Documentos de Académico

Documentos de Profesional

Documentos de Cultura

ASME V Interpretations

Cargado por

JuankgxTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

ASME V Interpretations

Cargado por

JuankgxCopyright:

Formatos disponibles

ASME BOILER AND PRESSURE VESSEL CODE

SECTION V

INTERPRETATIONS

Volume 62

Interpretations of the Code will be posted in January and July of 2014 and January of 2015 at http://cstools.asme.org/

interpretations.cfm. Interpretations of Section III, Divisions 1 and 2, are part of the update service to Section III, Subsection NCA.

Interpretations Volumes 60 and 61 were included with the update service to the 2010 Edition of the Code; Volume 62 is

the first Interpretations volume to be included with the update service to the 2013 Edition.

Section

--`,,,,```,`,```,,,`,,,,`,````,-`-`,,`,,`,`,,`---

I

II-A

II-B

II-C

II-D (Customary)

II-D (Metric)

III-NCA

III-3

III-5

IV

V

VI

VII

VIII-1

VIII-2

VIII-3

IX

X

XI

XII

Copyright ASME International (BPVC)

Provided by IHS under license with ASME X

No reproduction or networking permitted without license from IHS

Vol. 62

7/13

7/13

7/13

7/13

7/13

7/13

7/13

7/13

7/13

7/13

7/13

7/13

7/13

7/13

7/13

Licensee=BP International/5928366101

Not for Resale, 11/19/2013 07:35:55 MST

--`,,,,```,`,```,,,`,,,,`,````,-`-`,,`,,`,`,,`---

Copyright 2013 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All rights reserved

Copyright ASME International (BPVC)

Provided by IHS under license with ASME X

No reproduction or networking permitted without license from IHS

Licensee=BP International/5928366101

Not for Resale, 11/19/2013 07:35:55 MST

SECTION V INTERPRETATIONS VOL. 62

INTERPRETATIONS VOLUME 62 SECTION V

Replies to Technical Inquiries January 1, 2011 through December 31, 2012

FOREWORD

GENERAL INFORMATION

This publication includes all written interpretations issued between the indicated dates by the ASME Staff on behalf of

the ASME Boiler and Pressure Vessel Committee in response to inquiries concerning interpretations of the ASME Boiler

and Pressure Vessel Code. A contents is also included that lists subjects specific to the interpretations covered in the individual volume.

These interpretations are taken verbatim from the original letters, except for a few typographical and editorial corrections made for the purpose of improved clarity. In some instances, a review of the interpretation revealed a need for corrections of a technical nature. In these cases, a revised interpretation is presented bearing the original interpretation

number with the suffix R and the original file number with an asterisk. Following these revised interpretations, new interpretations and revisions to them issued during the indicated dates are assigned interpretation numbers in chronological order. Interpretations applying to more than one Code Section appear with the interpretations for each affected

Section.

ASME procedures provide for reconsideration of these interpretations when or if additional information is available

that the inquirer believes might affect the interpretation. Further, persons aggrieved by an interpretation may appeal

to the cognizant ASME committee or subcommittee. As stated in the Statement of Policy in the Code documents, ASME

does not approve, certify, rate, or endorse any item, construction, proprietary device, or activity.

An interpretation applies either to the Edition and Addenda in effect on the date of issuance of the interpretation or the

Edition and Addenda stated in the interpretation. Subsequent revisions to the Code may supersede the interpretation.

For detailed instructions, see "Submittal of Technical Inquiries to the ASME Boiler and Pressure Vessel Standards Committees" in the front matter.

SUBJECT AND NUMERICAL INDEXES

Subject and numerical indexes (if applicable) have been prepared to assist the user in locating interpretations by subject matter or by location in the Code. They cover interpretations issued from Volume 12 up to and including the present

volume, and will be updated with each volume.

--`,,,,```,`,```,,,`,,,,`,````,-`-`,,`,,`,`,,`---

Copyright ASME International (BPVC)

Provided by IHS under license with ASME X

No reproduction or networking permitted without license from IHS

225

Licensee=BP International/5928366101

Not for Resale, 11/19/2013 07:35:55 MST

SECTION V INTERPRETATIONS VOL. 62

Subject

Interpretation

Article 2, Mandatory Appendix VIII, VIII-210 (2007 Edition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Article 2, T-276.2(a) (2010 Edition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Article 4, Mandatory Appendix III (2010 Edition), Proper Calibration Blocks for Piping Examinations

When Using TOFD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Article 4, T-434.3 and Article 5, T-534.2 (2010 Edition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Article 6, T-642 (2010 Edition), Surface Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Article 6, Table T-621 (2004 Edition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Article 9, T-921.3 (2010 Edition), Demonstration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UT Requirements for Forgings Examined per SA-388/SA-388M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V-10-01

V-10-06

08-1626

10-1445

V-10-02

V-10-05

V-10-07

V-10-03

V-10-04

V-10-08

09-1539

10-1860

11-381

10-1452

10-1649

11-1265

--`,,,,```,`,```,,,`,,,,`,````,-`-`,,`,,`,`,,`---

226

Copyright ASME International (BPVC)

Provided by IHS under license with ASME X

No reproduction or networking permitted without license from IHS

Licensee=BP International/5928366101

Not for Resale, 11/19/2013 07:35:55 MST

File No.

SECTION V INTERPRETATIONS VOL. 62

Interpretation: V-10-01

Subject: Article 2, Mandatory Appendix VIII, VIII-210 (2007 Edition)

Date Issued: April 19, 2011

File: 08-1626

Question: Which paragraphs of Article 2, Mandatory Appendix III are applicable to computed radiography (phosphor

imaging plate) applications performed in accordance with Article 2, Mandatory Appendix VIII?

Reply: Paragraph III-286 of Article 2, Mandatory Appendix III is applicable.

Interpretation: V-10-02

Subject: Article 4, Mandatory Appendix III (2010 Edition), Proper Calibration Blocks for Piping Examinations When Using

TOFD

Date Issued: April 19, 2011

File: 09-1539

Question: Is it the intent of Article 4, Mandatory Appendix III that for the examination of a weld in a pipe, the basic

calibration block shown in Fig. III-434.2.1(a) is to be used?

Reply: Yes.

Interpretation: V-10-03

Subject: Article 6, Table T-621 (2004 Edition)

Date Issued: April 19, 2011

File: 10-1452

Question: Table T-621 lists minimum and maximum time periods between steps as an essential variable to be addressed in the written procedure. Per T-643, is it necessary to establish only a minimum time for cleaning solutions to

dry?

Reply: Yes.

Interpretation: V-10-04

Subject: Article 9, T-921.3 (2010 Edition), Demonstration

Date Issued: April 19, 2011

File: 10-1649

Question: When a procedure has been demonstrated to the satisfaction of the Inspector, does each subsequent examination performed to that procedure require demonstration?

Reply: No.

227

--`,,,,```,`,```,,,`,,,,`,````,-`-`,,`,,`,`,,`---

Copyright ASME International (BPVC)

Provided by IHS under license with ASME X

No reproduction or networking permitted without license from IHS

Licensee=BP International/5928366101

Not for Resale, 11/19/2013 07:35:55 MST

SECTION V INTERPRETATIONS VOL. 62

Interpretation: V-10-05

Subject: Article 4, T-434.3 and Article 5, T-534.2 (2010 Edition)

Date Issued: October 11, 2011

File: 10-1860

Question: Paragraph T-434.3 of Article 4 indicates that the piping calibration block thickness shall be within 25% of

the nominal thickness of the component to be examined. Paragraph T-534.2 of Article 5 indicates that casting calibration

blocks shall be the same thickness 25% as the castings to be examined. Do the different wordings of these two paragraphs actually specify identical requirements?

Reply: Yes.

Interpretation: V-10-06

Subject: Article 2, T-276.2(a) (2010 Edition)

Date Issued: June 20, 2012

File: 10-1445

Question: Paragraph T-276.2(a) of Article 2 indicates that, for welds with reinforcement, the IQI is based on the nominal

single-wall thickness plus the estimated weld reinforcement not to exceed the maximum permitted by the referencing

Code Section. Does the term weld reinforcement, as used in T-276.2(a), include both external and internal reinforcement

when both are present?

Reply: Yes.

Interpretation: V-10-07

Subject: Article 6, T-642 (2010 Edition), Surface Preparation

Date Issued: June 20, 2012

File: 11-381

Question: According to T-642(a), surface preparation by grinding, machining, or other methods may be necessary

where surface irregularities could mask indications on parts in the as-welded, as-rolled, as-cast, or as-forged conditions.

According to Table T-621, surface preparation is an essential variable. Does T-621.2 require the demonstration of all surface preparation methods and surface cleaning methods listed in the procedure?

Reply: In accordance with T-150(a), the procedure is required to be demonstrated to the satisfaction of the Inspector.

228

--`,,,,```,`,```,,,`,,,,`,````,-`-`,,`,,`,`,,`---

Copyright ASME International (BPVC)

Provided by IHS under license with ASME X

No reproduction or networking permitted without license from IHS

Licensee=BP International/5928366101

Not for Resale, 11/19/2013 07:35:55 MST

SECTION V INTERPRETATIONS VOL. 62

Interpretation: V-10-08

Subject: UT Requirements for Forgings Examined per SA-388/SA-388M

Date Issued: June 20, 2012

File: 11-1265

Question (1): Paragraph 8.3.3 of SA-388/SA-388M in Article 23 specifies that when both the I.D. and O.D. notch can be

detected, the examination must be performed from the hollow forgings outside diameter. May indications detected during the scanning from the outside surface be further evaluated from the inside surface?

Reply (1): Neither T-571.2 of Article 5 nor SA-388/SA-388M in Article 23 contain alternate techniques for the further

evaluation of detected indications.

Question (2): Paragraph 8.3.3 of SA-388/SA-388M in Article 23 specifies that the reference line is required to be drawn

through the peaks of the first reflections obtained from the I.D. and O.D. notches. How far beyond the notch peaks is the

reference line to be drawn?

Reply (2): Neither T-571.2 of Article 5 nor SA-388/SA-388M in Article 23 specify the distance beyond the notch peaks

that the reference line is to be drawn.

Question (3): If an indication is detected when performing an angle beam examination per SA-388/SA-388M, and its

sweep position is prior to the first I.D. notch or after the first O.D. notch positions, how is it to be evaluated?

Reply (3): Neither T-571.2 of Article 5 nor SA-388/SA-388M in Article 23 specify how an indication appearing prior to

the first I.D. notch or after the first O.D. notch is to be evaluated.

229

--`,,,,```,`,```,,,`,,,,`,````,-`-`,,`,,`,`,,`---

Copyright ASME International (BPVC)

Provided by IHS under license with ASME X

No reproduction or networking permitted without license from IHS

Licensee=BP International/5928366101

Not for Resale, 11/19/2013 07:35:55 MST

INTENTIONALLY LEFT BLANK

--`,,,,```,`,```,,,`,,,,`,````,-`-`,,`,,`,`,,`---

Copyright ASME International (BPVC)

Provided by IHS under license with ASME X

No reproduction or networking permitted without license from IHS

230

Licensee=BP International/5928366101

Not for Resale, 11/19/2013 07:35:55 MST

También podría gustarte

- Astm e 1001Documento9 páginasAstm e 1001KEN KAún no hay calificaciones

- Methodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesDocumento1 páginaMethodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesEphraim John Tangelon AquinoAún no hay calificaciones

- Acoustic EmissionDocumento10 páginasAcoustic Emissionzamaniu1Aún no hay calificaciones

- Ect MAD 8D Calibration Procedure: Using The Vertical Volts MethodDocumento7 páginasEct MAD 8D Calibration Procedure: Using The Vertical Volts MethodShanmukhaTeliAún no hay calificaciones

- SOP-030 - Rev0 Mic10 Mic20Documento2 páginasSOP-030 - Rev0 Mic10 Mic20Stephen LewellenAún no hay calificaciones

- Industrial radiography A Complete Guide - 2019 EditionDe EverandIndustrial radiography A Complete Guide - 2019 EditionAún no hay calificaciones

- Procedure Qualification Requirements For Flaw SizingDocumento2 páginasProcedure Qualification Requirements For Flaw SizingAngelTinocoAún no hay calificaciones

- ASME Code Case 2600 PDFDocumento2 páginasASME Code Case 2600 PDFrotero_pujolAún no hay calificaciones

- PA Probe Catalog en 201308Documento24 páginasPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaAún no hay calificaciones

- E797e797m 21Documento9 páginasE797e797m 21Jlaraneda SantiagoAún no hay calificaciones

- Measuring Ultrasonic Velocity in Materials by Comparative Pulse-Echo MethodDocumento14 páginasMeasuring Ultrasonic Velocity in Materials by Comparative Pulse-Echo MethodRoman D100% (1)

- Se 797Documento7 páginasSe 797donaldoguerreroAún no hay calificaciones

- AGR Field Operations TD Focus-Scan Data SheetDocumento2 páginasAGR Field Operations TD Focus-Scan Data SheetJeganeswaranAún no hay calificaciones

- Thickness Gauging Level 2 (Questions & Answers)Documento3 páginasThickness Gauging Level 2 (Questions & Answers)kingston100% (2)

- E390-11 Standard Reference Radiographs For Steel Fusion WeldsDocumento4 páginasE390-11 Standard Reference Radiographs For Steel Fusion WeldsAhmed Shaban KotbAún no hay calificaciones

- Air Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsDocumento4 páginasAir Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsTim WilsonAún no hay calificaciones

- Ut ProcedureDocumento7 páginasUt Procedurearavindan100% (1)

- Form PAUTDocumento2 páginasForm PAUTLuong Ho Vu100% (1)

- Code Case 181-2 Section 7 & 8 Flaw Evaluation Worksheet (Short)Documento81 páginasCode Case 181-2 Section 7 & 8 Flaw Evaluation Worksheet (Short)庄查理Aún no hay calificaciones

- ASME BPVC-Section V: Key Changes 2019 EditionDocumento7 páginasASME BPVC-Section V: Key Changes 2019 EditionArjun RawatAún no hay calificaciones

- BS 583-3 PDFDocumento10 páginasBS 583-3 PDFwiAún no hay calificaciones

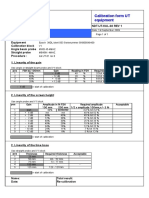

- Calibration Sheet Ultrasonic Test EquipmentDocumento1 páginaCalibration Sheet Ultrasonic Test EquipmentjohnAún no hay calificaciones

- DGS DiagramDocumento3 páginasDGS DiagramDhanasekaran R100% (1)

- Liquid Penetrant Testing Procedure - IDocumento2 páginasLiquid Penetrant Testing Procedure - IManivannanMudhaliarAún no hay calificaciones

- Article 4 Metodo UltrasonidoDocumento24 páginasArticle 4 Metodo UltrasonidoLessly Lorena Apala RamirezAún no hay calificaciones

- Astm E1065 E1065m 20Documento10 páginasAstm E1065 E1065m 20Mohamed AboelkhierAún no hay calificaciones

- Certification and personnel qualification for ultrasonic testing of steel plateDocumento8 páginasCertification and personnel qualification for ultrasonic testing of steel plateNooruddin SheikAún no hay calificaciones

- Calibration BlocksDocumento3 páginasCalibration BlocksvenkatAún no hay calificaciones

- Simulation and experiments of tandem ultrasonic techniquesDocumento10 páginasSimulation and experiments of tandem ultrasonic techniquesAbd Rahman AliasAún no hay calificaciones

- Sa 263Documento8 páginasSa 263Wagner Renato AraújoAún no hay calificaciones

- Astm E1025 PDFDocumento6 páginasAstm E1025 PDFmga_4566472Aún no hay calificaciones

- ASME P-NumbersDocumento9 páginasASME P-NumbersAamer MohammedAún no hay calificaciones

- E1936-97 Evaluating Digitization SystemsDocumento4 páginasE1936-97 Evaluating Digitization SystemsNDT Div, MedequipAún no hay calificaciones

- PAUT of ''CRA WELDSDocumento7 páginasPAUT of ''CRA WELDSDurgamadhaba Mishra100% (1)

- Chapter 1: "Phased Array Introduction and Principles": Practice QuestionsDocumento5 páginasChapter 1: "Phased Array Introduction and Principles": Practice QuestionsMarcus Antonius100% (1)

- PCN TOFD Rules and QuestionsDocumento12 páginasPCN TOFD Rules and QuestionsIslam FawzyAún no hay calificaciones

- Ruane MTDocumento40 páginasRuane MT9703422499Aún no hay calificaciones

- Sizing Piping Calibration Blocks For ASME V: Holloway NDT & Engineering IncDocumento5 páginasSizing Piping Calibration Blocks For ASME V: Holloway NDT & Engineering IncJulio SaintDLCAún no hay calificaciones

- En 1713 (1998) - NDTDocumento20 páginasEn 1713 (1998) - NDTTaesik Kim100% (1)

- NDT-Verify Steel WeldsDocumento1 páginaNDT-Verify Steel Weldskinglordofato100% (1)

- When Is CP-189 RequiredDocumento3 páginasWhen Is CP-189 RequiredAhmad DanielAún no hay calificaciones

- High Temperature Ultrasonic ScanningDocumento7 páginasHigh Temperature Ultrasonic ScanningscribdmustaphaAún no hay calificaciones

- National Step Tablet Vs Step Wedge Comparision FilmDocumento4 páginasNational Step Tablet Vs Step Wedge Comparision FilmManivannanMudhaliarAún no hay calificaciones

- 4 5847992272976611240 PDFDocumento8 páginas4 5847992272976611240 PDFAyyappanSubramanianAún no hay calificaciones

- ULTRASONIC TESTING PROCEDUREDocumento14 páginasULTRASONIC TESTING PROCEDUREshifa0% (1)

- NDT RT NDS1Documento46 páginasNDT RT NDS1naganathanAún no hay calificaciones

- Ultrasonic Testing BasicsDocumento51 páginasUltrasonic Testing BasicsJohn OLiverAún no hay calificaciones

- Sa 435 (Ed 2013)Documento4 páginasSa 435 (Ed 2013)Mohd Idris MohiuddinAún no hay calificaciones

- VT For NDT - 2017Documento29 páginasVT For NDT - 2017Selvakpm06Aún no hay calificaciones

- 1 Paut ReportDocumento1 página1 Paut ReportAhmedAún no hay calificaciones

- API UT21 ThicknessProcedure 20190304Documento7 páginasAPI UT21 ThicknessProcedure 20190304michaelAún no hay calificaciones

- Astm e 426Documento4 páginasAstm e 426김경은Aún no hay calificaciones

- Astm e 1158Documento5 páginasAstm e 1158KEN KAún no hay calificaciones

- PAUT - Phased Array and ToFD - V - Radiography PDFDocumento14 páginasPAUT - Phased Array and ToFD - V - Radiography PDFdarouichAún no hay calificaciones

- E2906E2906M-13 Standard Practice For Acoustic Pulse Reflectometry Examination of Tube BundlesDocumento6 páginasE2906E2906M-13 Standard Practice For Acoustic Pulse Reflectometry Examination of Tube BundlesMohamed100% (1)

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989De EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookAún no hay calificaciones

- Welding Chapter9Documento38 páginasWelding Chapter9JuankgxAún no hay calificaciones

- 38 W 4Documento3 páginas38 W 4JuankgxAún no hay calificaciones

- Weldinghuide Eng BohlerDocumento515 páginasWeldinghuide Eng BohlerJorge VasquezAún no hay calificaciones

- ASME Code Requirements PDFDocumento5 páginasASME Code Requirements PDFsusanwebAún no hay calificaciones

- Effects of Alloying Elements on Steel PropertiesDocumento2 páginasEffects of Alloying Elements on Steel PropertiesAhmedAún no hay calificaciones

- Effects of Alloying Elements on Steel PropertiesDocumento2 páginasEffects of Alloying Elements on Steel PropertiesAhmedAún no hay calificaciones

- EOTA TR29 Design of Bonded AnchorsDocumento36 páginasEOTA TR29 Design of Bonded Anchorsl282Aún no hay calificaciones

- GEIT 20117EN - Ultrasonic Transducer CatalogDocumento47 páginasGEIT 20117EN - Ultrasonic Transducer CatalogMd Firoz Alam KhanAún no hay calificaciones

- Digital Ultrasonic Flaw Detector Operation ManualDocumento70 páginasDigital Ultrasonic Flaw Detector Operation ManualJuankgx80% (5)

- Welding Data DictionaryDocumento74 páginasWelding Data Dictionarygohjh80Aún no hay calificaciones

- Defectologia Radiografia AgfaDocumento21 páginasDefectologia Radiografia AgfaJuankgxAún no hay calificaciones

- Science Technology & SocietyDocumento24 páginasScience Technology & SocietyJuankgxAún no hay calificaciones

- LT 9Documento2 páginasLT 9ariwibowoAún no hay calificaciones

- Manufacturing ProcessesDocumento2 páginasManufacturing ProcessespmagrawalAún no hay calificaciones

- Nancy Stern Hofstra University Robert A. Stern: Nassau Community CollegeDocumento79 páginasNancy Stern Hofstra University Robert A. Stern: Nassau Community CollegeVinod MallaAún no hay calificaciones

- C# .NET Lab Manual for 4th Sem BCA StudentsDocumento34 páginasC# .NET Lab Manual for 4th Sem BCA Studentssreenu_pes100% (1)

- 1 Introduction To DatabasesDocumento23 páginas1 Introduction To DatabasesJoana Key Abat SalvadorAún no hay calificaciones

- Finalize Resume - ZetyDocumento2 páginasFinalize Resume - ZetyAlok KulkarniAún no hay calificaciones

- ADE X5 Quick Guide 1.0Documento2 páginasADE X5 Quick Guide 1.0rosasojedaAún no hay calificaciones

- Chakrir Potrika-4 - 3-2016Documento8 páginasChakrir Potrika-4 - 3-2016Uddyam TawfiqAún no hay calificaciones

- Transport Layer: Unit - IVDocumento19 páginasTransport Layer: Unit - IVHarishmaAún no hay calificaciones

- IOT Protocols and Overview (SSI)Documento29 páginasIOT Protocols and Overview (SSI)Strategic Systems InternationalAún no hay calificaciones

- Toshiba FAB EMMC-1511507Documento3 páginasToshiba FAB EMMC-1511507Wagner WagrilloAún no hay calificaciones

- DN2800MT ProductGuide02 English PDFDocumento62 páginasDN2800MT ProductGuide02 English PDFP_I_P_HAún no hay calificaciones

- Titanium Gr. 2 Pipe Schedule and WeightsDocumento2 páginasTitanium Gr. 2 Pipe Schedule and WeightsKiran Kumar KondapalliAún no hay calificaciones

- Design of Normal Concrete Mixes: D C Teychenné, R E Franklin, H C Erntroy, D W Hobbs, B K MarshDocumento9 páginasDesign of Normal Concrete Mixes: D C Teychenné, R E Franklin, H C Erntroy, D W Hobbs, B K MarshSamuel SinteiAún no hay calificaciones

- RebarCAD Usage Hints and Tips PDFDocumento8 páginasRebarCAD Usage Hints and Tips PDFVijayAún no hay calificaciones

- Over The Rainbow Lesson PlanDocumento4 páginasOver The Rainbow Lesson Planapi-279598006Aún no hay calificaciones

- Ncom N102Documento16 páginasNcom N102RixroxAún no hay calificaciones

- 1xEV RF Optimization Guidelines R24Documento83 páginas1xEV RF Optimization Guidelines R24lady_sAún no hay calificaciones

- Hidraulic Hammers Yekn0343Documento12 páginasHidraulic Hammers Yekn0343Andy DellepianeAún no hay calificaciones

- LG 42lh40ed (-Sa) 42lh45ed (-SB) Chassis Lj92jDocumento76 páginasLG 42lh40ed (-Sa) 42lh45ed (-SB) Chassis Lj92jJose Fco. Aleman Arriaga100% (1)

- Ruskin Fd-35 SubmittalDocumento4 páginasRuskin Fd-35 SubmittalNedunuri.Madhav MurthyAún no hay calificaciones

- Catalogo Particulas PM10PM25 - T640 Sales LiteratureDocumento2 páginasCatalogo Particulas PM10PM25 - T640 Sales LiteraturePedro PerezAún no hay calificaciones

- Lab Security PolicyDocumento5 páginasLab Security PolicyPhan TomAún no hay calificaciones

- JSON Guide - Data Interchange Format Specification and History"TITLE"Intro to JSON - JavaScript Object Notation Definition and UsageDocumento18 páginasJSON Guide - Data Interchange Format Specification and History"TITLE"Intro to JSON - JavaScript Object Notation Definition and UsageAnirudh BellamkondaAún no hay calificaciones

- Modbus PVC To PowerFlex4MDocumento4 páginasModbus PVC To PowerFlex4MEduardo Pinto VargasAún no hay calificaciones

- ADLY Bullseye Owners ManualDocumento45 páginasADLY Bullseye Owners ManualAnna RyanAún no hay calificaciones

- BS en 12507-2010Documento18 páginasBS en 12507-2010Yonathan Kristiawan B HutapeaAún no hay calificaciones

- TDS - Masterflow 648CPDocumento3 páginasTDS - Masterflow 648CPVenkata RaoAún no hay calificaciones

- Objectwindows Tutorial: Turbo C ++Documento172 páginasObjectwindows Tutorial: Turbo C ++Lalit SinghAún no hay calificaciones

- Anac CF34 Engine PDFDocumento10 páginasAnac CF34 Engine PDFEstevamAún no hay calificaciones