Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Magnaflux-Spotcheck Red Operating Instructions 10-14

Cargado por

jimoteDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Magnaflux-Spotcheck Red Operating Instructions 10-14

Cargado por

jimoteCopyright:

Formatos disponibles

SPOTCHECK

DYE PENETRANT

OPERATING

INSTRUCTIONS

HOW TO USE YOUR SPOTCHECK KIT

The dye penetrant method of inspection with Spotcheck is a nondestructive test for defects open to the surface. It may be used on

such materials as aluminum, magnesium, brass, copper, cast iron,

steel, stainless steel, carbides, stellite, certain plastics and ceramics.

The essentials of the method are: penetration of the defect by the Dye

Penetrant - removal of the excess Penetrant from the surface development of the indication - inspection. A deep red indication will

mark the defect.

Surfaces should be free of foreign materials and paint. Grease, oils,

etc., prevent penetration and should be removed by precleaning with

Cleaner/Remover or by solvent degreasing. Scale, sand, dirt, etc. trap

penetrant and hinder removal, therefore wire brushing or similar

precleaning is necessary. Paint must be removed from areas to be

tested.

1. Cleaning - For precleaning, coat the part or

section to be inspected with Spotcheck

Cleaner/Remover. Allow cleaner to remain on part

long enough to dissolve dirt or film. Wipe dry with a

clean cloth. Repeat if necessary. After final clean

wiping, allow time to dry before using Spotcheck

Penetrant. Clean the same day inspection is

conducted.

1. Cleaning

S pray or brus h the part or

s ection to be ins pected s o that s urface is

covered with S potcheck P enetrant. If P enetrant

pulls back in droplets s top and clean part again.

(R efer to S tep 1). Allow P enetrant to remain on

the part from 10-30 minutes . Longer penetration

times may be needed for locating extremely ne,

tight dis continuities .

When s uf cient

penetration time has been allowed, wipe the

s urface clean with a clean towel or cloth. R epeat

if neces s ary. S ome s urfaces will require only

wiping. In general, however, remove exces s

s urface P enetrant with clean cloths premois tened

with C leaner/R emover. DO NOT us h s urfac e

with C leaner/R emover bec aus e this will impair

s ens itivity. R epeat this procedure with additional

wiping until res idual s urface P enetrant has been

removed.

S hake the pres s ure

can vigorous ly until the agitators rattle ins ide, or

thoroughly s tir bulk Developer. S pray the part or

s ection to be ins pected with S potcheck

Developer, jus t enough to wet the part thinly and

evenly, no more. P roper thicknes s will dry to an

even white layer. Too much Developer will mas k

indications ; too little will not develop the

indication s uf ciently. For eas e of application,

hold s pray can 8 to 12 inches above part and

s pray s hort 6 to 8 inch sections at a time. Allow

Developer to dry. Watch for large cracks to show

up immediately. S maller cracks may take a few

minutes to develop the bes t indication.

Defects will be marked by a deep red

S potcheck indication. A line or dotted line marks

a crack, lap, forging burs t or cold s hut. If wide

and deep, the indication will grow and s pread.

P oros ity, s hrinkage, lack of bond, and leaks will

appear as dots or local areas of color. Thes e, too,

will grow and s pread if the defect is large or

extens ive.

155 Harlem Ave Glenview, IL 60025

(847)657-5300 fax:(847) 657-5388

También podría gustarte

- NAS1303 CoastFabricationDocumento2 páginasNAS1303 CoastFabricationsje productionAún no hay calificaciones

- DCS Ka-50 Guide PDFDocumento97 páginasDCS Ka-50 Guide PDFChristian SilvaAún no hay calificaciones

- Ms 21919Documento4 páginasMs 21919Зариф ЗарифовAún no hay calificaciones

- Id00 25 113 F16 1 Wa 1 - 01 Mar 2014 - 0 - 01 Mar 2014 - CompDocumento18 páginasId00 25 113 F16 1 Wa 1 - 01 Mar 2014 - 0 - 01 Mar 2014 - CompArif Nugroho SantosoAún no hay calificaciones

- Astm A36Documento3 páginasAstm A36Negro PretoAún no hay calificaciones

- UrazenDocumento3 páginasUrazenLuis Barrios ArandaAún no hay calificaciones

- Quality TestDocumento92 páginasQuality TestAhmed Shaban KotbAún no hay calificaciones

- Nas451 3Documento3 páginasNas451 3joeAún no hay calificaciones

- Aerospace Material Specification: Steel Strip (0.90 - 1.04C) (SAE 1095) Hard Temper (Composition Similar To UNS G10950)Documento6 páginasAerospace Material Specification: Steel Strip (0.90 - 1.04C) (SAE 1095) Hard Temper (Composition Similar To UNS G10950)raulAún no hay calificaciones

- TM 9 8000Documento781 páginasTM 9 8000r17g100% (1)

- Mil C 9084Documento20 páginasMil C 9084john_gouveia_8Aún no hay calificaciones

- 13-8 PHteDocumento1 página13-8 PHtegeorgeAún no hay calificaciones

- Beryllium CopperDocumento2 páginasBeryllium Coppershawntsung100% (1)

- USD260789 NCC-1701 Enterprise Design PatentDocumento2 páginasUSD260789 NCC-1701 Enterprise Design PatentfuccioniAún no hay calificaciones

- ASTM 675-90aDocumento4 páginasASTM 675-90aManivasagan VasuAún no hay calificaciones

- QQ S 698 PDFDocumento11 páginasQQ S 698 PDFMike FiorenAún no hay calificaciones

- Welch Owners Manual1975 PDFDocumento98 páginasWelch Owners Manual1975 PDFAna Karen Landa100% (1)

- Sae Arp1331Documento12 páginasSae Arp1331niky186Aún no hay calificaciones

- Carbolite Furnace (Leading Heat Technology)Documento100 páginasCarbolite Furnace (Leading Heat Technology)Anonymous Wi2Pd2UgPIAún no hay calificaciones

- B925-03 - Standard Practices For Production and Preparation of PM Test Specimens PDFDocumento15 páginasB925-03 - Standard Practices For Production and Preparation of PM Test Specimens PDFakjeevananthamAún no hay calificaciones

- SB 1197BDocumento9 páginasSB 1197B80proofAún no hay calificaciones

- Lo 10-3530-205-12-1Documento4 páginasLo 10-3530-205-12-1AdvocateAún no hay calificaciones

- Nas 1329Documento4 páginasNas 1329randoll jamesAún no hay calificaciones

- LEONARDO Brochure CompressedDocumento9 páginasLEONARDO Brochure CompressedEmmanuel Rei Zamora0% (1)

- MS15001ADocumento1 páginaMS15001ApradellesAún no hay calificaciones

- ASNA2536-collars CortaduraDocumento6 páginasASNA2536-collars CortaduraCurro Espadafor Fernandez AmigoAún no hay calificaciones

- QQ S 698Documento11 páginasQQ S 698Mike FiorenAún no hay calificaciones

- Wiring Diagram Manual (525A-0300 and On)Documento1911 páginasWiring Diagram Manual (525A-0300 and On)francklin1912Aún no hay calificaciones

- Mil H 6875GDocumento29 páginasMil H 6875Gfordsho95Aún no hay calificaciones

- Phenolics TableDocumento2 páginasPhenolics TableKULDEEP THAKUR100% (1)

- ASTM E 1219 99 Exam Penet Fluoresc Lavable SolventeDocumento6 páginasASTM E 1219 99 Exam Penet Fluoresc Lavable SolventeMarisol VivianoAún no hay calificaciones

- TM 10-4930-238-12PDocumento180 páginasTM 10-4930-238-12PAdvocateAún no hay calificaciones

- Asna 2531 2006-09 K 2Documento7 páginasAsna 2531 2006-09 K 2Speeder JohnAún no hay calificaciones

- A356.0 Alloy DetailDocumento2 páginasA356.0 Alloy DetailAdrian LimantoAún no hay calificaciones

- Carbolite Gero General PDFDocumento128 páginasCarbolite Gero General PDFzsmithAún no hay calificaciones

- Ura-Zen Plus Polyurethane Topcoat Revision: October 2015: Product Description Physical PropertiesDocumento2 páginasUra-Zen Plus Polyurethane Topcoat Revision: October 2015: Product Description Physical PropertiesJustformedia JustformediaAún no hay calificaciones

- A-A 59503A (Nitrogen)Documento6 páginasA-A 59503A (Nitrogen)mtcengineeringAún no hay calificaciones

- Astm B 138 - B 138M - 06Documento4 páginasAstm B 138 - B 138M - 06Ramsi AnkziAún no hay calificaciones

- DCS AJS-37 Viggen Guide PDFDocumento148 páginasDCS AJS-37 Viggen Guide PDFBorna JosipovićAún no hay calificaciones

- 2 USDoD-ANC-18-Design of Wood Aircraft StructuresDocumento242 páginas2 USDoD-ANC-18-Design of Wood Aircraft Structuresd2meyerAún no hay calificaciones

- Asna2025: Docmaster: Uncontrolled Copy When PrintedDocumento5 páginasAsna2025: Docmaster: Uncontrolled Copy When Printedpym31Aún no hay calificaciones

- Component of End Item ListingDocumento128 páginasComponent of End Item ListingEsidro HernandezAún no hay calificaciones

- Ferolite: Ferolite NAM39 Ferolite NAM37Documento4 páginasFerolite: Ferolite NAM39 Ferolite NAM37Lizandro zapata nievesAún no hay calificaciones

- CUCV SINCGARS RadioDocumento50 páginasCUCV SINCGARS RadioSteven KnightAún no hay calificaciones

- SAE AMS 5516p-2012Documento5 páginasSAE AMS 5516p-2012Mehdi MokhtariAún no hay calificaciones

- COMMANDER 114B Ilustrated Parts CatalogDocumento488 páginasCOMMANDER 114B Ilustrated Parts CatalogRik AraujAún no hay calificaciones

- SAEJ1512 V 001Documento2 páginasSAEJ1512 V 001koalaboiAún no hay calificaciones

- Astm 510Documento7 páginasAstm 510Arnold Bohorquez Acevedo100% (1)

- 052892Documento84 páginas052892starsalingsoul8000Aún no hay calificaciones

- JB Nas77Documento1 páginaJB Nas77Xto PeregrinAún no hay calificaciones

- 711100Documento1147 páginas711100duythienddtAún no hay calificaciones

- Astm A513 PDFDocumento3 páginasAstm A513 PDFgaminAún no hay calificaciones

- F-15 Park Jet Plans Assembly Drawing TiledDocumento2 páginasF-15 Park Jet Plans Assembly Drawing TiledNestor Omar AmbesiAún no hay calificaciones

- The ABC's of Nondestructive Weld ExaminationDocumento11 páginasThe ABC's of Nondestructive Weld ExaminationKeng LengAún no hay calificaciones

- TM10-7360-206-23P Kitchen TrailermountedDocumento216 páginasTM10-7360-206-23P Kitchen TrailermounteddieudecafeAún no hay calificaciones

- ISO 3452 Dye Penetration Test - Liquid Penetrant Examination Magnaflux InstructionDocumento2 páginasISO 3452 Dye Penetration Test - Liquid Penetrant Examination Magnaflux InstructionMurshidi MarzukiAún no hay calificaciones

- Dye Penetrant Operating Instructions: How To Use Your Spotcheck KitDocumento2 páginasDye Penetrant Operating Instructions: How To Use Your Spotcheck Kitiscristin26Aún no hay calificaciones

- How To Do Visible Dye Penetrant TestingDocumento2 páginasHow To Do Visible Dye Penetrant TestingSrikanth Kabbal MAún no hay calificaciones

- Dye Penetrant TestDocumento4 páginasDye Penetrant TestRavi kumarAún no hay calificaciones

- How To Do Fluorescent Penetrant TestingDocumento2 páginasHow To Do Fluorescent Penetrant TestingLina Balanta - Taesmet SasAún no hay calificaciones

- EinScan-PRO-H BrochureDocumento8 páginasEinScan-PRO-H BrochurejimoteAún no hay calificaciones

- Worldskills Mechanical EngineeringDocumento8 páginasWorldskills Mechanical EngineeringrajatAún no hay calificaciones

- 640314-En Manual Pirometro VogelDocumento5 páginas640314-En Manual Pirometro VogeljimoteAún no hay calificaciones

- Catalogo NordLockDocumento16 páginasCatalogo NordLockjimoteAún no hay calificaciones

- Integrated Finite Elements Analysis and Design of StructuresDocumento50 páginasIntegrated Finite Elements Analysis and Design of Structuresaeiou321Aún no hay calificaciones

- Design of Lifting and Tailing LugsNetsc001Documento30 páginasDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Catalogo - Seals Hidraulic HALLITE CasdelDocumento321 páginasCatalogo - Seals Hidraulic HALLITE CasdelCarlos Alberto Coaguila Torres100% (1)

- Machine Shop Inspection Form 5.82Documento3 páginasMachine Shop Inspection Form 5.82jimoteAún no hay calificaciones

- Komatsu TruckDocumento16 páginasKomatsu TruckLuis Ramirez100% (1)

- TYCO Burbach Knife-Gate - Valves.vk enDocumento2 páginasTYCO Burbach Knife-Gate - Valves.vk enjimoteAún no hay calificaciones

- ASTM A36 Steel, Plate - Material Property DataDocumento1 páginaASTM A36 Steel, Plate - Material Property DatajimoteAún no hay calificaciones

- Magnaflux - Shelf Life SpanishDocumento1 páginaMagnaflux - Shelf Life SpanishjimoteAún no hay calificaciones

- SolidWorks Guide Efficient TeamDocumento12 páginasSolidWorks Guide Efficient TeamjimoteAún no hay calificaciones

- Polymer TestingDocumento5 páginasPolymer TestingjimoteAún no hay calificaciones

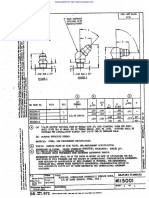

- Welding Neck Flanges RF 150 LbsDocumento4 páginasWelding Neck Flanges RF 150 LbsjimoteAún no hay calificaciones

- GSM 06 InterfacesDocumento17 páginasGSM 06 Interfacesamitcool26Aún no hay calificaciones

- Standard Operating Procedure-Standard Maintenace ProcedureDocumento11 páginasStandard Operating Procedure-Standard Maintenace ProcedureVikram JitAún no hay calificaciones

- IntegratingBIMTechnologyintoLA (2014) PDFDocumento115 páginasIntegratingBIMTechnologyintoLA (2014) PDFArnaldo RuizAún no hay calificaciones

- 8.3 Solving Equilibrium Problems For Bases (SCH4U)Documento3 páginas8.3 Solving Equilibrium Problems For Bases (SCH4U)Michelle NgAún no hay calificaciones

- Va Mri Design Plan Drawings and LayoutDocumento19 páginasVa Mri Design Plan Drawings and Layoutkusnanto erinAún no hay calificaciones

- Design and Analysis For Crane HookDocumento6 páginasDesign and Analysis For Crane Hookmukeshsonava076314Aún no hay calificaciones

- Kleene ClosureDocumento6 páginasKleene ClosurepbhmmmmAún no hay calificaciones

- Non Vital BleachingDocumento19 páginasNon Vital BleachingPriyabrat Pattanaik100% (1)

- Technical Specification of Stay InsulatorDocumento11 páginasTechnical Specification of Stay Insulatorraj_stuff006Aún no hay calificaciones

- VECU - Manual de Producción 70312913Documento33 páginasVECU - Manual de Producción 70312913RainorSS100% (2)

- Shower CatalogueDocumento36 páginasShower CataloguekavyaAún no hay calificaciones

- Marking and Ordering Code System (Capacitors)Documento6 páginasMarking and Ordering Code System (Capacitors)José TurinAún no hay calificaciones

- Manual COMPRESOR DEWALT PDFDocumento56 páginasManual COMPRESOR DEWALT PDFJorgeBrambilaAún no hay calificaciones

- Civil Works BuildingDocumento22 páginasCivil Works BuildingSarinAún no hay calificaciones

- Catalyser: Magnetic Effects of Electric Current Faculty Sheet SolutionDocumento4 páginasCatalyser: Magnetic Effects of Electric Current Faculty Sheet SolutionShalika SinhaAún no hay calificaciones

- Weidmuller HazLoc Catalog 2014 LIT1315EDocumento12 páginasWeidmuller HazLoc Catalog 2014 LIT1315Evaseem shaikAún no hay calificaciones

- 01-09-04MIL On, DTCs P1545, P0121, P0123, P0221 or P0222 Stored in ECM Fault MemoryDocumento7 páginas01-09-04MIL On, DTCs P1545, P0121, P0123, P0221 or P0222 Stored in ECM Fault MemoryKilobyte202005Aún no hay calificaciones

- MSC PracticalsDocumento13 páginasMSC PracticalslinubinoyAún no hay calificaciones

- AISC Properties ViewerDocumento3 páginasAISC Properties ViewerrubenAún no hay calificaciones

- Cs6212 Programming and Data Structures Laboratory I Laboratory ManualDocumento28 páginasCs6212 Programming and Data Structures Laboratory I Laboratory Manualprasath_676303Aún no hay calificaciones

- VSL Technical Report - PT ExternalDocumento36 páginasVSL Technical Report - PT ExternalTran Nguyen KhiemAún no hay calificaciones

- Inlet DuctDocumento14 páginasInlet DuctAhmad ArmanAún no hay calificaciones

- Topic 05 All Possible QuestionsDocumento9 páginasTopic 05 All Possible QuestionsMaxamed Cabdi KariimAún no hay calificaciones

- Freno Motor ISMDocumento6 páginasFreno Motor ISMFabiiam Kiimtero100% (2)

- Design and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesDocumento26 páginasDesign and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesVijay SakhareAún no hay calificaciones

- 06-DC Compound MotorDocumento44 páginas06-DC Compound MotorN. iManAún no hay calificaciones

- SAIC-Q-1043 Asphalt Core Density Testing InspectionDocumento3 páginasSAIC-Q-1043 Asphalt Core Density Testing InspectionAbdul HannanAún no hay calificaciones

- SEPG and Consulting ProcessDocumento20 páginasSEPG and Consulting ProcesszafzAún no hay calificaciones

- 3-Oracle Application Framework (OAF) Training Guide - EO, VO, Page, Query Region, LOV, PPRDocumento73 páginas3-Oracle Application Framework (OAF) Training Guide - EO, VO, Page, Query Region, LOV, PPRPreethi KishoreAún no hay calificaciones