Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Valves Quality Control Plan

Cargado por

jok1974Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Valves Quality Control Plan

Cargado por

jok1974Copyright:

Formatos disponibles

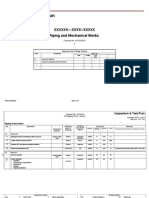

Page :

TEMPLATE D0010861

SPX Cooling Technologies

VALVE(S) Quality Control Plan

- AIRCOOLED STEAM CONDENSER (ACC)

SPX Ref. Nr

: WB1-101-000467_QCP4840_

File Nr.

Date

: D0204482_

18/07/2014

Client

Issued by

Approved by

: CBR

: SNA

This inspection plan is intended to inform the vendor about the minimum extent of inspection foreseen for the order by SPX Contractor, Client and/or their representatives.

RD = Review Documentation (test report)

Pos. Rev.

2

2.1

Test description

HP = Hold Point

RTC = Review Test Certificate

Evaluation

criteria / codes

Inspection codes

END CLIENT

Vendor

SPX

Client

DATE

Code Sign. Code Sign. Code Sign. Code Sign. (month/year)

RD

Conform to requisition / valve list

ANSI

Valve list

RD

RD

RD

RD

Conform to requisition / valve list

RD

RD

DIN 50049 - 3.1. / EN 10204 - 3.1.

RD

RD

RD

RD

RD

RD

RD

RD

Vendor internal quality system

Conform to WPS, applicable codes

According to WPS, applicable codes

RD

RD

All

According to code(s):ANSI

Result conform to code(s):ANSI

RD

RI

All

Conform to code(s):ANSI/API

RD

RI

Conform to requisition / datasheet

RD

RI

RI

RI

All

2.2

Drawings

All

2.3

Valve data

3

3.1

0

0

WP = Witness Point

Execution

procedures / codes

RD

Check vendor/

subvendor certification

DESIGN

Design standard

3.2

RI = Random Inspection

Test

Frequency

or %

Review agreement

Approved vendor

Vendor internal quality system

ANSI

Vendor internal quality system

1 per type Vendor internal quality system

MATERIAL

Raw material certificates

1 per batch

pressure parts

Raw material certificates

1 per batch

non pressure parts

WELDING DOCUMENTS

WPQ / WQ / WPQR

All

(if applicable)

WPS / ( weldmap )

All

(if applicable)

VISUAL WELDING EXAMINATION

All welds

100%

Check certificates ( type )

or ASTM equivalent

Check certificates ( type )

DIN 50049 - 2.2 / EN 10204 - 2.2

or ASTM equivalent

4

4.1

4.2

5

5.1

10

10.1

10.2

TESTING

(Hydrostatic) pressure test

(1.5 * design pressure)

Seat leakage test

10.3

Functional test with actuator

All

According to code(s):

ANSI/API

Vendor internal quality system

11

11.1

VISUAL MATERIAL CHECK

Quantity and type

All

Vendor internal quality system

Conform to requisition / valve list

11.2

Dimensional check

Sampling

Vendor internal quality system

Conform to ( vendor ) drawing / ANSI

RI/RD

RI

11.3

Sampling

Vendor internal quality system

Conform to requisition / drawing

RI/RD

RI

11.4

Auxiliaries

(fixation,material etc )

Preservation

Sampling

Vendor internal quality system

Conform to requisition

RI/RD

RI

11.5

Tagging

Sampling

Vendor internal quality system

Conform to requisition

RI

RI

11.6

All

Vendor internal quality system

Conform to requisition

RI

RI

12

12.1

Packing & Marking

Transport preparation

GENERAL

Final inspection

All

According to ( vendor ) quality plan

Conform to contractual documents

RD

RI

12.2

Review manuals

Conform to requisition

RD

RD

Note :

Vendor internal quality system

ASME IX

According vendor standard

1 per type

Vendor internal quality control plan is also applicable.

Approval stamp on welding documents

ASME IX

WPS certified by WPQ

PLACE

1 /1

También podría gustarte

- ITP-000 Piping Fabrication (Exemple)Documento5 páginasITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- 400kV Transmission Lines Materials TenderDocumento69 páginas400kV Transmission Lines Materials Tenderahmadove1Aún no hay calificaciones

- Factory Production ControlDocumento7 páginasFactory Production ControlSandy D. RockAún no hay calificaciones

- Supplier ITP Inspection PlanDocumento4 páginasSupplier ITP Inspection PlanHassan SajidAún no hay calificaciones

- Sintex Bapl LTD Quality Procedure Manual: Customer Satisfaction Feedback FormDocumento1 páginaSintex Bapl LTD Quality Procedure Manual: Customer Satisfaction Feedback FormJitesh KumarAún no hay calificaciones

- GS 118-4 Storage and Control of Welding Consumables: August 1997Documento14 páginasGS 118-4 Storage and Control of Welding Consumables: August 1997Mohd KhairulAún no hay calificaciones

- ITP Kheirgoo - Arsanjan Gas Compressor Stations Project ITP for Flange MaterialsDocumento6 páginasITP Kheirgoo - Arsanjan Gas Compressor Stations Project ITP for Flange MaterialsHamid Taghipour ArmakiAún no hay calificaciones

- Drawing Distribution RecordDocumento2 páginasDrawing Distribution RecordsufiyaAún no hay calificaciones

- 10 - Annexure - 01 - Exception Deviation Clarification FormDocumento1 página10 - Annexure - 01 - Exception Deviation Clarification FormAmit SharmaAún no hay calificaciones

- Qam 3Documento35 páginasQam 3Arunachalam AvanashiAún no hay calificaciones

- SAUNDERS Industrial Diaphragm ValvesDocumento52 páginasSAUNDERS Industrial Diaphragm ValvesGohilakrishnan ThiagarajanAún no hay calificaciones

- Change Request Log TemplateDocumento3 páginasChange Request Log TemplatevrsreeAún no hay calificaciones

- Purchase 1Documento20 páginasPurchase 1N.Usha RaoAún no hay calificaciones

- Process Control Plan SCM100113Documento14 páginasProcess Control Plan SCM100113aravindhAún no hay calificaciones

- Safety Relief Valve - Selection, Operation & TroubleShootingDocumento2 páginasSafety Relief Valve - Selection, Operation & TroubleShootingMohamed AlkhawagaAún no hay calificaciones

- Quality Assurance Manual: MIL-STD-45208ADocumento37 páginasQuality Assurance Manual: MIL-STD-45208AJessica JamesAún no hay calificaciones

- RFPGlovesAug2019 Compressed PDFDocumento112 páginasRFPGlovesAug2019 Compressed PDFKULDEEP KUMARAún no hay calificaciones

- Outsourcing and ISO 9001Documento62 páginasOutsourcing and ISO 9001Mihai GradAún no hay calificaciones

- Resume Suda Mara IDocumento5 páginasResume Suda Mara IMd AkhtarAún no hay calificaciones

- Vendor InspectionDocumento3 páginasVendor Inspectionzahid_497100% (1)

- Certificate of Conformity Document SummaryDocumento1 páginaCertificate of Conformity Document SummaryVipin Rana100% (1)

- RMA and ReturnsDocumento19 páginasRMA and Returnsविजय शर्माAún no hay calificaciones

- Contractor Daily Quality Control ReportDocumento1 páginaContractor Daily Quality Control Reportpuivgi2012Aún no hay calificaciones

- AB-518b Quality Manual and Audit ChecklistDocumento24 páginasAB-518b Quality Manual and Audit ChecklistStan Lee PaulsonAún no hay calificaciones

- ISO 9001 Quality Manual-WOLSTDocumento29 páginasISO 9001 Quality Manual-WOLSTSergioAún no hay calificaciones

- Section 5 - Supplier Quality Surveillance: 1.0 GeneralDocumento3 páginasSection 5 - Supplier Quality Surveillance: 1.0 Generalanishgirme100% (1)

- Certificate of Conformance 31Documento1 páginaCertificate of Conformance 31Jose Ruiz (Externo)Aún no hay calificaciones

- Design FMEA and Quality ChecklistsDocumento16 páginasDesign FMEA and Quality ChecklistsDevendra GandhiAún no hay calificaciones

- ATEX Unit VerificationDocumento16 páginasATEX Unit VerificationJairo WilchesAún no hay calificaciones

- QSP-010 R0 QSP For Field Inspection & Test PlanDocumento21 páginasQSP-010 R0 QSP For Field Inspection & Test PlanjennyAún no hay calificaciones

- Dimensional Inspection Report: Sample Production Lot/BatchDocumento1 páginaDimensional Inspection Report: Sample Production Lot/BatchCristina TinaAún no hay calificaciones

- Method Statement OF Air Blowing / Water Flushing of PipesDocumento19 páginasMethod Statement OF Air Blowing / Water Flushing of Pipesarun kumarAún no hay calificaciones

- Supplier Performance Evaluation - CPQ205.0615 - Rev. 3Documento2 páginasSupplier Performance Evaluation - CPQ205.0615 - Rev. 3karupukamalAún no hay calificaciones

- ITP For Bolts & NutsDocumento6 páginasITP For Bolts & NutsHamid Taghipour ArmakiAún no hay calificaciones

- NS-1-10. Material CertificationDocumento6 páginasNS-1-10. Material CertificationWHWENAún no hay calificaciones

- Part Sample WarrantDocumento1 páginaPart Sample WarrantmageroteAún no hay calificaciones

- NCR Supplier Scorecard ProcessDocumento11 páginasNCR Supplier Scorecard ProcesssamcbsivAún no hay calificaciones

- SSPC QN 1 Audit ChecklistDocumento9 páginasSSPC QN 1 Audit Checklistdatuk2Aún no hay calificaciones

- Manufacturing Process AuditDocumento3 páginasManufacturing Process AuditVaishaliYadavAún no hay calificaciones

- (Signed) Quality Manual Revision K 7th EditionDocumento32 páginas(Signed) Quality Manual Revision K 7th EditionCricri Cri100% (1)

- Production and Storage ProcedureDocumento3 páginasProduction and Storage ProcedurePeracha EngineeringAún no hay calificaciones

- QM and Process Flow Chart BKT SideDocumento3 páginasQM and Process Flow Chart BKT SideDebashis SarkarAún no hay calificaciones

- Bidding & Contract ReviewDocumento8 páginasBidding & Contract ReviewreineckedjAún no hay calificaciones

- Wartsila India Ltd Boiler Hydro Test ProcedureDocumento2 páginasWartsila India Ltd Boiler Hydro Test ProcedureKarthi KeyanAún no hay calificaciones

- GQADocumento26 páginasGQARaduz HaduzAún no hay calificaciones

- Butt Fusion Procedure - r201505 PDFDocumento15 páginasButt Fusion Procedure - r201505 PDFTsihatesfaAún no hay calificaciones

- Quality ManualDocumento43 páginasQuality ManualSunil Jaglan0% (1)

- Iso 1500 Iso 1000 Iso 680 Iso 460 Iso 320 Iso 220 Iso 150 Iso 100Documento1 páginaIso 1500 Iso 1000 Iso 680 Iso 460 Iso 320 Iso 220 Iso 150 Iso 100coleiroAún no hay calificaciones

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocumento6 páginasFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoAún no hay calificaciones

- NPI - Project Quality PlanDocumento2 páginasNPI - Project Quality PlanVirginia GrandoAún no hay calificaciones

- S 296001 QAA With Production Material SuppliersDocumento9 páginasS 296001 QAA With Production Material Suppliersbytzu89Aún no hay calificaciones

- Sae Air81d PDFDocumento12 páginasSae Air81d PDFfarhad pashaei mehrAún no hay calificaciones

- Itp HeDocumento15 páginasItp HeAldeline SungahidAún no hay calificaciones

- 6743 6 52 0053Documento72 páginas6743 6 52 0053svijay1969100% (1)

- Inspection and Test Plan For Pressure Reliving Devices 1707841397Documento16 páginasInspection and Test Plan For Pressure Reliving Devices 1707841397BernathTurnipAún no hay calificaciones

- SM 001 SRV SpecDocumento5 páginasSM 001 SRV Specvardan_vardanAún no hay calificaciones

- Inspection & Test PlanDocumento19 páginasInspection & Test Planaszliza100% (1)

- Pressure Safety Valves SDRL Rev 1Documento3 páginasPressure Safety Valves SDRL Rev 1salesAún no hay calificaciones

- Anubar SpecDocumento8 páginasAnubar SpecSHIVAJI CHOUDHURYAún no hay calificaciones

- Consortium (Ioic) Inspection and Test Plan/Quality Control PlanDocumento3 páginasConsortium (Ioic) Inspection and Test Plan/Quality Control PlanRushabh KapadiaAún no hay calificaciones

- Paint Inspection:: Daily Coating Inspection ReportDocumento1 páginaPaint Inspection:: Daily Coating Inspection ReportEhsan KhanAún no hay calificaciones

- Arc Welding of Nonferrous MetalsDocumento83 páginasArc Welding of Nonferrous Metalsapply19842371Aún no hay calificaciones

- Inspection & Test Plans 1 of 50Documento49 páginasInspection & Test Plans 1 of 50jok1974Aún no hay calificaciones

- TESTINGDocumento7 páginasTESTINGSoner Kulte100% (1)

- AWS D10.4,10.6,10.7,10.8,10.10,10.11,10.12,10.13 Committee Recommended Practices For WeldingDocumento148 páginasAWS D10.4,10.6,10.7,10.8,10.10,10.11,10.12,10.13 Committee Recommended Practices For Weldinglram7083% (6)

- Q&A-15 How Polarity Affects Electrode Performance in Arc WeldingDocumento1 páginaQ&A-15 How Polarity Affects Electrode Performance in Arc Weldingnineapril82Aún no hay calificaciones

- Preventingdelayedcracks in Ship WeldsDocumento20 páginasPreventingdelayedcracks in Ship WeldsWahyu Nur ArifiantoAún no hay calificaciones

- Arc BlowDocumento3 páginasArc BlowApostolie IulianAún no hay calificaciones

- BS en 20898-1-1992Documento26 páginasBS en 20898-1-1992consultach100% (4)

- Jazz Theory Resources - Volume1& 2Documento498 páginasJazz Theory Resources - Volume1& 2zmenendez1100% (3)

- The Shielding Gas Handbook - AGADocumento79 páginasThe Shielding Gas Handbook - AGAjok1974100% (1)

- PantechSteel CatalogueDocumento36 páginasPantechSteel Cataloguejok1974Aún no hay calificaciones

- Weld Duplex Ss SteelDocumento12 páginasWeld Duplex Ss SteelSan JaAún no hay calificaciones

- Precision machining parametersDocumento1 páginaPrecision machining parametersjok1974Aún no hay calificaciones

- PQR Template (Asme)Documento2 páginasPQR Template (Asme)jok1974Aún no hay calificaciones

- The Shielding Gas Handbook - AGADocumento79 páginasThe Shielding Gas Handbook - AGAjok1974100% (1)

- Max Safe Working Pressure PipesDocumento1 páginaMax Safe Working Pressure Pipesjok1974Aún no hay calificaciones

- Maintenance and Repair Welding On Board (UNITOR)Documento1 páginaMaintenance and Repair Welding On Board (UNITOR)jok1974100% (1)

- FillermetalsDocumento2 páginasFillermetalsjok1974Aún no hay calificaciones

- Sajjad Hussain Sociology 2021 Iiui IsbDocumento323 páginasSajjad Hussain Sociology 2021 Iiui IsbTaskeen MansoorAún no hay calificaciones

- Derivation of Root Means Square (RMS Voltage)Documento1 páginaDerivation of Root Means Square (RMS Voltage)Wilson (Electrical Engineer)Aún no hay calificaciones

- Understanding culture through sociological perspectivesDocumento3 páginasUnderstanding culture through sociological perspectivesAnjaneth Cabutin0% (1)

- Cumene-to-phenol process & future production of phenolDocumento2 páginasCumene-to-phenol process & future production of phenolChaiwatTippuwanan100% (2)

- Mizpah Community Christian Academe Inc.: 3rd Periodical Test Understanding CultureDocumento4 páginasMizpah Community Christian Academe Inc.: 3rd Periodical Test Understanding CultureGabriel YuAún no hay calificaciones

- Project Report BCA Final Year-AayushDocumento36 páginasProject Report BCA Final Year-Aayushaayush83% (6)

- Sas Lesson - MathDocumento6 páginasSas Lesson - Mathapi-280008473Aún no hay calificaciones

- Bulk Storage SilosDocumento5 páginasBulk Storage SilosMiran VidovićAún no hay calificaciones

- Soc300 Final Study GuideDocumento3 páginasSoc300 Final Study GuidenoudlezzAún no hay calificaciones

- Scepticism and Animal Rationality: The Fortune of Chrysippus' Dog in The History of Western ThoughtDocumento31 páginasScepticism and Animal Rationality: The Fortune of Chrysippus' Dog in The History of Western ThoughtNicolás Antonio Rojas CortésAún no hay calificaciones

- Siemens Arrester Hand Book PDFDocumento120 páginasSiemens Arrester Hand Book PDFRatilal M JadavAún no hay calificaciones

- RAS06 Delta Module2 Features & Main ParametersDocumento123 páginasRAS06 Delta Module2 Features & Main ParametersRadiowiecAún no hay calificaciones

- Market Research Company in IndiaDocumento8 páginasMarket Research Company in Indiaaditya adityaAún no hay calificaciones

- Assignment 1 - ProsperDocumento9 páginasAssignment 1 - ProsperMuhammad Amirullah SanadiAún no hay calificaciones

- MCT-MST Summative Teaching Placement Assessment Rubric - EPC 4406 - 17 PagesDocumento17 páginasMCT-MST Summative Teaching Placement Assessment Rubric - EPC 4406 - 17 PagesHuda HamadAún no hay calificaciones

- JapaneseDocumento250 páginasJapaneseAlberto VillalbaAún no hay calificaciones

- The Origins of Anglo-Saxon Kingdoms PDFDocumento361 páginasThe Origins of Anglo-Saxon Kingdoms PDFEric DubourgAún no hay calificaciones

- How To Do Magic That Works by Genevieve DavisDocumento114 páginasHow To Do Magic That Works by Genevieve DavisFarzad ArabiAún no hay calificaciones

- Young Pianist CompetitionDocumento2 páginasYoung Pianist CompetitionAleksa SarcevicAún no hay calificaciones

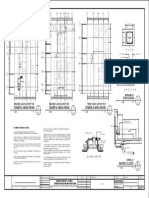

- Cath Basin: Detailed ofDocumento1 páginaCath Basin: Detailed ofGwapo AkoAún no hay calificaciones

- 2-Amino-5-Aryl-2-Oxazolines.: (,ee TableDocumento7 páginas2-Amino-5-Aryl-2-Oxazolines.: (,ee TableChristopher HowellAún no hay calificaciones

- 06 - SS - 09082021 To 20082021 Bridge, SR - DEnDocumento52 páginas06 - SS - 09082021 To 20082021 Bridge, SR - DEnAl OkAún no hay calificaciones

- Karen Horney Abduls PDFDocumento31 páginasKaren Horney Abduls PDFlala123Aún no hay calificaciones

- B777 Fuel SystemsDocumento0 páginasB777 Fuel Systemsandrinjo100% (3)

- The Past Question of Physics Wassce in 2022 - Google SearchDocumento1 páginaThe Past Question of Physics Wassce in 2022 - Google SearchMessi Ronaldo Saha100% (2)

- E-Viva Werkplaatshandboek PDFDocumento76 páginasE-Viva Werkplaatshandboek PDFAntónio PedrosaAún no hay calificaciones

- ADANI POWER LIMITED: POWERING INDIA'S GROWTH WITH A 2030 OUTLOOKDocumento26 páginasADANI POWER LIMITED: POWERING INDIA'S GROWTH WITH A 2030 OUTLOOKAnonymous V4jDKjUR6Aún no hay calificaciones

- 14902-37163-1-PB JPVDocumento12 páginas14902-37163-1-PB JPVridwanAún no hay calificaciones

- Bus 428Documento236 páginasBus 428Emeka Ken Nwosu100% (1)

- Artificial - Intelligence - Master Program - SlimupDocumento25 páginasArtificial - Intelligence - Master Program - Slimupswapnil suryawanshiAún no hay calificaciones