Documentos de Académico

Documentos de Profesional

Documentos de Cultura

2.2L Engine PDF

Cargado por

Ulises Perez CandiaDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

2.2L Engine PDF

Cargado por

Ulises Perez CandiaCopyright:

Formatos disponibles

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

2003 ENGINE

Engine Mechanical - 2.2L (L61) - Saturn L Series

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Fastener Tightening Specifications

Specification

Application

A/C Compressor-to-Block Bolt

Air Pipe Bolts

Air Pipe Nut

Balance Shaft Chain Guide (Adjustable) Bolt

Balance Shaft Chain Guide (Fixed) Bolts

Balance Shaft Chain Guide (Upper) Bolts

Balance Shaft Chain Tensioner Bolts

Balance Shaft Drive Sprockets

Balance Shaft Retaining Bolts

Ball Stud-to-Steering Knuckle Nuts

Battery Terminal Bolts

Cam Cover Bolts-to-Hold J 43649 . See Special Tools and

Equipment.

Camshaft Bearing Cap Bolts

Camshaft Cover Bolts

Camshaft Cover Ground Strap Fastener

Camshaft Sprocket Bolts

First Pass

Metric

25 N.m

25 N.m

16 N.m

10 N.m

10 N.m

10 N.m

10 N.m

55 N.m

10 N.m

100 N.m

17 N.m

English

18 lb ft

18 lb ft

11 lb ft

89 lb in

89 lb in

89 lb in

89 lb in

41 lb ft

89 lb in

74 lb ft

13 lb ft

10 N.m

89 lb in

10 N.m

10 N.m

10 N.m

89 lb in

89 lb in

89 lb in

85 N.m

63 lb ft

30 degrees

Final Pass

Connecting Rod Bolts

25 N.m

First Pass

18 lb ft

100 degrees

Final Pass

Coolant Jacket Plug

20 N.m

15 lb in

Crankshaft Bearing Cap Initial Torque (Lower Crankcase-to-Block Bolts)

20 N.m

15 lb ft

First Pass

70 degrees

Final Pass

Crankshaft Damper Pulley Bolt

First Pass

Final Pass

100 N.m

74 lb ft

75 degrees

steve

Monday, May 09, 2011 12:52:16

12:51:59 PM

Page 1

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Crankshaft Position Sensor Bolt

Crankshaft Pulley Bolt

First Pass

10 N.m

89 lb in

100 N.m

74 lb ft

75 degrees

Final Pass

Cylinder Head Air Bleed Tube Fastener

Cylinder Head Bolts

First Pass

15 N.m

11 lb in

30 N.m

22 lb ft

155 degrees

Final Pass

Cylinder Head Front Bolts

Cylinder Head Front Chaincase Bolts

Cylinder Head Oil Gallery Plug

Degas Hose Bracket Bolt

Drive Belt Tensioner Bolt

EGR Cover Bolts

Engine Coolant Temperature Sensor

Engine Harness Bracket Bolts

Engine Mount Bracket-to-Engine Bolts

Engine Mount-to-Body Bolts

Engine Mount-to-Engine Mount Bracket Bolts

Exhaust Manifold Heat Shield Bolts

Exhaust Manifold Pipe-to-Exhaust Manifold Nuts

Exhaust Manifold Pipe-to-Resonator Bolts

Exhaust Manifold Studs-to-Cylinder Head

Exhaust Manifold-to-Cylinder Head Nuts

Flywheel Bolt

First Pass

35 N.m

20 N.m

35 N.m

10 N.m

45 N.m

25 N.m

20 N.m

10 N.m

90 N.m

55 N.m

55 N.m

25 N.m

30 N.m

20 N.m

10 N.m

12 N.m

26 lb ft

15 lb ft

26 lb ft

89 lb in

33 lb ft

18 lb ft

15 lb ft

89 lb in

66 lb ft

41 lb ft

41 lb ft

18 lb ft

22 lb ft

15 lb ft

89 lb in

9 lb ft

53 N.m

39 lb ft

25 degrees

Final Pass

Front Cover-to-Block Bolts

Fuel Line Bolt

Fuel Rail Bracket Stud

Ignition Coil-to-Camshaft Cover Bolts

Intake Camshaft Rear Bearing Cap Bolts

Intake Manifold Studs

Intake Manifold-to-Cylinder Head Bolts

Intake Manifold-to-Cylinder Head Nuts

Intake Manifold-to-Cylinder Head Studs

Knock Sensor Bolt

Knock Sensor-to-Engine Block Bolt

Lower Crankcase-to-Block Peripheral Bolts

25 N.m

10 N.m

10 N.m

8 N.m

25 N.m

6 N.m

10 N.m

10 N.m

6 N.m

25 N.m

25 N.m

25 N.m

18 lb ft

89 lb in

89 lb in

71 lb in

18 lb ft

56 lb in

89 lb in

89 lb in

60 lb in

18 lb in

18 lb ft

18 lb ft

steve

Monday, May 09, 2011 12:51:59 PM

Page 2

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Lower Engine-to-Transmission Bell Housing Bolts

Oil Drain Plug

Oil Filter Cap

Oil Gallery Plug

Oil Gallery Plug (Rear)

Oil Level Indicator Tube-to-Intake Manifold Bolt

Oil Pan-to-Block Bolts

Oil Pressure Switch

Oil pump Gerotor Cover Bolts

Oil Pump Pressure Relief Valve Plug

Oxygen Sensor Bolts

Power Steering Pump Bolts

Shift Control Rod Pinch Bolt

First Pass

65 N.m

25 N.m

25 N.m

35 N.m

60 N.m

10 N.m

25 N.m

10 N.m

6 N.m

40 N.m

30 N.m

25 N.m

48 lb ft

18 lb ft

18 lb ft

26 lb ft

44 lb ft

89 lb in

18 lb ft

89 lb in

53 lb in

3 lb in

22 lb ft

18 lb ft

12 N.m

9 lb ft

180 degrees

Final Pass

Spark Plugs

Stabilizer Link-to-Strut Assembly

Steering Gear-to-Intermediate Shaft Pinch Bolt

Support Plate-to-Engine Block

Suspension Support Bolts

First Pass

20 N.m

65 N.m

30 N.m

10 N.m

15 lb ft

50 lb ft

22 lb ft

89 lb in

100 N.m

74 lb ft

45 degrees

Final Pass

Thermostat Housing-to-Block Bolts

Throttle Body Bolts

Throttle Body Nuts

Throttle Body Studs-to-Cylinder Head

Tie Rod end Linkage Installer

Tie Rod Nut

Timing Chain Guide (Adjustable) Bolt

Timing Chain Guide (Fixed) Bolts

Timing Chain Guide (Upper) Bolts

Timing Chain Guide Bolt Access Hole Plug

Timing Chain Oil Nozzle Bolt

Timing Chain Tensioner Bolts

Torque Converter Bolts

Transmission Nose Bracket Bolts

Upper Bell Housing Bolts

Water Pump Bolts

Wheel Bolts (Final Torque)

Wheel Bolts (Initial Torque)

10 N.m

10 N.m

10 N.m

6 N.m

45 N.m

60 N.m

10 N.m

10 N.m

10 N.m

40 N.m

10 N.m

75 N.m

75 N.m

35 N.m

65 N.m

25 N.m

125 N.m

63 N.m

89 lb in

89 lb in

89 lb in

60 lb in

35 lb ft

45 lb ft

89 lb in

89 lb in

89 lb in

30 lb ft

89 lb in

55 lb ft

55 lb ft

26 lb ft

48 lb ft

18 lb ft

92 lb ft

46 lb ft

steve

Monday, May 09, 2011 12:51:59 PM

Page 3

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

ENGINE MECHANICAL SPECIFICATIONS

Engine Mechanical Specifications

Specification

Application

Metric

English

General Data

Engine Type

Displacement

RPO

Liter (VIN)

Bore

Inline 4 Cylinder

2.2 L

134 CID

L61

F

85.992-86.008 mm

3.3855-3.3861 in

9.5:01

Compression Ratio

Balance Shaft

0.030-0.063 mm

0.0012-0.0025 in

Bearing Diameter - Inside - Carrier

20.050-20.063 mm

0.7894-0.7899 in

Bearing Diameter - Outside - Carrier

41.975-41.995 mm

1.6526-1.6534 in

Bearing Journal Diameter

20.000-20.020 mm

0.7874-0.7882 in

Bushing Clearance

0.033-0.102 mm

0.0013-0.0040 in

Bushing Diameter - Inside

36.776-36.825 mm

1.4479-1.4498 in

Bushing Journal Diameter

36.723-36.743 mm

1.4458-1.4466 in

End Play

0.100-0.300 mm

0.0020-0.0118 in

Bearing Clearance

Block

Balance Shaft Bearing Bore Diameter - Carrier

42.000-42.016 mm

1.6535-1.6542 in

Balance Shaft Bushing Bore Diameter

40.763-40.776 mm

1.6048-1.6054 in

Crankshaft Main Bearing Bore Diameter

64.068-64.082 mm

2.5224-2.5229 in

Cylinder Bore Diameter

85.992-86.008 mm

3.3855-3.3861 in

Cylinder Bore Out-of-Round - Maximum

0.010 mm

0.0004 in

Cylinder Bore Taper - Maximum

0.010 mm

0.0004 in

Cylinder Head Deck Surface Flatness - Transverse

0.030 mm

0.0012 in

Cylinder Head Deck Surface Flatness - Longitude

0.050 mm

0.002 in

0.08 mm

0.0031 in

0.040-0.144 mm

0.0016-0.0057 in

Cylinder Head Deck Surface Flatness - Overall

Camshaft

Camshaft End Play

Camshaft Journal Diameter

26.935-26.960 mm

1.0604-1.0614 in

Camshaft Thrust Surface

21.000-21.052 mm

0.8268-0.8252 in

steve

Monday, May 09, 2011 12:51:59 PM

Page 4

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Connecting Rod

0.029-0.069 mm

0.0011-0.0027 in

Connecting Rod Bore Diameter - Bearing End

52.118-52.134 mm

2.0519-2.05252 in

Connecting Rod Bore Diameter - Pin End

20.007-20.021 mm

0.7877-0.7882 in

Connecting Rod Side Clearance

0.070-0.370 mm

0.0028-0.0146 in

Connecting Rod Straightness - Bend - Maximum

0.021 mm

0.0083 in

Connecting Rod Straightness - Twist - Maximum

Crankshaft

0.04 mm

0.0157 in

49.000-49.014 mm

1.9291-1.9297 in

Connecting Rod Bearing Clearance

Connecting Rod Journal Diameter

Crankshaft End Play

0.050-0.380 mm

0.0012-0.0150 in

Crankshaft Main Bearing Clearance

0.031-0.067 mm

0.0012-0.0026 in

55.994-56.008 mm

2.2045-2.2050 in

Crankshaft Main Journal Diameter

Cylinder Head

Surface Flatness - Block Deck - Transverse

0.030 mm

0.0012 in

Surface Flatness - Block Deck - Longitude

0.050 mm

0.002 in

Surface Flatness - Block Deck - Overall

0.1 mm

0.004 in

Valve Guide Bore - Exhaust

6.000-6.012 mm

0.2362-0.2367 in

Valve Guide Bore - Intake

6.000-6.012 mm

0.2362-0.2367 in

Valve Lifter Bore Diameter - Stationary Lash

Adjusters

Lubrication System

12.013-12.037 mm

0.4730-0.4739 in

Oil Pressure - Minimum - @1000 RPM

Piston Rings

344.75-551.60 kPa

50-80 psi

Piston Ring End Gap - First Compression Ring

0.20-0.40 mm

0.008-0.016 in

Piston Ring End Gap - Second Compression Ring

0.35-0.55 mm

0.014-0.022 in

Piston Ring End Gap - Oil Control Ring - Rails

0.25-0.76 mm

0.010-0.030 in

Piston Ring to Groove Clearance - First Compression

Ring

0.04-0.08 mm

0.0015-0.0031 in

Piston Ring to Groove Clearance - Second

Compression Ring

0.030-0.069 mm

0.0012-0.0027 in

Piston Ring to Groove Clearance - Oil Control Ring

0.090-0.106 mm

0.0035-0.0042 in

Piston Ring Thickness - First Compression Ring

1.170-1.190 mm

0.0461-0.0469 in

Piston Ring Thickness - Second Compression Ring

1.471-1.490 mm

0.0579-0.0587 in

Piston Ring Thickness - Oil Control Ring - Rail Maximum

0.43 mm

0.0169 in

steve

Monday, May 09, 2011 12:51:59 PM

Page 5

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Piston Ring Thickness - Oil Control Ring - Spacer

Pistons and Pins

1.574-1.651 mm

0.0620-0.0650 in

Piston - Piston Diameter - @14.5 mm up

85.967-85.982 mm

3.3845-3.3851 in

Piston - Piston Pin Bore Diameter

20.002-20.007 mm

0.07875-0.7877 in

Piston - Piston Ring Grove Width - Top

1.23-1.25 mm

0.0484-0.0492 in

Piston - Piston Ring Grove Width - Second

1.52-1.54 mm

0.0598-0.0606 in

Piston - Piston Ring Grove Width - Oil Control

2.52-2.54 mm

0.0992-0.1000 in

Piston - Piston To Bore Clearance

0.010-0.041 mm

0.0004-0.0016 in

Pin - Piston Pin Clearance to Connecting Rod Bore

0.007-0.026 mm

0.0003-0.0010 in

Pin - Piston Pin Clearance to Piston Pin Bore

0.002-0.012 mm

0.0001-0.0005 in

Pin - Piston Pin Diameter

19.995-20.000 mm

0.7872-0.7874 in

0.19-1.16 mm

0.0075-0.0461 in

Pin - Piston Pin End Play

Valve System

Valves - Valve Face Runout - Maximum

0.04 mm

0.0016 in

Valves - Valve Seat Runout - Maximum

0.05 mm

0.0020 in

Valves - Valve Stem Diameter - Intake

5.955-5.970 mm

0.2344-0.2355 in

Valves - Valve Stem Diameter - Exhaust

5.935-5.950 mm

0.2337-0.2343 in

Valves - Valve Stem to Guide Clearance - Intake

0.030-0.057 mm

0.0012-0.0022 in

Valves - Valve Stem to Guide Clearance - Exhaust

0.050-0.077 mm

0.0020-0.0026 in

Valve Lifters - Valve Lifter Diameter - Stationary

Lash Adjuster

11.986-12.000 mm

0.0005-0.0020 in

Valve Lifters - Valve Lifter-to-Bore Clearance Stationary Lash Adjuster

0.013-0.051 mm

3.2210-3.2299 in

Valve Springs - Valve Spring Load - Closed - @32.5

mm

245.0-271.0 N. - Eng Spec.

Valve Springs - Valve Spring Load - Open - @32.5

mm

525.0-575.0 N. - Eng Spec.

SEALERS, ADHESIVES, AND LUBRICANTS

Sealers, Adhesives, and Lubricants

Application

# 6 Intake Rear Camshaft Cap

Balance Shaft Lobes

Cam Lobes

Connecting Rod Bearings

Type of Material

Sealant

Lubricant

Lubricant

Lubricant

Part Number

Permatex Anaerobic Gasket

Maker 51813

5 W 30 or equivalent

Engine Oil Supplement

5 W 30 or equivalent

steve

Monday, May 09, 2011 12:51:59 PM

Page 6

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Crank Sensor O-ring

Crankshaft Main Bearings

Cylinder Bore

Cylinder Head Plugs

Dipstick Tube O-rings

Engine Block Threaded Plugs

Engine Block To Bed Plate

Engine Oil

Engine Oil Level Indicator Tube O-ring

Fuel Injector O-rings

Fuel Injector Tip Insulators

Intake and Exhaust Valve Stems

Oil Filter Cap (Threads and O-ring Lead-in

Chamfers)

Oil Pan to Bedplate Joint

Oil Pump - Pump Elements

Oxygen Sensor Threads

Piston Pins

Stationary Hydraulic Lash Adjusters

Timing Chain Guide Bolt Access Hole Plug

Valve Rocker Arm / Valve Tip

Water Feed Tube O-rings

Water Pump Drain Plug

Engine Oil

Lubricant

Lubricant

Threadlocker

Lubricant

Sealant

Sealant

5 quarts

Lubricant

Engine Oil

Engine Oil

Lubricant

5 W 30 or equivalent

5 W 30 or equivalent

5 W 30 or equivalent

21485277

Engine Oil Supplement

21485278

21019581

5 W 30 or equivalent

Engine Oil Supplement

5 W 30 or equivalent

5 W 30 or equivalent

Engine Oil Supplement

Engine Oil

5 W 30 or equivalent

Sealant

Engine Oil

Antiseize

Lubricant

Lubricant

Threadlocker

Lubricant

Lubricant

Sealant

21019581

5 W 30 or equivalent

12397953

5 W 30 or equivalent

Engine Oil Supplement

21485277

Engine Oil Supplement

Silicone Gel Lubricant

21485278

THREAD REPAIR SPECIFICATIONS

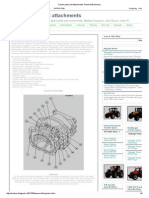

Engine Block - Front View

steve

Monday, May 09, 2011 12:51:59 PM

Page 7

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 1: Engine Block - Front View

Courtesy of GENERAL MOTORS CORP.

Engine Block - Front View

Service

Call

Thread

Counterbore

Out

Size

Insert Drill

Tool

J 423851

M10 x 1.5 215

211

212

2

M8 x 1.25 210

206

207

M12 x

3

855

856

857

1.75

4

M8 x 1.25 210

206

207

5

M6 x 1

205

201

202

6

M6 x 1

205

201

202

7

M6 x 1

205

201

202

8

M6 x 1

205

201

202

9

M8 x 1.25 210

206

207

10

M6 x 1

205

201

202

11

M6 x 1

205

201

202

12

M6 x 1

205

201

202

13

M6 x 1

205

201

202

Drill Depth

Tap Driver (Maximum)

MM (IN)

213

214 24.5 0.96

208

209 23.5 0.93

Tap Depth

(Maximum)

MM (IN)

19.5 0.77

18.5 0.73

Engineering

Hole

Number

117

109

858

859

33.5 1.32 26.5 1.04

114

208

203

203

203

203

208

203

203

203

203

209

204

204

204

204

209

204

204

204

204

23.5

20

20

20

20

25.5

20

20

20

20

110

129

130

125

126

111

127

122

128

124

0.93 18.5 0.73

0.787 16 0.63

0.787 16 0.63

0.787 16 0.63

0.787 16 0.63

1.00

THRU

0.787 16 0.63

0.787 16 0.63

0.787 16 0.63

0.787 16 0.63

steve

Monday, May 09, 2011 12:51:59 PM

Page 8

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

14

15

16

17

18

19

20

21

22

M6 x 1

M6 x 1

M6 x 1

M6 x 1

M8 x 1.25

M8 x 1.25

M8 x 1.25

M12 x

1.75

M12 x

1.75

205

205

205

205

210

210

210

201

201

201

201

206

206

206

202

202

202

202

207

207

207

203

203

203

203

208

208

208

204

204

204

204

209

209

209

20

20

20

20

23.5

55

23.5

0.787 16 0.63

0.787 16 0.63

0.787 16 0.63

0.787 16 0.63

0.93 18.5 0.73

2.17

THRU

0.93 18.5 0.73

123

131

119

120

106

112

108

855

856

857

858

859

33.5 1.32 26.5 1.04

116

855

856

857

858

859

33.5 1.32 26.5 1.04

115

Engine Block - Back View

Fig. 2: Engine Block - Back View

Courtesy of GENERAL MOTORS CORP.

Engine Block - Back View

Service

Engineering

Call

Thread

Counterbore

Drill Depth Tap Depth

Hole

Out

Size

Tool

Insert Drill

Tap Driver (Maximum) (Maximum) Number

J 42385MM (IN) MM (IN)

M12 x

steve

Monday, May 09, 2011 12:51:59 PM

Page 9

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

1

2

3

4

5

6

7

1.75

M16 x 1.5

M10 x 1.5

M8 x 1.25

855

860

215

210

854

M8 x 1.25 No

Flange

M16 x 1.5 860

M12 x

855

1.75

856

861

211

206

857

862

212

207

858

863

213

208

859

864

214

209

39

21

29

18

1.535 33.5 1.32

0.827 15 0.59

1.161

THRU

0.709

THRU

204

214

206

209

206

207

208

209

18

0.709

208

861

862

863

864

21

0.827

0.59

213

856

857

858

859

39

1.535 33.5 1.32

203

THRU

15

Engine Block - Left Side View

Fig. 3: Engine Block - Left Side View

Courtesy of GENERAL MOTORS CORP.

Engine Block - Left Side View

Service

Call

Thread

Counterbore

Drill Depth

Out

Size

Insert Drill

Tool

Tap Driver (Maximum)

J 42385MM (IN)

M12 x

1

865

856

857

858

859 19.50 0.768

1.75

Tap Depth

(Maximum)

MM (IN)

Engineering

Hole

Number

-

12.5 0.49

515

steve

Monday, May 09, 2011 12:51:59 PM

Page 10

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

2

3

4

5

6

7

8

9

10

M6 x 1.0

M12 x

1.75

M10 x 1.5

M10 x 1.5

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M12 x

1.75

205

201

202

203

204

865

856

857

858

859

19.50 0.768 12.5 0.49

514

215

215

205

205

205

205

211

211

201

201

201

201

212

212

202

202

202

202

213

213

203

203

203

203

214

214

204

204

204

204

23.50

23.50

20.50

20.50

20.50

-

0.73

0.73

0.63

0.63

0.63

521

519

513

512

511

-

865

856

857

858

859

19.50 0.768 12.5 0.49

516

0.925

0.925

0.807

0.807

0.807

-

18.5

18.5

16.0

16.0

16.0

-

Engine Block - Bottom View

Fig. 4: Engine Block - Bottom View

Courtesy of GENERAL MOTORS CORP.

Engine Block - Bottom View

steve

Monday, May 09, 2011 12:51:59 PM

Page 11

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Service

Thread

Call

Size

Out

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

M10 x 1.5

M10 x 1.5

M8 x 1.25

M10 x 1.5

M10 x 1.5

M8 x 1.25

M8 x 1.25

M10 x 1.5

M10 x 1.5

M10 x 1.5

M10 x 1.5

M8 x 1.25

M8 x 1.25

M10 x 1.5

M10 x 1.5

M8 x 1.25

M10 x 1.5

M10 x 1.5

M8 x 1.25

M10 x 1.5

M10 x 1.5

M8 x 1.25

M10 x 1.5

M10 x 1.5

M10 x 1.5

M10 x 1.5

M8 x 1.25

M10 x 1.5

M10 x 1.5

M8 x 1.25

Insert

514

514

210

514

514

210

210

514

514

514

514

210

210

514

514

210

514

514

210

514

514

210

514

514

514

514

210

514

514

210

Counterbore

Drill

Tool

J 42385511

N/A

511

N/A

206

207

511

N/A

511

N/A

206

207

206

207

511

N/A

511

N/A

511

N/A

511

N/A

206

207

206

207

511

N/A

511

N/A

206

207

511

N/A

511

N/A

206

207

511

N/A

511

N/A

206

207

511

N/A

511

N/A

511

N/A

511

N/A

206

207

511

N/A

511

N/A

206

207

Drill Depth

Tap Driver (Maximum)

MM (IN)

512

513

60 2.362

512

513

60 2.362

208

209

28 1.102

512

513

60 2.362

512

513

60 2.362

208

209

28 1.102

208

209

28 1.102

512

513

60 2.362

512

513

60 2.362

512

513

60 2.362

512

513

60 2.362

208

209

28 1.102

208

209

28 1.102

512

513

60 2.362

512

513

60 2.362

208

209

28 1.102

512

513

60 2.362

512

513

60 2.362

208

209

28 1.102

512

513

60 2.362

512

513

60 2.362

208

209

28 1.102

512

513

60 2.362

512

513

60 2.362

512

513

60 2.362

512

513

60 2.362

208

209

28 1.102

512

513

60 2.362

512

513

60 2.362

208

209

28 1.102

Tap Depth

(Maximum)

MM (IN)

53.5 2.11

53.5 2.11

22 0.87

53.5 2.11

53.5 2.11

22 0.87

22 0.87

53.5 2.11

53.5 2.11

53.5 2.11

53.5 2.11

22 0.87

22 0.87

53.5 2.11

53.5 2.11

22 0.87

53.5 2.11

53.5 2.11

22 0.87

53.5 2.11

53.5 2.11

22 0.87

53.5 2.11

53.5 2.11

53.5 2.11

53.5 2.11

22 0.87

53.5 2.11

53.5 2.11

22 0.87

Engineering

Hole

Number

1415

1408

1425

1416

1409

1426

1432

1404

1417

1422

1406

1431

1430

1412

1421

1429

1411

1420

1428

1410

1419

1427

1405

1418

1413

1403

1423

1414

1407

1424

Engine Block - Right Side View

steve

Monday, May 09, 2011 12:51:59 PM

Page 12

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 5: Engine Block - Right Side View

Courtesy of GENERAL MOTORS CORP.

Engine Block - Right Side View

Service

Call

Thread

Counterbore

Out

Size

Insert Drill

Tool

J 42385M12 x

1

865

856

857

1.75

M12 x

2

865

856

857

1.75

3

M6 x 1.0 205

201

202

M12 x

4

865

856

857

1.75

5

M8 x 1.25 210

206

207

6

M8 x 1.25 210

206

207

7

M8 x 1.25 210

206

207

M12 x

8

855

856

857

1.75

9

M8 x 1.25 210

206

207

10 M8 x 1.25 210

206

207

11 M8 x 1.25 210

206

207

12 M8 x 1.25 210

206

207

Drill Depth Tap Depth

Tap Driver (Maximum) (Maximum)

MM (IN) MM (IN)

Engineering

Hole

Number

-

858

859

19.50 0.778 12.5 0.49

613

858

859

19.50 0.778 12.5 0.49

612

203

204

20.50 0.807 16.5 .065

610

858

859

15.50 0.610 12.5 0.49

606

208

208

208

209

209

209

23.50 0.925 18.0 0.71

23.50 0.925 18.0 0.71

23.50 0.925 18.0 0.71

609

608

607

858

859

33.50 1.319 26.5 1.04

617

208

208

208

208

209

209

209

209

30.50

30.50

30.50

30.50

604

605

603

601

1.201

1.201

1.201

1.201

22.5

22.5

22.5

22.5

0.89

0.89

0.89

0.89

steve

Monday, May 09, 2011 12:51:59 PM

Page 13

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

13

14

15

M8 x 1.25

M12 x

1.75

M12 x

1.75

210

206

207

208

209

30.50 1.201 22.5 0.89

602

855

856

857

858

859

33.50 1.319 26.5 1.04

616

865

856

857

858

859

19.50 0.778 12.5 0.49

614

Engine Block - Top View

Fig. 6: Engine Block - Top View

Courtesy of GENERAL MOTORS CORP.

Engine Block - Top View

Service

Call

Thread

Counterbore

Drill Depth

Out

Size

Insert Drill

Tool

Tap Driver (Maximum)

J 42385MM (IN)

1

M11 x 1.5 507

504

N/A

505

506 113.30 4.461

Tap Depth

(Maximum)

MM (IN)

107.3 4.22

Engineering

Hole

Number

308

steve

Monday, May 09, 2011 12:51:59 PM

Page 14

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

M12 x

1.75

M11 x 1.5

M11 x 1.5

M11 x 1.5

M11 x 1.5

M11 x 1.5

M11 x 1.5

M11 x 1.5

M8 x 1.25

M8 x 1.25

M8 x 1.25

M11 x 1.5

M8 x 1.25

M11 x 1.5

M12 x

1.75

865

856

857

858

859

13.50 0.531 12.5 0.49

317

507

507

507

507

507

507

507

210

210

210

507

210

507

504

504

504

504

504

504

504

206

206

206

504

206

504

N/A

N/A

N/A

N/A

N/A

N/A

N/A

207

207

207

N/A

207

N/A

505

505

505

505

505

505

505

208

208

208

505

208

505

506

506

506

506

506

506

506

209

209

209

506

209

506

113.30

113.30

113.30

113.30

113.30

113.30

113.30

23.50

23.50

23.50

113.30

23.50

113.30

4.22

4.22

4.22

4.22

4.22

4.22

4.22

0.73

0.73

0.73

4.22

0.73

4.22

309

310

302

305

304

303

301

313

311

312

306

314

307

865

856

857

858

859

13.50 0.531 12.5 0.49

316

4.461

4.461

4.461

4.461

4.461

4.461

4.461

0.925

0.925

0.925

4.461

0.925

4.461

107.3

107.3

107.3

107.3

107.3

107.3

107.3

18.5

18.5

18.5

107.3

18.5

107.3

Lower Crankcase - Front View

Fig. 7: Identifying Front Lower Crankcase Thread Sizes

Courtesy of GENERAL MOTORS CORP.

Lower Crankcase - Front View

Service

Engineering

Thread

Counterbore

Drill Depth Tap Depth

Call

Hole

Size

Tool

Out

Insert Drill

Tap Driver (Maximum) (Maximum) Number

J 42385MM (IN) MM (IN)

1

M8 x 1.25 210

206

207

208

209 23.50 0.925 18.5 0.73

138

2

M8 x 1.25 210

206

207

208

209 30.50 1.201 25.5 1.00

139

steve

Monday, May 09, 2011 12:51:59 PM

Page 15

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

3

4

M8 x 1.25

M8 x 1.25

210

210

206

206

207

207

208

208

209

209

30.50 1.201 25.5 1.00

23.50 0.925 18.5 0.73

140

141

Lower Crankcase - Back View

Fig. 8: Identifying Rear Lower Crankcase Thread Sizes

Courtesy of GENERAL MOTORS CORP.

Lower Crankcase - Back View

Service

Engineering

Call

Thread

Counterbore

Drill Depth Tap Depth

Hole

Out

Size

Tool

Insert Drill

Tap Driver (Maximum) (Maximum) Number

J 42385MM (IN) MM (IN)

1

M10 x 1.5 215

211

212

213

214 29.50 1.161

THRU

207

Lower Crankcase - Bottom View

steve

Monday, May 09, 2011 12:51:59 PM

Page 16

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 9: Identifying Lower Bottom Crankcase Thread Sizes

Courtesy of GENERAL MOTORS CORP.

Lower Crankcase - Bottom View

Service

Call

Thread

Counterbore

Out

Size

Insert Drill

Tool

J 423851

M8 x 1.25 210

206

207

2

M8 x 1.25 210

206

207

3

M8 x 1.25 210

206

207

4

M8 x 1.25 210

206

207

5

M8 x 1.25 210

206

207

6

M8 x 1.25 210

206

207

7

M8 x 1.25 210

206

207

8

M8 x 1.25 210

206

207

9

M8 x 1.25 210

206

207

10 M8 x 1.25 210

206

207

11 M8 x 1.25 210

206

207

Drill Depth

Tap Driver (Maximum)

MM (IN)

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

208

209 23.50 0.925

Tap Depth

(Maximum)

MM (IN)

18.5 0.73

18.5 0.73

18.5 0.73

18.5 0.73

18.5 0.73

18.5 0.73

18.5 0.73

18.5 0.73

18.5 0.73

18.5 0.73

18.5 0.73

Engineering

Hole

Number

415

416

417

418

419

405

406

407

408

409

410

steve

Monday, May 09, 2011 12:52:00 PM

Page 17

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

12

13

14

15

M8 x 1.25

M8 x 1.25

M8 x 1.25

M8 x 1.25

210

210

210

210

206

206

206

206

207

207

207

207

208

208

208

208

209

209

209

209

23.50

23.50

23.50

23.50

0.925

0.925

0.925

0.925

18.5

18.5

18.5

18.5

0.73

0.73

0.73

0.73

411

412

413

414

Lower Crankcase - Left View

Fig. 10: Identifying Lower Left Crankcase Thread Sizes

Courtesy of GENERAL MOTORS CORP.

Lower Crankcase - Left View

Service

Call

Thread

Counterbore

Out

Size

Insert Drill

Tool

J 423851

M10 x 1.5 215

211

212

2

M10 x 1.5 215

211

212

3

M10 x 1.5 215

211

212

Drill Depth

Tap Driver (Maximum)

MM (IN)

213

214 28.50 1.122

213

214 28.50 1.122

213

214 28.50 1.122

Engineering

Tap Depth

Hole

(Maximum) Number

MM (IN)

22.5 0.89

518

22.5 0.89

517

22.5 0.89

520

Lower Crankcase - Right View

steve

Monday, May 09, 2011 12:52:00 PM

Page 18

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 11: Identifying Lower Right Crankcase Thread Sizes

Courtesy of GENERAL MOTORS CORP.

Lower Crankcase - Right View

Service Thread

Counterbore

Drill Depth

Call Out Size Insert Drill

Tool

Tap Driver (Maximum)

J 42385MM (IN)

M8 x

1

210

211

212

213

214 30.50 1.201

1.25

Tap Depth

(Maximum)

MM (IN)

Engineering

Hole

Number

-

22.5 0.886

615

Cylinder Head - Top View

steve

Monday, May 09, 2011 12:52:00 PM

Page 19

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 12: Cylinder Head - Top View

Courtesy of GENERAL MOTORS CORP.

Cylinder Head - Top View

Service

Call

Thread

Counterbore

Out

Size

Tool

Insert Drill

J 423851

M6 x 1.0 205

852

N/A

2

M6 x 1.0 205

852

N/A

3

M6 x 1.0 205

201

202

4

M6 x 1.0 205

201

202

5

M6 x 1.0 205

201

202

6

M6 x 1.0 205

852

N/A

7

M6 x 1.0 205

852

N/A

854

8

M8 x 1.25 No

206

207

Flange

9

M6 x 1.0 205

201

202

10

M6 x 1.0 205

201

202

11

M6 x 1.0 205

852

N/A

12

M6 x 1.0 205

852

N/A

13

M6 x 1.0 205

201

202

14

M6 x 1.0 205

201

202

Drill Depth

Tap Driver (Maximum)

MM (IN)

203

204

24 0.945

203

204

24 0.945

203

204

20 0.787

203

204

20 0.787

203

204

20 0.787

203

204

24 0.945

203

204

24 0.945

208

209

203

203

203

203

203

203

204

204

204

204

204

204

THRU

20

20

24

24

16

16

0.787

0.787

0.945

0.945

0.630

0.630

Engineering

Tap Depth

Hole

(Maximum) Number

MM (IN)

20 0.787

2515

20 0.787

2514

16 0.630

2812

16 0.630

2820

16 0.630

2710

20 0.787

2513

20 0.787

2512

THRU

2980

16 0.630

16 0.630

20 0.787

20 0.787

THRU

THRU

2811

2810

2510

2511

2910

2911

steve

Monday, May 09, 2011 12:52:00 PM

Page 20

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M8 x 1.25

M8 x 1.25

35

M8 x 1.25

36

M8 x 1.25

37

38

39

40

41

42

43

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

M6 x 1.0

205

205

205

205

205

205

205

205

205

205

205

205

205

205

205

205

205

205

210

210

854

No

Flange

854

No

Flange

210

205

205

210

210

205

205

852

852

201

201

852

852

201

852

852

201

852

852

201

201

852

852

201

201

206

206

N/A

N/A

202

202

N/A

N/A

202

N/A

N/A

202

N/A

N/A

202

202

N/A

N/A

202

202

207

207

203

203

203

203

203

203

203

203

203

203

203

203

203

203

203

203

203

203

208

208

204

204

204

204

204

204

204

204

204

204

204

204

204

204

204

204

204

204

209

209

24

24

20

20

24

24

20

24

24

20

24

24

20

20

24

24

20

20

25

25

0.945

0.945

0.787

0.787

0.945

0.945

0.787

0.945

0.945

0.787

0.945

0.945

0.787

0.787

0.945

0.945

0.787

0.787

0.984

0.984

20

20

16

16

20

20

16

20

20

16

20

20

16

16

20

20

16

16

20

20

0.787

0.787

0.630

0.630

0.787

0.787

0.630

0.787

0.787

0.630

0.787

0.787

0.630

0.630

0.787

0.787

0.630

0.630

0.787

0.787

2520

2521

2815

2816

2523

2522

2817

2525

2524

2821

2527

2526

2818

2822

2529

2528

2819

2823

2621

2622

853

N/A

208

209

25

0.984

20

0.787

2541

853

N/A

208

209

25

0.984

20

0.787

2540

206

852

852

206

206

852

852

207

N/A

N/A

207

207

N/A

N/A

208

203

203

208

208

203

203

209

204

204

209

209

204

204

20

24

24

20

20

24

24

0.787

0.945

0.945

0.787

0.787

0.945

0.945

16

20

20

16

16

20

20

0.630

0.787

0.787

0.630

0.630

0.787

0.787

2814

2519

2518

2711

2813

2517

2516

Cylinder Head - Intake Manifold Deck View

steve

Monday, May 09, 2011 12:52:00 PM

Page 21

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 13: Cylinder Head - Intake Manifold Deck View

Courtesy of GENERAL MOTORS CORP.

Cylinder Head - Intake Manifold Deck View

Service

Call

Thread

Counterbore

Out

Size

Insert Drill

Tool

J 423851

M6 x 1.0 205

201

202

2

M6 x 1.0 205

201

202

3

M6 x 1.0 205

201

202

4

M6 x 1.0 205

201

202

5

M6 x 1.0 205

201

202

6

M6 x 1.0 205

201

202

7

M6 x 1.0 205

201

202

8

M6 x 1.0 205

201

202

9

M6 x 1.0 205

201

202

Drill Depth

Tap Driver (Maximum)

MM (IN)

203

204

20 0.787

203

204

20 0.787

203

204

20 0.787

203

204

20 0.787

203

204

20 0.787

203

204

20 0.787

203

204

20 0.787

203

204

20 0.787

203

204

20 0.787

Engineering

Tap Depth

Hole

(Maximum) Number

MM (IN)

16 0.630

4117

16 0.630

4116

16 0.630

4115

16 0.630

4114

16 0.630

4113

16 0.630

4112

16 0.630

4111

16 0.630

4110

16 0.630

4118

Cylinder Head - Exhaust Manifold Deck View

steve

Monday, May 09, 2011 12:52:00 PM

Page 22

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 14: Cylinder Head - Exhaust Manifold Deck View

Courtesy of GENERAL MOTORS CORP.

Cylinder Head - Exhaust Manifold Deck View

Service

Thread

Counterbore

Call

Size

Insert Drill

Tool

Out

J 423851

M8 x 1.25 210

206

207

2

M8 x 1.25 210

206

207

3

M8 x 1.25 210

206

207

4

M27 x 2.0 N/A N/A

N/A

5

M8 x 1.25 210

206

207

6

M8 x 1.25 210

206

207

7

M8 x 1.25 210

206

207

8

M8 x 1.25 210

206

207

9

M8 x 1.25 210

206

207

10 M8 x 1.25 210

206

207

11

M6 x 1.0 205

201

202

12 M8 x 1.25 210

206

207

13 M8 x 1.25 210

206

207

14 M8 x 1.25 210

206

207

Drill Depth

Tap Driver (Maximum)

MM (IN)

208

209

25 0.984

208

209

25 0.984

208

209

25 0.984

N/A N/A

THRU

208

209

25 0.984

208

209

25 0.984

208

209

25 0.984

208

209

25 0.984

208

209

25 0.984

208

209

25 0.984

203

204

20 0.78

208

209

25 0.984

208

209

25 0.984

208

209

25 0.984

Tap Depth

(Maximum)

MM (IN)

20 0.78

20 0.78

20 0.78

12 0.78

20 0.78

20 0.78

20 0.78

20 0.78

20 0.78

20 0.78

16 0.630

20 0.78

20 0.78

20 0.78

Engineering

Hole

Number

3118

3119

3210

3810

3110

3111

3112

3113

3114

3115

3310

3116

3610

3117

Cylinder Head - Front View

steve

Monday, May 09, 2011 12:52:00 PM

Page 23

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 15: Cylinder Head - Front View

Courtesy of GENERAL MOTORS CORP.

Cylinder Head - Front View

Service

Call

Thread

Counterbore

Drill Depth

Out

Insert Drill

Tap Driver (Maximum)

Size

Tool

J 42385MM (IN)

1

M8 x 1.25 210

206

207

208

209

25 0.984

2

M6 x 1.0 205

201

202

203

204

20 0.787

Tap Depth

(Maximum)

MM (IN)

20 0.787

16 0.630

Engineering

Hole

Number

6310

6210

Cylinder Head - Back View

steve

Monday, May 09, 2011 12:52:00 PM

Page 24

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 16: Cylinder Head - Back View

Courtesy of GENERAL MOTORS CORP.

Cylinder Head - Back View

Service

Call

Thread

Counterbore

Out

Size

Insert Drill

Tool

J 42385M12 x

1

865

856

857

1.75

M12 x

2

865

856

857

1.75

3

M8 x 1.25 210

206

207

4

M8 x 1.25 210

206

207

M12 x

5

865

856

857

1.75

M12 x

6

865

856

857

1.75

7

M8 x 1.25 210

206

207

854

8

M8 x 1.25 No

206

207

Flange

Drill Depth Tap Depth

Tap Driver (Maximum) (Maximum)

MM (IN) MM (IN)

Engineering

Hole

Number

-

858

859

17

0.670

14

0.551

5011

858

859

17

0.670

14

0.551

5010

208

208

209

209

25

25

0.984

0.984

20

20

0.787

0.787

5031

5030

858

859

17

0.670

14

0.551

5310

858

859

17

0.670

14

0.551

5020

208

209

25

0.984

THRU

5111

208

209

25

0.984

THRU

5110

steve

Monday, May 09, 2011 12:52:00 PM

Page 25

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Note: 1, 2, 5, 6 holes are oil passages.

Cylinder Head - Bottom View

Fig. 17: Cylinder Head - Bottom View

Courtesy of GENERAL MOTORS CORP.

Cylinder Head - Bottom View

Service

Thread

Counterbore

Call

Size

Insert Drill

Tool

Out

J 42385M12 x

1

865

856

857

1.75

2

N/A

N/A N/A

N/A

3

N/A

N/A N/A

N/A

4

N/A

N/A N/A

N/A

5

N/A

N/A N/A

N/A

Engineering

Drill Depth Tap Depth

Hole

Tap Driver (Maximum) (Maximum) Number

MM (IN) MM (IN)

858

859

17

0.670

14

0.551

1510

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

1213

1212

1211

1210

COMPONENT LOCATOR

DISASSEMBLED VIEWS

steve

Monday, May 09, 2011 12:52:00 PM

Page 26

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 18: Cylinder Head and Components

Courtesy of GENERAL MOTORS CORP.

Callouts For Fig. 18

Callout

Component Name

1

Engine Oil Fill Cap

2

Ignition Module and Coil Housing Assembly Bolt

3

Ignition Module and Coil Housing Assembly

4

Camshaft Cover

5

Camshaft Cover Gasket

steve

Monday, May 09, 2011 12:52:00 PM

Page 27

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Camshaft Bearing Cap Bolt

Camshaft Bearing Cap

Fuel Rail Assembly Bolt

Fuel Line Assembly

Injector Wiring Harness

Fuel Rail Assembly (with Fuel Injectors)

Cylinder Head

Front Engine Lift Bracket

Engine Lift Bracket Bolt

Cylinder Head Bolt

Oil Flow Check Valve

Exhaust Manifold Stud

Exhaust Valve

Intake Valve

Camshaft Cover Grounding Strap Bolt

Cylinder Head Oil Passage Plug

Cylinder Head Oil Passage Plug

Spark Plug

Valve Stem Seal

Valve Spring

Valve Spring Retainer

Valve Keys

Hydraulic Lash Adjuster

Roller Finger Follower

Rear Engine Lift Bracket Bolt

Rear Engine Lift Bracket

EGR Port Cover Gasket

EGR Port Cover

EGR Port Cover Bolt

Camshaft Bearing Cap

Camshaft Bearing Cap Bolt

Camshaft Bearing Cap

Camshaft Bearing Cap Bolt

Exhaust Camshaft

Intake Camshaft

Camshaft Cover Grounding Strap

Camshaft Cover Grounding Strap Bolt

Camshaft Cover Bolt

steve

Monday, May 09, 2011 12:52:00 PM

Page 28

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 19: Engine Block and Components

Courtesy of GENERAL MOTORS CORP.

Callouts For Fig. 19

steve

Monday, May 09, 2011 12:52:00 PM

Page 29

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Callout

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Component Name

Thermostat Housing

Thermostat Housing to Engine Block Seal

Water Transfer Pipe

Water Transfer Pipe to Water Pump Seal

Water Pump Bolt

Water Pump

Water Pump to Engine Block Seal

Water Pump Bolt

Oil Filter Cap

Oil Filter

Oil Filter to Engine Block Seal

Cylinder Head Alignment Pin

Intake Balance Shaft Rear Bearing

Intake Balance Shaft

Intake Balance Shaft Bearing Carrier

Intake Balance Shaft Drive Sprocket

Intake Balance Shaft Drive Sprocket Bolt

Exhaust Balance Shaft Drive Sprocket Bolt

Exhaust Balance Shaft Drive Sprocket

Exhaust Balance Shaft Bearing Carrier Bolt

Exhaust Balance Shaft

Exhaust Balance Shaft Rear Bearing Engine

Front Cover Alignment Pin

Engine Oil Passage Plug

Engine Oil Passage Plug

Top Compression Piston Ring

Second Compression Piston Ring

Piston Oil Ring Assembly

Piston

Piston Pin

Piston Pin Retainer

Connecting Rod

Connecting Rod Cap Bolt

Connecting Rod Bearing

Crankshaft Thrust Bearing

Crankshaft Bearing

Crankshaft Damper Alignment Key

Crankshaft

Crankshaft Rear Seal

Starter Ring Gear

steve

Monday, May 09, 2011 12:52:00 PM

Page 30

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

Flywheel

Flywheel to Crankshaft Bolt

Engine Oil Pan Baffle

Engine Oil Pan

Pan Drain Plug

Engine Oil Pan Nut

Engine Oil Pan Stud

Engine Oil Pan Bolt

Engine Oil Pickup

Lower Crankcase to Engine Block Bolt

Lower Crankcase to Engine Block Bolt

Crankshaft Bearing Bolt

Lower Crankcase to Engine Block Bolt

Lower Crankcase

Lower Crankcase Alignment Pin

Lower Crankcase Alignment Pin

Engine Block

Water Jacket Plug

Engine Block to Transmission Alignment Pin

Cylinder Head to Engine Block Bolt

Water Jacket Drain Plug

Water Pump to Engine Block Bolt

Thermostat Housing to Engine Block Bolt

Thermostat Housing to Engine Block Bolt

Thermostat Gasket

Thermostat

steve

Monday, May 09, 2011 12:52:00 PM

Page 31

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 20: Timing Chain and Components

Courtesy of GENERAL MOTORS CORP.

Callouts For Fig. 20

Callout

Component Name

1

Upper Timing Chain Guide Bolt

2

Upper Timing Chain Guide

3

Timing Chain

4

Intake Camshaft Sprocket

5

Intake Camshaft Sprocket to Camshaft Bolt

6

Fixed Timing Chain Guide Bolt

7

Fixed Timing Chain Guide

8

Fixed Timing Chain Guide Bolt

9

Oil Pump Cover Bolt

10

Oil Pump Cover

11

Oil Pump Inner Gerotor

12

Oil Pump Outer Gerotor

13

Engine Front Cover Gasket

14

Engine Front Cover

15

Engine Front Cover Access Plate Bolt

16

Front Crankshaft Seal

17

Crankshaft Damper

steve

Monday, May 09, 2011 12:52:00 PM

Page 32

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Crankshaft Damper Bolt

Engine Front Cover Bolt

Oil Pressure Relief Valve Plunger

Oil Pressure Relieve Valve Spring

Oil Pressure Relief Valve Plug

Crankshaft Sprocket Alignment Key

Timing Chain Oil Nozzle

Exhaust Camshaft Sprocket to Camshaft Bolt

Timing Chain Drive Sprocket

Adjustable Timing Chain Guide Bolt

Adjustable Timing Chain Guide

Timing Chain Tensioner Seal

Timing Chain Tensioner

Drive Chain Guide Bolt

Balance Shaft Drive Chain Guide

Balance Shaft Drive Sprocket

Adjustable Balance Shaft Drive Chain Guide Bolt

Adjustable Balance Shaft Drive Chain Guide

Balance Shaft Drive Chain Tensioner Assembly

Water Pump

Water Pump Drive Sprocket Bolt

Balance Shaft Drive Chain Guide

Balance Shaft Drive Chain Guide Bolt

Engine Front Cover Access Plate Seal

Engine Front Cover Access Plate

steve

Monday, May 09, 2011 12:52:00 PM

Page 33

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 21: Intake Manifold and Components

Courtesy of GENERAL MOTORS CORP.

Callouts For Fig. 21

steve

Monday, May 09, 2011 12:52:00 PM

Page 34

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Callout

1

2

3

4

5

6

7

8

9

10

11

12

Component Name

Fuel Pressure Regulator Vacuum Line

Accelerator Control Cable Bracket

Throttle Body Nut

Throttle Body Nut

Throttle Body Bolt

Throttle Body

Intake Manifold Bolt

Throttle Body Seal

Intake Manifold

Intake Manifold Gasket

Map Sensor

Throttle Body Stud

steve

Monday, May 09, 2011 12:52:00 PM

Page 35

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

steve

Monday, May 09, 2011 12:52:00 PM

Page 36

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 22: Exhaust Manifold and Components

Courtesy of GENERAL MOTORS CORP.

Callouts For Fig. 22

Callout

Component Name

1

Exhaust Manifold Heat Shield

2

Air Pipe Nut

3

Air Pipe

4

Air Pipe Bolt

5

Air Pipe Gasket

6

Exhaust Manifold Heat Shield Stud

7

Exhaust Manifold Gasket

8

Exhaust Manifold

9

Exhaust Flex Decoupler Stud

10

Exhaust Manifold Nut

steve

Monday, May 09, 2011 12:52:00 PM

Page 37

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Fig. 23: Accessory and Engine Drive Belt Components

Courtesy of GENERAL MOTORS CORP.

Callouts For Fig. 23

Callout

Component Name

steve

Monday, May 09, 2011 12:52:00 PM

Page 38

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

1

2

3

4

5

6

7

8

9

10

11

12

13

Power Steering Pump

Power Steering Pressure Line

Generator Bolt

Generator Pulley

Accessory Drive Belt

Air Compressor Bolt

Air Conditioning Compressor

Accessory Drive Belt Tensioner Bolt

Accessory Drive Belt Tensioner

Generator Assembly

Starter Assembly

Power Steering Pump Bolt

Starter Assembly to Engine Block Bolt

DIAGNOSTIC INFORMATION AND PROCEDURES

DRIVE BELT AND TENSIONER COMPLAINT/CONDITION CHART

Drive Belt and Tensioner Complaint/Condition Chart

Complaint/Condition

Possible Cause(s)

Wrong belt. Belt routing and

alignment on pulleys.

Tension too High

Wrong pulley.

Tension too Low

Tensioner inoperative.

Wrong belt.

Worn belt.

Tensioner inoperative or broken

internal spring.

Wrong pulley.

Wrong belt.

Belt misaligned.

Belt Chirp

Belt installed incorrectly.

Tensioner inoperative.

Tensioner partially seized.

Tensioner inoperative.

Tensioner/idler pulley bearing.

Tensioner inoperative.

Correction(s)

Replace belt, check belt, and

pulleys for proper belt installation

and

alignment in grooves.

Check pulley diameters against

another vehicle or good parts.

Replace tensioner.

Replace belt.

Replace belt.

Replace tensioner.

(Do not attempt to repair)

Check pulley diameters against

another vehicle or good parts.

Check belt tension.

Check pulley alignment.

Check for belt alignment in

grooves.

Check belt tensioner motion.

Check tensioner movement.

Check belt tension.

Check tensioner/idler pulley

bearings.

Check belt tension.

steve

Monday, May 09, 2011 12:52:00 PM

Page 39

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Tensioner/idler pulley bearing.

Wrong belt.

Intermittent Squeal or Whistle

Noise

Notice: Diagnosis is difficult.

Requires accessory drive belt

removal and engine cold starts to

validate concern. Do not run

engine for more than 3 minutes

with accessory drive belt off.

Worn belt.

Excessive pulley radial/axial

runout.

Belt misaligned.

Water pump, power steering

pump, generator, A/C

compressor, tensioner or idler

bearing/loads.

Oil pump pressure regulator.

IMPORTANT:

Do not disassemble the belt

tensioner.

Accessory Drive Growl with A/C

On During Acceleration and/or

Belt tensioner (internal).

Growl from Belt Tensioner.

Water pump, power steering

pump, generator, A/C

compressor, tensioner, or idler

bearing.

Hoot or Growl Noise

Idler pulley bearing.

Check tensioner/idler pulley

bearings.

Check for proper belt.

Inspect belt for wear and check

tension.

Replace pulley.

Check pulley alignment.

Check all accessories for

bearing/component seizure.

Replace oil pump pressure

regulator valve.

Check belt tensioner movement.

Check belt tension.

Replace faulty component.

Replace idler pulley bearing.

IMPORTANT: Saturn service tool SA9217NE Chassis Ear Tool (or equivalent) should be used

to locate source(s) of noises caused by vibration(s).

DIAGNOSTIC STARTING POINT - ENGINE MECHANICAL

Begin the system diagnosis by reviewing the Disassembled Views, Engine Component Description,

Lubrication Description, and New Product Information in Engine Unit Repair. Reviewing the description and

operation information will help you determine the correct symptom diagnostic procedure when a malfunction

exists. Reviewing the description and operation information will also help you determine if the condition

described by the customer is normal operation. Refer to Symptoms - Engine Mechanical in order to identify

the correct procedure for diagnosing the system and where the procedure is located.

SYMPTOMS - ENGINE MECHANICAL

Strategy Based Diagnostics

1. Perform the DIAGNOSTIC STARTING POINT -- ENGINE CONTROLS in Self-Diagnostics - 2.2L

in Engine Performance before using the symptom tables, if applicable.

2. Review the system operations in order to familiarize yourself with the system functions. Refer to

Disassembled Views, Engine Component Description, and Lubrication Description in Engine Unit

steve

Monday, May 09, 2011 12:52:00 PM

Page 40

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

Repair.

All diagnosis on a vehicle should follow a logical process. Strategy based diagnostics is a uniform approach for

repairing all systems. The diagnostic flow may always be used in order to resolve a system condition. The

diagnostic flow is the place to start when repairs are necessary.

Visual/Physical Inspection

Inspect for aftermarket devices which could affect the operation of the engine.

Inspect the easily accessible or visible system components for obvious damage or conditions which could

cause the symptom.

Check for the correct oil level, proper oil viscosity, and correct filter application.

Verify the exact operating conditions under which the concern exists. Note factors such as engine RPM,

ambient temperature, engine temperature, amount of engine warm-up time, and other specifics.

Compare the engine sounds, if applicable, to a known good engine and make sure you are not trying to

correct a normal condition.

Intermittent

Test the vehicle under the same conditions that the customer reported in order to verify the system is operating

properly.

Symptom List

Refer to a symptom diagnostic procedure from the following list in order to diagnose the symptom:

Base Engine Misfire without Internal Engine Noises

Base Engine Misfire with Abnormal Internal Lower Engine Noises

Base Engine Misfire with Abnormal Valve Train Noise

Base Engine Misfire with Coolant Consumption

Base Engine Misfire with Excessive Oil Consumption

Engine Compression Test

Engine Noise on Start-Up, but Only Lasting a Few Seconds

Upper Engine Noise, Regardless of Engine Speed

Lower Engine Noise, Regardless of Engine Speed

Engine Noise Under Load

Engine Will Not Crank - Crankshaft Will Not Rotate

Oil Consumption Diagnosis

Oil Pressure Diagnosis and Testing

Oil Leak Diagnosis

Coolant in Combustion Chamber

Coolant in Engine Oil

steve

Monday, May 09, 2011 12:52:00 PM

Page 41

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

BASE ENGINE MISFIRE WITHOUT INTERNAL ENGINE NOISES

Base Engine Misfire without Internal Engine Noises

Cause

Correction

Abnormalities, severe cracking, bumps, or missing Replace the drive belt.

areas in the accessory drive belt

Abnormalities in the accessory drive system and/or

components may cause engine RPM variations and

lead to a misfire DTC. A misfire code may be

present without an actual misfire condition.

Worn, damaged, or mis-aligned accessory drive

Inspect the components, and repair or replace as

components or excessive pulley runout may lead to required.

a misfire DTC.

A misfire code may be present without an actual

misfire condition.

A loose or improperly installed engine flywheel or Repair or replace the flywheel and/or balancer as

crankshaft balancer

required.

A misfire code may be present without an actual

misfire condition.

Restricted exhaust system

Repair or replace as required.

A severe restriction in the exhaust flow can cause

significant loss of engine performance and may set a

DTC. Possible causes of restrictions include

collapsed or dented pipes or plugged mufflers and/or

catalytic converters.

Improperly installed or damaged vacuum hoses

Repair or replace as required.

Improper sealing between the intake manifold and Replace the intake manifold, gaskets, cylinder

cylinder heads or throttle body.

heads, and/or throttle body as required.

Improperly installed or damaged MAP sensor

Repair or replace the MAP sensor as required.

The sealing grommet of the MAP sensor should not

be torn or damaged.

Damage to the MAP sensor housing

Replace the intake manifold.

Worn or loose rocker arms

Replace the valve rocker arms as required.

The rocker arm bearing end caps and/or needle

bearings should be intact and in the proper position.

Stuck valves

Repair or replace as required.

Carbon buildup on the valve stem can cause the

valve not to close properly.

Excessively worn or mis-aligned timing chain

Replace the timing chain and sprockets as required.

Worn camshaft lobes

Replace the camshaft and valve lifters.

Excessive oil pressure

Perform an oil pressure test. Refer to Oil

A lubrication system with excessive oil pressure

Pressure Diagnosis and Testing.

may lead to excessive valve lifter pump up and loss

Repair or replace the oil pump as required.

of compression.

Faulty cylinder head gaskets and/or cracking or

Inspect for spark plugs saturated by coolant.

steve

Monday, May 09, 2011 12:52:00 PM

Page 42

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

other damage to the cylinder heads and engine block

cooling system passages

Coolant consumption may or may not cause the

engine to overheat.

Worn piston rings

Oil consumption may or may not cause the engine to

misfire.

A damaged crankshaft reluctor wheel

A damaged crankshaft reluctor wheel can result in

different symptoms depending on the severity and

location of the damage.

Inspect the cylinder heads, engine block,

and/or head gaskets.

Repair or replace as required.

Inspect the spark plugs for oil deposits.

Inspect the cylinders for a loss of

compression. Refer to Engine Compression

Test.

Perform cylinder leak down and compression

testing to identify the cause.

Repair or replace as required.

Replace the sensor and/or crankshaft as required.

Systems with electronic communications, DIS

or coil per cylinder, and severe reluctor ring

damage may exhibit periodic loss of

crankshaft position, stop delivering a signal,

and then re-sync the crankshaft position.

Systems with electronic communication, DIS

or coil per cylinder, and slight reluctor ring

damage may exhibit no loss of crankshaft

position and no misfire may occur. However,

a P0300 DTC may be set.

Systems with mechanical communications,

high voltage switch, and severe reluctor ring

damage may cause additional pulses and

effect fuel and spark delivery to the point of

generating a P0300 DTC or P0336.

BASE ENGINE MISFIRE WITH ABNORMAL INTERNAL LOWER ENGINE NOISES

Base Engine Misfire with Abnormal Internal Lower Engine Noises

Cause

Correction

Abnormalities, severe cracking, bumps or missing Replace the drive belt.

areas in the accessory drive belt

Abnormalities in the accessory drive system and/or

components may cause engine RPM variations,

noises similar to a faulty lower engine, and also lead

to a misfire condition. A misfire code may be

present without an actual misfire condition.

Worn, damaged, or mis-aligned accessory drive

Inspect the components, repair or replace as

components or excessive pulley runout

required.

steve

Monday, May 09, 2011 12:52:00 PM

Page 43

2006 Mitchell Repair Information Company, LLC.

2003 Saturn L200

2003 ENGINE Engine Mechanical - 2.2L (L61) - Saturn L Series

A misfire code may be present without an actual

misfire condition.

Loose or improperly installed engine flywheel or

crankshaft balancer

A misfire code may be present without an actual

misfire condition.

Worn piston rings

Oil consumption may or may not cause the engine

to misfire.

Repair or replace the flywheel and/or balancer as

required.

Inspect the spark plugs for oil deposits.

Inspect the cylinders for a loss of

compression. Refer to Engine Compression

Test.

Perform cylinder leak down and compression

testing to determine the cause.

Repair or replace as required.

Replace the crankshaft and bearings as required.

Worn crankshaft thrust bearings

Severely worn thrust surfaces on the crankshaft

and/or thrust bearing may permit fore and aft

movement of the crankshaft, and create a DTC

without an actual misfire condition.

BASE ENGINE MISFIRE WITH ABNORMAL VALVE TRAIN NOISE

Base Engine Misfire with Abnormal Valve Train Noise

Cause

Correction

Worn or loose rocker arms

Replace the valve rocker arms as required.

The rocker arm bearing end caps and/or needle

bearings should intact within the rocker arm

assembly.

Stuck valves

Repair or replace as required.

Carbon buildup on the valve stem can cause the

valve to not close properly.

Excessively worn or mis-aligned timing chain

Replace the timing chain and sprockets as required.

Worn camshaft lobes

Replace the camshaft and valve lifters.

Sticking lifters

Replace as required.

BASE ENGINE MISFIRE WITH COOLANT CONSUMPTION

Base Engine Misfire with Coolant Consumption

Cause

Faulty cylinder head gaskets and/or cracking, or

other damage to the cylinder heads and engine block

cooling system passages.

Coolant consumption may or may not cause the

engine to overheat.

Correction