Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Factsheet HVDC e

Cargado por

1996siddhuTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Factsheet HVDC e

Cargado por

1996siddhuCopyright:

Formatos disponibles

Fact Sheet

High-voltage direct current transmission (HVDC)

Status July 2012

Technology:

A high-voltage direct current (HVDC) transmission link consists primarily of a

converter station, in which the AC voltage of the conventional power grid is

converted into DC voltage, a transmission line, and another converter station on

the other end, where the voltage is converted back into AC.

The electricity can be transported in both directions. The lines can go across

land as overhead or underground lines, or be installed in water as submarine

cables. Also a combined installation, e.g. cable and overhead line or submarine

and underground line is possible.

Transmission losses are lower than for AC voltage. DC voltage amounts to

several hundred thousand volts. The higher the voltage, the lower the

transmission losses are, and the more electricity can be transmitted via the line.

Siemens commissioned the first HVDC transmission link rated at 800,000 volts

in China at the end of 2009, thereby establishing itself as a technology leader.

Siemens will also install the first submarine HVDC cable with a voltage rating of

600,000 volts to connect Scotland and England.

www.siemens.com/presse/wismar

Generally, an HVDC transmission link has two poles (and also two lines between

them) over which half of the electricity is transmitted. If one pole or line were to

fail, half of the remaining power would still be available. Usually the

connections are designed for a temporally limited overload operation.

Besides conventional HVDC transmission technology, there is also the spacesaving variant HVDC Plus, which is used especially on offshore platforms. In

addition, HVDC Plus is the HVDC solution for built-up urban environments as can

be encountered in San Francisco, for example.

Advantages:

HVDC transmission has typically 30-50% less transmission loss than comparable

alternating current overhead lines. (For comparison: given 2500 MW

transmitted power on 800 km of overhead line, the loss with a conventional

400-kv AC line is 9.4%; with HVDC transmission at 500 kV, it is only 6%, and at

800 kV it is just 2.6%.)

Generally, given the same width of the cable run, 30-40% more energy

transmission is possible than with conventional overhead lines carrying

alternating current.

As a firewall, HVDC can prevent the transmission of faults between connected

AC grids and hence prevent from blackouts.

For lengths of about 600 km or more, overhead lines using HVDC transmission

technology are more cost-effective than AC technology.

Cable links longer than approximately 80 km are only possible with HVDC

transmission. Thats because for underground or submarine cables, hardly any

electricity is delivered when AC lines are 80 km or longer (The cable capacities

absorb the usable electricity). For an HVDC transmission link using submarine

cable, such as the one planned between Scotland and England at 600 kV and

2,200 MW, there will be an energy loss of less than 3% in total (including cable

and converter losses).

www.siemens.com/presse/wismar

Market:

The power transmission market is basically volatile, since it is influenced by largescale projects.

The global power transmission market (incl. HVDC transmission) will amount to

5-9 billion per year in the next five years.

The HVDC transmission market, which is included in this figure, is expected to

double within the next five years from a current 3 billion per year.

The demand for HVDC transmission is increasing rapidly. In the last 40 years,

HVDC transmission links with a total capacity of 100 gigawatts (equivalent to the

capacity of 100 large power plants) were installed. Another 250 gigawatts will be

added in this decade alone!

With a market share of more than one-third, Siemens is one of the two biggest

suppliers in the HVDC transmission sector.

Siemens has completed about 40 HVDC transmission projects worldwide, one

quarter of which were in China. Through these Siemens-built HVDC transmission

links flows an amount of electricity sufficient to meet the average power demand

of entire countries, such as Spain or Italy.

Drivers:

Connecting offshore wind farms to the grid: cable lengths of approximately 80

km and more are only possible with HVDC transmission technology.

o Germany: Wind farm projects are far offshore due to landscape

protection and higher wind yield (160 km of sea cable for Sylwin/Dan Tysk for

example) which practically creates a northern Desertec in the North and

Baltic Sea.

o Great Britain: Future wind farms are far offshore due to the higher yield

and because the near-coastal regions were already contracted out in rounds 1

and 2. For round 3 with 32 GW of wind power, areas have been identified for

wind farms that are between 40 and 200 km off the coast.

Trans-national grid connections: This creates integrated grids that can

compensate for regional fluctuations in the production or consumption of

electricity. For example: Western Link (England-Scotland), Inelfe (France-Spain)

and BritNed (UK-Netherlands)

www.siemens.com/presse/wismar

Power supply for areas in which no new power plant is to be built (often via lines

running through water). Examples: Mallorca and San Francisco

Back-to-back links, which connect two AC grids and serve as a firewall to prevent

faults from passing into the neighboring grid (e.g., Georgia - Turkey, New York New Jersey)

China, India, and Brazil in particular are boom countries, because their energy

demand is growing rapidly and large distances must be bridged to ensure a supply

of electricity from renewables projects.

Quotes by Tim Dawidowsky, CEO Business Unit Transmission Solutions, Power

Transmission Division, Siemens Energy Sector:

HVDC is essential for offshore projects located far out at sea. HVDC technology is

therefore a vital pillar for the energy turnaround.

Germany will not be able to achieve its goals of expanding renewable power

without a north to south power highway. Over long distances HVDC technology is

the more economical option:"

Orders for HVDC lines with a total capacity of 250 gigawatts (GW) are anticipated

for this decade. This is an enormous boom when you consider that a total of only

100 gigawatts was installed over the last 40 years.

There is a great deal of interest in HVDC technology from Siemens.

We are currently building the first HVDC subsea cable link in the world with 600

kilovolts (kV). This higher voltage helps increase line capacity by 20% and reduces

transmission losses by nearly a third. This is also the first subsea cable with a

transmission capacity of 2,200 megawatts (MW), enabling the power from 600

medium-size offshore wind turbines to be transported.

HVDC is also ideal for use in power generation when a power plant is not wanted,

or would not be profitable or for which there is no suitable space such as on

Mallorca or in San Francisco.

Our HVDC link between France and Spain can be seen as a type of model. These

types of lines can be used to gradually eliminate the bottlenecks in the transmission

networks throughout Europe.

www.siemens.com/presse/wismar

También podría gustarte

- Advt 16 2019 Engl PDFDocumento40 páginasAdvt 16 2019 Engl PDFShivam GoyalAún no hay calificaciones

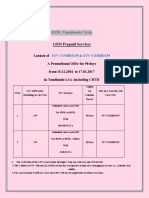

- Extension of The "NESAM GOLD" Promotional Prepaid Plan Under GSM Mobile Services in Tamilnadu LSA For A Period of 90 DaysDocumento2 páginasExtension of The "NESAM GOLD" Promotional Prepaid Plan Under GSM Mobile Services in Tamilnadu LSA For A Period of 90 Days1996siddhuAún no hay calificaciones

- UPSCDocumento26 páginasUPSC1996siddhuAún no hay calificaciones

- BSNL Prepaid Mobile Special Tariff Vouchers (STVDocumento1 páginaBSNL Prepaid Mobile Special Tariff Vouchers (STVYunus KhanAún no hay calificaciones

- NewRoam STVs Sep 15Documento1 páginaNewRoam STVs Sep 151996siddhuAún no hay calificaciones

- Circle Adalat Jun 2017Documento1 páginaCircle Adalat Jun 20171996siddhuAún no hay calificaciones

- Welcome Offer New MNP CustomerDocumento1 páginaWelcome Offer New MNP Customer1996siddhuAún no hay calificaciones

- Advt 16 2019 Engl PDFDocumento40 páginasAdvt 16 2019 Engl PDFShivam GoyalAún no hay calificaciones

- BSNL Prepaid Mobile Special Tariff Vouchers (STVDocumento1 páginaBSNL Prepaid Mobile Special Tariff Vouchers (STVYunus KhanAún no hay calificaciones

- Post Paid Offers 010617Documento1 páginaPost Paid Offers 0106171996siddhuAún no hay calificaciones

- Telecom District (Ssa) Level Telephone AdalatDocumento2 páginasTelecom District (Ssa) Level Telephone Adalat1996siddhuAún no hay calificaciones

- WasteDocumento3 páginasWaste1996siddhuAún no hay calificaciones

- ETT590 OfferDocumento1 páginaETT590 Offer1996siddhuAún no hay calificaciones

- Post Paid Data Offer 010617Documento1 páginaPost Paid Data Offer 0106171996siddhuAún no hay calificaciones

- BSNL Tamilnadu Promo: Full Usage 160 Rs. Top-UpDocumento1 páginaBSNL Tamilnadu Promo: Full Usage 160 Rs. Top-Up1996siddhuAún no hay calificaciones

- BSNL Tamilnadu Circle: GSM Prepaid ServicesDocumento1 páginaBSNL Tamilnadu Circle: GSM Prepaid Services1996siddhuAún no hay calificaciones

- Nesam Gold Final 20062015Documento1 páginaNesam Gold Final 200620151996siddhuAún no hay calificaciones

- BSNL Tamilnadu Circle GSM Prepaid ServicesDocumento1 páginaBSNL Tamilnadu Circle GSM Prepaid Services1996siddhuAún no hay calificaciones

- One Day Offer: BSNL Tamilnadu CircleDocumento1 páginaOne Day Offer: BSNL Tamilnadu Circle1996siddhuAún no hay calificaciones

- BSNL Tamilnadu launches STV 786 for RamzanDocumento1 páginaBSNL Tamilnadu launches STV 786 for Ramzan1996siddhuAún no hay calificaciones

- BSNL Tamilnadu launches STV 786 for RamzanDocumento1 páginaBSNL Tamilnadu launches STV 786 for Ramzan1996siddhuAún no hay calificaciones

- WatDocumento3 páginasWat1996siddhuAún no hay calificaciones

- Introduction of Promotional Voice STV 149 Viz. Elite (On Seconds Basis)Documento1 páginaIntroduction of Promotional Voice STV 149 Viz. Elite (On Seconds Basis)1996siddhuAún no hay calificaciones

- Combo Voucher 58Documento1 páginaCombo Voucher 581996siddhuAún no hay calificaciones

- Full Talk Time 220 JulyDocumento1 páginaFull Talk Time 220 July1996siddhuAún no hay calificaciones

- Fulltalktimers100 27062015Documento1 páginaFulltalktimers100 270620151996siddhuAún no hay calificaciones

- FTT 220 30062015Documento1 páginaFTT 220 300620151996siddhuAún no hay calificaciones

- 10% Extra Usage Value On Topup of MRP Rs.6000: Tamilnadu LSA (Including CHTD) Under GSM Prepaid Mobile ServicesDocumento1 página10% Extra Usage Value On Topup of MRP Rs.6000: Tamilnadu LSA (Including CHTD) Under GSM Prepaid Mobile Services1996siddhuAún no hay calificaciones

- Full Talk Time 220 JulyDocumento1 páginaFull Talk Time 220 July1996siddhuAún no hay calificaciones

- Full Talk Time 220 JulyDocumento1 páginaFull Talk Time 220 July1996siddhuAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- EstimateDocumento6 páginasEstimateSansar PanchalAún no hay calificaciones

- Data Governance Case Study Ciba FinalDocumento37 páginasData Governance Case Study Ciba FinalAbdelhamid HarakatAún no hay calificaciones

- Viswanath ResumeDocumento3 páginasViswanath ResumePRASHANT KANTEAún no hay calificaciones

- Volvo EeeeDocumento6 páginasVolvo Eeeenarendra singh0% (1)

- Scrum Online Quiz - Testing ExcellenceDocumento16 páginasScrum Online Quiz - Testing ExcellenceKRISHNAPRIYAAún no hay calificaciones

- N P Rajeswara Reddy: Ummary of KillsDocumento2 páginasN P Rajeswara Reddy: Ummary of KillskiranAún no hay calificaciones

- Process Validation ProtocolDocumento10 páginasProcess Validation ProtocolDivya SekarAún no hay calificaciones

- Mechanical and Tribological Performance of Aluminium Metal Matrix CompositesDocumento27 páginasMechanical and Tribological Performance of Aluminium Metal Matrix CompositesPradeepkumar SamanthulaAún no hay calificaciones

- BigFix User GuideDocumento29 páginasBigFix User GuidepriteshjAún no hay calificaciones

- API DocumentationDocumento115 páginasAPI DocumentationEric ScrivnerAún no hay calificaciones

- Investigation and Analysis of Cold Shut Casting Defect ReductionDocumento3 páginasInvestigation and Analysis of Cold Shut Casting Defect Reductionvivek1312Aún no hay calificaciones

- Rotorcraft Forecast Sample - R013Documento14 páginasRotorcraft Forecast Sample - R013Genaire LimitedAún no hay calificaciones

- Cais 0308 - 2021-12 (308, 103S08)Documento7 páginasCais 0308 - 2021-12 (308, 103S08)Muhammad UmarAún no hay calificaciones

- Bearing Detail PDFDocumento1152 páginasBearing Detail PDFJayesh MachhiAún no hay calificaciones

- Common SAP Testing Terminology Ensures Project UnderstandingDocumento8 páginasCommon SAP Testing Terminology Ensures Project UnderstandingZelimir KovacevicAún no hay calificaciones

- 18.5Documento32 páginas18.5andresfido123Aún no hay calificaciones

- GIS Tugas I Off LDocumento7 páginasGIS Tugas I Off LTaufan Azhari Nur BaladijayaAún no hay calificaciones

- Culturally Inspired Design Education A Nigerian Case StudyDocumento19 páginasCulturally Inspired Design Education A Nigerian Case StudyPsamuel AdelabuAún no hay calificaciones

- CAD Specification for Network Rail ProjectsDocumento3 páginasCAD Specification for Network Rail ProjectsManoj Kumar MAún no hay calificaciones

- Microsoft Dynamics Ax InstallationDocumento22 páginasMicrosoft Dynamics Ax InstallationsacchishuklaAún no hay calificaciones

- Cif PmiDocumento1 páginaCif PmiC.K DavisAún no hay calificaciones

- Total Quality Management - ProjectDocumento2 páginasTotal Quality Management - ProjectRachel KuAún no hay calificaciones

- BD+ CD+ XD+ - tcm833-3534072Documento20 páginasBD+ CD+ XD+ - tcm833-3534072MisterMMAún no hay calificaciones

- Library Management System: Assignment No.02Documento13 páginasLibrary Management System: Assignment No.02Neha PandeyAún no hay calificaciones

- Astm C490Documento5 páginasAstm C490Horacio ApolayoAún no hay calificaciones

- Project Completion, Handover and Operations GuideDocumento11 páginasProject Completion, Handover and Operations GuideJustine Sheinna SebleroAún no hay calificaciones

- OM - Session 24 Quality Control Lean MFGDocumento70 páginasOM - Session 24 Quality Control Lean MFGSiddhant Singh100% (1)

- No. Description Oper Date: Production Routing ChartDocumento2 páginasNo. Description Oper Date: Production Routing Chartpubg loversAún no hay calificaciones

- Rethinking Limits - Cleaning ValidationDocumento12 páginasRethinking Limits - Cleaning ValidationSatyaaammireddyAún no hay calificaciones

- Lifecycle of A Project Management: Prepared By: Rosida Binti Ahmad (Psa) 1Documento55 páginasLifecycle of A Project Management: Prepared By: Rosida Binti Ahmad (Psa) 1Nik AliffAún no hay calificaciones