Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Elac Failure A320

Cargado por

Panagiotis DiakidisTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Elac Failure A320

Cargado por

Panagiotis DiakidisCopyright:

Formatos disponibles

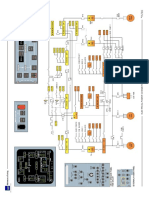

Review of flight control system architecture revealed that under normal operation, elevator control is

performed by ELAC 2 via the inboard (green and yellow) elevator servos. The outboard (blue) servos

act in the damping mode. Trimmable horizontal stabilizer (THS) control is accomplished by ELAC 2 via

pitch trim actuator (PTA) number one.

The ELACs and spoiler elevator computers (SECs) also actively monitor the mode valve transducer on

each elevator servo. A discrepancy results in a mode fault. According to Airbus engineers, "ELAC 2 pitch

fault followed by elevator servo fault are a consequence of the mode valve transducer monitoring

performed by ELAC2 and SEC2," possibly caused by "defect on the common part of the wiring

installation of the transducer between ELAC2 and SEC 2."

During normal operation, detection of an elevator or THS fault disengages the pitch axis of ELAC 2

(both elevators and THS). ELAC 1 assumes control of the elevators, via the outboard (blue) elevator

servos, and the THS via PTA number two. According to Northwest Airlines procedures, scheduled

operational checks of ELAC 1 are accomplished during the C check.

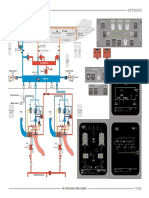

The ELACs and SECs actively monitor actuator commands (orders) and corresponding positions. A

preset bias between the order and position results in a fault. With regard to the THS, a fault is triggered

when the discrepancy between the THS order and the measured THS position becomes greater than

0.6 degrees for at least 100 milliseconds. Airbus' evaluation of DFDR traces indicates a THS order

occurred immediately prior to the ELAC 1 pitch fault with no corresponding THS movement. "When the

order is sufficient, there is a quick THS movement counteracted by the autopilot because this movement

is out of phase."

During trouble shooting of the airplane, the elevator servo damping test was completed with no errors

and the THS trim functioned normally during the maintenance test. The right outboard (blue) elevator

servo was cold soaked with nitrogen. When cooled, a coil in the servo controller electrovalve, part

number 30973-222, faulted with an open circuit.

ELAC 2 and THS components were examined under the supervision of the Bureau Enquetes-Accidents.

ELAC 2, serial number 1364, was tested, May 9, 1996, by Sextant Industries. During the test, the K10

relay was discovered to be faulty. Sextant's evaluation of the fault disclosed that the faulty relay was not

related to the pitch excursions. The failure of the relay was described as a "known" phenomenon

covered by Sextant Service Letter SXT/A320-064.

The THS actuator, serial number 454, was tested at Airbus Industries. When installed on the standard

test platform (iron bird) the actuator functioned normally.

The servo motor, serial number 1724, and electronic module, serial number 1618, were tested by Lucas

Aerospace. The motor functioned normally. The electronic module was found to have a defective diode

on the command link of one of the power transistors. The defect produced an intermittent loss of

electrical motor power during transient, closed loop control of the actuator.

También podría gustarte

- 08rr410306 Jet Propulsion and Rocket EngineeringDocumento6 páginas08rr410306 Jet Propulsion and Rocket EngineeringsmijusAún no hay calificaciones

- Technical Ground School Study Guide: AIRBUS A319/320/321 2009 - 2010Documento15 páginasTechnical Ground School Study Guide: AIRBUS A319/320/321 2009 - 2010Ravi Vikram SinghAún no hay calificaciones

- Nov-23 Main Fcom QRH FCTM Changes A320Documento17 páginasNov-23 Main Fcom QRH FCTM Changes A320Joe FalchettoAún no hay calificaciones

- Instrument Rating Pts Change5 PDFDocumento66 páginasInstrument Rating Pts Change5 PDFMarco Antonio ValdiviesoAún no hay calificaciones

- CB List 320Documento12 páginasCB List 320AmbgAmbgAún no hay calificaciones

- Apuntes A320Documento64 páginasApuntes A320diablohuno50% (2)

- VTSPDocumento10 páginasVTSPdr3xAún no hay calificaciones

- GaugeDocumento3 páginasGaugesantadkAún no hay calificaciones

- Flight Path StabilityDocumento11 páginasFlight Path StabilityAlvin AnthonyAún no hay calificaciones

- Ltfj/Saw: 1. General 1. General 1. General 1. GeneralDocumento43 páginasLtfj/Saw: 1. General 1. General 1. General 1. GeneralYigit Omer CiftciAún no hay calificaciones

- EDLWDocumento11 páginasEDLWVST88Aún no hay calificaciones

- Standard Equipment List P68C Glass V7Documento7 páginasStandard Equipment List P68C Glass V7Ishant BaliyanAún no hay calificaciones

- Fly by Wire and Fly by OpticsDocumento7 páginasFly by Wire and Fly by OpticsvenkatsahulAún no hay calificaciones

- Phase 1 Theory Check: Flight Rules and Air LawDocumento16 páginasPhase 1 Theory Check: Flight Rules and Air LawEthan PoonAún no hay calificaciones

- Amm - 12 11 28 650 005 ADocumento7 páginasAmm - 12 11 28 650 005 Araiday84Aún no hay calificaciones

- A330-Fire ProtectionDocumento25 páginasA330-Fire ProtectionShifu Chip100% (1)

- EASA TCDS A.110 Airbus A380Documento17 páginasEASA TCDS A.110 Airbus A380kiecard33% (3)

- Assignment 3 Phase Transformer HarithDocumento8 páginasAssignment 3 Phase Transformer HarithAhmad FakhruddinAún no hay calificaciones

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Documento6 páginasAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanAún no hay calificaciones

- B767 L3 ATA 29 Hydraulic PowerDocumento134 páginasB767 L3 ATA 29 Hydraulic PowerOliver IrrazabalAún no hay calificaciones

- Bài 4 - Longitudinal Motion (Stick Fixed) (2008)Documento32 páginasBài 4 - Longitudinal Motion (Stick Fixed) (2008)Tuan Anh PhamAún no hay calificaciones

- Section 14 - AutopilotDocumento23 páginasSection 14 - AutopilotversineAún no hay calificaciones

- MP - Chapter 9 - Airline and Airport Support PDFDocumento12 páginasMP - Chapter 9 - Airline and Airport Support PDFsyukardinAún no hay calificaciones

- CBT Otr AtrDocumento5 páginasCBT Otr Atrmaria pulungAún no hay calificaciones

- Aircraft Power Plants: Learning ObjectiveDocumento22 páginasAircraft Power Plants: Learning ObjectivePimenta boa100% (1)

- Blade ElementDocumento6 páginasBlade ElementJd ValleAún no hay calificaciones

- 00 Cockpit DoorDocumento18 páginas00 Cockpit DoorKıvanc Terzioglu100% (1)

- P180 Avanti-Flap SystemDocumento4 páginasP180 Avanti-Flap SystemravAún no hay calificaciones

- Exterior Inspection B737-800Documento14 páginasExterior Inspection B737-800Me KeenAún no hay calificaciones

- Cabri G2 - Weight and Balance v1.06-1Documento1 páginaCabri G2 - Weight and Balance v1.06-1Arnong PhetsaiseeAún no hay calificaciones

- Chapter 18 CVR & FDRDocumento41 páginasChapter 18 CVR & FDRveenadivyakishAún no hay calificaciones

- Cospas Sarsat PDFDocumento6 páginasCospas Sarsat PDFKaushik ShankarAún no hay calificaciones

- Airworthiness DirectivesDocumento3 páginasAirworthiness DirectivesDuzzysAún no hay calificaciones

- Resumen Autoflight ATA 22Documento21 páginasResumen Autoflight ATA 22Denisse Castañeda Gonzalez100% (1)

- Omdb/Dxb Dubai, Uae: Darax 1T Bubin 3TDocumento25 páginasOmdb/Dxb Dubai, Uae: Darax 1T Bubin 3TMohannad AlamayrehAún no hay calificaciones

- Use of Summaries in The QRHDocumento1 páginaUse of Summaries in The QRHFran FerrandoAún no hay calificaciones

- ATA 5-12 Ground Handling & ServicingDocumento70 páginasATA 5-12 Ground Handling & Servicingامیر شعاعیAún no hay calificaciones

- VTSPDocumento26 páginasVTSPTTurbo180100% (1)

- Ata 24Documento18 páginasAta 24jontis jasoliyaAún no hay calificaciones

- 00 Ground Handling PDFDocumento6 páginas00 Ground Handling PDFlsthanhlsthanhAún no hay calificaciones

- A320 FCOM Vol 1 ISS Rev 43DDocumento1337 páginasA320 FCOM Vol 1 ISS Rev 43DRiccardo Casarosa0% (1)

- ATA 35 Oxygen PDFDocumento12 páginasATA 35 Oxygen PDFناتاليا ناتاليا100% (1)

- Asiana Flight 214: National Transportation Safety Board Interview SummariesDocumento140 páginasAsiana Flight 214: National Transportation Safety Board Interview SummariesKQED NewsAún no hay calificaciones

- Fully Stressed Design in MSC - NastranDocumento23 páginasFully Stressed Design in MSC - NastrankkayaturkAún no hay calificaciones

- A 330 Approach Briefing/Flows Guide - : W Weather - Obtain ATIS Automation FlowsDocumento24 páginasA 330 Approach Briefing/Flows Guide - : W Weather - Obtain ATIS Automation Flowspilote_a320Aún no hay calificaciones

- Chapter 8 - Environmental Control System: REV 3, May 03/05Documento40 páginasChapter 8 - Environmental Control System: REV 3, May 03/05julian marinAún no hay calificaciones

- ATA 36 AIRBUS 319/320: TH THDocumento2 páginasATA 36 AIRBUS 319/320: TH THIrvan AlbabAún no hay calificaciones

- Single Aisle Technical Training Manual Maintenance Course - T1 (V2500-A5/Me) OxygenDocumento60 páginasSingle Aisle Technical Training Manual Maintenance Course - T1 (V2500-A5/Me) OxygenEvanildoLealAún no hay calificaciones

- A380 Level I Ata 51 Structure PDFDocumento10 páginasA380 Level I Ata 51 Structure PDFGuyAún no hay calificaciones

- M50-AL QuestionsDocumento2 páginasM50-AL QuestionsOwen Chieng OCAún no hay calificaciones

- Flight Operations Transmission - Fot: Customer Services DirectorateDocumento4 páginasFlight Operations Transmission - Fot: Customer Services DirectorateVincenzo ParisiAún no hay calificaciones

- 1.1.008 - Approval of MEL and CDL - Rev 2Documento28 páginas1.1.008 - Approval of MEL and CDL - Rev 2Mansour Bu MusabAún no hay calificaciones

- Bank of Essay QuestionsDocumento2 páginasBank of Essay Questionssiti hasanahAún no hay calificaciones

- Ref No S000123A7ANO Incident Investigation Report: in The Name of GodDocumento7 páginasRef No S000123A7ANO Incident Investigation Report: in The Name of GodVikram PrabhuAún no hay calificaciones

- Map ChartDocumento2 páginasMap Chart김종호Aún no hay calificaciones

- MC 35-14 Amendment To Pcar Part 4 11unmanned Aerial Vehicle UavDocumento11 páginasMC 35-14 Amendment To Pcar Part 4 11unmanned Aerial Vehicle UavJayson RagasaAún no hay calificaciones

- A32-21-002 - "VENT ANVCS SYS FAULT" ECAM Warning - AEVC V06 and SKIN Air Valves PDFDocumento1 páginaA32-21-002 - "VENT ANVCS SYS FAULT" ECAM Warning - AEVC V06 and SKIN Air Valves PDFAmeer HamzaAún no hay calificaciones

- Task 213100-05Documento7 páginasTask 213100-05yamidruzAún no hay calificaciones

- ELT Commissioning TrainingDocumento50 páginasELT Commissioning Trainingqureshihakeem2005Aún no hay calificaciones

- A321 Ata24 Electrical Power SchematicDocumento1 páginaA321 Ata24 Electrical Power SchematicPanagiotis DiakidisAún no hay calificaciones

- 8130 21FDocumento81 páginas8130 21FPanagiotis DiakidisAún no hay calificaciones

- A3c Trimmable Horizontal Stabilizer B1Documento1 páginaA3c Trimmable Horizontal Stabilizer B1Panagiotis Diakidis100% (1)

- FAST37Documento23 páginasFAST37Panagiotis DiakidisAún no hay calificaciones

- Slats and Flaps Control System B1 - B2Documento1 páginaSlats and Flaps Control System B1 - B2Panagiotis DiakidisAún no hay calificaciones

- Fin EntryDocumento60 páginasFin EntryPanagiotis DiakidisAún no hay calificaciones

- Slats and Flaps Control System B1 - B2Documento1 páginaSlats and Flaps Control System B1 - B2Panagiotis DiakidisAún no hay calificaciones

- A320 Ata28-00Documento1 páginaA320 Ata28-00Panagiotis DiakidisAún no hay calificaciones

- A321 Ata21-00 PDFDocumento1 páginaA321 Ata21-00 PDFkpilAún no hay calificaciones

- FAC B1 - B2 - B2redDocumento1 páginaFAC B1 - B2 - B2redPanagiotis DiakidisAún no hay calificaciones

- Quick Reference Guide General Pneumatic: SR TechnicsDocumento2 páginasQuick Reference Guide General Pneumatic: SR TechnicsPanagiotis Diakidis0% (1)

- Airbus A320 Idg ServiceDocumento22 páginasAirbus A320 Idg ServicePanagiotis Diakidis100% (5)

- A320 Ata38-00Documento1 páginaA320 Ata38-00Panagiotis DiakidisAún no hay calificaciones

- Rudder Control B1Documento1 páginaRudder Control B1Panagiotis DiakidisAún no hay calificaciones

- AIRBUS A320 Removal Power PlantDocumento28 páginasAIRBUS A320 Removal Power PlantPanagiotis Diakidis100% (3)

- Stations Nacelles and PylonsDocumento3 páginasStations Nacelles and PylonsPanagiotis Diakidis100% (1)

- Airbus AbreviationsDocumento12 páginasAirbus AbreviationsPanagiotis DiakidisAún no hay calificaciones

- Jeppesen Glossary LegendsDocumento118 páginasJeppesen Glossary LegendssolebAún no hay calificaciones

- Mod 06 - Knowledge Requirements & Levels - B1.1 & B1.3Documento3 páginasMod 06 - Knowledge Requirements & Levels - B1.1 & B1.3Panagiotis DiakidisAún no hay calificaciones

- ΛΕΞΙΚΟ ΑΕΡΟΠΟΡΙΚΩΝ ΟΡΩΝDocumento589 páginasΛΕΞΙΚΟ ΑΕΡΟΠΟΡΙΚΩΝ ΟΡΩΝfgousiosAún no hay calificaciones

- Airbus A320 Offwing Esc Slide, Infl ReservoirDocumento20 páginasAirbus A320 Offwing Esc Slide, Infl ReservoirPanagiotis DiakidisAún no hay calificaciones

- Airbus A320 MLG Doors GviDocumento6 páginasAirbus A320 MLG Doors GviPanagiotis DiakidisAún no hay calificaciones

- Airbus A320 Inst Power PlantDocumento42 páginasAirbus A320 Inst Power PlantPanagiotis Diakidis100% (1)

- Station StringersDocumento1 páginaStation StringersPanagiotis Diakidis50% (2)

- Airbus A320 MLG Doors GviDocumento6 páginasAirbus A320 MLG Doors GviPanagiotis DiakidisAún no hay calificaciones

- Airbus A320 Eng OilDocumento13 páginasAirbus A320 Eng OilPanagiotis Diakidis100% (2)

- Airbus A320 Eng Starter SRVDocumento8 páginasAirbus A320 Eng Starter SRVPanagiotis Diakidis100% (1)

- Mod8, B1, B2, Basic AerodynamicsDocumento65 páginasMod8, B1, B2, Basic AerodynamicsPanagiotis DiakidisAún no hay calificaciones

- Airbus A320 Brake Accu PNCDocumento19 páginasAirbus A320 Brake Accu PNCPanagiotis Diakidis100% (1)

- Aircraft Drawing - Chap 2 PDFDocumento24 páginasAircraft Drawing - Chap 2 PDFnotonectal100% (1)

- Smart Robot Car KitDocumento109 páginasSmart Robot Car KitEdenilson Guedes100% (3)

- Finding Simplicity and Efficiency in Servo Press FeedsDocumento3 páginasFinding Simplicity and Efficiency in Servo Press FeedsSIMONEAún no hay calificaciones

- GFF-0102 CNC Application Note Alpha ServoDocumento1 páginaGFF-0102 CNC Application Note Alpha ServoSam eagle goodAún no hay calificaciones

- Military Vehicle Electrical SystemsDocumento588 páginasMilitary Vehicle Electrical Systemsd3xterAún no hay calificaciones

- Catalogo ServomotorDocumento36 páginasCatalogo ServomotorLuis LopezAún no hay calificaciones

- Echolab TestDocumento78 páginasEcholab Testtchma hichamAún no hay calificaciones

- The University of Texas at Arlington Timers, Capture/Compare/PWMDocumento22 páginasThe University of Texas at Arlington Timers, Capture/Compare/PWMadamwaiz100% (1)

- Data Transfer Using VLCDocumento15 páginasData Transfer Using VLCAnurag MohantyAún no hay calificaciones

- pc2000 Motion Controller User Guide PDFDocumento120 páginaspc2000 Motion Controller User Guide PDFaboralaf100% (1)

- Tendon-Gear Mechanism For Robot Arm (School Project)Documento17 páginasTendon-Gear Mechanism For Robot Arm (School Project)Grace Firsta LukmanAún no hay calificaciones

- Processing Motor ControlDocumento9 páginasProcessing Motor Controljosé_huisa_7Aún no hay calificaciones

- PDVMARINA RTflx50 PDFDocumento93 páginasPDVMARINA RTflx50 PDFGera ChacoaAún no hay calificaciones

- Servomechanism Question BankDocumento4 páginasServomechanism Question BankShreepad ShivkarAún no hay calificaciones

- Turbo PMAC TrainingDocumento472 páginasTurbo PMAC TrainingOwais JafriAún no hay calificaciones

- Falcon Aero Club (Salem) : Session 1Documento2 páginasFalcon Aero Club (Salem) : Session 1karthipriyaAún no hay calificaciones

- User Guide: Supermarine Spitfire MK XVIDocumento17 páginasUser Guide: Supermarine Spitfire MK XVIPedro ValdezAún no hay calificaciones

- Mitsubishi CNC Alarms Servo Troubleshooting PDFDocumento2 páginasMitsubishi CNC Alarms Servo Troubleshooting PDFStefano Capanni50% (2)

- Covid 19 Thermal Screening: Manipal School Information ScienceDocumento22 páginasCovid 19 Thermal Screening: Manipal School Information ScienceNIHAARIKA MANJUNATHAún no hay calificaciones

- JNC 40M Manual (English)Documento44 páginasJNC 40M Manual (English)maddee.sabrieAún no hay calificaciones

- Position Control of Pick and Place Robotic ArmDocumento5 páginasPosition Control of Pick and Place Robotic Armavinashs2410_41108610% (1)

- V80647 Parker Series 15-30P High Pressure FiltersDocumento12 páginasV80647 Parker Series 15-30P High Pressure FiltersPaulPaucarCamposAún no hay calificaciones

- MPDFDocumento6 páginasMPDFFrancisco Javier Mendoza Patiño0% (6)

- Product ListDocumento11 páginasProduct Listavijit1976Aún no hay calificaciones

- Chapter 2 ActuatorsDocumento20 páginasChapter 2 ActuatorsMuhammad AniqAún no hay calificaciones

- Yasnac MRC Alarm and Error CodeDocumento80 páginasYasnac MRC Alarm and Error Codesunhuynh100% (2)

- L17025eng CDocumento164 páginasL17025eng CAdhi SetyokoAún no hay calificaciones

- PacerencodersDocumento2 páginasPacerencodersesau hernandezAún no hay calificaciones

- iHSS60 EnglishManualDocumento21 páginasiHSS60 EnglishManualcastellano_rAún no hay calificaciones

- Alphatronic Remote Control SystemDocumento29 páginasAlphatronic Remote Control SystemrecutuAún no hay calificaciones