Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Toshiba - Service Factor

Cargado por

Carlos Camayo0 calificaciones0% encontró este documento útil (0 votos)

42 vistas4 páginasToshiba - Service Factor

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoToshiba - Service Factor

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

42 vistas4 páginasToshiba - Service Factor

Cargado por

Carlos CamayoToshiba - Service Factor

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 4

Issue 6 / November/December 2014

The Mining & Minerals Monthly

Application Guidelines to Keep You Better Informed

SERVICE FACTOR

MOTORS RUNNING INTO

SERVICE FACTOR (SF)

All NEMA frame low voltage motors are typically

designed with a 1.15 Service Factor (SF). It is common

on some higher horsepower, or application-specific

motors to be 1.0 SF based on special design, enclosure

size etc. There are two aspects to SF:

The first is motor temperature. Temperature rise

is described thoroughly in last months issue. The

relationship between motor heating and current is a

square function, and motor current draw is generally

proportional to load. Heating is a function of current2 x

resistance x time. This is usually referred to as current2

x time, or I2t. At SF loading, if current is 1.15 x rated, the

heating effect will be 1.152 = 1.32 x normal. This roughly

means that if the temperature rise at full load is 80C (B

rise) the temperature rise at 1.15 SF loading will be in

the order of (1.15)2 x 80C = 105.8C (F rise). This is why

most manufacturers design a motor to have a B rise or

less at full load for a 1.15 SF motor.

[ASIDE: This clearly shows how a motor designed with

a B rise @ 1.15 SF, which is 90C, is better than a motor

with a B rise @ 1.0 SF, because this motor with a B rise

@ 1.0 SF, loaded to 1.15 SF will have a temperature rise of

105.8C.]

In general, Toshiba motors use an insulation system that

is Class F (155C) rated and has B rise or less @ 1.0

SF (80C), and in the case of the EQP Global series,

all motors 445T frame and smaller have a B rise or less

@ 1.15 SF. This means that the insulation will be well

below design temperature of the insulation system even

when operated at continuous overload up to 115% of

nameplate. The smaller the motor frame, the larger the

thermal margin, and the greater the overload a motor can

continued on next page

The Mining & Minerals Monthly

Issue 6 | November/December 2014: Service Factor

handle. This is why youll often see motor manufacturers

advertise as a 1.25 SF rating on the smaller frames.

Furthermore, in the case of TEAO (Totally Enclosed

Air Over) motors used in ventilation fans for the mining

industry, the increased air flow from being mounted in the

center of the fan (3000 ft./min.) often allows for 1.35 SF

as standard.

The second issue is mechanical capability. Bearings

are an important part of the mechanical capability and

life of a motor. For every 15C hotter that a bearing runs,

the grease life is cut in half. Open-style bearings run

cooler than sealed or even shielded bearings. When a

motor is run into its SF, it runs hotter and consequently,

so does the bearings. As a result, grease life, or regreasing intervals, is reduced.

Shaft strength is another consideration when designing a

motor with a SF capability. A 1.15 SF motor has a strong

enough shaft to handle the additional continuous shaft

load. Although this is not usually an issue with smaller

HP motors, it becomes a real consideration on larger

machines. Just because a motor is specified with a B rise

at full load doesnt necessarily mean that it is suitable to

be rated as a 1.15 SF motor.

The Mining & Minerals Monthly

Issue 6 | November/December 2014: Service Factor

The preceding issues are concerned with sinusoidal

operation. When an ASD is utilized, the motor sees

additional heating over and above the I2t heating effect.

This is due to the harmonic content of the drives output

waveform. This additional heating can range from 5%

extra heating for a good quality PWM drive with an

adequately high carrier frequency to up to 30% additional

heating for a square wave variable voltage inverter (VVI)

drive. When using an ASD on a 1.15 SF motor, as a rule

of thumb, you should now treat your motor as being a 1.0

SF motor, as a result of the heating from the ASD.

A 1.15 SF motor installed across the line can be

operated at 1.15 SF. However, you will theoretically get

a varying insulation life depending on the operational

temperature of a motor on a specific application. For

a fixed set of conditions on an application, the motor

manufacturer with the largest thermal margin (difference

between actual design temperature rise v. insulation

class) will give you a longer insulation life span overall.

Having said the above, even though a 1.15 SF motor

can be operated at 1.15 SF, when sizing motors for a

new installation, Service Factor should be considered as

a Safety Factor, allowing some thermal margin for the

following reasons:

Voltage Unbalances

Error in the Distribution Transformer Tap Connection

Unstable Utility Voltage Supply

Poor Power Supply Connections

Open Delta Transformer Systems

Improper Functioning Capacitor Banks

Unbalanced Power Supply

Increased Overload Requirements

Additional Ambient Temperature

Higher Altitude Installation

Longer Motor Life

Longer Grease Life

Brown-outs

Furthermore, a motors optimum efficiency and power

factor is at approximately 75 to 100% load, which

changes to less favorable values as you move further

away from this load range.

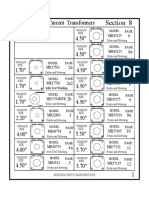

INSULATION CLASSIFICATION

WINDING RISE C

Insulation Class

1.0 SF

1.15 SF

Total

80

90

130

105

155

125

115

180

The Mining & Minerals Monthly

Issue 6 | November/December 2014: Service Factor

NEXT MONTHS ISSUE: REPETITIVE STARTS

mining@tic.toshiba.com

www.toshiba.com/tic

También podría gustarte

- Informative guidelines on motor service factors and how they impact temperature rise and insulation life when motors are continuously overloadedDocumento2 páginasInformative guidelines on motor service factors and how they impact temperature rise and insulation life when motors are continuously overloadedsameerray12Aún no hay calificaciones

- Hot Spot AllowanceDocumento4 páginasHot Spot AllowanceCarlosAún no hay calificaciones

- Motor Winding Temperature ClassDocumento2 páginasMotor Winding Temperature ClassExecutive Engineer I & C, Ashuganj SouthAún no hay calificaciones

- The Hot Issue of Motor Temperature Ratings - Ed Cowern-EC&MDocumento5 páginasThe Hot Issue of Motor Temperature Ratings - Ed Cowern-EC&MGyogi MitsutaAún no hay calificaciones

- Engineering Letter: IntegralmotorsforcentrifugalfansDocumento4 páginasEngineering Letter: IntegralmotorsforcentrifugalfansjameeloAún no hay calificaciones

- Motor Winding Temperature ClassDocumento2 páginasMotor Winding Temperature ClassDeepak JoyAún no hay calificaciones

- AG05 (Temperature Rise)Documento2 páginasAG05 (Temperature Rise)aries26marchAún no hay calificaciones

- The Service FactorDocumento6 páginasThe Service FactorsxpAún no hay calificaciones

- Nameplate PDFDocumento8 páginasNameplate PDFobida adailehAún no hay calificaciones

- Motor Temperature RatingsDocumento5 páginasMotor Temperature RatingsFaizan Tahir ButtAún no hay calificaciones

- Nameplate of InductionDocumento6 páginasNameplate of InductionARUNPRASADEEEAún no hay calificaciones

- 2010 Edition Electric Motors and Drives Technical ManualDocumento346 páginas2010 Edition Electric Motors and Drives Technical ManualWilson Pinacate100% (1)

- Service Factor - What's It All AboutDocumento4 páginasService Factor - What's It All Aboutabdulyunus_amirAún no hay calificaciones

- Siemens - Motor SpecificationsDocumento50 páginasSiemens - Motor SpecificationsArtifoxAún no hay calificaciones

- Service Factors BaldorDocumento1 páginaService Factors BaldornautelAún no hay calificaciones

- Motor Temperature Ratings: DefinitionsDocumento4 páginasMotor Temperature Ratings: DefinitionstekhakkoAún no hay calificaciones

- How To Read A Motor NameplateDocumento8 páginasHow To Read A Motor Nameplateabdulyunus_amirAún no hay calificaciones

- How To Read A Motor NameplateDocumento12 páginasHow To Read A Motor Nameplatearchie zambranoAún no hay calificaciones

- R&T 2004 - VFD Evaporators - JekelDocumento23 páginasR&T 2004 - VFD Evaporators - JekelPRKrauseAún no hay calificaciones

- NEMA Standards InsulationDocumento3 páginasNEMA Standards Insulationadhwa alshamalAún no hay calificaciones

- Open-phase Protection for MotorsDocumento5 páginasOpen-phase Protection for MotorsAnamarialuzAún no hay calificaciones

- Induction Motor NameplateDocumento6 páginasInduction Motor NameplateYudhaMuhamadFauziAún no hay calificaciones

- Motor Rating and Protection ConsiderationsDocumento21 páginasMotor Rating and Protection Considerationsjosenit1787Aún no hay calificaciones

- Induction To AC Motors FAQDocumento24 páginasInduction To AC Motors FAQSrini VasanAún no hay calificaciones

- NEMA Insulation Classes For Motors - Drives and AutomationDocumento7 páginasNEMA Insulation Classes For Motors - Drives and AutomationMohamed MiraAún no hay calificaciones

- Baldor Basics: Motors: Edward Cowern, P.EDocumento6 páginasBaldor Basics: Motors: Edward Cowern, P.Ebagus adhitiawarmanAún no hay calificaciones

- Baldor BasicsDocumento6 páginasBaldor Basicsmaryam javedAún no hay calificaciones

- Energy Savings Audit in Textile IndustryDocumento10 páginasEnergy Savings Audit in Textile Industrymawais15Aún no hay calificaciones

- Accelerating and Breakdown TorqueDocumento44 páginasAccelerating and Breakdown TorqueekonurudinahmadAún no hay calificaciones

- Ahorro de EnergiaDocumento4 páginasAhorro de Energiaclide_050793Aún no hay calificaciones

- Phase Conversion Technologies & How They WorkDocumento4 páginasPhase Conversion Technologies & How They WorkstoragebinAún no hay calificaciones

- Motor Nameplate Information Required by NEMA Standards: 1. Manufacturer's TypeDocumento12 páginasMotor Nameplate Information Required by NEMA Standards: 1. Manufacturer's TypeWulan NursyifaAún no hay calificaciones

- DGsetDocumento14 páginasDGsetAntony HegdeAún no hay calificaciones

- Energy Answers For MotorsDocumento4 páginasEnergy Answers For Motorsdetroit44Aún no hay calificaciones

- Understanding Variable Speed Drives: Basic VFD TheoryDocumento7 páginasUnderstanding Variable Speed Drives: Basic VFD TheorynikecerreroAún no hay calificaciones

- GTT Module IiiDocumento38 páginasGTT Module IiiKushal SinghAún no hay calificaciones

- Motor Protection SeminarDocumento73 páginasMotor Protection SeminarErstendrain EngAún no hay calificaciones

- Compatibility of Motor & VFDDocumento3 páginasCompatibility of Motor & VFDorkwfdet sharklasersAún no hay calificaciones

- Understanding The Motor NameplateDocumento25 páginasUnderstanding The Motor NameplatevenkatsvAún no hay calificaciones

- VFD TutorialDocumento21 páginasVFD TutorialDaniel Taiti Kimathi100% (3)

- MEO Class 2 Orals Function 4 & 6 Q & ADocumento8 páginasMEO Class 2 Orals Function 4 & 6 Q & Aneeraj118578% (9)

- Agn013 CDocumento10 páginasAgn013 Cmohsen_cumminsAún no hay calificaciones

- Abb Crane Duty Motor CatalogDocumento10 páginasAbb Crane Duty Motor Catalogyaduvanshi1Aún no hay calificaciones

- Electric Motor Brake Horsepower Calculations 2Documento7 páginasElectric Motor Brake Horsepower Calculations 2osamaAún no hay calificaciones

- Lecture 3Documento33 páginasLecture 3Heleana Faye BundocAún no hay calificaciones

- DG Set System: Syllabus Diesel Generating System: Factors Affecting Selection, Energy Performance Assessment ofDocumento14 páginasDG Set System: Syllabus Diesel Generating System: Factors Affecting Selection, Energy Performance Assessment ofJitendra PatilAún no hay calificaciones

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)De EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Calificación: 1 de 5 estrellas1/5 (3)

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004De EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Calificación: 3 de 5 estrellas3/5 (1)

- Marine Electrics Made Simple or How to Keep the Batteries ChargedDe EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedAún no hay calificaciones

- Southern Marine Engineering Desk Reference: Second Edition Volume IiDe EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiAún no hay calificaciones

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesAún no hay calificaciones

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualCalificación: 3.5 de 5 estrellas3.5/5 (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualAún no hay calificaciones

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAún no hay calificaciones

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsDe EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsAún no hay calificaciones

- System Protection Coordination Study For Electrical Distribution SystemDocumento6 páginasSystem Protection Coordination Study For Electrical Distribution SystemCarlos CamayoAún no hay calificaciones

- Circuit Protection Methods 1492 Wp001 - en PDocumento20 páginasCircuit Protection Methods 1492 Wp001 - en PFábio SeabraAún no hay calificaciones

- 2CSC420004B0201 - RCDs EN PDFDocumento80 páginas2CSC420004B0201 - RCDs EN PDFmanoledan81Aún no hay calificaciones

- Unique Features: Fault Cleared Fault Cleared Fault Detected Fault DetectedDocumento2 páginasUnique Features: Fault Cleared Fault Cleared Fault Detected Fault DetectedCarlos CamayoAún no hay calificaciones

- Dsp-Ohmni: C-EG30EM Instruction Manual V2, June 2020Documento50 páginasDsp-Ohmni: C-EG30EM Instruction Manual V2, June 2020Carlos CamayoAún no hay calificaciones

- Methods For Coordinating System Protective EquipmentDocumento17 páginasMethods For Coordinating System Protective EquipmentMichael Parohinog GregasAún no hay calificaciones

- C-550EB Pressure Arc DetectorDocumento2 páginasC-550EB Pressure Arc DetectorAugusto SiuAún no hay calificaciones

- Type VR Electrically Operated Ground and Test DeviceDocumento29 páginasType VR Electrically Operated Ground and Test DeviceCarlos CamayoAún no hay calificaciones

- SD - SESShield Project #1 Belfi-Cosapi 4Documento1 páginaSD - SESShield Project #1 Belfi-Cosapi 4Carlos CamayoAún no hay calificaciones

- ATP Motor Starting PDFDocumento13 páginasATP Motor Starting PDFgilbertomjcAún no hay calificaciones

- Vibration CMAS 100-SL GE ValuesDocumento4 páginasVibration CMAS 100-SL GE ValuesWaqas WakeelAún no hay calificaciones

- Pressed PDFDocumento39 páginasPressed PDFCarlos CamayoAún no hay calificaciones

- Presentación Estudio de Arc Flash 7-13Documento7 páginasPresentación Estudio de Arc Flash 7-13Carlos CamayoAún no hay calificaciones

- Type VR Electrically Operated Ground and Test DeviceDocumento29 páginasType VR Electrically Operated Ground and Test DeviceCarlos CamayoAún no hay calificaciones

- SD - SESShield Project #1 Belfi-Cosapi 3Documento1 páginaSD - SESShield Project #1 Belfi-Cosapi 3Carlos CamayoAún no hay calificaciones

- Harmonic Analysis of Reactor and Capacitor - Jong-Gyeum Kim & Young-Jeen Park & Dong-Ju LeeDocumento6 páginasHarmonic Analysis of Reactor and Capacitor - Jong-Gyeum Kim & Young-Jeen Park & Dong-Ju LeeCarlos CamayoAún no hay calificaciones

- SD - SESShield Project #1 Belfi-Cosapi 2Documento1 páginaSD - SESShield Project #1 Belfi-Cosapi 2Carlos CamayoAún no hay calificaciones

- LSG2 150Documento2 páginasLSG2 150Carlos CamayoAún no hay calificaciones

- @practical Guide To Electrical Grounding, 1st Edition, 1999Documento131 páginas@practical Guide To Electrical Grounding, 1st Edition, 1999cyong7788100% (15)

- Split-Core AC Current Transformer: 2.00" Opening With 400 To 1600 Amps Ratings With 5 Amp OutputDocumento1 páginaSplit-Core AC Current Transformer: 2.00" Opening With 400 To 1600 Amps Ratings With 5 Amp OutputCarlos CamayoAún no hay calificaciones

- 7UT6x Manual A4 V040300 enDocumento694 páginas7UT6x Manual A4 V040300 enAnonymous m65TTcfOTAún no hay calificaciones

- 2CDC112128D0201Documento14 páginas2CDC112128D0201Carlos CamayoAún no hay calificaciones

- CPC 100 Brochure ENUDocumento48 páginasCPC 100 Brochure ENUCarlos CamayoAún no hay calificaciones

- Area Classification IEC NECDocumento18 páginasArea Classification IEC NECin107247100% (1)

- Net A Becoming 2009Documento12 páginasNet A Becoming 2009Carlos CamayoAún no hay calificaciones

- Net A 08 Brochure FinalDocumento8 páginasNet A 08 Brochure FinalbuntysuratAún no hay calificaciones

- Protection PrimerDocumento61 páginasProtection PrimerCarlos CamayoAún no hay calificaciones

- Shougang GET 8419Documento2 páginasShougang GET 8419Carlos CamayoAún no hay calificaciones

- Hydraulic Vs Mechanical+SnubbersDocumento1 páginaHydraulic Vs Mechanical+SnubbersJordana VeigaAún no hay calificaciones

- Training Program for Newly Recruited AEEsDocumento7 páginasTraining Program for Newly Recruited AEEsakstrmec23Aún no hay calificaciones

- Philadelphia University Faculty of Engineering and Technology Department of Mechanical EngineeringDocumento8 páginasPhiladelphia University Faculty of Engineering and Technology Department of Mechanical EngineeringTamer JafarAún no hay calificaciones

- DSP Lab - ScilabDocumento17 páginasDSP Lab - ScilabSai Nikshipth MaddhugaruAún no hay calificaciones

- Katie Nelson PDFDocumento3 páginasKatie Nelson PDFKatie NAún no hay calificaciones

- Phase-Field Models For The Evolution of Complex SystemsDocumento37 páginasPhase-Field Models For The Evolution of Complex SystemsMathis PlappAún no hay calificaciones

- Positive Role The Indian Youth Can Play in PoliticsDocumento2 páginasPositive Role The Indian Youth Can Play in PoliticsArul ChamariaAún no hay calificaciones

- Valve Type Trim Type CF XTDocumento1 páginaValve Type Trim Type CF XTAye KyweAún no hay calificaciones

- Jason Capital Screw Jobs PDFDocumento50 páginasJason Capital Screw Jobs PDFДжек П100% (3)

- INCaDocumento47 páginasINCaMehdi SoltaniAún no hay calificaciones

- Teaching Load FinalDocumento12 páginasTeaching Load FinalEdward BarberAún no hay calificaciones

- Resil Mojares Writing About OurselvesDocumento21 páginasResil Mojares Writing About OurselvesSalimAún no hay calificaciones

- Accountability Report Ba CharityDocumento24 páginasAccountability Report Ba CharityBintang sonda sitorus PaneAún no hay calificaciones

- Week 5 - Creativity in ResearchDocumento4 páginasWeek 5 - Creativity in ResearchD Barik100% (1)

- Suffolk Bus S92 Schedule Effective 5-2712Documento2 páginasSuffolk Bus S92 Schedule Effective 5-2712RiverheadLOCAL67% (6)

- Personal Data Form: World English Placement Test Package Photocopiable © 2011 Heinle, Cengage LearningDocumento2 páginasPersonal Data Form: World English Placement Test Package Photocopiable © 2011 Heinle, Cengage Learningadri shimizuAún no hay calificaciones

- Present Environment and Sustainable Development - Annual Review Report 2015Documento7 páginasPresent Environment and Sustainable Development - Annual Review Report 2015catalinlungeanu758Aún no hay calificaciones

- C6713 Lab ManualDocumento51 páginasC6713 Lab Manualsmganorkar100% (1)

- Cooperating Sequential Processes (Dijkstra) - PaperDocumento74 páginasCooperating Sequential Processes (Dijkstra) - PaperCole AroraAún no hay calificaciones

- Engine Retrofit Guide v8Documento70 páginasEngine Retrofit Guide v8Romulo AlvarezAún no hay calificaciones

- Willie Soon, Peter Frick, and Sallie BaliunasDocumento4 páginasWillie Soon, Peter Frick, and Sallie BaliunasMiguel CervantesAún no hay calificaciones

- Nervous System Reaction PaperDocumento3 páginasNervous System Reaction PaperJohn Ruel Sanchez IIAún no hay calificaciones

- Openroads Designer User ManualDocumento112 páginasOpenroads Designer User ManualNilay BhavsarAún no hay calificaciones

- Midterm Exam: Cecor2 - Hydraulics and Geotechnical EngineeringDocumento2 páginasMidterm Exam: Cecor2 - Hydraulics and Geotechnical EngineeringEjay EmpleoAún no hay calificaciones

- Disaster Readiness Exam SpecificationsDocumento2 páginasDisaster Readiness Exam SpecificationsRICHARD CORTEZAún no hay calificaciones

- From Self Disorders To The Schizophrenic Self: Riccardo Piero Dalle LucheDocumento31 páginasFrom Self Disorders To The Schizophrenic Self: Riccardo Piero Dalle LucheMichel de NostredameAún no hay calificaciones

- Jet RevisedDocumento8 páginasJet RevisedDharavGosaliaAún no hay calificaciones

- A Fracture Mechanics Analysis of The Texture of Fried Potato Crust PDFDocumento7 páginasA Fracture Mechanics Analysis of The Texture of Fried Potato Crust PDFRomaric OuetchehouAún no hay calificaciones

- Adolescent InterviewDocumento9 páginasAdolescent Interviewapi-532448305Aún no hay calificaciones

- Expansion Joint Treatment Materials and TechniquesDocumento15 páginasExpansion Joint Treatment Materials and TechniquesMAHAK GUPTAAún no hay calificaciones

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-1-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)