Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Tornillos Autoperforantes Parker

Cargado por

guilloteARGDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Tornillos Autoperforantes Parker

Cargado por

guilloteARGCopyright:

Formatos disponibles

40

SCREWS

TO

FORM

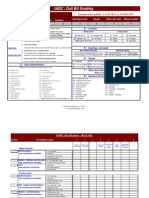

These families group products extremely different one

from the other, either in shape or in application.

In order to clarify the possibilities of the Agrati Group for

the most varied requirements, the various product

TS

THE

THREAD

characteristics are presented separately (head, thread,

point, assembled washer) leaving the freedom to

assembly the screw according to the individual

requirements.

TF

Version with captive washer

TABLE

TF

TS

DESCRIPTION

Thread profiles and points

Head shape

TABLE

R

DESCRIPTION

Captive washer version

SPECIFICATIONS AND REFERENCE STANDARDS

Tolerances

ISO 4759-1

International Std.

Plain

Finish

Requirements for electroplating are covered in ISO 4042.

If different electroplating requirements are desired or if requirements are needed

for other finishes, they should be agreed between customer and supplier.

For acceptance procedure see ISO 3269

Acceptability

AGRATI

GROUP

ED. 2001-A

41

SCREWS

TO

FORM

THE

THREAD

TAPPING FOR METALS

TABLE TF1 : THREAD AND END

EN ISO 1478

Rounded corners

P

d2

d1

60

Thread profile

Thread (ST)

y

d3

455

Type C point

Nominal thread

diameter

Designation

Pitch

d1

d2

d3

c

y ref.

N

P

max.

min.

max.

min.

max.

min.

max.

type C

type F

ST

2.2

2

0.8

2.24

2.10

1.63

1.52

1.47

1.37

0.10

2.00

1.60

ST

2.6

3

0.9

2.57

2.43

1.90

1.80

1.73

1.60

0.10

2.30

1.80

Type F point

ST

2.9

4

1.1

2.90

2.76

2.18

2.08

2.01

1.88

0.10

2.60

2.10

ST

3.3

5

1.3

3.30

3.12

2.39

2.29

2.21

2.08

0.10

3.00

2.50

ST

3.5

6

1.3

3.53

3.35

2.64

2.51

2.41

2.26

0.10

3.20

2.50

ST

3.9

7

1.3

3.91

3.73

2.92

2.77

2.67

2.51

0.10

3.50

2.70

ST

4.2

8

1.4

4.22

4.04

3.10

2.95

2.84

2.69

0.10

3.70

2.80

ST

4.8

10

1.6

4.80

4.62

3.58

3.43

3.30

3.12

0.15

4.30

3.20

ST

5.5

12

1.8

5.46

5.28

4.17

3.99

3.86

3.68

0.15

5.00

3.60

ST

6.3

14

1.8

6.25

6.03

4.88

4.70

4.55

4.34

0.15

6.00

3.60

ST

8

16

2.1

8.00

7.78

6.20

5.99

5.84

5.64

0.15

7.50

4.20

mm.

ST

9.5

20

2.1

9.65

9.43

7.85

7.59

7.44

7.24

0.15

8.00

4.20

Approximate hole sizes, see extract UNI 6946. (page 162-163)

SPECIFICATIONS AND REFERENCE STANDARDS

Material

Casehardening steel

HV 450 min.

Surface hardness

Mechanical

properties

Core hardness

HV 270 390

International Std.

EN ISO 2702

AGRATI

GROUP

ED. 2001-A

42

SCREWS

TO

FORM

THE

THREAD

TAPPING FOR METALS

TABLE TF2 : THREAD AND END

ASME B18.6.4

Rounded corners

455

d2

d1

60

Type AB point

Nominal thread

diameter

Designation

Thread per inch

Pitch

d1

d2

c

P

max.

min.

max.

min.

max.

Thread profile

mm.

ST

9.5

3/8

ST

2.9

4

ST

3.3

5

ST

3.5

6

ST

3.9

7

ST

4.2

8

ST

4.8

10

ST

5.5

12

ST

6.3

1/4

ST

8

5/16

24

20

20

19

18

16

14

14

12

12

1.058

2.896

2.743

2.184

2.083

0.101

1.270

3.302

3.124

2.388

2.286

0.101

1.270

3.531

3.353

2.642

2.515

0.101

1.337

3.912

3.734

2.921

2.769

0.101

1.411

4.216

4.039

3.099

2.946

0.101

1.588

4.801

4.623

3.581

3.429

0.152

1.814

5.461

5.283

4.166

3.988

0.152

1.814

6.248

6.020

4.877

4.699

0.152

2.117

8.001

7.772

6.198

5.994

0.152

2.117

9.652

9.423

7.849

7.595

0.152

Approximate Hole sizes, see extract ASME B18.6.4. (page 164)

SPECIFICATIONS AND REFERENCE STANDARDS

Material

Casehardening steel

HR 15N

Surface hardness

Mechanical

properties

83 min.

Core hardness

HRC 28 38

Standard

ASME B18.6.4

AGRATI

GROUP

ED. 2001-A

43

SCREWS

TAPPING

TO

FORM

THE

THREAD

SCREWS FOR PLASTIC MATERIALS

TABLE TF3 : DUBLE START THREAD AND

POINT FOR SOFT OR PLASTIC MATERIALS

UNI 9702

P/2

c2

Rounded corners

c1

60

d4

455

d3

d2

30

Two profile double

start thread

d1

Rounded corners

y1

y2

Type TZ.point

Type TA point

Nominal thread

diameter

Pitch

d1

d2

d3

d4

c1 = c2

y1

y2

Approximate

Hole sizes

mm.

3.5

4.5

5.5

P

max.

min.

max.

min.

max.

min.

max.

min.

max.

max.

max.

2.10

3.15

2.95

2.59

2.39

1.95

1.75

1.90

1.70

0.15

2.30

1.90

2.50

3.65

3.35

2.89

2.59

2.15

1.85

2.00

1.80

0.15

2.60

2.40

2.70

4.10

3.80

3.29

2.99

2.45

2.15

2.30

2.10

0.15

3.00

2.60

2.80

4.65

4.35

3.59

3.29

2.65

2.35

2.50

2.30

0.15

3.20

3.00

3.00

5.10

4.80

3.94

3.64

3.00

2.70

2.80

2.60

0.20

3.70

3.60

3.00

5.60

5.30

4.44

4.14

3.50

3.20

3.25

3.05

0.20

4.30

3.90

3.10

6.10

5.80

4.94

4.64

3.90

3.60

3.65

3.45

0.20

4.80

4.00

3.50

7.15

6.85

5.89

5.59

4.85

4.55

4.60

4.35

0.20

5.80

4.20

max.

2.30

2.60

2.90

3.30

3.70

4.20

4.70

5.60

min.

2.00

2.20

2.50

2.80

3.10

3.60

4.00

4.90

SPECIFICATIONS AND REFERENCE STANDARDS

Casehardening steel

Material

Surface hardness

Mechanical

properties

HV 450 min.

Core hardness

HV 270 390

Standard

UNI 7323-12

AGRATI

GROUP

ED. 2001-A

44

SCREWS

TAPPING

FORM

TO

THE

THREAD

SCREWS FOR PLASTIC MATERIALS

TABLE TF4 : TWO PROFILE DOUBLE

START THREAD AND END POINT

P/2

F

Rounded corners

Rounded corners

60 5

30 5

Two profile double start thread

455

d2

d1

Type TZ point

Type TA point

mm.

Nominal thread

diameter

Pitch

d

d1

d2

F

Approximate

Hole sizes

3.5

4.5

5.5

10

12

P

max.

min.

max.

min.

max.

min.

max.

2

3.10

2.80

2.80

2.60

2.15

2.00

0.15

2.5

3.60

3.40

3.00

2.80

2.30

2.15

0.15

2.5

4.10

3.85

3.30

3.10

2.45

2.30

0.15

2.5

4.60

4.35

3.60

3.30

2.70

2.40

0.15

3

5.10

4.85

4.00

3.65

3.00

2.70

0.20

3

5.60

5.35

4.50

4.15

3.50

3.20

0.20

3

6.10

5.85

5.00

4.65

3.90

3.60

0.20

3/3.5

7.10

6.85

5.90

5.55

4.80

4.50

0.20

3.5

8.10

7.80

6.90

6.50

5.80

5.50

0.25

3.5

10.10

9.80

8.90

8.40

7.80

7.45

0.25

3.5

12.20

11.80

10.80

10.30

9.80

9.40

0.25

max.

2.30

2.60

2.90

3.30

3.70

4.20

4.70

5.60

6.50

8.50

10.50

min.

2.00

2.20

2.50

2.80

3.10

3.60

4.00

4.90

5.90

7.90

9.90

SPECIFICATIONS AND REFERENCE STANDARDS

Casehardening steel

Material

HV 450 min.

Surface hardness

Mechanical

properties

Core hardness

HV 270 390

Standard

UNI 7323 - 12

AGRATI

GROUP

ED. 2001-A

45

SCREWS

TO

FORM

THE

THREAD

TAPPING SCREWS FOR PLASTIC MATERIALS

TABLE TF5 : TYPE K`` THREAD AND END POINT

d2

d1

30

Nominal

Pitch

d1

d2

K

P

K30

1.35

3

1.62

K35

1.56

3.5

1.90

K40

1.78

4

2.16

K50

2.2

5

2.70

K60

2.6

6

3.27

K70

3.14

7

3.67

K80

3.59

8

4.18

mm.

K100

4.49

10

5.20

SPECIFICATIONS AND REFERENCE STANDARDS

Casehardening steel

Material

Surface hardness

Mechanical

properties

HV 450 min.

Core hardness

HV 270 390

International Std.

EN ISO 2702

AGRATI

GROUP

ED. 2001-A

46

SCREWS

FORM

TO

THREAD

TABLE TF6

THE

THREAD

ROLLING SCREWS

THREAD AND END

UNI 8109

c2

P

c1

c3

End with trilobular cross section TT

mm.

Nominal thread

diameter

Pitch

d*

c1 *

c2

c3

M2.5

M3

M3.5

M4

M5

P

0.45

0.5

0.6

0.7

0.8

2.50

3.00

3.50

4.00

5.00

max.

2.10

2.50

2.90

3.40

4.40

max.

2.57

3.07

3.58

4.08

5.09

max.

2.13

2.58

2.99

3.40

4.31

max.

1.60

1.80

2.10

2.40

2.80

max.

y

0.90

1.00

1.20

1.40

1.60

min.

*These dimensions indicate the diametral measure set on an apex of the triangular section.

M6

M8

1

6.00

5.20

6.10

5.30

3.50

2.00

1.25

8.00

7.10

8.13

6.92

4.40

2.50

Approximate Hole sizes, See extract UNI 8108 (page 167)

SPECIFICATIONS AND REFERENCE STANDARDS

Material

Casehardening steel or other agreed material

Surface hardness

Mechanical

properties

Thread cutting

point features

HV 450 min.

Core hardness

HV 270 390

International Std.

EN ISO 7085

The formed thread shall accept fasteners having tolerance class 6h

AGRATI

GROUP

ED. 2001-A

47

SCREWS

FORM

TO

THREAD

THE

THREAD

CUTTING SCREWS

TABLE TF7 : THREAD AND END

DIN 7513 DIN 7516

The screw thread shall be such that the thread formed by the

screw shall be capable of accepting a threaded fastener

tolerance class 6h. Threaded point:

d/2

mm.

Nominal thread

diameter

Pitch

Approximate

Hole sizes

d

P

M2.5

M3

M4

M5

M6

M8

0.45

0.5

0.7

0.8

1.25

max.

2.26

2.76

3.67

4.57

5.57

7.49

min.

2.20

2.70

3.60

4.50

5.50

7.40

SPECIFICATIONS AND REFERENCE STANDARDS

Material

Casehardening steel or other agreed materials

HV 450 min.

Surface hardness

Mechanical

properties

Core hardness

HV 240 370

DIN 7513 DIN 7516

Standard

AGRATI

GROUP

ED. 2001-A

48

SCREWS

TO

FORM

THE

THREAD

DRILLING SCREWS

TABLE TF8 : THREAD AND

EN ISO 1478

END

UNI 8115

WITH

Rounded corners

d2

d1

60

Thread profile

d3

Thread (ST)

First full thread

Y

Drilling point

mm.

Size N2

Nominal thread

diameter

Designation

Pitch

d1

d2

d3

c

y

Plate

thickness

Size N3

N

P

max.

min.

max.

min.

max.

min.

max.

ST

2.9

4

ST

3.5

6

ST

4.2

8

ST

4.8

10

ST

5.5

12

ST

6.3

14

ST

3.5

6

ST

4.2

8

ST

4.8

10

ST

5.5

12

ST

6.3

14

1.1

2.90

2.76

2.18

2.08

2.29

2.18

0.10

4.10

1.3

3.53

3.35

2.64

2.51

2.80

2.67

0.10

4.80

1.4

4.22

4.04

3.10

2.95

3.28

3.15

0.10

5.40

1.6

4.80

4.62

3.58

3.43

3.76

3.63

0.15

6.00

1.8

5.46

5.28

4.17

3.99

4.32

4.19

0.15

7.00

1.8

6.25

6.03

4.88

4.70

5.03

4.90

0.15

8.10

1.3

3.53

3.35

2.64

2.51

2.89

2.79

0.10

5.60

1.4

4.22

4.04

3.10

2.95

3.45

3.33

0.10

6.40

1.6

4.80

4.62

3.58

3.43

3.96

3.83

0.15

7.60

1.8

5.46

5.28

4.17

3.99

4.57

4.44

0.15

9.00

1.8

6.25

6.03

4.88

4.70

5.79

5.66

0.15

10.00

max.

2.00

2.30

2.50

2.80

3.60

4.40

2.80

3.60

4.40

5.30

5.30

SPECIFICATIONS AND REFERENCE STANDARDS

Material

Casehardening steel or other agreed materials

HV 530 min.

Surface hardness

Mechanical

properties

Core hardness

d ST4.2 HV5 320 400

EN ISO 10666

International Std.

d > ST4.2 HV10 320 400

AGRATI

GROUP

ED. 2001-A

49

SCREWS

TO

FORM

:

TABLE TS

THE

THREAD

HEAD SHAPE

Optional indentation

Optional socket or recess

Pz recess

Ph recess

Ph combined

recess

Pz comb

ned recess

Hexalobular

socket

TS1 : Hexagonal

Nominal thread

diameter

Designation

S

K

ST2.2

ST2.9

ST3.5

ST4.2

ST4.8

ST5.5

ST6.3

ST8

ST9.5

2

3.20

1.60

4

5.00

2.30

6

5.50

2.60

8

7.00

3.00

10

8.00

3.80

12

8.00

4.10

14

10.00

4.70

16

13.00

6.00

20

16.00

7.50

Optional indentation

Optional socket or recess

Ph recess

s

dc

Pz recess

Ph combined

recess

Pz combined

recess

Hexalobular

socket

TS2 : Hexagonal with collar

ST2.2

ST2.9

ST3.5

ST3.9

ST4.2

ST4.8

ST5.5

ST6.3

ST8

2

3.00

2.00

4.20

4

4.00

2.80

6.30

6

5.50

3.40

8.30

7

5.50

3.40

8.30

8

7.00

4.10

8.80

10

8.00

4.30

10.50

12

8.00

5.40

11.00

14

10.00

5.90

13.50

16

13.00

7.00

18.00

dk

Nominal thread

diameter

Designation

S

K

d2

k

TS3 : Pan with slot

Nominal thread

diameter

Designation

dk

K

ST2.2

ST2.9

ST3.5

ST4.2

ST4.8

ST5.5

ST6.3

ST8

ST9.5

2

4.00

1.30

4

5.60

1.80

6

7.00

2.10

8

8.00

2.40

10

9.50

3.00

12

11.00

3.20

14

12.00

3.60

16

16.00

4.80

20

20.00

6.00

AGRATI

GROUP

ED. 2001-A

50

SCREWS

TO

FORM

:

THREAD

HEAD SHAPE

dk

90

TABLE TS

THE

Slot

Ph recess

Pz recess

Hexagonal Hexalobular Hexalobular

socket socket with pin

socket

Antiheft

recess

k

TS4 : Countersunk with slot, recess or socket

ST2.2

ST2.9

ST3.5

ST4.2

ST4.8

ST5.5

ST6.3

ST8

ST9.5

2

3.80

1.10

4

5.50

1.70

6

7.30

2.35

8

8.40

2.60

10

9.30

2.80

12

10.30

3.00

14

11.30

3.15

16

15.80

4.65

20

18.30

5.25

Slot

Ph recess

Pz recess

Hexagonal Hexalobular Hexalobular

socket socket with pin

socket

dk

90

Nominal thread

diameter

Designation

dk

Actual

K

Antiheft

recess

f

TS5 : Countersunk raised with slot, recess or socket

ST2.2

ST2.9

ST3.5

ST4.2

ST4.8

ST5.5

ST6.3

ST8

ST9.5

2

3.80

1.10

0.50

4

5.50

1.70

0.70

6

7.30

2.35

0.80

8

8.40

2.60

1.00

10

9.30

2.80

1.20

12

10.30

3.00

1.30

14

11.30

3.15

1.40

16

15.80

4.65

2.00

20

18.30

5.25

2.30

dk

Nominal thread

diameter

Designation

dk

Actual

K

f

Hexagonal

socket

Hexalobular Hexalobular

socket with pin

socket

Ph recess

Pz recess

Ph combined Pz combined

recess

recess

k

TS6 : Cheese with slot, recess or socket

Nominal thread

diameter

Designation

dk

K

ST2.2

ST2.9

ST3.5

ST4.2

ST4.8

ST5.5

ST6.3

ST8

ST9.5

2

4.00

1.60

4

5.60

2.40

6

7.00

2.60

8

8.00

3.10

10

9.50

3.70

12

11.00

4.00

14

12.00

4.60

16

16.00

6.00

20

20.00

7.50

AGRATI

GROUP

ED. 2001-A

51

SCREWS

TO

FORM

TABLE TS

THE

THREAD

HEAD SHAPE

TS7 : Hexagonal with slot

TS8 : Hexagonal flanged

countersunk 1

TS9 : Hexagonal flanged

countersunk 2

TS10 : Hexagonal countersunk

TS11 : Hexagonal flanged with slot

TS12 : Hexalobular flanged

Hexagonal Hexalobular Hexalobular

socket

socket with pin

socket

Ph recess

Hexagonal Hexalobular Hexalobular

socket socket with pin

socket

Pz recess

Ph recess

TS13 : Pan with socket or recess

TS14 : Pan with socket or recess and collar

Hexagonal Hexalobular

socket

socket

Hexagonal Hexalobular Hexalobular

socket

socket

socket with pin

Ph recess

Pz recess

Pz recess

Hexalobular 12 points

socket with pin

TS15 : Pan with socket or recess and collar

and double shaft diameter

TS16 : Cylindrical with socket

TS17 : Pan antiheft

AGRATI

GROUP

ED. 2001-A

52

SCREWS

TO

TABLE R

FORM

THE

THREAD

ASSEMBLED WASHERS

R1 : Plain

R2 : Plain large or extra large

R3 : Thick plain

R4 : Plain with projections

R5 : Curved spring

R6 : Spring crinkled

R7 : Serrated lock

R8 : Conical spring

R9 : Curved spring plus plain

R10 : Spring crinkled plus plain

R11 : Serrated lock plus plain

R12 : Conical spring plus plain

AGRATI

GROUP

ED. 2001-A

También podría gustarte

- Tpping Screws - Chapter 4Documento13 páginasTpping Screws - Chapter 4Miguel QueirosAún no hay calificaciones

- Parafusos PT SemblexDocumento10 páginasParafusos PT SemblexSBonderAún no hay calificaciones

- Centerline Catalog V7Documento76 páginasCenterline Catalog V7agungAún no hay calificaciones

- 6 Series Tube Fittings 131119Documento46 páginas6 Series Tube Fittings 131119Brunno Vasques100% (1)

- Dimensions and specifications for Taper-Lock bushingsDocumento10 páginasDimensions and specifications for Taper-Lock bushingsdjenanAún no hay calificaciones

- PVH Sight Glass Data SheetDocumento11 páginasPVH Sight Glass Data SheetANIKET PATILAún no hay calificaciones

- SmtdataDocumento8 páginasSmtdataDaftDeveloperAún no hay calificaciones

- Threading Tools (SST Series)Documento8 páginasThreading Tools (SST Series)Gilberto ManhattanAún no hay calificaciones

- Thread MillDocumento40 páginasThread MillferAún no hay calificaciones

- Tech Data TapStandardISODocumento23 páginasTech Data TapStandardISOBalram JiAún no hay calificaciones

- 2642 Ni 71350002Documento56 páginas2642 Ni 71350002ToudAún no hay calificaciones

- Grundfos InstructionDocumento22 páginasGrundfos InstructionSajeev NerurkarAún no hay calificaciones

- 6 Series Tube FittingsDocumento43 páginas6 Series Tube FittingsNilesh MistryAún no hay calificaciones

- Ai Cylinders - Heavyduty PDFDocumento15 páginasAi Cylinders - Heavyduty PDFGM HerbalsAún no hay calificaciones

- Din 8140-3-1993Documento5 páginasDin 8140-3-1993ashkansoheyl50% (2)

- ROSCASDocumento3 páginasROSCASDilucom EspeciasAún no hay calificaciones

- High Pressure Needle ValvesDocumento11 páginasHigh Pressure Needle ValvesNilesh MistryAún no hay calificaciones

- Bernard Q - Gun Parts Break DownDocumento13 páginasBernard Q - Gun Parts Break DownullwnAún no hay calificaciones

- Unj Roscas InsertosDocumento6 páginasUnj Roscas InsertosCreativo2013Aún no hay calificaciones

- Stress Relief Boreback BoxDocumento3 páginasStress Relief Boreback BoxDaisuke Numata100% (1)

- Product and Dimensional Standards For FastenersDocumento7 páginasProduct and Dimensional Standards For Fastenersmech_abhiAún no hay calificaciones

- 47 D0541Documento1 página47 D0541Abd RaHmanAún no hay calificaciones

- Grundfosliterature - CRI Ensambles 1 A 5Documento17 páginasGrundfosliterature - CRI Ensambles 1 A 5Rudo RockAún no hay calificaciones

- 60 Series Tube Fittings and TubingDocumento5 páginas60 Series Tube Fittings and TubingNilesh MistryAún no hay calificaciones

- Drill Stem Components GuideDocumento28 páginasDrill Stem Components Guidechonubobby100% (1)

- Bolt EqualentsDocumento1 páginaBolt EqualentsvkturkiAún no hay calificaciones

- Orifice Plate - Monobloc: DatasheetDocumento8 páginasOrifice Plate - Monobloc: Datasheetbiomed systechAún no hay calificaciones

- Pole RssDocumento2 páginasPole Rssgenial72Aún no hay calificaciones

- 37° Tube Fittings: Instrumentation SolutionsDocumento9 páginas37° Tube Fittings: Instrumentation SolutionsNilesh MistryAún no hay calificaciones

- IADC Dull Bit GradingDocumento9 páginasIADC Dull Bit Gradingzerocool2kAún no hay calificaciones

- Taha Associates CatalogueDocumento34 páginasTaha Associates CatalogueZAHIDAún no hay calificaciones

- WE FastenersDocumento120 páginasWE FastenersOmar MokhtarAún no hay calificaciones

- uPVC Pipes According to DIN StandardsDocumento7 páginasuPVC Pipes According to DIN Standardsしんちゃん ナカリンAún no hay calificaciones

- SD II PDF - OCRDocumento18 páginasSD II PDF - OCRSuraj KumarAún no hay calificaciones

- Used Machine Tools 4 Sale: BSI ShopDocumento3 páginasUsed Machine Tools 4 Sale: BSI ShopnihadbisicAún no hay calificaciones

- Protect equipment and processes with a compact line strainerDocumento3 páginasProtect equipment and processes with a compact line strainersanthoshkrishnaAún no hay calificaciones

- DrillingDocumento9 páginasDrillingHakan ÖzkaraAún no hay calificaciones

- BitsstuffDocumento13 páginasBitsstuffscrbdgharaviAún no hay calificaciones

- Filter FW, F & TF Series (MS-01-92) R3Documento8 páginasFilter FW, F & TF Series (MS-01-92) R3herysyam1980Aún no hay calificaciones

- MMT Series For Precise and Efficient ThreadingDocumento2 páginasMMT Series For Precise and Efficient Threadingdante eyzaguirreAún no hay calificaciones

- ITT ValvesDocumento40 páginasITT Valvesseramon100% (1)

- Clamping ToolsDocumento190 páginasClamping ToolsИван РадивојевићAún no hay calificaciones

- Flow Meters and Orifice PlatesDocumento4 páginasFlow Meters and Orifice PlatesayberkAún no hay calificaciones

- Surface Vehicle Standard: InternationalDocumento45 páginasSurface Vehicle Standard: InternationalshivendrakumarAún no hay calificaciones

- Find specifications for ASTM A325 and A490 structural boltsDocumento6 páginasFind specifications for ASTM A325 and A490 structural boltsalexortiz83Aún no hay calificaciones

- Orifice Plate - Multi-Holes: DatasheetDocumento10 páginasOrifice Plate - Multi-Holes: DatasheetMarcelo PellizzaAún no hay calificaciones

- Product InformationDocumento56 páginasProduct InformationJose Enrique Mendoza RodriguezAún no hay calificaciones

- 10186590Documento74 páginas10186590qualidadesiderAún no hay calificaciones

- Rotating Tools - DrillingDocumento329 páginasRotating Tools - DrillingAlexandru Marian BucurAún no hay calificaciones

- Trap RodDocumento21 páginasTrap Rodrush_oceanAún no hay calificaciones

- RDT High Torque ConnectionsDocumento4 páginasRDT High Torque ConnectionsJohan Medina TovarAún no hay calificaciones

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAún no hay calificaciones

- Pocket Guide to Flanges, Fittings, and Piping DataDe EverandPocket Guide to Flanges, Fittings, and Piping DataCalificación: 3.5 de 5 estrellas3.5/5 (22)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsCalificación: 4.5 de 5 estrellas4.5/5 (10)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceCalificación: 5 de 5 estrellas5/5 (1)

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsDe EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsCalificación: 5 de 5 estrellas5/5 (1)

- Atlas of Fatigue CurvesDocumento534 páginasAtlas of Fatigue CurvesДимитрина Киндова-Петрова92% (26)

- Characterization of Parametric Internal Structures For ComponentsDocumento224 páginasCharacterization of Parametric Internal Structures For ComponentsguilloteARGAún no hay calificaciones

- Solidworks Simulation WeldsDocumento38 páginasSolidworks Simulation Weldsfiuto_rights_1404802100% (2)

- Labview - Modeling Programming and SimulationsDocumento318 páginasLabview - Modeling Programming and Simulationstvs_krishnavarmaAún no hay calificaciones

- Characterization of Parametric Internal Structures For ComponentsDocumento224 páginasCharacterization of Parametric Internal Structures For ComponentsguilloteARGAún no hay calificaciones

- References and solutions for noise, vibration and heat insulationDocumento6 páginasReferences and solutions for noise, vibration and heat insulationguilloteARGAún no hay calificaciones

- Merle C. Potter - Termodinâmica - Soluções em InglêsDocumento16 páginasMerle C. Potter - Termodinâmica - Soluções em InglêsAdautozanataAún no hay calificaciones

- Manual Fagor 8055Documento516 páginasManual Fagor 8055guilloteARG100% (1)

- Materials Methodology Stress FactorsDocumento21 páginasMaterials Methodology Stress Factors538540Aún no hay calificaciones

- Plastic Properties HandbookDocumento15 páginasPlastic Properties HandbookguilloteARGAún no hay calificaciones

- CSWP Examen de EjemploDocumento3 páginasCSWP Examen de EjemploJoa Molina100% (8)

- Solidworks Simulation WeldsDocumento38 páginasSolidworks Simulation Weldsfiuto_rights_1404802100% (2)

- Refer Also To The 2011 World Finals Competition RegulationsDocumento14 páginasRefer Also To The 2011 World Finals Competition RegulationsguilloteARGAún no hay calificaciones

- Accurate Steel Blocks for Dimensional ChecksDocumento14 páginasAccurate Steel Blocks for Dimensional ChecksShyam VimalKumarAún no hay calificaciones

- Machining Operations and Machine Tools: JNTU WorldDocumento18 páginasMachining Operations and Machine Tools: JNTU WorldSreedhar KummaraguntlaAún no hay calificaciones

- Forging Vs CastingDocumento1 páginaForging Vs CastingsdsadAún no hay calificaciones

- Pilger Production Improvement PlanDocumento10 páginasPilger Production Improvement PlanTushar PachlangiaAún no hay calificaciones

- Ramset Wallmate AnchorDocumento2 páginasRamset Wallmate Anchoryhfg27Aún no hay calificaciones

- WPS PresentationDocumento27 páginasWPS PresentationSenthil Kumar50% (2)

- Aluminium Wheel RepairDocumento26 páginasAluminium Wheel RepairAndrew MatsovkinAún no hay calificaciones

- Wilson Tool - Scule Standard, Speciale Si Accesorii Pentru Masini Thick TurretDocumento145 páginasWilson Tool - Scule Standard, Speciale Si Accesorii Pentru Masini Thick TurretSM TECH SRLAún no hay calificaciones

- 08 22338Documento1 página08 22338Shreyas IyengarAún no hay calificaciones

- Getting More Bang For Your Deburring Buck: Related SuppliersDocumento6 páginasGetting More Bang For Your Deburring Buck: Related SuppliersMariver LlorenteAún no hay calificaciones

- Delta AddDocumento10 páginasDelta Addavstella-2009Aún no hay calificaciones

- Industrial Training Report at Star Wire Ind LtdDocumento17 páginasIndustrial Training Report at Star Wire Ind LtdYogesh DeshwalAún no hay calificaciones

- WC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemDocumento7 páginasWC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemryneleeAún no hay calificaciones

- CMT overturns the received doctrine on joining steel to aluminiumDocumento2 páginasCMT overturns the received doctrine on joining steel to aluminiumvonipkoAún no hay calificaciones

- PQR FormDocumento2 páginasPQR Formpokok assamAún no hay calificaciones

- 14.automatic Rotating Table With Sequence Operating MachineDocumento2 páginas14.automatic Rotating Table With Sequence Operating MachineChockalingam AthilingamAún no hay calificaciones

- MAPAL Catalogue Pages HSK-A enDocumento9 páginasMAPAL Catalogue Pages HSK-A ensivanesanmailAún no hay calificaciones

- Tapping ChucksDocumento14 páginasTapping ChucksDHAMODHARANAún no hay calificaciones

- Mechanical 2Documento14 páginasMechanical 2dvanupkleAún no hay calificaciones

- Overall Welding Progress: Nidoco Phase #3 Project Welding SummaryDocumento9 páginasOverall Welding Progress: Nidoco Phase #3 Project Welding SummaryKareem ZidanAún no hay calificaciones

- Cycle Car With Moto WheelDocumento83 páginasCycle Car With Moto Wheelsapientwon7712100% (1)

- 06 Gear Changing of Center LatheDocumento4 páginas06 Gear Changing of Center Lathekabbirhossain100% (1)

- Secoroc Rock Drilling Tools Grinding Equipment Product CatalogueDocumento3 páginasSecoroc Rock Drilling Tools Grinding Equipment Product CatalogueMarcio Herbert Vilcapoma BravoAún no hay calificaciones

- Bar ClampDocumento19 páginasBar Clampapi-200253170Aún no hay calificaciones

- Welding SymbolsDocumento9 páginasWelding SymbolsChristian GervacioAún no hay calificaciones

- ISCAR Cutting Tools - Metal Working Tools - Milling - Shouldering - EPNI-FDocumento2 páginasISCAR Cutting Tools - Metal Working Tools - Milling - Shouldering - EPNI-FHumberto MontañoAún no hay calificaciones

- Failure of Jigs & FixtureDocumento27 páginasFailure of Jigs & FixtureTooling ganeshAún no hay calificaciones

- Usman Liaqat (17MME-S1-313) Shot PeeningDocumento6 páginasUsman Liaqat (17MME-S1-313) Shot PeeningUsman GujjarAún no hay calificaciones

- UNE S315MC - Chemical Composition, Properties, Heat Treatment, Steel EquivalentDocumento2 páginasUNE S315MC - Chemical Composition, Properties, Heat Treatment, Steel EquivalentJèManziAún no hay calificaciones