationCalificación: 4.5 de 5 estrellas4.5/5 (158)

- The Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldDe EverandThe Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldCalificación: 4.5 de 5 estrellas4.5/5 (53)