Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Services Manual Telescope Control Box

Cargado por

Angel DlsgDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Services Manual Telescope Control Box

Cargado por

Angel DlsgCopyright:

Formatos disponibles

PAT America, Inc.

Rheinmetall Elektronik

DS350 MODULAR

BOOM CONTROL EXTENSION

FOR

GROVE CRANE TMS/TTS 870

TROUBLESHOOTING MANUAL

P/N 031-300-190-061 Rev. B 02/12/01

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

NOTICE

The information in this document is subject

to change without notice.

PAT makes no warranty of any kind with regard

to this material, including, but not limited

to, the implied warranties of merchantability

and fitness for a particular purpose.

PAT shall not be liable for errors contained herein

or for incidental or consequential damages in

connection with the furnishing, performance

or use of this manual.

This document contains proprietary information

which is protected by copyright. All rights are

reserved. No part of this document may be

photocopied, reproduced, or translated to

another language without prior consent of PAT.

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

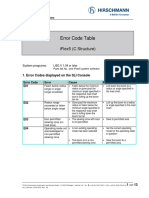

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

TABLE OF CONTENTS

GENERAL INFORMATION

REFERENCE MATERIAL

SERVICE AND MAINTENANCE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Boom Control Interface

Getting Started

Boom length percentage problem

Boom out of sequence in auto mode

E83 - Outer mid and fly section are not retracted

E61 - Error in the bus extension

No tele function in auto mode

Proximity switch location and adjustment

Boom - LMI Hardware

Length transducer- Inner mid section

Length transducer- Center mid section

Length angle transducer- Overall boom length

Length transducer adjustment

Turntable - LMI Hardware

Boom control - bus extension

Electric wiring - Central unit

Electric wiring - Bus extension

Electric wiring Turntable

Electric wiring Lower

Electric wiring Boom

Console - Boom control data display Relay output logic for the two-way-valves

031-300-190-061 Rev. B 02/12/01 // WB //

1

2

3

4

5

6

16

26

31

33

39

40

41

42

43

44

45

46

47

48

49

50

51

53

54

190061_B.doc

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

GENERAL INFORMATION

This troubleshooting manual is designed to assist a service or maintenance person in

identifying LMI (Load Moment Indicator) problem areas or malfunctions. A digital

voltmeter with the capability to also measure current will be required. Regular

maintenance and service tools will also be required.

NOTE: Knowledge of how to use a voltmeter to measure both voltage and current is

assumed.

For system operation refer to the Operators Manual for the console. This may differ from

crane manufacturer and model.

Section 2 provides the drawings and reference material that will be used in the

troubleshooting flowcharts of this manual. Use the reference drawings in conjunction

with the flowcharts to help understand the operation of the system.

The PAT LMI DS 350 Modular with Boom Control Extension has been designed to provide

the crane with the essential information required to operate the machine within the

designed parameters.

Using different sensing devices, the DS 350 LMI monitors various crane functions and

provides the operator with a continuous display of the cranes capacity. The display

continually changes as the crane moves through the motions needed to make a lift.

The DS 350 Modular LMI provides the operator with information regarding the boom

length and boom angle of the main boom, working radius rated load and the total

calculated weight being lifted by the crane.

If non-permitted conditions are approached, the DS 350 LMI will warn the operator

by sounding an audible alarm and lighting a warning light. In addition the LMI

system has the capability to provide a signal to the solenoids and thereby locking

out those functions that may aggravate the cranes condition.

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

WARNINGS

The DS 350 load moment indicator (LMI) with boom control extension is an operational

aid that warns the crane operator when approaching an overload condition, a two block

condition and an out of boom sequence condition.

Prior to operating the crane, the operator must carefully and thoroughly read and

understand the information provided by the crane and load moment indicator

manufacturer.

The responsibility for safe crane operation shall remain with the crane operator who shall

ensure that all warnings and instructions supplied are fully understood and observed.

It still remains the operators responsibility to verify the operation and to select the correct

mode during crane operations.

The DS 350 Modular with boom control extension is not, and shall not, be a substitute for

good operator judgment, experience and use of accepted safe crane operating procedure

Proper functioning depends upon proper daily inspection and observance of the operating

instructions provided with the crane and load moment indicator.

The manual mode is a rigging mode. Lifting loads in manual mode is prohibited.

Should an out of sequence condition occur, the crane operator is responsible to select

manual mode to return the sections into sequence before continuing the lift.

REFERENCE MATERIAL

Document

Parts & Installation Manual

Operators Manual

031-300-190-061 Rev. B 02/12/01 // WB //

PAT- Part number

031-300-150-713

50\350\19_1319e.doc

Grove- Part number

9-333-103628

190061_B.doc

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

SERVICE AND MAINTENANCE

Daily maintenance of the load moment indicator consists of inspecting:

1. The electrical wiring connecting the various parts of the system.

If electrical wiring is damaged, it shall be replaced immediately.

2. If the insulation is worn on the length sensor cable or cable guides are damaged, these

parts shall be replaced.

3. Check the anti two-block limit switches for freedom of movement.

4. The cable reel must be under tension to operate properly.

5. Check the pressure transducers at the hoist cylinder(s) and the connecting hoses for oil

leakage.

Other than correcting the problems identified in the Malfunctions Table and replacing

faulty mechanical parts and cables, no other repairs shall be performed by non expert

personnel.

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

031-300-190-061 Rev. B 02/12/01 // WB //

P1

P2

A1

Analog input

L1

LMI Console

Analog

input

Analog

output

Digital

output

AI

1

AI

2

AO1

K5

K4

K3

K2

K5

NO

K5

NC

K4

DI 7

DI 6

DI 5

DI 4

Prop.

OM- 2way solenoids

CM- 2way solenoids

IM- 2way solenoids

Prop. retract

Prop.extend

Out of sequence warning

Inner mid % reset

Inner mid retracted

Center mid retracted & % reset

OM/Fly retracted

Automode on

Boom retract

Crane

interface

connector

RxD

TxD

Boom

Control Bus

Extension

Digital

Input

DI 3

DI 2

DI 3

Boom extend

Crane interface

connector

DS 350 Modular

Central Unit

Digital Inputs

DI 1

DI 2

House pin engaged

on rubber over front

Piston pressure transducer

Rod pressure transducer

Angle sensor

Main boom length sensor

Inner Mid length sensor

Center Mid length sensor

OM- 2way solenoid valve

CM- 2way solenoid valve

IM- 2way solenoid valve

Out of sequence warning

light in cabin

Proportional pressure

reducing valve extend

Proportional pressure

reducing valve retract

Prox.switch on base section

Prox.switch on IM section

Prox.switch on base section

Prox.switch on CM section

Automode switch in cabin

P-switch retract pilot pressure

P-switch extend pilot pressure

House pin switch

On rubber - over front switch

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

1. BOOM CONTROL INTERFACE

Cable reel

190061_B.doc

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

2. GETTING STARTED

This section explains how to handle a problem that may arise with the PAT DS 350

Modular LMI boom control extension. The procedures are given in flowchart format for the

following sections. Start with the general flowchart below that will guide you to one of

the detailed flowcharts shown in Sections 1.1 to 1.7. The drawings that are referenced in

these sections can be found in Section 2.1 to 2.13.

Start

Boom length %

problem

Boom out of sequence

in Auto mode

E83

Outer mid/ fly section is

not fully retracted or

center mid section is

not fully extended.

E61

Error in the boom

control extension

Start with section 1.3

Start with section 1.4

Start with section 1.5

Start with section 1.6

No tele function at all in

automode

Start with section 1.7

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

3. BOOM LENGTH PERCENTAGE PROBLEM

Start

Boom length percentage problem

Switch to Manual Mode and retract the boom

completely against the stop block.

Check the percentage indication (1%,0%,0%).

Wrong?

No

Yes

IM and/ or CM retract signal not recognized. Check

proximity switch target adjustment. Refer to

section 2, drawing 2.1. If damage is visible install

new switch.

Correct?

Continue with section 1.4

No

Yes

Measure the voltage supply to IM switch at terminal

1(+24V) and 3 (GND) in the length transducer

LG 321 . Refer to section 2, drawing 2.3 and 2.8 to

2.12

Adjust the target and switch.

Refer to section 2, drawing 2.1

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Measure the voltage at terminal

25(+24V) and terminal 27 (GND) in the

bus extension unit.

Yes

Failure in bus extension.

Check connectors, fuses

and bus extension power

supply. Refer to section 2,

drawing 2.7 and 2.9.

No

Correct?

Yes

Faulty wiring between bus

extension and LG 321.

Check wiring. Refer to

section 2, drawing 2.7 to

2.12.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Measure voltage at terminal 1or 2 (+24V) and

5 or 6 (GND) in the switch junction box. Refer to

section 2, drawing 2.2 and 2.12.

No

Correct?

Yes

Measure the voltage at terminal 1 (+24V) and 5

(GND) in the inner mid junction box.

Refer to section 2, drawing 2.2 and 2.12.

Faulty wiring between length

transducer LG 321 and switch

junction box. Check wiring.

No

Correct?

Yes

Measure the IM reset switch signal at terminal 3

(+24V) and 5 (GND) in the proximity switch junction

box. Refer to section 2, drawing 2.2 and 2.12.

Faulty wiring between length

transducer LG 321 and inner

mid junction box. Check wiring.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Yes

Measure the IM reset switch signal at wire 2

(+24V)(fast-on connector) and terminal 3 (GND) in the

length transducer LG321. Refer to section 2, drawing

2.3 and 2.12.

Faulty switch wiring or

defective switch. Replace IM

reset proximity switch. Adjust

switch and target. Refer to

section 2, drawing 2.1.

No

Correct?

Yes

Measure the IM retract switch signal at terminal 4

(+24V) and 5 (GND) in the switch junction box.

Refer to section 2, drawing 2.2 and 2.12.

Faulty wiring between length

transducer LG 321 and switch

junction box. Check wiring.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

10

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Correct?

No

Yes

Measure the IM retract switch signal at wire 4 (+24V)

(fast-on connector) and 3 (GND) in the length

transducer LG321. Refer to section 2,

drawing 2.3 and 2.12.

Correct?

Faulty switch. Replace IM

retract proximity switch. Adjust

switch and target. Refer to

section 2, drawing 2.1.

No

Yes

Measure the CM retract switch signal at terminal 6

(+24V) and 5 (GND) in the inner mid junction box.

Refer to section 2, drawing 2.2 and 2.12.

Faulty wiring between length

transducer LG 321 and switch

junction box. Check wiring.

No

Correct?

Yes

Measure the CM retract switch Yes

signal at terminal 8

(+24V) and 3 (GND) in the length transducer LG321.

Refer to section 2, drawing 2.2, 2.3 and 2.12 .

Defective switch. Replace CM

retract proximity switch. Adjust

switch and target. Refer to

section 2, drawing 2.1.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

11

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Yes

Measure the IM retract switch signal at terminal 39

(+24V) and 27 (GND) in the bus extension. Refer to

section 2, drawing 2.7 and 2.9.

Faulty wiring between length

transducer LG 321 and switch

junction box.

Check wiring.

No

Correct?

Yes

Measure the IM reset switch signal at terminal 41

(+24V) and 27 (GND) in the bus extension. Refer to

section 2, drawing 2.7 and 2.9.

Faulty wiring between bus

extension and length

transducer LG 321. Check

wiring.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

12

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Yes

Measure the CM retract switch signal at terminal 37

(+24V) and 27 (GND) in the bus extension. Refer to

section 2, drawing 2.7 and 2.9.

No

Correct?

Faulty wiring between bus

extension and length

transducer LG 321. Check

wiring.

Yes

Measure OM retract switch power supply at terminal

X1/11 (+24V) and X1/7 (GND) in the LG 321 (CM).

Refer to section 2, drawing 2.2 and 2.8 to 2.12.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

13

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Yes

Measure at CM junction box terminal 11 (+24V) and 9

(GND) . Refer to section 2, drawing 2.2 and 2.12.

Faulty wiring between bus

extension and length

transducer LG 321(CM). Check

wiring.

No

Correct?

Yes

Measure OM retract switch signal at CM junction

box terminal 10 (+24V) and 9 (GND). Refer to

section 2, drawing 2.2 and 2.8 to 2.12.

Faulty wiring between CM

junction box and length

transducer LG 321(CM). Check

wiring.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

14

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Yes

Measure signal at terminal X1/8 (+24V) and X1/7

(GND) in the LG 321(CM). Refer to section 2, drawing

2.2 and 2.12.

Faulty wiring between bus

extension and length

transducer LG 321(CM). Check

wiring.

No

Correct?

Yes

Measure signal at bus extension terminal X1/35

(+24V) and X1/27 (GND). Refer to section 2,

drawing 2.7 and 2.9.

Faulty wiring between CM

junction box and length

transducer LG 321(CM). Check

wiring.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

15

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Yes

Digital input defective on bus extension. Check

LED's on bus extension. Contact authorized service

for the replacement procedure.

Faulty wiring between bus

extension and length

transducer LG 321(CM). Check

wiring.

End

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

16

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

4. BOOM OUT OF SEQUENCE IN AUTOMODE

Start

Problem:

In Auto Mode the boom becomes out of

sequence, the warning light is on.

Select manual mode.

With no load suspended retract the boom completely.

Disengage the boom stop block and retract the boom

completely. Check the percentage indication

(should be 0%,0%,0%).

Correct?

No

Yes

Inspect the spooling of the length cable on both drums.

Continue with section 1.3

-Boom length (%) error-

No

Correct?

Yes

Remove the lid from the length (angle) transducer

LG 321 and LWG 309. Carefully reset the length

transducer potentiometer. Refer to section 2,

drawing 2.5 for instruction. Repeat testing the boom

sequence in automode.

Correct the spooling manually.

CAUTION:

Drum is under tension.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

17

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Failed?

No

Yes

In manual mode retract the boom. Disengage the boom stop block to

retract all section completely. Re-check the length potentiometer

adjustment. Refer to section 2, drawing 2.5.

End

No

Correct?

Yes

Remove lid from LG321(IM length) and measure

supply voltage at terminal X1/1 (+24V) and X1/3

(GND).

Adjust gear assembly and check O-ring

in gear wheel. Replace O-ring if wear is

visible.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

18

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Measure the voltage at terminal

X1/ 25(+24V) and terminalX1/27(GND)

in the bus extension. Refer to section 2,

drawing 2.9.

Yes

Failure in bus extension.

Check connectors, fuses

and bus extension power

supply. Refer to section 2

drawing 2.7.

No

Correct?

Yes

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty wiring between bus extension

and LG 321 (IM). Check wiring.

Refer to section 2, drawing 2.8 to 2.12.

190061_B.doc

19

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Turn the length potentiometer in the LG 321 (IM)

counter clockwise to a soft stop. Refer to section 2,

drawing 2.5.

Measure the voltage at terminal X1/2(1V) and terminal

X1/3(GND). Refer to section 2, drawing 2.3.

No

Correct?

Switch power off. Remove wire 2 from

LG 321 terminal X1/2. Switch power on.

Measure electrical current at terminal

X1/2(+ 4mA ) and X1/3 (GND).

Yes

Switch power off.

Re- connect wire 2 to

terminal X1/2.

Faulty length sensor unit.

Replace length sensor unit.

Refer to section 2,

drawing 2.3.

No

Correct?

Yes

Switch power off. Re -connect wire 2

to terminal X1/2.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty wiring between length transducer

LG 321 and bus extension. Check

wiring. Refer to section 2, drawing 2.3

and 2.8 - 2.12.

190061_B.doc

20

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Turn the length potentiometer in the LG 321 (IM)

clockwise to a soft stop (10 turns).

Measure the voltage at terminal X1/2(5.6V) and

terminal X1/3(GND).

Correct?

No

Yes

Switch power off. Remove wire 2 from LG 321

terminal X1/2. Switch power on. Measure

electrical current at terminal

X1/2(+ 20mA ) and X1/3(GND).

Switch power off.

Re- connect wire 2 to

terminal X1/2.

Defective length sensor

unit. Replace length

potentiometer assembly.

Refer to section 2,

drawing 2.3.

Remove lid from LG321(CM length) and measure

supply voltage at terminal X1/1 (+24V) and X1/3

(GND).

No

Correct?

Yes

Switch power off. Re -connect wire 2

to terminal X1/2.

Faulty wiring between length

transducer LG 321 and bus extension.

Check wiring.

No

Correct?

Yes

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty wiring between bus extension

and LG 321 (CM). Check wiring.

Refer to section 2, drawing 2.8 to 2.12.

190061_B.doc

21

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Turn the length potentiometer in the LG 321 (CM)

counter clockwise to a soft stop. Refer to section 2,

drawing 2.5.

Measure the voltage at terminal X1/2(1V) and terminal

X1/3(GND). Refer to section 2, drawing 2.3.

No

Correct?

Switch power off. Remove wire 2 from

LG 321(CM) terminal X1/2. Switch

power on. Measure electrical current at

terminal X1/2(+ 4mA ) and X1/3 (GND).

Yes

Switch power off.

Re- connect wire 2 to

terminal X1/2.

Faulty length sensor unit.

Replace length sensor unit.

Refer to section 2,

drawing 2.3.

No

Correct?

Yes

Switch power off. Re -connect wire 2

to terminal X1/2.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty wiring between length transducer

LG 321(CM) and bus extension. Check

wiring. Refer to section 2, drawing 2.3

and 2.8 - 2.12.

190061_B.doc

22

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Turn the length potentiometer in the LG 321 (IM) clockwise

to a soft stop (10 turns).

Measure the voltage at terminal X1/2(5.6V) and

terminal X1/3(GND).

Correct?

No

Yes

Switch power off. Remove wire 2 from LG 321

(CM) terminal X1/2. Switch power on.

Measure electrical current at terminal

X1/2(+ 20mA ) and X1/3(GND).

Switch power off.

Re- connect wire 2 to

terminal X1/2.

Defective length sensor

unit. Replace length

potentiometer assembly.

Refer to section 2,

drawing 2.3.

Remove lid from LG309(OM length) and measure

supply voltage at terminal X1/1 (+24V) and X1/3

(GND).

No

Correct?

Yes

Switch power off. Re -connect wire 2

to terminal X1/2.

Faulty wiring between length

transducer LG 321(CM) and bus

extension. Check wiring.

No

Correct?

Yes

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty wiring between bus extension

and LG 321 (CM). Check wiring.

Refer to section 2, drawing 2.8 to 2.12.

190061_B.doc

23

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Turn the length potentiometer in the LWG 309 counter

clockwise to a soft stop.

Measure the voltage at LWG 309 terminal X1/2(1V) and

terminal X1/3(GND). Refer to section 2, drawing 2.4.

No

Correct?

Switch power off. Remove wire 2 from

LWG 309 terminal X1/2. Switch power

on. Measure electrical current at

terminal X1/2(+ 4mA ) and X1/3 (GND).

Yes

Switch power off.

Re- connect wire 2 to

terminal X1/2.

Defective length sensor

unit. Replace length sensor

unit. Refer to section 2,

drawing 2.4.

No

Correct?

Yes

Switch power off. Re-connect wire 2

to terminal X1/2.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty wiring between length transducer

LWG 309 and central unit. Check

wiring. Refer to section 2,

drawing 2.8-2.12.

190061_B.doc

24

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Turn the length potentiometer in the LWG 309

clockwise to a soft stop (10 turns).

Measure the voltage at LWG 309 terminal X1/2(5.6V)

and terminal X1/3(GND). Refer to section 2,

drawing 2.4.

No

Correct?

Switch power off. Remove wire 2 from

LWG 309 terminal X1/2. Switch power on.

Measure electrical current at terminal

X1/2(+ 20mA ) and X1/3(GND).

Yes

Switch power off.

Re- connect wire 2 to

terminal X1/2.

Defective length sensor

unit. Replace length sensor

unit. Refer to section 2,

drawing 2.4.

Reset all length transducer

potentiometers. Refer to section 2,

drawing 2.3, 2.4 and 2.5. Select the

boom control data display. Refer to

section 2, drawing 2.13. Compare the

indicated IM length with the actual IM

length.

No

Correct?

Yes

Switch power off. Re-connect wire 2

to terminal X1/2. Refer to section 2,

drawing 2.4.

Faulty wiring between length transducer

LWG 309 and central unit.

Check wiring.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

25

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Yes

Correct?

No

Fault is not located in the LMI circuit.

Follow the crane service instructions to

continue.

Faulty bus extension module.

Contact PAT- Technical Support for

instruction.

End

End

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

26

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

5. [E83] OUTER MID AND FLY SECTION ARE NOT RETRACTING

Start

E83

Outer mid and fly section are

not fully retracted.

Switch to manual mode and

retract the outer mid section

fully.

E83 ?

No

Yes

Switch to automode and retract the boom (Caution:

Reduced load chart with E83).

Switch to automode and

continue normal crane

operation.

No

E83 ?

Yes

Visible check the position of the outer mid and fly

section.

Defect is not located in LMI

circuit. Refer to crane service

documentation to continue.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

27

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Correct ?

No

Yes

Switch to manual mode and retract the

outer mid section fully.

Check the OM retract proximity switch and

target adjustment. Refer to section 2,

drawing 2.1.

Defect is not located in LMI

circuit. Refer to crane service

documentation to continue.

Correct?

No

Yes

No

Yes

Measure the voltage at terminal

25(+24V) and terminal 27 (GND) in the

bus extension.

Correct?

Switch to automode and continue

normal crane operation.

Adjust the switch and the target.

Refer to section 2, drawing 2.1.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

28

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Correct ?

No

Yes

Measure OM retract switch power supply at LG

321 (CM) terminal X1/11 (+24V) and X1/7

(GND). Refer to section 2, drawing 2.2 and 2.8

to 2.12.

Correct?

Defective bus extension. Check

connectors, fuses and bus extension

power supply. Refer to section 2,

drawing 2.7 and 2.9.

No

Yes

Measure OM retract switch signal at

CM junction box terminal 10 (+24V) and

9 (GND). Refer to section 2, drawing

2.2 and 2.8 to 2.12.

Faulty wiring between bus extension

and LG 321. Check wiring. Refer to

section 2, drawing 2.7 to 2.12.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

29

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct?

Yes

Measure signal at terminal X1/8 (+24V) and X1/7

(GND) in the LG 321(CM). Refer to section 2, drawing

2.2 and 2.12.

Defective wiring between bus

extension and length

transducer LG 321(CM). Check

wiring.

No

Correct?

Yes

Measure signal at bus extension terminal X1/35

(+24V) and X1/27 (GND). Refer to section 2,

drawing 2.7 and 2.9.

Defective wiring between CM

junction box and length

transducer LG 321(CM). Check

wiring.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

30

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Correct?

No

Yes

Digital input defective on bus

extension. Check LED's on bus

extension. Contact authorized service

for the replacement procedure.

Defective wiring between bus

extension and length

transducer LG 321(CM). Check

wiring.

End

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

31

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

6. [E61] Error in the bus extension

Start

E61

Error in the bus extension

Check crane power, battery

voltage.

No

Correct ?

Yes

Measure the power supply at the bus extension

terminal X1/26(+24V) and 28(GND).

Correct?

Refer to the crane service

documentation to correct the

power failure.

No

Yes

Check bus extension fuse FX.

Faulty crane electric wiring.

Check wiring. Refer to

section 2, drawing 2.8 - 2.12.

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

32

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Correct ?

No

Yes

Refer to section 2, drawing 2.8 and 2.9. Check the bus

cable wiring and connections between bus extension

and central unit.

Switch power off. Replace the fuse.

Switch power on and check again.

No

Correct?

Yes

Faulty bus extension. Contact

authorized service

representative for replacement

instruction.

If damage is visible replace the cable,

otherwise rewire and tighten the

connections.

Caution: Twisted pairs must remain

twisted.

End

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

33

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

7. No tele function at all in Auto mode

Start

Error:

No tele-function at all in

automode

Remove load from hook. Make sure no other error or

warning is preventing you from extending or retracting

the boom. Switch to manual mode and attempt

extending and retracting the boom in manual mode.

No

Correct ?

Yes

Remove lid from bus extension enclosure. Measure

crane power supply at

terminal X1/26 (+24V) and X1/28 (GND). Refer to

section 2, drawing 2.6, 2.7 and 2.8.- 2.12.

Malfunction is not related to LMI or

boom control extension. Consult

the crane service documentation.

No

Correct ?

Yes

Continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty crane electric wiring. Refer to

section 2. drawing 2.8 - 2.12.

190061_B.doc

34

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Switch to auto mode. Start the engine.Operate the

extend control. Measure the extend signal at bus

extension terminal X1/29 (+24V) and X1/28 (GND).

Refer to section 2, drawing 2.7 and 2.8.- 2.12.

No

Correct ?

Yes

Start the engine.Operate the retract control. Measure the

retract signal at bus extension terminal X1/31 (+24V)

and X1/28 (GND). Refer to section 2, drawing 2.7 and

2.8.- 2.12.

Faulty pilot pressure switch in the tele

extend pilot pressure circuit or crane

electric harness faulty. Refer to crane

documentation.

No

Correct ?

Yes

continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty pilot pressure switch in the tele

retract pilot pressure circuit or crane

electric harness faulty. Refer to crane

documentation.

190061_B.doc

35

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Refer to section 2, drawing 2.13 and select the boom

control data display. Operate the extend control. The

ramp value for the appropriate section should increase

in steps from 0 to 255.

Correct?

No

Yes

Refer to section 2, drawing 2.13 and select the

boom control data display. Operate the retract

control. The ramp value for the appropriate

section should increase in steps from 0 to 255.

Repeat test using the extend control.

Faulty digital input 1 on bus

extension. Contact authorized

service to obtain replacement

instructions.

continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

36

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Correct ?

No

Yes

Select manual mode. Retract all sections. Switch power off. Remove

wire 2 from the analog output bord terminal A104 X1/2 (IM). Switch

power on. Operate retract or extend control. Measure the electrical

current (mA) between the wire 2 (removed from terminal) and the

terminal X1/2. The signal should increase from 0 mA to approximately

800 mA .

Note: In the ramping area the value may be < 800 mA.

Correct?

Faulty digital input 2 on bus

extension. Contact

authorized service to obtain

replacement instructions.

No

Check the power supply to the

analog output module A104

(IM). Measure at terminal X1/1

(+24V) and X1/4(GND).

Yes

Faulty wiring in bus

extension. Refer to

section 2, drawing 2.7

and 2.8-2.12 to check the

wiring.

No

Correct?

Yes

Operate retract or extend

control.

Measure Voltage at terminal

A104 X1/2 (>0V) and X1/4.

continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

continue on next

page

190061_B.doc

37

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

Continuation

Defective analog output board

A104 (IM). Contact authorized

service representative for

replacement instructions.

No

Correct ?

Yes

Refer to section 2, drawing 2.14 (K2,K6,K7

logic table) to check the two way valve

operation.

Re- connect wire 2 to terminal A104 X1/2.

Operate the extend control.

Measure at bus terminal X1/14 (>0V)) and X1/28(GND).

Operate the retract control.

Measure at bus terminal X1/15 (>0V) and X1/28(GND).

Check fuse F5 in the bus

extension. If blown replace

fuse. Check relay K5.

No

Correct?

Yes

continue on next

page

031-300-190-061 Rev. B 02/12/01 // WB //

Faulty crane wiring or defective valve coil.

Contact authorized service representative.

190061_B.doc

38

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

Continuation

No

Correct ?

Yes

Refer to section 2, drawing 2.14 and

measure the two way valve

signal (>/= +20V) at terminal 1or 2 (IM

junction Box) and terminal 1or 2 and 3

or4 (CM junction box)

Correct?

In the bus extension:

Check fuse F2 for relay K2 (IM 2 way valve).

Check fuse F6 for relay K6 (CM 2 way valve).

Check fuse F7 for relay K7 (OM 2 way valve).

Replace if blown. Refer to section 2,

drawing 2.7.

No

Yes

Faulty crane wiring or valve coil.

Refer to crane service Documentation.

Faulty wiring between bus extension and 2

way valve junction boxes on the IM and CM

section. Refer to section 2, drawing 2.8 - 2.14.

Check wiring.

END

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

39

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

8. Proximity switch location and adjustment

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

40

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

9. Boom Hardware -LMI

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

41

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

10. Length transducer - inner mid section

Slipring-assembly

Length-potentiometer

Gearwheel

Terminal X1

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

42

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

11. Length transducer - Center Mid section

Slipring-assembly

Length-potentiometer

Gearwheel

Terminal X1

To19 pin connector- connecting

boom and superstructure

To center mid

junction box

Drawing 2.3.2: LG 321- Center mid section

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

43

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

12. LENGTH ANGLE TRANSDUCER- OVERALL LENGTH

Angle sensor

Slipring assembly

Length potentiometer

Terminal X1

T o 7 p in c o n n e c to r - c o n n e c tin g

b o o m w ith s u p e rs tru c tu re

T o boom nose

ju n c tio n b o x

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

44

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

13.

LENGTH TRANSDUCER ADJUSTMENT

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

45

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

14. TMS/TTS 870 Turntable - LMI Hardware

Pressure Transducers

Boom control

bus extension

Console

Central unit

Crane electric

interface connection

Crane electric

interface connection

031-300-190-061 Rev. B 02/12/01 // WB //

Connect the turntable

hardware with the

boom hardware

190061_B.doc

46

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

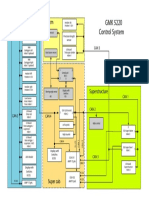

15. Boom Control - Bus Extension

Terminal X2

Analog output module

Analog input module

CPU - Module

Bus - extension

Terminal X1

Relay output fuse

F1 - F9

Drawing 2.7: Boom control bus extension

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

47

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

16. Electric Wiring - Central Unit

To bus extension

To 8 pin crane

electric connector

To area def.

switch interface

To console

To piston side

pressure transducer

To rod side pressure

transducer

To 7 pin boom

base connector

Drawing 2.8: Electrical chematic

- Central Unit DS 350 (Modular)

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

48

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

17. ELECTRIC WIRING - BUS EXTENSION

To 23 pin crane

interface connector

To 14 pin boom

base connector

To 19 pin boom

base connector

To central unit

Drawing 2.9: Electrical Schematic - Bus extension

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

49

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

18. Electric Wiring - Turntable

To bus extension

To central

unit

To central

unit

Drawing 2.10: Electrical Schematic - Turntable

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

50

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

19. Electric Wiring - Lower

To length angle

transducer LWG 309

To central unit

Boom base connector

To central unit

To central unit

Connector for

optional lightbar

To central unit

Console

031-300-190-061 Rev. B 02/12/01 // WB //

Drawing 2.11: Electrical Schematic - Lower

190061_B.doc

51

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

20. Electric Wiring - Boom

To bus extension

To pair of inner mid two

way valve

Drawing 2.12.1: Electrical Schematic - Boom

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

52

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

To bus extension

To central unit

To pairs of

two-way-valve

Drawing 2.12.2: Electrical Schematic - Boom

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

53

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

21. Console Service Display

/ /

Press the two outer keys simultaniously to view

the boom control data. Press again to hide the

data.

Drawing 2.13: Console - Boom control data display

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

54

DS350 - BOOM CONTROL EXTENSION TMS/TTS 870

22. RELAY OUTPUT LOGIC FOR TWO-WAY-VALVES

Relay

No.

Designation

2

6

7

Relay K2 on bus extension

Relay K6 on bus extension

Relay K7 on bus extension

Table A

out of sequence

IM ext/ret

CM ext/ret

OM ext/ret

Tele- Section

K2

0

0

1

1

IM two-way-valves

CM two-way-valves

OM two-way-valves

K6

0

1

0

1

K7

0

1

1

0

0 = no power output

1 = +24V output

Note: The two-way-valve must be powered to stop the section from moving and is

power-free when section is allowed to move.

031-300-190-061 Rev. B 02/12/01 // WB //

190061_B.doc

También podría gustarte

- Volvo 2004 Wiring DiagramsDocumento194 páginasVolvo 2004 Wiring DiagramsJadranko Stankovic85% (27)

- Service Manuel 40hDocumento152 páginasService Manuel 40hAngel DlsgAún no hay calificaciones

- Services Manual Lmi SystemDocumento76 páginasServices Manual Lmi SystemAngel Dlsg80% (5)

- DS350 At422tDocumento120 páginasDS350 At422tadfumegaAún no hay calificaciones

- DHB - 99904-01-02 LICCON2 PDFDocumento75 páginasDHB - 99904-01-02 LICCON2 PDFMgc Elektronik100% (2)

- ECOS 1 PresentationDocumento87 páginasECOS 1 PresentationLuis Jose Lloban100% (1)

- Grua Liebherr LTM 1090 - 4.1Documento136 páginasGrua Liebherr LTM 1090 - 4.1cesar alejandro scavoAún no hay calificaciones

- 2-5 New Error Codes PDFDocumento13 páginas2-5 New Error Codes PDFdacem torres cruz100% (1)

- DS 350 HC 248H Operators Link-Belt REV.ADocumento71 páginasDS 350 HC 248H Operators Link-Belt REV.AJosé Adelino0% (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDe EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusAún no hay calificaciones

- RCI510 400 CalibrationDocumento65 páginasRCI510 400 CalibrationBenjamin Gir PolAún no hay calificaciones

- Pat2manual PDFDocumento516 páginasPat2manual PDFgrineldo84Aún no hay calificaciones

- MicroGuard 500 Series - New BackgroundDocumento11 páginasMicroGuard 500 Series - New Backgroundjulio cesarAún no hay calificaciones

- Liccon LMB Liebherr Ltm1120Documento8 páginasLiccon LMB Liebherr Ltm1120Mgc ElektronikAún no hay calificaciones

- AC60 Training Manual Intranet1.3 PDFDocumento954 páginasAC60 Training Manual Intranet1.3 PDFDemagUral50% (2)

- DS85 Service Manual Pat 190166-F PDFDocumento58 páginasDS85 Service Manual Pat 190166-F PDFGustavo Cuba Diaz100% (1)

- GMK 3050 Pneumatic System: Deutsche GROVEDocumento6 páginasGMK 3050 Pneumatic System: Deutsche GROVEDaniel Castillo PeñaAún no hay calificaciones

- دائرة المشحمة لونش مانتوكDocumento138 páginasدائرة المشحمة لونش مانتوكMohamed Rashed100% (1)

- GMK5100 OperationDocumento666 páginasGMK5100 Operationvasil313100% (1)

- ErrorCodes 5220 V01 06Documento24 páginasErrorCodes 5220 V01 06Sarra Chouchene100% (1)

- ECOS Display FunctionsDocumento95 páginasECOS Display FunctionsAhmed Hassan Abo Asem100% (11)

- Carrier Hyd Schematic - 1 - With GraphicsDocumento1 páginaCarrier Hyd Schematic - 1 - With GraphicsAhmed Hassan Abo AsemAún no hay calificaciones

- LMI НС3926 PDFDocumento45 páginasLMI НС3926 PDFГригорий Григорян100% (3)

- Rt551 Lmi Greer 1Documento39 páginasRt551 Lmi Greer 1George JhonsonAún no hay calificaciones

- ECOS Data Report 3063Documento13 páginasECOS Data Report 3063Sarra Chouchene0% (1)

- DS350GM Service Handbook PDFDocumento63 páginasDS350GM Service Handbook PDFmekanicobucaro100% (2)

- 3B6 Mtech Service ManualDocumento1 página3B6 Mtech Service ManualUebi Alves100% (1)

- Changing EST units and removing telescope cylinderDocumento4 páginasChanging EST units and removing telescope cylinderrodolfof_31100% (1)

- GMK Schematic HandbookDocumento55 páginasGMK Schematic HandbookYukki Badamgarav100% (10)

- Operation Manual AML-C-ATF50G-3Documento26 páginasOperation Manual AML-C-ATF50G-3Mario BugiaAún no hay calificaciones

- LMI ServiceDocumento46 páginasLMI Serviceferanba100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Technical Manual SLI-System DS350C English PDFDocumento12 páginasTechnical Manual SLI-System DS350C English PDFstephen prosser100% (2)

- Technical Information LTM 1030/2: Outline of The Components With Identification (BMK)Documento28 páginasTechnical Information LTM 1030/2: Outline of The Components With Identification (BMK)josselin quatrainAún no hay calificaciones

- Pat DS350M870Documento57 páginasPat DS350M870Mohamed Harb100% (1)

- En Prm 中联重科zcc9800w力限器系统产品说明书Documento37 páginasEn Prm 中联重科zcc9800w力限器系统产品说明书Mustafa TamAún no hay calificaciones

- Pat 2 ManualDocumento504 páginasPat 2 ManualAngel Dlsg95% (19)

- Pat 2 ManualDocumento504 páginasPat 2 ManualAngel Dlsg95% (19)

- MG586 Operator and MantinanceDocumento29 páginasMG586 Operator and MantinanceAngel DlsgAún no hay calificaciones

- EKS 5 Sensor Adjustment GuideDocumento17 páginasEKS 5 Sensor Adjustment Guideemail4mobile100% (9)

- ACT6000 User Guide 1.18Documento38 páginasACT6000 User Guide 1.18sefovaraja100% (1)

- Manual Motor 1103 y 1104Documento120 páginasManual Motor 1103 y 1104Angel Dlsg100% (2)

- GMK 6220Documento14 páginasGMK 6220cornel_lupu100% (1)

- Power Integrity Simulation For High Speed Board Using CST PCBSDocumento5 páginasPower Integrity Simulation For High Speed Board Using CST PCBSjagadees21Aún no hay calificaciones

- I-Flex 5 Tms800e 224738Documento81 páginasI-Flex 5 Tms800e 224738Angel Dlsg100% (1)

- GMK5220 Super Pressure AdjustmentsDocumento9 páginasGMK5220 Super Pressure AdjustmentsAngel Dlsg100% (2)

- GMK5220 Super Pressure AdjustmentsDocumento9 páginasGMK5220 Super Pressure AdjustmentsAngel Dlsg100% (2)

- Iflex5 Service Manual - Skyazul PDFDocumento83 páginasIflex5 Service Manual - Skyazul PDFPAULO100% (1)

- Replacement Parts Suitable For GenieDocumento188 páginasReplacement Parts Suitable For GenieAngel Dlsg0% (1)

- Pat Ds350cDocumento68 páginasPat Ds350cMohamed HarbAún no hay calificaciones

- iFLEX 5 Service Manual PDFDocumento79 páginasiFLEX 5 Service Manual PDFlamine diag0% (2)

- 1operating and Service Manual ATF 110G-5 - 12.2004 - Crane Testing Instructions - 14Documento37 páginas1operating and Service Manual ATF 110G-5 - 12.2004 - Crane Testing Instructions - 14Mochamad fandi DharmawanAún no hay calificaciones

- W376 LMI ManualDocumento33 páginasW376 LMI ManualAnonymous yjK3peI7100% (1)

- DS 350 / 1361 Graphic RT875CC: WWW - Patamerica.co PAT America, IncDocumento46 páginasDS 350 / 1361 Graphic RT875CC: WWW - Patamerica.co PAT America, IncGoudjilAún no hay calificaciones

- VISIO-GMK 5220 SteuerungssystemDocumento1 páginaVISIO-GMK 5220 SteuerungssystemSarra ChoucheneAún no hay calificaciones

- ECOS Training NotesDocumento13 páginasECOS Training Notesazamen100% (3)

- 3500 Monitoring System Rack Installation and Maintenance ManuDocumento86 páginas3500 Monitoring System Rack Installation and Maintenance ManuDenis Jimenez100% (5)

- Train documentation for crane LTM 1055/1Documento88 páginasTrain documentation for crane LTM 1055/1José Signor100% (2)

- PAT DS 350G GW Service ManualDocumento64 páginasPAT DS 350G GW Service Manualddedaniel100% (7)

- 999 enDocumento52 páginas999 enMohamed Rashed100% (3)

- Manual Motor 1106Documento73 páginasManual Motor 1106Angel Dlsg100% (9)

- Manual Motor 1106Documento73 páginasManual Motor 1106Angel Dlsg100% (9)

- ECOS Connection PrincipleDocumento1 páginaECOS Connection PrincipleSarra ChoucheneAún no hay calificaciones

- DS350 Error CodesDocumento12 páginasDS350 Error Codesefrain revillaAún no hay calificaciones

- DS350 Graphic Console Description, Connections & Wiring DiagramDocumento504 páginasDS350 Graphic Console Description, Connections & Wiring DiagramDanilo Marin100% (1)

- 18SP664 Cambio Actuador TurboDocumento6 páginas18SP664 Cambio Actuador TurboAngel DlsgAún no hay calificaciones

- Pat II Manual 6 2005Documento557 páginasPat II Manual 6 2005Angel Dlsg100% (3)

- 6200 - 1 Superstructure MalfunctionsDocumento82 páginas6200 - 1 Superstructure Malfunctionsrenat100% (1)

- Notice: Service Manual iFLEX5Documento2 páginasNotice: Service Manual iFLEX5lecuellarq85gmailcomAún no hay calificaciones

- Grove Pat Load Moment Indicator Ds350g Bcs Service ManualDocumento7 páginasGrove Pat Load Moment Indicator Ds350g Bcs Service ManualDonna100% (47)

- Iflex2 + Iscout Expert Compact LMI System For Grove RT / TM: Service ManualDocumento61 páginasIflex2 + Iscout Expert Compact LMI System For Grove RT / TM: Service ManualGustavo RodriguezAún no hay calificaciones

- Lec 074821Documento340 páginasLec 074821Mohamed Rashed100% (2)

- DS350M8701Documento57 páginasDS350M8701Frank William Romero OrjuelaAún no hay calificaciones

- ECOS Components Identity, Function and DescriptionDocumento25 páginasECOS Components Identity, Function and DescriptionEduardo Alves80% (5)

- Operating, Service Maintenance Manual: Vehicle Identification NoDocumento13 páginasOperating, Service Maintenance Manual: Vehicle Identification NoghggAún no hay calificaciones

- TSM-0066.PDF Spicer 24000Documento104 páginasTSM-0066.PDF Spicer 24000Angel Dlsg90% (10)

- Pat Lmi Manual - Ds150Documento15 páginasPat Lmi Manual - Ds150Anonymous yjK3peI7100% (1)

- Kurzanleitung Programm USDocumento16 páginasKurzanleitung Programm USfelipe iturra100% (2)

- COM TS Can PDFDocumento1 páginaCOM TS Can PDFAngel DlsgAún no hay calificaciones

- LBCE 534 Boom Mode Working Backwards RewireDocumento1 páginaLBCE 534 Boom Mode Working Backwards RewireAngel DlsgAún no hay calificaciones

- BMC IC80 Electrical Schematic PDFDocumento1 páginaBMC IC80 Electrical Schematic PDFAngel DlsgAún no hay calificaciones

- Metri-Pack Series 150 Connector GuideDocumento1 páginaMetri-Pack Series 150 Connector GuideAngel DlsgAún no hay calificaciones

- BMC CalibrationADocumento10 páginasBMC CalibrationAAngel DlsgAún no hay calificaciones

- Manual Motor 1100Documento128 páginasManual Motor 1100Angel DlsgAún no hay calificaciones

- TRTS0062 - 0811tms800e Gav-524Documento316 páginasTRTS0062 - 0811tms800e Gav-524Angel DlsgAún no hay calificaciones

- 201-09rev Ajuste Actuador Turbo S-60 EPA-04Documento6 páginas201-09rev Ajuste Actuador Turbo S-60 EPA-04Angel Dlsg100% (1)

- Manual Motor 1100Documento128 páginasManual Motor 1100Angel DlsgAún no hay calificaciones

- 2598Documento929 páginas2598Angel DlsgAún no hay calificaciones

- Rock Star Manual PDFDocumento78 páginasRock Star Manual PDFEduardo Joiner0% (1)

- Powerlink G3 Controller: Instruction BulletinDocumento24 páginasPowerlink G3 Controller: Instruction BulletinJaime MartinAún no hay calificaciones

- UNO-DM-1.2 - 2.0 - 3.3 - 4.0 - 4.6 - 5.0-TL-PLUS-Product Manual EN-RevC (M000036CG)Documento185 páginasUNO-DM-1.2 - 2.0 - 3.3 - 4.0 - 4.6 - 5.0-TL-PLUS-Product Manual EN-RevC (M000036CG)Mauricio SabinoAún no hay calificaciones

- Bonitron - Chopper ManualDocumento32 páginasBonitron - Chopper ManualnobodymagdesignAún no hay calificaciones

- Photo SensorDocumento5 páginasPhoto SensorbansalrAún no hay calificaciones

- PowerCalc Cisco 7609-SDocumento4 páginasPowerCalc Cisco 7609-Srajko2012Aún no hay calificaciones

- Invertek Optidrive E2 Single PhaseDocumento24 páginasInvertek Optidrive E2 Single PhaseFlavian GorceaAún no hay calificaciones

- Operation/Technical Manual: Full Digital Ultrasonic Diagnostic SystemDocumento72 páginasOperation/Technical Manual: Full Digital Ultrasonic Diagnostic SystemBilal AloulouAún no hay calificaciones

- DXM100-Sx Wireless Modbus Slave: Instruction ManualDocumento43 páginasDXM100-Sx Wireless Modbus Slave: Instruction ManualJEYSONAún no hay calificaciones

- PLC Industrial Control Board FX1N 20MRDocumento9 páginasPLC Industrial Control Board FX1N 20MRAnthonyAún no hay calificaciones

- 4 EWM1000 Diagnostics enDocumento54 páginas4 EWM1000 Diagnostics enMihaela CaciumarciucAún no hay calificaciones

- Eaton MTL Controlling, Operating and Protecting Assets in Harsh and Hazardous AreasDocumento2 páginasEaton MTL Controlling, Operating and Protecting Assets in Harsh and Hazardous AreasProcurement PardisanAún no hay calificaciones

- 3600 M Service Manual PDFDocumento102 páginas3600 M Service Manual PDFudthanhson100% (1)

- Price List Accessories CCTV: Contact Us at (021) 6000777, 0818810105 (PIN BB MEDUSA)Documento1 páginaPrice List Accessories CCTV: Contact Us at (021) 6000777, 0818810105 (PIN BB MEDUSA)biar berkahAún no hay calificaciones

- Bias Power Supply For TV and Monitor TFT LCD Panels: FeaturesDocumento36 páginasBias Power Supply For TV and Monitor TFT LCD Panels: FeaturesHiệp Đào PhướcAún no hay calificaciones

- Manual de Microondas FrigidaireDocumento52 páginasManual de Microondas FrigidaireFreddy Enrique Luna MirabalAún no hay calificaciones

- Measurement Device Rain Gauge Instruction Manual: Type: RM 200 / 202 Original Manual: GermanDocumento35 páginasMeasurement Device Rain Gauge Instruction Manual: Type: RM 200 / 202 Original Manual: GermanHARSHIT LEKHRAAún no hay calificaciones

- ENSAMBLAJE de MONORRIEL - Single Girder Assem Underrun Bridges-113533-92Documento28 páginasENSAMBLAJE de MONORRIEL - Single Girder Assem Underrun Bridges-113533-92VaniloAún no hay calificaciones

- How Home Electrical Systems WorkDocumento7 páginasHow Home Electrical Systems WorkJuanAún no hay calificaciones

- The Practical and Smart Solution For Garage DoorsDocumento12 páginasThe Practical and Smart Solution For Garage Doorsslimane AmAún no hay calificaciones

- ACS O&M ManualDocumento59 páginasACS O&M ManualDilan ThilangaAún no hay calificaciones

- BTS650Documento17 páginasBTS650Poongodi RangasamyAún no hay calificaciones

- IOT Based Smart Wearable Health Monitoring System For Corona DiagnosisDocumento28 páginasIOT Based Smart Wearable Health Monitoring System For Corona DiagnosisIJRASETPublicationsAún no hay calificaciones

- Operating Manual: Zhejiang Holip Electronic Technology Co., LTDDocumento92 páginasOperating Manual: Zhejiang Holip Electronic Technology Co., LTDAlcides celpaAún no hay calificaciones

- Harris - FalconII RF-5000 HF Long Range Tactical Radio - Datasheet PDFDocumento8 páginasHarris - FalconII RF-5000 HF Long Range Tactical Radio - Datasheet PDFdonboxAún no hay calificaciones

- Nex A Lab ManualDocumento8 páginasNex A Lab ManualAnees Khan NiaziAún no hay calificaciones

- Yaskawa Vs606 11 2h DasdasdasdDocumento218 páginasYaskawa Vs606 11 2h DasdasdasdМилош ЈовановићAún no hay calificaciones