Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Happy Bird EL Syn 2

Cargado por

Marius Nicusor RaduTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Happy Bird EL Syn 2

Cargado por

Marius Nicusor RaduCopyright:

Formatos disponibles

1

Technician: Tore Christoffersen

Date: 20-03-2014

UltraGas Happy Bird 20-03-2014

Electrical Inspection

The Vessel has a new Vsat unit installed; the old unit has not

been removed because one of the switches being used by the

new Vsat is powered through the old Unit.

All cables for the antenna have been disconnected; the only

wires left are power, and a few old network cables.

The power bar powering the old

Vsat and the network switches is

a clutter of wires.

The unused power cables should

be removed, and an extra power

bar installed, so that the

equipment still in use, has a

professional power installation.

The antenna cables, and Network cables to the new Vsat, needs to be correctly

marked, to insure they are identifiable in the future. At the moment they are marked

with writing on the cables.

The wiring in the Watch keeper control

not show great workmanship. Improper

used to divide the power inside the unit.

unit on bridge, those

terminals have been

The wiring should be fixed, and the lid,

should be mounted to protect the wiring

for the watch keeper

and the IP class.

The unit is placed in the chart table

the steering wheel.

cupboard in front of

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

Technician:

Christoffersen

TheTore

Inmarsat

LRIT has logon issues, and is because

Date: 20-03-2014

of this issue at current date not being used.

I recommend thats this be look into in order to

have the system up and running again.

Several places have been

found, where the concrete

penetrations have been opened

without correctly sealing them

again.

These issues need to be

attended, in order to prevent

fires from spreading.

The locations in the pictures

are as follows:

1. Radio stand where AIS is

located. Stb of the wheel

house.

2. Middle chart table

cupboard facing the

wheel house.

3. Penetration going up to

4. Penetration in ECC

5. Locker E captains deck.

6. Locker D captains Deck.

7. CCR Switchboard

main Vsat Antenna.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

Technician: Tore Christoffersen

Date: 20-03-2014

Two Roxtec Penetrations

have been found on the

sun deck above the

bridge.

One is in need of new

blocks to seal correctly.

The other has been poorly

assembled and needs to

be redone otherwise it will not be up to standard.

Extra blocks for the penetrations should be brought, and plenty of grease. The vessel,

should keep a little onboard to insure future installations.

I would also recommend to have some spare complete sets of penetrations, I hopes

thats this would motivate crew/technicians to do proper penetrations instead of

opening concrete penetration.

Concrete penetrations will never be 100 % when once opened.

A terminal block was found in the chartable cupboard,

this should be within a casing/JB protecting the wires,

and insuring that the access to the terminal block is

secured.

Within the Gyro control boxes, to

wires were found using the same

terminals.

These terminals are for the NMEA

output.

I would recommend installing a

NMEA splitter, to insure they each

get their own terminals and this

way decrease the risk of loose connections.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

Technician: Tore Christoffersen

Date: 20-03-2014

Wiring for the viper control panel on bring need to

be checked, wires have been removed and others

have been added, by none fixated using terminals.

I would also like to

point out that

several cables have

been found above

the ceilings, which

are not correctly

tied and supported.

The battery pack

for general

equipment have

been changed 1,5

years ago.

But the Battery

pack for the radio

equipment seems

to be very old, and in need to be changed.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

Technician:

Christoffersen

TheTore

putty

sealing the the JB C-JB-C

Date: 20-03-2014

in the hallway on the captains

deck has come loose and need to

be closed up again.

Within the CCR switch board I

found several issues.

Its seem some new installation has

been added to the system, the

new cables have been pulled

through a metal guard, without

placing some rubber or other to

protect the cables from the sharpe

edges of the metal guard.

This issue needs to be attended in

order to prevent future issues with

line break and low insulation.

On the terminals 103 and 104 on

terminal block TBB 45-120, a

jumper has been found.

The alarm bypassed was for UPS

failure.

The jumper has been removed and

system is working.

To cables were also found in the

switch board that seem to have been disconnected. As to why would need further

investigation.

At terminal block TBB 1-4 a none fixated terminal was found, I suspect this was done

because of a defective terminal. The terminal should be replaced in order to correctly

reconnect the wires.

In the ECR, they had an issue with the ME safety system.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

Technician:

Torewas

Christoffersen

There

a loop failure for the

Date: 20-03-2014

lube oil inlet to EXH. V/V actuator

LP. gage.

This was discovered to be a

defective card in the unit.

The card was replaced with a

spare card on an unused channel

before leaving Corpus Christi. I

recommend the have a couple of spare cards onboard the vessel.

Though the was still an issue with the pressure gage itself, a new gage new to be

ordered to replace the defective on.

The revelation counter placed in the ECC is not

working.

It is always showing 43, regardless whether the ME

is running or not.

The issue needs further attention in order to

determine the cause of the issue.

The Insulation monitoring for the

shaft generator has been

disconnected.

Even though that at the moment

the generator is not in us, this has

to be address, to be sure it is

reconnect when the shaft

generator is operational again.

At the moment the shaft generator is not operational, the chief engineer believes it to

be the clutch to the shaft, based on the opinion of a service technician for the shaft

generator that attended the issue some time ago.

I would recommend further investigation into this, when it is possible.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

Technician:

Toreloose

Christoffersen

Three

cables were found in the DG2 switch board, these

Date: 20-03-2014

cables are not connected in one end, but they are in the other.

They are only running with the DG2 switch board and can be

easily disconnected, as they should.

The cover for the motor

operated control box, beneath

the breaker of DG3. was not

fitted this is unwise and the

cover has been refitted.

I have checked the breaker

and the bus lines for dust.

It has been very hard to tell

how much dust has settled

on the bus lines. But

judging from the breaker I

would say that there is a

fine layer of dust all

through the MSB.

It would be wise to have the MSB cleaned to insure there are no accidents caused by

the statically charged dust.

When you have big installation with a lot of consumers and starter panels, it will

always be wise to once in while have the switchboard photographed thermally. This

can often revile accidents about to happen, such as loose connection and areas with

too high a load.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

Technician:

Tore Christoffersen

I discovered

a terminal

Date: 20-03-2014

block In the ECC where

the terminals are coming

of the DIN rail. These

should be re fitted.

But it would be wise not

to do tis whilst the vessel

is in voyage, I case of

loose connections.

It would be prudent to tighten the terminals after re fitting the terminals.

I wire was fund to be

disconnected, at the CCP

load control panel in the

ECC.

I recommend this to be

further investigated to

insure that everything is

working as it should.

One of the heaters has been disconnected for the

Calorifier.

The wires powering the relay have been removed

and the heater wires disconnected.

The reason for this is uncertain, and should be

investigated further.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

Technician:

Tore Christoffersen

A jumper

has been

Date: 20-03-2014

found in the

incinerator control

panel, between the

terminals D3 and D4.

The reason for this

jumper needs to be

further investigated.

I discovered three

wires which are

disconnected in a

junction box for the

cargo monitoring

system.

Seeing as this

system is crucial for

the vessel I highly

recommend this to be looked in to as soon as possible.

In the solenoid V/V cabinet for the v/v remote control

system a none fixated terminal was found, I suspect

this was done because of a defective terminal. The

terminal should be replaced in order to correctly

reconnect the wires.

The 400VA 440 to 20 V transformer for the control circuit of the cargo cooling/ballast

pump, is in very poor condition and needs to be replaced with a new one

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

10

Technician: Tore Christoffersen

Date: 20-03-2014

The relays for no. 1 and 2

F.W. hyd. Unit are not

correctly secured in the

starter panel.

This needs to be attended

in order to prevent future

loose connections.

One of the timers for the no 2 main air compressors has

been removed. There is no obvious reason as to why,

and I recommend this to be looked in to and sorted out.

The installation at this

breaker is of poor

standard. The cable

should be correct

fastened and placed so

that the vibration of the

vessel will not damage

it.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

11

Technician:

Tore Christoffersen

Several

poor

Date: 20-03-2014

connections have

been found in the

purifier control panels.

None fixated terminals

have been used to

complete some

circuits.

Either the wires

should be changed in

order to complete

the circuits correctly;

else wise the wires

should be connected

in fixated terminal to

secure against loose

connections.

In the picture on the left hand side, two wires are

interconnected with none fixated terminal. I

suspect that this is to jump a signal, and

recommend that it be further investigated.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

12

Technician:

Christoffersen

TheTore

motor

cable for

Date: 20-03-2014

main SW pump no 1,

and ME L/O pump no

1 needs a couple of

cable ties to secure

the cable and protect

the cable from

damage due to

vibration.

There was a loose

jumper in the JB,

JME-3.

This jumper has

been removed.

A suspicious

connection has

been found in the

bosun store.

This needs further

investigation, and

removed or

rectified using

correct

workmanship.

In the steering gear room fan starter panel, I discovered at cable which was not

connected.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

13

Technician:

Tore Christoffersen

It seems

to have

Date: 20-03-2014

been used as a

supply for the

lights above the

starter panel, or

the other way

around.

The cable needs

to be removed,

to discourage any one from powering the

equipment in a wrong fashion.

One of the breakers in the emergency generator

room is showing signs of dust.

It should be considered to have it cleaned, and

the bus lines along with it, to lower the risk of

static up build in the dust.

Some low insulation is seen on the insulation monitor

on the 220V emergency switchboard.

The consumers with low insulation should be

identified as to keep the continuity to ground as high

as possible.

Though this is not too high, it is always good to be

aware were the trouble spots are.

Both batteries for the emergency generator have

recently been changed.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

14

Technician:

Torewear

Christoffersen

Small

on

Date: 20-03-2014

insulation of the power

cables was found in

the em generator.

The cables have

gotten e few cables to

prevent vibration, and

some rubber has been

laid in to protect the

cables.

The wiring and the

rest of the generator

seem all in all to be in

ok condition.

Some wear and tear

and corrosion is to be

fund.

The wiring on D/G 1, 2 and 3 is in a very poor condition. None fixated terminals are

found several places on each generator.

None fixated

terminal do not

belong on a

generator and will

be in high risk of

loose connection.

Several of the wires

on the also show to

be in very poor

insulation condition, and other places the wires seem

to be on the edge of breaking.

It should be very much considered to change the

wiring on the generator, to insure running stability.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

15

Technician:

Christoffersen

TheTore

power

cables

Date: 20-03-2014

from D/G 2 have

insulation issues.

The vibration of

the generator has

been rubbing the

wires against each

other.

I have lain in

some rubber between the cables to prevent it from

getting any worse. This issue should be attended,

and the cables should be repaired before it gets

any worse.

Other than above mentioned issues D/G 2 seems

to be in good condition.

D/G 1 has a lot of wear and tear on

the power cables.

The cables have been temporarily

repaired and rubber has been laid

in between the cables to prevent

further damage.

This issue needs to be attended

with a permanent repair.

And the cables secured so this

wont happen again.

The heater for D/G 1 doesnt work

either and needs to be changed.

We have power to where it is connected; the heater just needs to be replaced.

The remaining parts of the generator seem to be in good working condition.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

16

Technician:

ToreofChristoffersen

Some

the flange for the D/G 3 connection box

Date: 20-03-2014

has been cut away; this leaves a gap at the length

of the box.

This should be repaired for safety reason, as dirt

and on knowing hands can gain access to the

connections inside through the gap.

The power cables seem to be in ok condition at first

glance, though it seems some repairs have been

made, and of the quality that should only be

temporary.

My recommendation is to insure the places are

correctly repaired.

Rest remaining of the

D/G 3 seems to be in ok

condition.

Though as well as D/G 1

the space heater

doesnt work on D/G 3

and needs to be

replaced.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

17

Technician:

Christoffersen

TheTore

connection

box for

Date: 20-03-2014

and the wires inside, are

in good condition on the

shaft generator.

Also the space heater is

working fine.

The ECC main server

alarm monitor is not

working.

And has not worked for

the last three months I

am told.

They suspect it is one

of the cards in the

alarm monitoring rack.

And this seem as the most likely reason, further investigation into the system is

needed to draw a precise conclusion.

The backup batteries for the alarm rack are to be changed with in a short time, new

batteries are onboard the vessel.

The ME FO supply pump no. 2 is not getting a standby

signal when running in auto mode, and will therefore

not start if the no 1 pump stops. This should be further

investigated and solved as soon as possible.

The standby unit is a Heem-2 from Hyundai, and it has a

manual with a flow chart that is very helpful when

trouble shooting the unit, though there is not one

onboard the vessel.

No 1 lube oil pump also has a standby issue, thouh it is a bit different from the fuel oil

pumps. The L.O. pump gets a standby signal and starts when the no. 2 pump is

stopped. Though it will only run 1 second and then stop. There seems to be problem

the self-holding circuit when starting has a standby pump, this needs to be further

investigated and rectified as soon as possible.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

18

Technician: Tore Christoffersen

Date: 20-03-2014

During black out test it was discovered that the PMS

may not working correctly. When we trip the breaker of

the running generator, the standby generator does not

start up.

Depending of the setup of the PMS this could be a

crucial error, and I recommend further investigation.

The emergency generator starts, within the 30 sec, as it

should.

In the 24V DC distribution board on the bridge, two

fuses have been discovered to be disconnected.

Its labeled to be for the power unit for the fire alarm,

though no jumpers or missing power is to be found in

the power unit. I recommend this to be further

investigated, so we know where these cable are

connected.

On the sun deck above

the bridge there is one

cable running from the

penetration above the

battery room which is

not secured. Cable

brackets needs for be

welded, in order to have

something to secure the cable to.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

19

Technician: Tore Christoffersen

Date: 20-03-2014

The radio antenna for the bridge radio should be considered relocated.

The smoke and

out onto the

the antenna.

heat from the incinerator is blasting

antenna, and could in time damage

On the sun deck there was also on cable for radio

equipment thats needs to be tied a secured.

On deck there

are 6 level

switches for

tanks.

The cables for

these switches

have been known

be damaged be

the waves

crashing on deck.

I would propose, that a box be fitted the length of the cable to protect it against the

waves. Though it should still be removable, in order to gain access to the tank, the

switch and the cable if need be.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

to

20

Technician: Tore Christoffersen

Date: 20-03-2014

The installation for the new Vsat requires having the cables for the antennas tied with

metal ties preferably coated ties. Unfortunately no ties were available in Corpus

Christi.

On deck the condition of the electrical equipment and installation was good.

All the cargo level alarms have been tested and found working.

The chief officer has informed me that they have issues with the stb side flood light

illuminating the deck; they have to change the light bulb very often. I suspect it is due

to vibrations, this light is shaking more than the others and I recommend extra

measures be taken to secure it.

While examining the floodlights I have not been able to find ex marking on the lamp,

maker is Mercury and the type is PF40M. On their website I have found newer models,

where they say the can be placed in industrial and chemical areas but I havent found

any type approval. This needs to be further investigated.

At the PS and STBS cargo manifolds there are a warning light, the cables for this light

is not correctly secured and needs to be fastened with some cable ties.

At the forward vapor sample station theres is a penetration which is showing some

cracks, nothing serious yet, but I advise keeping an eye on the penetration.

In the compressor room at in the forepeak there are two JB, which have two unused

glands each. These glands have to be replaced with blinders to uphold the IP class of

the JB.

The vessel has also had a lot of issues with the 4 fuel oil level switches; the position of

the installation makes the installation woundable to the waves.

A way of protecting the cable and connection needs to be implemented.

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

21

Technician:

Tore

Christoffersen

Chief

Engineers

signature

Date: 20-03-2014

Date

Date

Technician signature

CS Electrics ApS Lillebltsvej 6 6715 Esbjerg N Tlf: +45 75 13 45 09

Fax: +45 75 13 73 89

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Measuring The Level of Risk Exposure in Tanker Shipping Freight MarketsDocumento29 páginasMeasuring The Level of Risk Exposure in Tanker Shipping Freight MarketsMarius Nicusor RaduAún no hay calificaciones

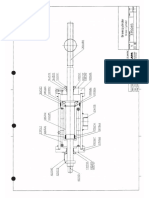

- Hydr CylinderDocumento2 páginasHydr CylinderMarius Nicusor RaduAún no hay calificaciones

- Boiler HeaterDocumento1 páginaBoiler HeaterMarius Nicusor RaduAún no hay calificaciones

- Electrical Inspection On BordDocumento13 páginasElectrical Inspection On BordMarius Nicusor RaduAún no hay calificaciones

- Electrical Inspection On BordDocumento13 páginasElectrical Inspection On BordMarius Nicusor RaduAún no hay calificaciones

- Theme For Exam Presentation For Disciplines Fatigue - and - Materials - 2015Documento2 páginasTheme For Exam Presentation For Disciplines Fatigue - and - Materials - 2015Marius Nicusor RaduAún no hay calificaciones

- Proiect Sabau Arbore AnsysDocumento18 páginasProiect Sabau Arbore AnsysMarius Nicusor Radu50% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2102)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Pediatric Medication Dosing GuildelinesDocumento2 páginasPediatric Medication Dosing GuildelinesMuhammad ZeeshanAún no hay calificaciones

- Cell Organelles 2Documento13 páginasCell Organelles 2Sadeeq ur RahmanAún no hay calificaciones

- DiffusionDocumento25 páginasDiffusionbonginkosi mathunjwa0% (1)

- CELLULAR RESPIRATION Review WorksheetDocumento8 páginasCELLULAR RESPIRATION Review WorksheetYasi0% (1)

- Charla Krupp - How To Never Look Fat Again - Over 1,000 Ways To Dress Thinner - Without Dieting!-Grand Central Publishing (2010) PDFDocumento316 páginasCharla Krupp - How To Never Look Fat Again - Over 1,000 Ways To Dress Thinner - Without Dieting!-Grand Central Publishing (2010) PDFben0% (1)

- Lithium Battery Handling RegulationDocumento11 páginasLithium Battery Handling RegulationFan Man ChungAún no hay calificaciones

- Nursing Care of A Family With An InfantDocumento26 páginasNursing Care of A Family With An InfantJc GarciaAún no hay calificaciones

- Manual L W26Documento436 páginasManual L W26Taufan ArifAún no hay calificaciones

- Critique PaperDocumento1 páginaCritique PapernicolealerAún no hay calificaciones

- Elasticity, Plasticity Structure of Matter: by DR R. HouwinkDocumento9 páginasElasticity, Plasticity Structure of Matter: by DR R. HouwinkKhlibsuwan RAún no hay calificaciones

- Solid Dosage Form Part 1Documento48 páginasSolid Dosage Form Part 1Claire Marie AlvaranAún no hay calificaciones

- Helicobacter Pylori InfectionDocumento18 páginasHelicobacter Pylori InfectionPMAún no hay calificaciones

- Goat AnatomyDocumento8 páginasGoat AnatomyLochi GmAún no hay calificaciones

- A Little BookDocumento75 páginasA Little Bookfati_cenAún no hay calificaciones

- 2006 SM600Documento2 páginas2006 SM600Ioryogi KunAún no hay calificaciones

- Crew Resource Management Phil O'DonnellDocumento39 páginasCrew Resource Management Phil O'DonnellMostafaAún no hay calificaciones

- X FEDEX EIDocumento13 páginasX FEDEX EINISREEN WAYAAún no hay calificaciones

- Instructions For UseDocumento14 páginasInstructions For UseEddie UnivoAún no hay calificaciones

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDocumento2 páginasKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyAún no hay calificaciones

- Beta CaroteneDocumento2 páginasBeta CaroteneValeria MarcuțăAún no hay calificaciones

- ABC Organic Gardener - MagazineDocumento86 páginasABC Organic Gardener - Magazinealexe012Aún no hay calificaciones

- QuestionnaireDocumento2 páginasQuestionnaireMili Gada100% (8)

- SCIENCE-DRRR - Q1 - W1 - Mod2Documento16 páginasSCIENCE-DRRR - Q1 - W1 - Mod2Jay DhelAún no hay calificaciones

- A Novel Procedure For Transient CFD Modeling of Basin Solar Stills, Coupling of Species and Energy EquationsDocumento16 páginasA Novel Procedure For Transient CFD Modeling of Basin Solar Stills, Coupling of Species and Energy EquationsAverroesAún no hay calificaciones

- Shelf Life ControlDocumento7 páginasShelf Life ControlRushikesh Deshpande100% (1)

- Translating Child Development Research Into Practice - Can Teachers Foster Children's Theory of Mind in Primary SchoolDocumento14 páginasTranslating Child Development Research Into Practice - Can Teachers Foster Children's Theory of Mind in Primary SchoolpecescdAún no hay calificaciones

- Steel Scrap Recycling Policy 06.11.2019 PDFDocumento31 páginasSteel Scrap Recycling Policy 06.11.2019 PDFAnshul SableAún no hay calificaciones

- Doka H20 BeamDocumento20 páginasDoka H20 Beamshoaib100% (1)

- Sacrament ChartDocumento3 páginasSacrament ChartXam PerezAún no hay calificaciones

- Perdev - Module 9Documento9 páginasPerdev - Module 9April Rose CortesAún no hay calificaciones