Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Construct Basement Structure

Cargado por

TAHER AMMAR0 calificaciones0% encontró este documento útil (0 votos)

64 vistas2 páginasMS

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoMS

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

64 vistas2 páginasConstruct Basement Structure

Cargado por

TAHER AMMARMS

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 2

METHOD STATEMENT & SEQUENCE OF WORK

TO CONSTRUCT BASEMENT STRUCTURE

SITE ADDRESS: 57 BRONDESBURY ROAD, LONDON, NW6 6BP.

PROJECT REF: 8819

Ref. to Dwg. 8819/SK01.

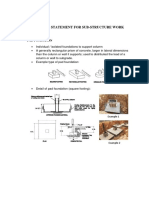

Underpinning

Excavate the individual bay to be underpinned to the new formation level.

The soffit of existing foundations is to be thoroughly cleaned and cut back to a sound

face before concreting and dry packing.

The existing corbelled brick foundations will be carefully cut back to the wall line on

the internal face. Extra precaution is to be taken in excavating further to allow

underpinning and bay widths are to be limited in width (1 max) or permanent props

installed.

Adequate temporary supports are to be provided where walls are to be underpinned

and arching of brickwork is deemed not to be present or brickwork not sound. Steel

prop supports shall be inserted locally if necessary after excavation beneath the

foundations and shall be bedded on the approved formation and concreted into the

underpinning.

Concrete to be GEN 3 (20 N) mass concrete uno.

The sequence of underpinning is to be agreed with the Engineer before proceeding

with the work. Each bay including excavation to be 1m wide maximum and to be

sequenced in conjunction with a sequencing plan drawing. Typically a 1-5 numbering

system for bays is provided for construction. Works to be sequenced to maintain

adequate foundation support to the building at all times.

Excavate and cast bays marked 1. Allow 24 48 hours to cure before dry packing.

Allow 24-48 hours to cure before excavating the subsequent bay.

Excavate and cast bays marked 2 and dry pack as above.

Repeat for 3, 4, 5 until underpinning complete, or similar sequencing (Note:

sequential ordering for bays in a length of wall is 1st bay, 3rd bay, 5th, 2nd, 4th and

so on, such that a subsequent bay is not located adjacent to a most recently

constructed bay uno).

Y:\Projects\8819-ms-001

The width of the underpinning base at formation level is to equal the width of the

existing brickwork foundations.

New Basement RC Retaining Wall Horizontal Restraint

Adequate temporary horizontal supports are to be provided to replace the horizontal

restraint the existing floor currently provides to the foundations during the works.

The permanent horizontal support is by means of a new internal basement RC

retaining wall constructed of reinforced concrete. This internal retaining wall provides

horizontal restraint up to the foundations. The walls and base are to be constructed

of 150mm thick reinforced concrete. Walls to be poured against the mass concrete

underpinning to the level of the existing floor slab. The base is to be constructed off

of 50mm level and compact blinding. Concrete to be grade RC40.

During construction adequate temporary horizontal supports are to be provided to

the head of the retaining wall as required where the floor is removed or the base not

fully constructed at all times.

New Basement Floor Slab

The new basement floor slabs are to be of ground bearing nominally reinforced

concrete construction. Slabs to be 150mm thick with A142 mesh in the centre of the

slab. Concrete to be grade RC40.

This report assumes a competent contractor is appointed to undertake the works.

Killian OReilly

Gurney Consulting Engineers

Y:\Projects\8819-ms-001

También podría gustarte

- UnderpinningDocumento58 páginasUnderpinningZoeyHakim100% (1)

- 10B UnderpinningDocumento24 páginas10B UnderpinningAlma AinaAún no hay calificaciones

- PG Tech Update Piled WallsDocumento6 páginasPG Tech Update Piled Wallsparamarthasom1974Aún no hay calificaciones

- Secant Piled Walls Dsign 160210011455Documento54 páginasSecant Piled Walls Dsign 160210011455ariyarathne100% (4)

- Secant Pile PDFDocumento54 páginasSecant Pile PDFK H V V MADUSHANKAAún no hay calificaciones

- UnderpinningDocumento46 páginasUnderpinningnanamallow100% (1)

- Reinforced BrickworkDocumento41 páginasReinforced BrickworkSwarali KokateAún no hay calificaciones

- Piling - Contiguous, Interlocking and SecantDocumento7 páginasPiling - Contiguous, Interlocking and Secantmudassir2640100% (2)

- CSE 521 Lecture 7Documento21 páginasCSE 521 Lecture 7Clara KeruboAún no hay calificaciones

- Secant Piles: What Are Secant Pile Walls?Documento3 páginasSecant Piles: What Are Secant Pile Walls?ulhas_nakashe100% (2)

- Construction Technology Assignment 01Documento13 páginasConstruction Technology Assignment 01Hashan PereraAún no hay calificaciones

- A Report On Reinforced Cement Concrete FloorsDocumento7 páginasA Report On Reinforced Cement Concrete FloorsAshish PandeyAún no hay calificaciones

- Boys Hostel's Construction Site Report: Submitted By-: Utkarsh Kumar 3 Sem/B.ArchDocumento37 páginasBoys Hostel's Construction Site Report: Submitted By-: Utkarsh Kumar 3 Sem/B.ArchIXWarXIAún no hay calificaciones

- Basement Floor Lowering Info Sheet For ClientsDocumento6 páginasBasement Floor Lowering Info Sheet For Clientshahaer77Aún no hay calificaciones

- 9 UnderpinningDocumento12 páginas9 UnderpinningTadiwanashe MangwiroAún no hay calificaciones

- UNDERPINNINGDocumento48 páginasUNDERPINNINGKHAIRINA FIKRIAH KHAIRUDDINAún no hay calificaciones

- Method Statement For Construction of Box Culvert - Anil KumarDocumento3 páginasMethod Statement For Construction of Box Culvert - Anil KumarAsad AshfaqAún no hay calificaciones

- Diaphragm WallsDocumento15 páginasDiaphragm WallsWan Eira100% (1)

- Prestress ConcreteDocumento135 páginasPrestress ConcreteNishant AgrawalAún no hay calificaciones

- MS007 Concrete Water TankDocumento5 páginasMS007 Concrete Water TankMhando IgnasAún no hay calificaciones

- Shoring, Underpinning and ScaffoldingDocumento50 páginasShoring, Underpinning and ScaffoldingTanvir ShovonAún no hay calificaciones

- Construction of Contiguous Bored Pile Wall: Open-Cut & Bottom-Up Construction MethodDocumento2 páginasConstruction of Contiguous Bored Pile Wall: Open-Cut & Bottom-Up Construction MethodHanri PakpahanAún no hay calificaciones

- Basements and Retaining WallDocumento49 páginasBasements and Retaining WallSakshi Rawat100% (1)

- Method of Construction for Administration Building مسودةDocumento7 páginasMethod of Construction for Administration Building مسودةM.ZEKEBA50% (2)

- 1689 ReportDocumento6 páginas1689 ReportAmin AminiAún no hay calificaciones

- UnderpinningDocumento30 páginasUnderpinningAimi Athirah ZahibAún no hay calificaciones

- Rrs PresentationDocumento69 páginasRrs PresentationPriyamvada Biju100% (1)

- Retaining Walls and Basement OnstructionDocumento18 páginasRetaining Walls and Basement Onstructionreemadepon0% (1)

- Chapter 6 BasementDocumento51 páginasChapter 6 BasementMUHAMMAD IMAN ASYRAF AHMAD NIZAAún no hay calificaciones

- Shoring and UnderpinningDocumento38 páginasShoring and UnderpinningSakshi RawatAún no hay calificaciones

- SHORINGDocumento10 páginasSHORINGIzzuddin ShahidanAún no hay calificaciones

- Construction and Design of Multi Storey Building by Abhimanyu ParidaDocumento38 páginasConstruction and Design of Multi Storey Building by Abhimanyu Paridadriverx47100% (19)

- Proposed Apartment - : Sankalp Imperial House at MysuruDocumento46 páginasProposed Apartment - : Sankalp Imperial House at MysuruMohammed AyanAún no hay calificaciones

- UnderpinningDocumento32 páginasUnderpinningkuruba saran rajAún no hay calificaciones

- 8.CE 483 Retaining Walls CH 17 3rd 1444 - 2Documento95 páginas8.CE 483 Retaining Walls CH 17 3rd 1444 - 2Saad MohammedAún no hay calificaciones

- DPT1Documento70 páginasDPT1jayawiadnyanaAún no hay calificaciones

- Construction of Footings and Flooring SystemsDocumento24 páginasConstruction of Footings and Flooring SystemsAlbert LiuAún no hay calificaciones

- Secant Pile ConstructionDocumento2 páginasSecant Pile ConstructionMohammed Azhar100% (2)

- Construction and Design of MultistoreyDocumento37 páginasConstruction and Design of MultistoreyFawadAún no hay calificaciones

- Top Down Construction Presentation.Documento13 páginasTop Down Construction Presentation.Gagan Goswami100% (1)

- Support of Deep Excavation in Soft Clay A Case History StudyDocumento8 páginasSupport of Deep Excavation in Soft Clay A Case History StudyAlfredo A LopezAún no hay calificaciones

- Assignment 3 (Infill Wall)Documento6 páginasAssignment 3 (Infill Wall)Mahmoud AlbhaisiAún no hay calificaciones

- Building TechnologyDocumento29 páginasBuilding TechnologyJohn Louie100% (1)

- Method Statement For Sub-Structure Work: Pad FondationDocumento6 páginasMethod Statement For Sub-Structure Work: Pad FondationAsyraf HakeemAún no hay calificaciones

- Building Technology 02: Ar. Agustin J. Servidad JRDocumento320 páginasBuilding Technology 02: Ar. Agustin J. Servidad JRErn NievaAún no hay calificaciones

- Reinforced BlockDocumento16 páginasReinforced BlockA NT LeilyAún no hay calificaciones

- Topic1 3 Foundations Footings 13Documento19 páginasTopic1 3 Foundations Footings 13Hussein JaberAún no hay calificaciones

- SHORINGDocumento33 páginasSHORINGKHAIRINA FIKRIAH KHAIRUDDINAún no hay calificaciones

- Methodology For Cast in Place Girder CastingDocumento10 páginasMethodology For Cast in Place Girder CastingHasnain Bukhari100% (2)

- Construction Design AssignmentDocumento8 páginasConstruction Design AssignmentkannanAún no hay calificaciones

- Unit - 5 Design MethodologyDocumento57 páginasUnit - 5 Design Methodologyci_balaAún no hay calificaciones

- Insurance Report Templates For Report Writing.Documento7 páginasInsurance Report Templates For Report Writing.sirajAún no hay calificaciones

- Strengthening The Foundations of An Existing Building During Installation of Foundations For An AdditionDocumento5 páginasStrengthening The Foundations of An Existing Building During Installation of Foundations For An Additionmahmoud morsyAún no hay calificaciones

- Foundation Part B PDFDocumento11 páginasFoundation Part B PDFKiprono VincentAún no hay calificaciones

- How to Build a Global Model Earthship Operation II: Concrete WorkDe EverandHow to Build a Global Model Earthship Operation II: Concrete WorkAún no hay calificaciones

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionDe EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionAún no hay calificaciones

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173De EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173Aún no hay calificaciones

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDe EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionAún no hay calificaciones

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcDe EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcCalificación: 5 de 5 estrellas5/5 (1)

- Technical SpecificationsDocumento37 páginasTechnical SpecificationsTAHER AMMARAún no hay calificaciones

- Construction Quality RequirementsDocumento20 páginasConstruction Quality RequirementsTAHER AMMAR100% (2)

- Scope of The Railway ProjectDocumento35 páginasScope of The Railway ProjectTAHER AMMARAún no hay calificaciones

- Maintenance StandardsDocumento39 páginasMaintenance StandardsTAHER AMMARAún no hay calificaciones

- BS - enDocumento22 páginasBS - enTAHER AMMARAún no hay calificaciones

- BS en 13231-1-2013Documento34 páginasBS en 13231-1-2013TAHER AMMAR100% (3)

- BS en 00933-6-2014Documento26 páginasBS en 00933-6-2014TAHER AMMARAún no hay calificaciones

- BS - enDocumento18 páginasBS - enTAHER AMMARAún no hay calificaciones

- BS en 00932-3-1997 (2004)Documento14 páginasBS en 00932-3-1997 (2004)TAHER AMMARAún no hay calificaciones

- BS en 00933-2-1996 (1999)Documento8 páginasBS en 00933-2-1996 (1999)TAHER AMMARAún no hay calificaciones

- 932 1-97Documento24 páginas932 1-97David Morán100% (1)

- Sample Submittal Form - ProjectDocumento1 páginaSample Submittal Form - ProjectTAHER AMMARAún no hay calificaciones

- Sample Submittal Form 2Documento1 páginaSample Submittal Form 2TAHER AMMARAún no hay calificaciones

- Understanding Building Construction Types - Firefighter Nation PDFDocumento3 páginasUnderstanding Building Construction Types - Firefighter Nation PDFRakeshAún no hay calificaciones

- Material EquivalentDocumento1 páginaMaterial EquivalentARIEF SADJAAún no hay calificaciones

- Practica 7 Life ElementaryDocumento2 páginasPractica 7 Life ElementaryJuan VelascoAún no hay calificaciones

- EspDocumento36 páginasEspprasenjitsayantanAún no hay calificaciones

- Unit 3 Moulding Processes: StructureDocumento18 páginasUnit 3 Moulding Processes: StructureChethan Madappady75% (4)

- Malaysia Namakkal Welfare Association (Ipoh Branch)Documento12 páginasMalaysia Namakkal Welfare Association (Ipoh Branch)Prasath RajuAún no hay calificaciones

- ASTM A995 A995M Castings Austenitic Ferritic Duplex Stainless SteelDocumento3 páginasASTM A995 A995M Castings Austenitic Ferritic Duplex Stainless Steeltayfun8282Aún no hay calificaciones

- 2.5.1 - Rollers Series PSVDocumento5 páginas2.5.1 - Rollers Series PSVJuan GalvesAún no hay calificaciones

- Manpower Schedule CAV - BAWINGDocumento3 páginasManpower Schedule CAV - BAWINGNeil Mark Solarte UndagAún no hay calificaciones

- PYRITES, CALCINED (Calcined Pyrites) Description: MSC 84/24/add.3 Annex 12 I:/MSC/84/24-Add-3Documento3 páginasPYRITES, CALCINED (Calcined Pyrites) Description: MSC 84/24/add.3 Annex 12 I:/MSC/84/24-Add-3JohnPaulMoloAún no hay calificaciones

- Airport Fuel Installation FireDocumento6 páginasAirport Fuel Installation Firermaffireschool100% (1)

- BarChip Fibres Replace Steel in Chilean HousingDocumento2 páginasBarChip Fibres Replace Steel in Chilean HousingPedro Augusto Delgado NascimentoAún no hay calificaciones

- Best Metal Casting DesignDocumento71 páginasBest Metal Casting DesignVijay Pawar100% (2)

- Olimpiada Engleza 2017 CL A 11B PDFDocumento6 páginasOlimpiada Engleza 2017 CL A 11B PDFAnthony AdamsAún no hay calificaciones

- Transportation Law (Atty. Ampil) Case DigestsDocumento112 páginasTransportation Law (Atty. Ampil) Case DigestsJerome MoradaAún no hay calificaciones

- Overview of Mining in Bangladesh ContextDocumento5 páginasOverview of Mining in Bangladesh ContextMusarratHossainAún no hay calificaciones

- 42 Crmo 4 (Germany / Din) : Material PropertiesDocumento4 páginas42 Crmo 4 (Germany / Din) : Material PropertiesmiladrahimianAún no hay calificaciones

- CCH 70-3 InglésDocumento81 páginasCCH 70-3 InglésDavid Andres Cañas SuarezAún no hay calificaciones

- GB Catalog Threading 2014 LRDocumento113 páginasGB Catalog Threading 2014 LRPrle TihiAún no hay calificaciones

- Fabrication of Embossing Die Synopsis Sheet Metal Embossing Is A Process For Producing Raised or Sunken Designs orDocumento9 páginasFabrication of Embossing Die Synopsis Sheet Metal Embossing Is A Process For Producing Raised or Sunken Designs orAnonymous j0aO95fgAún no hay calificaciones

- ChinaRoHS Packaging MarksDocumento7 páginasChinaRoHS Packaging MarksBrian SmithAún no hay calificaciones

- Accepted Engineering Practice StandardsDocumento5 páginasAccepted Engineering Practice StandardsMuhammad Shakil JanAún no hay calificaciones

- 1112sem2-Me4261 Me4261eDocumento4 páginas1112sem2-Me4261 Me4261eClarence S. WongAún no hay calificaciones

- Cement Types - Portland Cement Association (PCA)Documento3 páginasCement Types - Portland Cement Association (PCA)Eddy EffendiAún no hay calificaciones

- RHI CatalogueDocumento104 páginasRHI CatalogueRenaissance Heavy IndustriesAún no hay calificaciones

- A 97Documento1 páginaA 97AnuranjanAún no hay calificaciones

- Export Performance of Vegetables in BangladeshDocumento10 páginasExport Performance of Vegetables in Bangladesh'Manas SahaAún no hay calificaciones

- July 2015 Master Plumber Terms IncludedDocumento5 páginasJuly 2015 Master Plumber Terms Includedzenzen1100% (1)

- Case Study - Hot Tap, Stopple and By-PassDocumento2 páginasCase Study - Hot Tap, Stopple and By-Passowenh796Aún no hay calificaciones

- Constructive Total Loss - What Goes in To Calculating Quantum - Hellenic Shipping News WorldwideDocumento6 páginasConstructive Total Loss - What Goes in To Calculating Quantum - Hellenic Shipping News WorldwideManoj VarrierAún no hay calificaciones