Documentos de Académico

Documentos de Profesional

Documentos de Cultura

003-WPS For CS & Itcs With PWHT (C.S-19-40MM) (Itcs-20-44mm) PDF

Cargado por

Köksal PatanDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

003-WPS For CS & Itcs With PWHT (C.S-19-40MM) (Itcs-20-44mm) PDF

Cargado por

Köksal PatanCopyright:

Formatos disponibles

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.251.024

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No :

Project Rev.: D

Page 2 of 6

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

11.02.09

Issued for Cancellation

AB

EO

AG

IFC

23.03.08

Issued for Company Comments

BR

UA

ZG

ICC

17.03.08

Issued for Review

BR

UA

ZG

IIR

12.03.08

Issued for Internal Review

BR

UA

ZG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

LINDE ENGINEERING AG

WPS FOR CS & ITCS WITH PWHT (C.S-19-40MM) /

(ITCS-20-44MM)

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

WPS

QAC

GTL

003

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.251.024

Vendor Code

Rev No: A

TABLE OF CONTENTS

1.

001 2MH127-003-CS/ITCS-G+S

T-4.251.024 Rev. D

Page 4 of 6

GAMA

&

QATAR

...

Client:

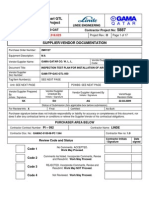

WELDING PROCEDURE SPECFICATIONS (WPS)

Reference: ASME B31.3, ASME Sec IX, AWS 0 1.1

_ _..

-.6!MlI"""~

SHELL or its PMC

Contractor: LINDE ENGINEERING AG

C2 ASU PEARL GTL PROJECT-RAS LAFFAN INDUSTRIAL CITY

Project Name:

Company Name:

GAMAQATAR

WPS No:

PQR No:

03-34

Date:

0

0

Rev:

001 2MH127- 003-CS/ITCSG+S

Rev:

GTAW+SMAW

Welding Process :

17.03.2008

10.11.2003

Date:

MANUAL

Type(s):

JOINTS ( QW - 402)

Joint Design:

AS DETAILED BELOW

Backing (Yesl No):

N/A

Backing Material (Type ):

-=--1

37 .52.5.

NO

~

1.6 0.8mm

-L

r -oj r--

-lm

31rnrn

Base Metals ( QW - 403) Also as per QW 420.2

PNo.

Group No.

To

PNo

Group No.

OR

Specification Type and Grade:

SA671CC65 OR Equivalent

Specification Type and Grade:

SA516Gr 70 OR Equivalent

To

OR

Chern.Analysis and Mech. Prop:

N/A

Chern.Analysis and Mech. Prop:

N/A

Thickness Range :

Groove:

To

CS-19 TO 40mm

Fillet:

ALL

Fillet:

ALL

ITCS-20 TO 44mrn

Diameter Range

Groove:

ALL

Others:

FILLER METALS(QW 404)

F No:

6&4

A-No

Spec No. (SFA):

5.18&5.1

AWS No. (Class):

ER 70S6 & E 7018-1

Size Of Filler Metals:

2.4-4.0

Other:

N/A

Other:

N/A

Deposited weld metal Thk.

Groove:

GTAW-5mm,SMAW-35mm

Fillet:

N/A

Electrode-Flux (Typet

Basic! E 7018-1)

Trade Name:

ESAB OK Tig rod 12.64 & FILARC35S

Consumables Insert:

N/A

POSITION(SHQW 405)

POST WELD HEAT TREATMENT(QW 407)

Positions Of Groove:

6G

Temperature Range:

580C-620C

Welding Progression:

UPHILL

Time Range:

2.5 min per mm

Position(s) of fillet:

ALL

Rate of heating:

Rate of Coolina:

200C

200C

GAMAREP

Preoared By

~.

(:J

LINDE REP

Checked Bv

~tAsUJ

.~

'~

,..,su

><

-{ pdi'\". c'l

QSGTL or its PMC

G!)

~

lo~t<UCI'l'~W

~Q<

'~o

,,'b

21

~\

~ QA/~"'~\

<"/-'):

.qSSUI/AN~

'"

GAMA

&~

QATAR

Iwps No:001

WELDING PROCEDURE SPECIFICATIONS (WPS)

Reference: ASME 831.3, ASME Sec IX, AWS 0 1.1

((1ldfo:t.fJ.w.,"'I"~

Rev. No: 0

2MH127- 003-CSfITCS-G+S

Date:

PRE- HEAT (QW - 406)

GAS (QW - 408)

Pre Heat Min:

80C

(Preheat to 50C if metal temp< 5C)

Interpass temp:

200C Max

Method of Heating: By LPGfPropane Gas Heating Torch

Shielding Gas(es):

Percent Composition(Mixture):

Shielding gas flow Rate:

Temp Monitoring Method:Thermo melt crayonsf Digital thermo meter

Trailing shielding gas composition:

17.03.2008

Argon

99.99%

12-15 LPM

Backing Gas(es):

NfA

NfA

ELECTRICALCHARACTERISTICS(QW - 409)

Current AC or DC

DC

Polarity

Amps Range

Min120Amps-Max175Amps

Tungsten Electrode Size and Type

2.0 EW-Th-2

Mode of Metal Transfer GMAW

NfA

Electrode Wire Feed Speed Range

NfA

Voltage range

Electrode -ve (GTAWl & Electrode +ve (SMAWI

Min10V-Max 26V

TECHNIQUE(QW - 410)

String or Weave Bead:

String-Root Pass Weave- FiII& Cap

Orifice or Gas Cup Size :

6f 8f11mm

Initial and Interpass Cleaning:

Grinding f Wire brushina

Method of Back gouging:

NfA

Oscillation

NfA

Contact Tube To Work Distance

NfA

Multiple Or Single Pass (per side)

Multiple Passes

Multiple or Single Electrodes

Single Electrode

Travel Speed(Range)

35 mmfmin - 90 mmfmin

OTHERS:

Piping Class:

Service:

PQR Impact test temperature:

-46C

Filler Metal

Weld Pass

Current

Process

Root-1

Hot-2

FILL-3-7

FILL-8-19

CAP-20-24

GTAW

GTAW

SMAW

SMAW

SMAW

Class

Diamm

Polarity

Amps

Range

ER 70S6

ER 70S6

E 7018-1

E 7018-1

E 7018-1

2.4

2.4

3.2

4.0

3.2

DCEN

DCEN

DCEP

DCEP

DCEP

135-140

165-175

120-130

145-150

125-130

Volts Range

Travel Speed

mmfmin

Heat Input

KJfmm (Max.)

10-12

10-13

22-25

23-26

22-24

35-45

65-75

70-80

80-90

65-75

2.88

2.1

2.78

2.92

2.88

Notes :

1. Above mentioned passes may vary depending on actual thickness of the joint.

2. Weaving width shall not exceed 3 times the diameter of electorde.

3. Electrodes shall be stored & handled as per approved consumable handling procedure-T.4.250.931 f manufacturers instructions.

4. Max: 3.0mm Deposit in one Layer.

GAMA REP

Iprepared Bv

~;~v

'.

ASU

'-

Checked bv

~~

'~~~1

PGiL-C2.

ASIJ

GAMQCRQAC-GTL-106

LINDE REP

QSGTL or its PMC

'->0

\~t"-r.

~

</l):

OAf OC{

2 ....

@

6'6

~,

-qss~~ t~~\

También podría gustarte

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDocumento7 páginas005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- 010-PREWPS FOR SS304 (2.5 - 11 MM) PDFDocumento7 páginas010-PREWPS FOR SS304 (2.5 - 11 MM) PDFKöksal PatanAún no hay calificaciones

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocumento28 páginas047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanAún no hay calificaciones

- 013-WPS FOR SS321 (1.5 - 26.6 MM) PDFDocumento26 páginas013-WPS FOR SS321 (1.5 - 26.6 MM) PDFKöksal PatanAún no hay calificaciones

- Welding Procedure Specification For Storage Tank & Piping SystemDocumento3 páginasWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadAún no hay calificaciones

- Ug PipingDocumento1 páginaUg PipingVinoth KumarAún no hay calificaciones

- PWHT Procedure For Petrol Steel - CoreDocumento9 páginasPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluAún no hay calificaciones

- Cold Tap Coating Report 2Documento1 páginaCold Tap Coating Report 2Jamal BakhtAún no hay calificaciones

- Hydrostatic Test ReportDocumento1 páginaHydrostatic Test ReportibicengAún no hay calificaciones

- WPS - Smaw - 2Documento6 páginasWPS - Smaw - 2Harkesh RajputAún no hay calificaciones

- Blasting & Painting Inspection Report Format For Bottom Plate 01Documento7 páginasBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteAún no hay calificaciones

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocumento2 páginasASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaAún no hay calificaciones

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocumento3 páginasWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoAún no hay calificaciones

- WPS FormatDocumento2 páginasWPS FormatAmit SarkarAún no hay calificaciones

- Acceptance Criteria Asme B31.3 PDFDocumento1 páginaAcceptance Criteria Asme B31.3 PDFAhmad RizkiAún no hay calificaciones

- ITP For Piping SystemsDocumento6 páginasITP For Piping SystemsGia Minh Tieu TuAún no hay calificaciones

- Flange Installation ProceduresDocumento3 páginasFlange Installation Proceduresgplese0100% (1)

- Wps For Smaw06-001 (Pipe 6g CS)Documento10 páginasWps For Smaw06-001 (Pipe 6g CS)walitedisonAún no hay calificaciones

- (786412530) Exhibit 4 - 2 - Asme TolerancesDocumento4 páginas(786412530) Exhibit 4 - 2 - Asme TolerancesMohd SharainiAún no hay calificaciones

- Utoc Preliminary Wps Shell Project 270807 PDFDocumento55 páginasUtoc Preliminary Wps Shell Project 270807 PDFErick HoganAún no hay calificaciones

- QAP For PQR'S - For Impact TestingDocumento3 páginasQAP For PQR'S - For Impact TestingDries VandezandeAún no hay calificaciones

- HYDRO Test ReportDocumento3 páginasHYDRO Test ReportHanuman RaoAún no hay calificaciones

- Jpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Documento9 páginasJpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Anoop N Kutty100% (1)

- Welder ID Card BRE KarahaDocumento5 páginasWelder ID Card BRE KarahaHerruSetiawan100% (1)

- Weld ShrinkageDocumento16 páginasWeld ShrinkageWeff JingAún no hay calificaciones

- WPS Pipe 08'' SHD 40 SMAW REV02Documento2 páginasWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejAún no hay calificaciones

- Pressure Vessel Dimension Inspection PDFDocumento17 páginasPressure Vessel Dimension Inspection PDFEqubal KhanAún no hay calificaciones

- Welding Repair ProcdureDocumento16 páginasWelding Repair Procdureprem nautiyal100% (1)

- BPV IX-16-3 QW-283 - ButteringDocumento1 páginaBPV IX-16-3 QW-283 - ButteringyutweldingAún no hay calificaciones

- Itp TankageDocumento7 páginasItp TankageIr FankovicAún no hay calificaciones

- QC Dossier 1Documento1 páginaQC Dossier 1VishnuGKAún no hay calificaciones

- Inspection Test Plan Fuel Gas Conditioning SkidDocumento19 páginasInspection Test Plan Fuel Gas Conditioning SkidDin AizuAún no hay calificaciones

- Wps Mig PDF FreeDocumento3 páginasWps Mig PDF Freehanz bermejoAún no hay calificaciones

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocumento1 páginaWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedAún no hay calificaciones

- Asme WPS Demo PWHT PDFDocumento3 páginasAsme WPS Demo PWHT PDFGanesh rohitAún no hay calificaciones

- Consumable Spec Rev 12Documento24 páginasConsumable Spec Rev 12megastar0604Aún no hay calificaciones

- Proposed WPSDocumento2 páginasProposed WPSChisom Ikengwu100% (2)

- Site Inspection and Test Plan For Tie-In Works: Subcontrac TorDocumento24 páginasSite Inspection and Test Plan For Tie-In Works: Subcontrac Torprabu palaniswamyAún no hay calificaciones

- Quality Assurance Protocol: Raw MaterialDocumento2 páginasQuality Assurance Protocol: Raw MaterialShah Newaz KabirAún no hay calificaciones

- Welding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Documento1 páginaWelding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Lipika GayenAún no hay calificaciones

- QA-R-04 - Visual Inspection ReportDocumento1 páginaQA-R-04 - Visual Inspection ReportvinothAún no hay calificaciones

- QAP For Conical StrainerDocumento2 páginasQAP For Conical StrainersatishchidrewarAún no hay calificaciones

- 1662 15Documento117 páginas1662 15RajamanikkamAún no hay calificaciones

- Hyundai Steel Mill TestDocumento1 páginaHyundai Steel Mill TestJamesAún no hay calificaciones

- 77731-ITP Rev.1Documento16 páginas77731-ITP Rev.1David SalgueroAún no hay calificaciones

- Daily Welding Report PLD LogoDocumento1 páginaDaily Welding Report PLD Logonike_y2kAún no hay calificaciones

- WPQ-1083 3G PDFDocumento2 páginasWPQ-1083 3G PDFduendex360100% (1)

- Inspection Test Plan For Pipeline JobsDocumento6 páginasInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينAún no hay calificaciones

- Sample API 1104 WpsDocumento1 páginaSample API 1104 Wpsippon_osoto100% (1)

- Project Department Kuwait National Petroleum Company: Daily Welding Inspection ReportDocumento1 páginaProject Department Kuwait National Petroleum Company: Daily Welding Inspection ReportMuthazhagan SaravananAún no hay calificaciones

- 2G & 5GDocumento2 páginas2G & 5GRahul MoottolikandyAún no hay calificaciones

- SAIC-W-2XXX-11 Control of Welding ConsumablesDocumento5 páginasSAIC-W-2XXX-11 Control of Welding ConsumablesAnsuman KalidasAún no hay calificaciones

- WPS PQR-05Documento10 páginasWPS PQR-05Ranjan KumarAún no hay calificaciones

- 011-PREWPS FOR SS304 (6.3 - 18.7 MM) PDFDocumento9 páginas011-PREWPS FOR SS304 (6.3 - 18.7 MM) PDFKöksal PatanAún no hay calificaciones

- 043-ITP FOR Water Proofing (Buildings) PDFDocumento13 páginas043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 032-Itp For Painting and Coating PDFDocumento19 páginas032-Itp For Painting and Coating PDFKöksal Patan80% (20)

- Calculation of Secondary Superheater 01.02.2012 00Documento45 páginasCalculation of Secondary Superheater 01.02.2012 00brintopvAún no hay calificaciones

- Ea 682808 001 R05Documento7 páginasEa 682808 001 R05anbarasusivaprakasam100% (1)

- Datasheet For Nitrogen Bottle Rack 4B.4300 SAI S0003 ISGP U48000 MS 2105...Documento10 páginasDatasheet For Nitrogen Bottle Rack 4B.4300 SAI S0003 ISGP U48000 MS 2105...vydaniAún no hay calificaciones

- 040-ITP For Repair of Steam Distribution Manifold PDFDocumento11 páginas040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanAún no hay calificaciones

- 016-CIVIL - MS Anchor Bolt Installation PDFDocumento14 páginas016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 015-Method Statement For Painting Works (Building) PDFDocumento21 páginas015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocumento23 páginas014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanAún no hay calificaciones

- 015-MS For Night Works PDFDocumento16 páginas015-MS For Night Works PDFKöksal Patan80% (5)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocumento18 páginas017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 014-MS For General Scaffolding PDFDocumento33 páginas014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 013-MS For Mass Concrete Works PDFDocumento26 páginas013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 048-Itp For Installation of Hvac Unit PDFDocumento8 páginas048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 049-Itp For Lighting and Small Power (Building) PDFDocumento15 páginas049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocumento16 páginas012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 041 - ITP For Painting (Building) PDFDocumento12 páginas041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 013-MS Utilization of Hilti DX 76 PDFDocumento51 páginas013-MS Utilization of Hilti DX 76 PDFKöksal PatanAún no hay calificaciones

- 050-Itp For Installation of Air Intake Filter PDFDocumento17 páginas050-Itp For Installation of Air Intake Filter PDFKöksal PatanAún no hay calificaciones

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocumento18 páginas012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanAún no hay calificaciones

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocumento10 páginas044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 010-MS For Grouting PDFDocumento33 páginas010-MS For Grouting PDFKöksal PatanAún no hay calificaciones

- 011-Method Statement For Repair of Concrete Works PDFDocumento25 páginas011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocumento17 páginas010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanAún no hay calificaciones

- 009-Method Statement - Main Erection Sequence For Acc PDFDocumento68 páginas009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocumento10 páginas045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocumento18 páginas046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanAún no hay calificaciones

- 008-CIVIL-MS Backfilling Works PDFDocumento16 páginas008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 009-Civil-Ms Concrete Works PDFDocumento27 páginas009-Civil-Ms Concrete Works PDFKöksal PatanAún no hay calificaciones

- 043-ITP FOR Water Proofing (Buildings) PDFDocumento13 páginas043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 040-ITP For Repair of Steam Distribution Manifold PDFDocumento11 páginas040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanAún no hay calificaciones

- 038-Itp For Coldboxes PDFDocumento25 páginas038-Itp For Coldboxes PDFKöksal PatanAún no hay calificaciones

- 039-Itp For Embedded Plate PDFDocumento7 páginas039-Itp For Embedded Plate PDFKöksal PatanAún no hay calificaciones

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocumento23 páginas008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanAún no hay calificaciones

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocumento25 páginas007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanAún no hay calificaciones

- List of Marketing Metrics and KpisDocumento5 páginasList of Marketing Metrics and KpisThe KPI Examples ReviewAún no hay calificaciones

- D2165151-003 Preliminary SGRE ON SG 6.0-170 Site Roads and HardstandsDocumento46 páginasD2165151-003 Preliminary SGRE ON SG 6.0-170 Site Roads and HardstandsMarcelo Gonçalves100% (1)

- Automatic Access Control System Using Student Identification Card Based On Rfid TechnologyDocumento100 páginasAutomatic Access Control System Using Student Identification Card Based On Rfid TechnologythgnguyenAún no hay calificaciones

- Common Rail Injector Tester CR-C +S60H Multifunction Test MachineDocumento3 páginasCommon Rail Injector Tester CR-C +S60H Multifunction Test MachineAlen HuangAún no hay calificaciones

- Reading in MCJ 216Documento4 páginasReading in MCJ 216Shela Lapeña EscalonaAún no hay calificaciones

- Psychological Well Being - 18 ItemsDocumento5 páginasPsychological Well Being - 18 ItemsIqra LatifAún no hay calificaciones

- Cics 400 Administration and Operations GuideDocumento343 páginasCics 400 Administration and Operations GuidedafraumAún no hay calificaciones

- Physics Cheat SheetDocumento8 páginasPhysics Cheat SheetJeremiah MoussaAún no hay calificaciones

- P Training For ResilienceDocumento35 páginasP Training For ResilienceLbrito01100% (1)

- The Goldfish and Its Culture. Mulertt PDFDocumento190 páginasThe Goldfish and Its Culture. Mulertt PDFjr2010peruAún no hay calificaciones

- Pay Scale WorkshopDocumento5 páginasPay Scale WorkshopIbraAún no hay calificaciones

- Gulfpub Wo 201805Documento81 páginasGulfpub Wo 201805Patricia.PAún no hay calificaciones

- Evelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Documento290 páginasEvelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Lucia QuirogaAún no hay calificaciones

- Gender Inequality and Its Impact On Mental HealthDocumento20 páginasGender Inequality and Its Impact On Mental Healthbanipreet kaurAún no hay calificaciones

- Electric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)Documento3 páginasElectric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)SonNguyenAún no hay calificaciones

- Chapter - 01 Geography The Earth in The Solar SystemDocumento10 páginasChapter - 01 Geography The Earth in The Solar SystemKarsin ManochaAún no hay calificaciones

- C779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesDocumento7 páginasC779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesFahad RedaAún no hay calificaciones

- 2018-3-27 MIDAS Civil Presentation Curved BridgesDocumento57 páginas2018-3-27 MIDAS Civil Presentation Curved BridgesShishir Kumar NayakAún no hay calificaciones

- Asia Pacific SAR Plan V2.0Documento38 páginasAsia Pacific SAR Plan V2.0Joci SimõesAún no hay calificaciones

- Rights of An Accused Under Custodial InvestigationDocumento17 páginasRights of An Accused Under Custodial Investigationadrianfrancis9100% (1)

- ElectricityDocumento196 páginasElectricityjingcong liuAún no hay calificaciones

- Defining Who Is A Volunteer ConceptualDocumento21 páginasDefining Who Is A Volunteer ConceptualYosep Trisaputro WahyuAún no hay calificaciones

- Bruner, Jerome - The Growth of MindDocumento11 páginasBruner, Jerome - The Growth of MindTalia Tijero100% (1)

- Neoclassical CounterrevolutionDocumento1 páginaNeoclassical CounterrevolutionGraziella ValerioAún no hay calificaciones

- Continuous Improvement SYMPOSIUM SCRIPTDocumento3 páginasContinuous Improvement SYMPOSIUM SCRIPTChanda Marie AsedillaAún no hay calificaciones

- Unit 9 TelephoningDocumento14 páginasUnit 9 TelephoningDaniela DanilovAún no hay calificaciones

- Week 5 Teradata Practice ExerciseDocumento14 páginasWeek 5 Teradata Practice ExerciseWooyeon ChoAún no hay calificaciones

- Manual Safety Installation Operations Tescom en 123946Documento23 páginasManual Safety Installation Operations Tescom en 123946Karikalan JayAún no hay calificaciones

- Accuracy of Transferring Analog Dental Casts To A Virtual ArticulatorDocumento9 páginasAccuracy of Transferring Analog Dental Casts To A Virtual ArticulatorNetra TaleleAún no hay calificaciones

- Worship Aid - May Crowning 2020Documento5 páginasWorship Aid - May Crowning 2020Kevin RyanAún no hay calificaciones