Documentos de Académico

Documentos de Profesional

Documentos de Cultura

WPS Sa 335 P91 Pipe

Cargado por

csankarananthTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

WPS Sa 335 P91 Pipe

Cargado por

csankarananthCopyright:

Formatos disponibles

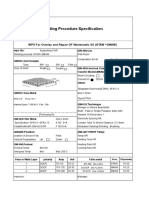

Welding Procedure Specification (WPS)

Company Name:

SAVITA CONSTRUCTION PVT LTD

Welding Procedure Specification N:

Revision N:

W-10

0

Welding Process(es)

1. GTAW

2. GMAW

3. NA

by: Hasmukh Patel

Date:

3-May-06

Date:

4. NA

Type

(QW-402) JOINTS

Supporting PQR N:

by:

Automatic

Manual

PQR-10

Semi-Automatic

Machine

Specific Joint Details

Joint Design

See Specific Joint Details

Backing

Backing material (Type)

None

N/A

Retainers

Retainer material

Other

Page: 1 of 3

Yes

Yes

No

No

Not Applicable

(QW-403) / BASE METALS

P-N:

5B

Group:

To

Or

To

Specification, Type Grade

SA 335 P91

Other

Thickness Range: 1.6mm TO 22.2mm

Pipe Range 73mnm O/D to Unlimited

P-N:

5B

Group:

Specification, Type Grade

1

SA 335 P91

Groove:

Groove:

SINGLE 'v'

Fillet:

Fillet:

NA

1. Deposited Weld Metal

Groove:

SIngle V

Fillet:

2. Deposited Weld Metal

Groove:

Fillet:

3. Deposited Weld Metal

Groove:

Fillet:

4. Deposited Weld Metal

Groove:

Fillet:

(QW-404) / FILLER METALS

Deposited Weld Metal Thickness Range

Maximum (t) : for one pass

Welding Process QW 405

1. GTAW

2. SMAW

3. N/A

4. N/A

F-N. Or Other

.5

A-N. Or Other

.5

AWS N (Class)

ER 90S B3

E9015 B3

.6

of Filler Metal

2.4 mm

3.15, 4 mm

N.A

N.A

N.A

N.A

N.A

N.A

5.28

5.5

with filler

.4

.7

of Filler Metal > 1/4" (6 mm)

.9

Electrode Flux (Class)

.10 Alloying Flux

.12 Specification (SFA)

with filler

Solid

Solid

.23 Solid or Tubular Electrode

N.A

N.A

.24 Supplemental Filler Metal

N.A

N.A

.27 Alloying Elements

N.A

N.A

.29 Flux Trade Name

N.A

N.A

.34 Flux (Type)

N.A

N.A

.35 Flux Wire Class

N.A

N.A

.36 Recurshed Slag

N.A

N.A

.50 Penetration Effecting Flux

N.A

N.A

.14 With or Without Filler Metal

.22 Consumable Insert

Welding Procedure Specification (WPS)

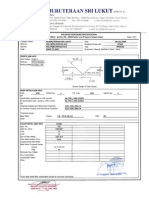

(QW-405) POSITION

(QW-407) PWHT

Position(s) of Groove

1G

1G-R 2G

3G

Page: 2 of 3

Temperature Range

4G

5G

6G

None / Keine

Time Range

Position(s) of Fillet

1F

1F-R

2F 2F-R

Welding Progression

3F

4F

N.A

5F

(QW-406) / PREHEAT

Preheat Temp. Min.

Interpass Temperature Maximum

130C

260C

Other

(QW-408) / GAS

Shielding Gas(es)

Type

Yes

Composition %

Flow rate

No

Welding Procedure Specification (WPS)

Preheat Maintenance

Argon

None / Keine

Other

(QW-409) / ELECTRICAL DATA

Tungsten Electrode

99.95

Gas Backing

2.4mm

Tungsten Type

Page: 3 of 3

Type

8-10 litre/min.

Yes

Composition %

No

Flow rate

2%Thori

Mode of Metal Transfer

Spray

Short Circuit

See Table below for:Current, polarity, amp

Other

Trailing Gas

Yes

No

Type

Composition %

Flow rate

(QW-410) / TECHNIQUE

Schweiverfahren / Welding Process

.1 String or Weave

.3 mm Gas Cup Size

20mm

.5 Method of initial and interpass Cleaning

Brushing

.6 Method of back Gouging

Grinding / Brushing

.7 Oscillation

.8 Contact Tube to Work Distance

1 Mtr.

.9 Multiple or Single Pass (per Side)

Mulitple

.10 Multiple or Single Electrodes

Single Electrode

.11 VacumeChamber Welding

.26 Peening

None Permitted

Filler Metals

Weld Layer

Root String & Final Weave

Current

Process

GTAW

2

3

SMAW

SMAW

Travel Speed

AWS Class

mm

Type

Polarity

Amps

Volts

SFA 5.28

ER90S B3 & SFA

5.5-E9015 B3

2.5

DC

-VE

70 - 80

16 - 19

60mm/min

3.15

4

DC

DC

+

+

80 -100

80 - 100

18 - 20

18 - 20

80mm/min

80mm/min

PIPE INSIDE ARGON PURGING.

1.

NA

Certified By

Certified By

TUV

TPI

SCPL

Manufacturer

También podría gustarte

- Wps p91 - BhelDocumento2 páginasWps p91 - BhelAshish Gupta100% (4)

- P 91 - Welding WPSDocumento2 páginasP 91 - Welding WPSSuhailshah123475% (4)

- 1035 03Documento2 páginas1035 03Anuj ShahiAún no hay calificaciones

- WPS PQR 12Documento9 páginasWPS PQR 12Ranjan KumarAún no hay calificaciones

- WPS-PQR (Er309l Mo)Documento4 páginasWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- For Fillet Weld Joint Project:Production ManifoldDocumento1 páginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocumento1 páginaPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarAún no hay calificaciones

- Welding Procedure Specification For Storage Tank & Piping SystemDocumento3 páginasWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadAún no hay calificaciones

- MIZAT PWHT Procedure Ensures Welded Joints Meet StandardsDocumento9 páginasMIZAT PWHT Procedure Ensures Welded Joints Meet StandardsM. R. Shahnawaz KhanAún no hay calificaciones

- Qualified Welder List Valid Until - 03-12-2019Documento2 páginasQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- WPS 2014-002 006 - 6G PipeDocumento3 páginasWPS 2014-002 006 - 6G PipejeswinAún no hay calificaciones

- Welding Procedure SpecificationDocumento3 páginasWelding Procedure SpecificationAhmed saber100% (1)

- WPS - EngineerDocumento20 páginasWPS - Engineerhunghoanglong100% (1)

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Documento1 páginaWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenAún no hay calificaciones

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 páginas163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraAún no hay calificaciones

- WPS - Welding Instruction - FUCHSDocumento23 páginasWPS - Welding Instruction - FUCHSShanoor ASAún no hay calificaciones

- Multiple PQR QualificationDocumento4 páginasMultiple PQR QualificationKarthikeyan ShanmugavelAún no hay calificaciones

- Welding Procedure Specification for Vertical Storage TanksDocumento6 páginasWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghAún no hay calificaciones

- APSM WPS 008R Rev. 0Documento3 páginasAPSM WPS 008R Rev. 0Amir NorAún no hay calificaciones

- Smaw Wps FinalDocumento3 páginasSmaw Wps FinalsheikmoinAún no hay calificaciones

- Welder Visual Inspection ReportsDocumento24 páginasWelder Visual Inspection ReportsKyAún no hay calificaciones

- Fermi Lab Orbital Welding ProcedureDocumento2 páginasFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- Gta+sma PQRDocumento3 páginasGta+sma PQRRahul MoottolikandyAún no hay calificaciones

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 páginas(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- 19403955-WPS M.S. Is 2062Documento10 páginas19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- 004 Gtaw P5aDocumento16 páginas004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Multi Process Welding Procedures QW200.4 (ASME IX)Documento1 páginaMulti Process Welding Procedures QW200.4 (ASME IX)HoangAún no hay calificaciones

- PQR Template (Asme)Documento2 páginasPQR Template (Asme)jok1974Aún no hay calificaciones

- Welder Performance Qualification-Interactive Form QW-484ADocumento1 páginaWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPS - 024Documento4 páginasWPS - 024MAT-LIONAún no hay calificaciones

- WPS for 316L Pipe WeldingDocumento3 páginasWPS for 316L Pipe WeldingRichard Periyanayagam100% (3)

- Wps Format Asme Sec - IxDocumento2 páginasWps Format Asme Sec - IxDeepu ChandranAún no hay calificaciones

- PQRDocumento2 páginasPQRSreenivas Kamachi Chettiar100% (1)

- KSL Wps PQR 012 DuplexDocumento33 páginasKSL Wps PQR 012 DuplexJunaidi Minhat100% (6)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocumento5 páginasWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocumento2 páginasElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- Gtaw WPQDocumento3 páginasGtaw WPQMuhammadShabbirAún no hay calificaciones

- Asme PQR DemoDocumento3 páginasAsme PQR DemoMuthusamy AyyanapillaiAún no hay calificaciones

- WPS 316 L PDFDocumento4 páginasWPS 316 L PDFIrinaAún no hay calificaciones

- Metrode - P92 WPS PDFDocumento3 páginasMetrode - P92 WPS PDFXing ChenAún no hay calificaciones

- LBW WOPQ REV. 2010a Interactive FormDocumento1 páginaLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- WPQR Welding Procedure QualificationDocumento3 páginasWPQR Welding Procedure QualificationThanasis KyrgiazoglouAún no hay calificaciones

- P91 Repair With NiCrDocumento76 páginasP91 Repair With NiCrElias KapaAún no hay calificaciones

- P91 Profile WpsDocumento6 páginasP91 Profile WpsManzar KhanAún no hay calificaciones

- PQR 01 PDFDocumento2 páginasPQR 01 PDFVijay BhaleraoAún no hay calificaciones

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocumento3 páginasEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Loading Unloading Temperature Welding ProgressionDocumento5 páginasLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- Fcaw 16 THKDocumento5 páginasFcaw 16 THKparesh2387Aún no hay calificaciones

- Welder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#Documento1 páginaWelder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#satnamAún no hay calificaciones

- Welding Procedure Specification For GTAW & GMAWDocumento4 páginasWelding Procedure Specification For GTAW & GMAWanh thoAún no hay calificaciones

- Wps Is 2062 GR B Butt-OkDocumento2 páginasWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- 10-01265-015-D-061706180619abc-Qc-Wps PQR001 - Moisture Separator WPS PQR and Weld Map - RD PDFDocumento65 páginas10-01265-015-D-061706180619abc-Qc-Wps PQR001 - Moisture Separator WPS PQR and Weld Map - RD PDFmarghoob100% (1)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Documento2 páginas(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaAún no hay calificaciones

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocumento4 páginasWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidAún no hay calificaciones

- WPS Sitelca S002Documento2 páginasWPS Sitelca S002Jose Antonio GomezAún no hay calificaciones

- WPS FormatDocumento2 páginasWPS FormatAmit SarkarAún no hay calificaciones

- WPS 316 LDocumento4 páginasWPS 316 Llaz_k100% (2)

- WPS GTAW pipe welding procedureDocumento2 páginasWPS GTAW pipe welding procedureRichard PeriyanayagamAún no hay calificaciones

- WPS TITLEDocumento2 páginasWPS TITLERichard Periyanayagam86% (14)

- WPS GTAW Stainless SteelDocumento4 páginasWPS GTAW Stainless SteelAnand NarayananAún no hay calificaciones

- KPKDocumento183 páginasKPKcsankarananthAún no hay calificaciones

- Ullathai Killathey 1Documento8 páginasUllathai Killathey 1vapi123Aún no hay calificaciones

- World Best Stories in Tamil TranslationDocumento193 páginasWorld Best Stories in Tamil Translationwriterhari100% (7)

- Reference Chart - Velocity ChartDocumento2 páginasReference Chart - Velocity ChartAnonymous AlhzFE9EVNAún no hay calificaciones

- As A Man ThinkethDocumento22 páginasAs A Man ThinkethcsankarananthAún no hay calificaciones

- WHB2CH10Documento22 páginasWHB2CH10zagrimagriiAún no hay calificaciones

- June 13, 2000 00:08:59 Information Handling Services, 2000Documento44 páginasJune 13, 2000 00:08:59 Information Handling Services, 2000zagrimagriiAún no hay calificaciones

- Discontinuities and DefectsDocumento12 páginasDiscontinuities and DefectsPatrick Dominguez100% (1)

- Radiography Interpretation PDFDocumento220 páginasRadiography Interpretation PDFVijay Kumar100% (1)

- 10 March 2018 - 15 March 2018Documento4 páginas10 March 2018 - 15 March 2018Abdul Ahad LoneAún no hay calificaciones

- GuidelineDocumento26 páginasGuidelineDani Teixeira - WELDGINAún no hay calificaciones

- Ofppt CoursDocumento17 páginasOfppt CoursAymen HssainiAún no hay calificaciones

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Documento2 páginasWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Senior Welding Inspector Guide BookDocumento327 páginasSenior Welding Inspector Guide Bookpalani22100% (4)

- PRAXAIR Shielding-GasesDocumento20 páginasPRAXAIR Shielding-GasesAnonymous l1bU4xmdoAún no hay calificaciones

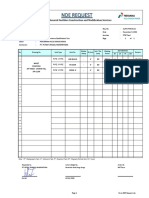

- Request NDT Welder TestDocumento1 páginaRequest NDT Welder TestFerdie OSAún no hay calificaciones

- Ref Doc 1 - Blank M207 Weld Schedule Development SheetDocumento1 páginaRef Doc 1 - Blank M207 Weld Schedule Development SheetYong YHAún no hay calificaciones

- Tube to Tube Welding ProcedureDocumento1 páginaTube to Tube Welding ProceduresbmmlaAún no hay calificaciones

- Mbm-Italien EnuDocumento285 páginasMbm-Italien EnuRadwan AL TrougAún no hay calificaciones

- Cswip 31 Practical PDFDocumento4 páginasCswip 31 Practical PDFJigar PrajapatiAún no hay calificaciones

- 2012 General CatalogueDocumento80 páginas2012 General CatalogueTiberiu OrmosAún no hay calificaciones

- WPQ Format Sec IxDocumento2 páginasWPQ Format Sec IxParminder SinghAún no hay calificaciones

- ESP Erection ManualDocumento35 páginasESP Erection Manualneeraja100% (1)

- Visual Welding Inspection: Course Reference WIS 1EDocumento136 páginasVisual Welding Inspection: Course Reference WIS 1ENgoc Bang100% (3)

- WPS 01 WQT PDFDocumento1 páginaWPS 01 WQT PDFkiki270977Aún no hay calificaciones

- Work Method ErectionDocumento40 páginasWork Method ErectionZainal AbidinAún no hay calificaciones

- Service Manual Ivt Geo 312 C Bosch Compress 7000Documento60 páginasService Manual Ivt Geo 312 C Bosch Compress 7000Yusef CevaAún no hay calificaciones

- Iso 15607 2003Documento24 páginasIso 15607 2003umur kaçamaklı100% (2)

- UM M Series Air-Cooled Type A4 enDocumento172 páginasUM M Series Air-Cooled Type A4 enTuấn LiuAún no hay calificaciones

- Welding Procedure SpecificationDocumento2 páginasWelding Procedure SpecificationhuicholeAún no hay calificaciones

- DSP Split Unit Technical ManualDocumento31 páginasDSP Split Unit Technical Manualfarshan296015100% (1)

- Tools Materials Equipment SMAW NCIIDocumento3 páginasTools Materials Equipment SMAW NCIIGie Ko100% (3)

- MASTER LIST OF PROCEDURE RECORDSDocumento2 páginasMASTER LIST OF PROCEDURE RECORDSsivagnanam sAún no hay calificaciones

- Universal WPS for pipe to plate fillet weldingDocumento1 páginaUniversal WPS for pipe to plate fillet weldingIbrahim shaikAún no hay calificaciones

- Electricity Application FormDocumento4 páginasElectricity Application FormdanruttleAún no hay calificaciones

- Tugas 2 WeldingDocumento9 páginasTugas 2 WeldingMuhammad AndriAún no hay calificaciones

- Elektrik K2BhgCK3BhgB PelajarDocumento2 páginasElektrik K2BhgCK3BhgB PelajarA. SuhaimiAún no hay calificaciones

- NO Welder Id Welder Name: Team LeaderDocumento1 páginaNO Welder Id Welder Name: Team LeaderHAKANAún no hay calificaciones