Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Klüberplex BEM 41-132: High-Temperature Long-Term Grease For Rolling Bearings

Cargado por

marcalasanTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Klüberplex BEM 41-132: High-Temperature Long-Term Grease For Rolling Bearings

Cargado por

marcalasanCopyright:

Formatos disponibles

Klberplex BEM 41-132

High-temperature long-term grease for rolling bearings

Description:

Klberplex BEM 41-132 is based

on synthetic hydrocarbon oil,

mineral oil and special lithium

soap. Selected additives ensure

optimum resistance to oxidation,

wear and corrosion. Klberplex

BEM 41-132 is also very resistant

to high temperatures, provides

good functional reliability and

ensures a long service life.

Behaviour towards elastomers

and plastics

Good wear and corrosion

High reliability, long service life

Material

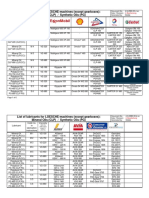

Time / Temperature

72 NBR 902

168 h / 100 C

Volume (%)

75 ACM 370

168 h / 140 C

83 FKM 575

168 h / 150 C

81 VMQ 542

168 h / 150 C

10

Hardness (Shore A)

13

Tensile strength (%)

10

12

48

44

18

33

16

Elongation at tear (%)

Prior to series application we recommend testing the compatibility of the

lubricant and all materials in contact with the lubricant (our test results are

based on random samples and do not release the user from conducting his own

tests).

Product data:

Base oil/thickener

Synthetic

hydrocarbon oil, mineral oil,

special Li soap

Service temperature range*, C

for rolling bearings in automotive

components

clutch bearings

generator bearings

water pump bearings

visco fan bearings

30 to 150

FAG-FE 9 test, DIN 51 821/2, Fa = 1500 N,

n = 6000 rpm, 150 C, L10-/L50 operating time, h

340 / 480

Flow pressure, DIN 51 805, at 30 C, mbar

< 1600

Low-temperature starting torque in acc. with

IP 186/85 at 30 C, starting/running torque, N/mm

Base oil viscosity, DIN 51 561

at 40 C, mm2, approx.

at 100 C, mm2, approx.

Klberplex BEM 41-132 meets the

requirements established by the

German Armed Forces Office for

Military Technology and Procurement (BWB) in TL 9150-0075,

Lubricating Grease, Rolling

Bearings, NATO-Code: G 421.

Speed factor** for deep groove ball bearings

(n x dm), mm x min1, approx.

Drop point, DIN ISO 2176, C

> 220

Anticorrosion behaviour (Emcor test), DIN 51 802,

1 week, dist. water, rating

3

Density, DIN 51 757, at 20 C, g/cm , approx.

**

265 to 295

600 000

Apparent viscosity, Klber viscosity grade***

Colour

< 1000 / < 100

120

14

Worked penetration, DIN ISO 2137, at 25 C; 0.1 mm

Minimum shelf life:

Pack sizes:

up to 150 C

protection

Klberplex BEM 41-132 is suitable

for long-term and lifetime lubrication of rolling bearings in a service temperature range* between

approx. 70 to 150 C, for example

The minimum shelf life is approx.

36 months if the product is stored in

the original closed container in a

dry place.

Rolling bearing grease

Resistant to temperatures

The elastomers listed below were

tested for compatibility with

Klberplex BEM 41-132 for a period

of 168 h at 100 C und 120 C.

Application:

for rolling bearings in

paper machines (dry section)

textile machines (drying

installations)

electric motors

hot air fans

drying kilns

wind classifiers in the base

materials industry

generators in wind power stations

Klberplex BEM 41-132

1

0.9

yellow

Service temperatures are guide values which depend on the lubricants composition, the intended use and the application method. Lubricants change their consistency, apparent dynamic viscosity or viscosity depending on the mechanodynamical loads, time, pressure and temperature. These changes in product characteristics may affect the function of a

component.

Speed factors are guide values which depend on the type and size of the rolling bearing type and the local operating

conditions, which is why they have to be confirmed in tests carried out by the user in each individual case.

*** Klber viscosity grades: EL = extra light lubricating grease; L = light lubricating grease; M = medium lubricating grease;

S = heavy lubricating grease; ES = extra heavy lubricating grease

25 kg bucket

180 kg drum

Product information 5.262 e

Edition 02.02, replaces edition 07.01

Klberplex BEM 41-132

Safety Data Sheet

1.1 Product name: Klberplex BEM 41-132

Code-No.:

020 256

31.05.2001

1.2 Klber Lubrication Mnchen KG

Emergency telephone no.:

Geisenhausenerstrae 7

++49 - 89 7876 - 0

D-81379 Mnchen

Tel. ++49 - 89 78 76 - 0 telephone exchange

Fax: ++49 - 89 78 76 - 333

2.

Composition / information on ingredients

Chemical characterization (preparation): Mineral oil, synthetic hydrocarbon oil, special lithium soap

3.

Hazards identification

No particular hazards known

4.

5.

6.

7.

8.

First aid measures

After inhalation: Not applicable

After contact with skin: Wash off with soap and plenty of water

After contact with eyes: Rinse with plenty of water

After ingestion: Do not induce vomiting. Obtain medical attention

Advice to doctor: Treat symptomatically

Fire-fighting measures

Suitable extinguishing media: Water spray, foam, dry powder,

carbon dioxide (CO2)

Unsuitable extinguishing media: High volume water jet

Special Hazards: In case of fire the following can be released: Carbon

monoxide, hydrocarbons

Special protective equipment for firefighters: Standard procedure for

chemical fires

Additional information: Water mist may be used to cool closed

containers. In the event of fire and/or explosion do not breathe fumes

Accidental release measures

Personal precautions: Not required

Environmental precautions: Do not flush into surface water or sanitary

sewer system

Methods for cleaning up / taking up: Use mechanical handling equipment. Dispose of absorbed material in accordance with the regulations

Additional information: None

Handling and storage

Advice on safe handling: No special handling advice required

Advice on protection against fire and explosion: No special precautions

required

Requirements on storage rooms and vessels: Store at room temperature

in the original container

Incompatible materials: Incompatible with oxidizing agents. Do not store

together with food

Further information on storage conditions: None

Exposure controls / personal protection

Additional advice on system design: Not applicable

Ingredients and specific control parameters: None

Respiratory protection: No special protective equipment required

Hand protection: No special protective equipment required

Eye protection: No special protective equipment required

Body protection: No special protective equipment required

Other protection measures: No special protective equipment required

General protection and hygiene measures: Avoid prolonged and/or

repeated contact with skin. Remove soiled or soaked clothing immediately. Clean skin thoroughly after work; apply skin cream

9.

Physical and chemical properties

Form

paste

Colour

yellow

Odour

characteristic

Drop point

> 240 C, DIN ISO 2176

Flash point

> 200 C (base oil)

Ignition temperature

not applicable

Lower explosion limit

not applicable

Upper explosion limit

not applicable

Vapour pressure-first

not applicable

Density

approx. 0.9 g/cm3, 20 C

Water solubility

insoluble

pH value

not applicable

Kinematic viscosity

not applicable

Further information

none

10. Stability and reactivity

Conditions to avoid: None

Materials to avoid: Strong oxidizing agents

Hazardous decomposition products: None under normal use

Additional information: None

11. Toxicological information

The toxicological data has been taken from products of similar

composition

Acute toxicity: LD50/oral/rat = > 2 g/kg (literature data)

Chronic toxicity: None

Human experience: Prolonged skin contact may cause skin irritation

and/or dermatitis

12. Ecological information

Information on elimination (persistence and degradability): Product is

insoluble in water. May be separated out mechanically in purification

plants

Behaviour in environmental compartments: Ecological injuries are not

known or expected under normal use

Ecotoxic effects: Aquatic toxicity is unlikely due to low solubility

Additional information: Should not be released into the environment

13. Advice on Disposal

Code of waste: 120 112, Wastes from shaping and surface treatment

of metals and plastics; wastes from shaping (including forging, welding,

pressing, drawing, turning, cutting and filling); spent waxes and fats

Disposal: Can be incinerated when in compliance with local, state and

federal regulations. The code of waste has to correspond to the Council

Directive 75/442/EEC and be specific as far as the related sector and

process are concerned

Dispose of contaminated packaging and recommended cleaning: Offer

rinsed packaging material to local recycling facilities

14. Transport information

GGVS / GGVE:

not applicable

ADN / ADNR:

not applicable

IMDG-Code:

not applicable

ICAO / IATA-DGR:

not applicable

Further information: Not classified as dangerous in the meaning of

transport regulations

15. Regulatory information

Labelling according to EU-guidelines: The product does not require a

hazard warning label in accordance with EC-directives/German

regulations on dangerous substances

National regulations

16. Other information

Issue-department of Safety Data Sheet: Chemical Documentation,

Tel.: ++49 - 89 7876 - 564

The data in this product information is based on our general experience and knowledge at the time of printing and is intended to give information of possible applications to a

reader with technical experience. It constitutes neither an assurance of product properties nor does it release the user from the obligation of performing preliminary tests with the

selected product. We recommend contacting our Technical Consulting Staff to discuss your specific application. If required and possible we will be pleased to provide a sample

for testing. Klber products are continually improved. Therefore, Klber Lubrication reserves the right to change all the technical data in this product information at any time

without notice.

Klber Lubrication Mnchen KG, a member of the Freudenberg group

Publisher and Copyright:

Klber Lubrication Mnchen KG

Reprints, total or in part, are permitted if source

is indicated and voucher copy is forwarded.

Klber Lubrication Mnchen KG

Postfach 70 10 47, D-81310 Mnchen

Tel. (0 89) 78 76-0, Telefax (0 89) 78 76-333

También podría gustarte

- FUCHS LUBRITECH Product RangeDocumento76 páginasFUCHS LUBRITECH Product RangeBurak GüleşAún no hay calificaciones

- Lubrication Guide for Mobile Crushing UnitsDocumento14 páginasLubrication Guide for Mobile Crushing UnitsMf LuiAún no hay calificaciones

- CentoplexDocumento2 páginasCentoplexAnandh VairakkannuAún no hay calificaciones

- IR Lubricants ListDocumento42 páginasIR Lubricants ListPalika MedinaAún no hay calificaciones

- Kluber-Brochure Lubrication of Various ComponentsDocumento17 páginasKluber-Brochure Lubrication of Various ComponentsjalalAún no hay calificaciones

- ROCOL Metalworking BrochureDocumento28 páginasROCOL Metalworking BrochureYahya TürAún no hay calificaciones

- Kluber Lubrication ServicesDocumento7 páginasKluber Lubrication Servicescesar_lubAún no hay calificaciones

- Speciality Lubricants For Machine ToolsDocumento15 páginasSpeciality Lubricants For Machine ToolsDarmawan PutrantoAún no hay calificaciones

- Kluber Synthetic OilDocumento14 páginasKluber Synthetic OilRajiv SrivastavaAún no hay calificaciones

- Kluber PresentationDocumento79 páginasKluber PresentationZegera MgendiAún no hay calificaciones

- How To Choose An Industrial Lubricant (Kluber)Documento2 páginasHow To Choose An Industrial Lubricant (Kluber)Avyan KelanAún no hay calificaciones

- Klubersynth UH1 14-151Documento2 páginasKlubersynth UH1 14-151fermarpinAún no hay calificaciones

- Zug ENDocumento4 páginasZug ENadelfawzy1234Aún no hay calificaciones

- Lubricants For AUMA Products Grease or Oil Filling in The Gear Housing PDFDocumento1 páginaLubricants For AUMA Products Grease or Oil Filling in The Gear Housing PDFWidya Makmur Abadi100% (1)

- Kluber - Klubersynth Eg 4 Series - En¡ TDS¡¿Documento4 páginasKluber - Klubersynth Eg 4 Series - En¡ TDS¡¿cesar_lubAún no hay calificaciones

- Molykote 103brochureDocumento94 páginasMolykote 103brochurevemanreddy29Aún no hay calificaciones

- Centoplex GLP 102 - 101 - 100 - 100 - 00 BHDocumento2 páginasCentoplex GLP 102 - 101 - 100 - 100 - 00 BHsvntamil_159541837100% (3)

- Bechem Berutox M 21 KN 9007601 (GB)Documento1 páginaBechem Berutox M 21 KN 9007601 (GB)Luciano de Carvalho100% (2)

- Technical Focus: UV Curing Short Runs BearingsDocumento68 páginasTechnical Focus: UV Curing Short Runs BearingsRicardo Reno RibeiroAún no hay calificaciones

- Grease 082504referenceDocumento6 páginasGrease 082504referencesmhea123Aún no hay calificaciones

- Rust X Brouser PDFDocumento4 páginasRust X Brouser PDFPradeep KatiyarAún no hay calificaciones

- Kluber Bearing LubricationDocumento9 páginasKluber Bearing Lubricationmotosega78100% (1)

- Ferrocote 6130: Blank-Washing Rust Preventive OilDocumento2 páginasFerrocote 6130: Blank-Washing Rust Preventive Oilsumit100% (1)

- Maintenance Tips On OilDocumento12 páginasMaintenance Tips On OilAndrea StoneAún no hay calificaciones

- Authorized Dealer for Dewalt, Strub, Divinol, Kluber, and Welding EquipmentDocumento1 páginaAuthorized Dealer for Dewalt, Strub, Divinol, Kluber, and Welding EquipmentRamesh DamseAún no hay calificaciones

- Precision Bearing Greases SelectionDocumento4 páginasPrecision Bearing Greases Selectionvyhtran4731Aún no hay calificaciones

- Advantages of Zinc-Free Hydraulic OilsDocumento2 páginasAdvantages of Zinc-Free Hydraulic OilsAnonymous F2TxS3YoaAún no hay calificaciones

- RENOLIT LST 00 Technical Data SheetDocumento1 páginaRENOLIT LST 00 Technical Data SheetQuoc HungAún no hay calificaciones

- 7557 - Lubricants Brochure PDFDocumento6 páginas7557 - Lubricants Brochure PDFrachitmailAún no hay calificaciones

- X - Hydraulic Fluids Electronic HandoutDocumento41 páginasX - Hydraulic Fluids Electronic HandoutRay Cepeda Mena100% (1)

- Industrial Lubricants - Viscosities Equivalent ISO-VG GradeDocumento3 páginasIndustrial Lubricants - Viscosities Equivalent ISO-VG GradeArifinAún no hay calificaciones

- History of Rocol and Sapphire Bearing GreasesDocumento11 páginasHistory of Rocol and Sapphire Bearing GreasesMehul PatelAún no hay calificaciones

- Global Industrial Gear Oil MarketDocumento16 páginasGlobal Industrial Gear Oil MarketSanjay MatthewsAún no hay calificaciones

- Food-grade Lubricants Focus: Regulations, Certification, TrendsDocumento3 páginasFood-grade Lubricants Focus: Regulations, Certification, TrendsSridhar ReddyAún no hay calificaciones

- Loesche List of Lubricants 03 2015 - enDocumento6 páginasLoesche List of Lubricants 03 2015 - enphucdc095041Aún no hay calificaciones

- Velvex Industrial Oil - Nandan Petrochem LTDDocumento27 páginasVelvex Industrial Oil - Nandan Petrochem LTDNandan Petrochem Ltd0% (1)

- SS-150 Servo System Oil Details PDFDocumento1 páginaSS-150 Servo System Oil Details PDFJagadeesh SharanAún no hay calificaciones

- Lubrication Table FOK 4x en-GB - 11Documento22 páginasLubrication Table FOK 4x en-GB - 11balaasenthil0% (1)

- 03 BPA Bakery IndustryDocumento12 páginas03 BPA Bakery IndustryMAYANK AGARWALAún no hay calificaciones

- Kluberplex AG 11 462 eDocumento2 páginasKluberplex AG 11 462 eseegna100% (2)

- UntitledDocumento28 páginasUntitledapi-133947076Aún no hay calificaciones

- Speciality Lubricants For The Railway Industry B090000102 PDFDocumento11 páginasSpeciality Lubricants For The Railway Industry B090000102 PDFJavier Alejandro Muralles ReyesAún no hay calificaciones

- HiTEC 2240Documento2 páginasHiTEC 2240Pranit More Arabian Petroleum LimitedAún no hay calificaciones

- Rating of Hydraulic Fluids For Rexroth Hydraulic Components Re90235 - 2015-02 PDFDocumento8 páginasRating of Hydraulic Fluids For Rexroth Hydraulic Components Re90235 - 2015-02 PDFDennis Huanuco CcamaAún no hay calificaciones

- Viscosity ClassificationsDocumento6 páginasViscosity ClassificationsDarmawan PutrantoAún no hay calificaciones

- List of Products Related To Danieli Standard 0.000.001 - Rev.15Documento11 páginasList of Products Related To Danieli Standard 0.000.001 - Rev.15cotteAún no hay calificaciones

- Global High Temperature Grease Market ReportDocumento6 páginasGlobal High Temperature Grease Market ReportHari PurwadiAún no hay calificaciones

- Lubricants For Textile Industry - Spinning / Preparation MachinesDocumento6 páginasLubricants For Textile Industry - Spinning / Preparation MachinesAbd Allatife AlshehabiAún no hay calificaciones

- The Most Common Worldwide-Were Introduced in The Early 1940s. Lithium Complex GreasesDocumento14 páginasThe Most Common Worldwide-Were Introduced in The Early 1940s. Lithium Complex GreasesKiran DuggarajuAún no hay calificaciones

- Plant Maintenance Lubricants 026224Documento4 páginasPlant Maintenance Lubricants 026224Koohestani Afshin100% (1)

- UNIVERSAL HIGH PERFORMANCE GREASES AND FIRE RESISTANT FLUIDSDocumento2 páginasUNIVERSAL HIGH PERFORMANCE GREASES AND FIRE RESISTANT FLUIDSAlstome PowerAún no hay calificaciones

- Lubimax Pib 2400sa - TDSDocumento1 páginaLubimax Pib 2400sa - TDSkarthibenAún no hay calificaciones

- Ss Mobilith SHCDocumento2 páginasSs Mobilith SHCFarrukh JamalAún no hay calificaciones

- Rig Spares - Used New Surplus InventoryDocumento16 páginasRig Spares - Used New Surplus InventoryProject Sales CorpAún no hay calificaciones

- VELVEX - Automotive LubesDocumento4 páginasVELVEX - Automotive LubesVaradrajan jothiAún no hay calificaciones

- Lubricants: 11 February 2014Documento2 páginasLubricants: 11 February 2014Thai TrinhAún no hay calificaciones

- GreaseDocumento3 páginasGreaseWac GunarathnaAún no hay calificaciones

- Ficha Tecnica Shell Oil 9156 PDFDocumento1 páginaFicha Tecnica Shell Oil 9156 PDFcarlos arturo piedrahitaAún no hay calificaciones

- Lubricants KSA Market OverviewDocumento10 páginasLubricants KSA Market OverviewTawfikahmed Alsadawi0% (1)

- Detecting and Controlling Water in OilDocumento9 páginasDetecting and Controlling Water in OilmarcalasanAún no hay calificaciones

- Hydraulic Pump and Motor Case DrainsDocumento3 páginasHydraulic Pump and Motor Case DrainsmarcalasanAún no hay calificaciones

- Preventing Mechanical FailuresDocumento15 páginasPreventing Mechanical Failuresmarcalasan0% (1)

- Sludge and Varnish in Turbine SystemsDocumento10 páginasSludge and Varnish in Turbine SystemsmarcalasanAún no hay calificaciones

- To Other Needs, Example,: 1956 Twenty-Ti-Ii RD ConferenceDocumento11 páginasTo Other Needs, Example,: 1956 Twenty-Ti-Ii RD ConferencemarcalasanAún no hay calificaciones

- Journal Bearing PreDocumento4 páginasJournal Bearing PremarcalasanAún no hay calificaciones

- Symptoms of Common Hydraulic Problems and Their Root CausesDocumento3 páginasSymptoms of Common Hydraulic Problems and Their Root CausesmarcalasanAún no hay calificaciones

- How Not To Lubricate A GearboxDocumento5 páginasHow Not To Lubricate A GearboxmarcalasanAún no hay calificaciones

- Grease BasicsDocumento5 páginasGrease Basicsmarcalasan100% (1)

- Reduce maintenance costs and downtime with a lubrication excellence programDocumento6 páginasReduce maintenance costs and downtime with a lubrication excellence programmarcalasanAún no hay calificaciones

- Nine Reasons Why Oil Analysis Programs FailDocumento4 páginasNine Reasons Why Oil Analysis Programs FailmarcalasanAún no hay calificaciones

- Corrosion FailuresDocumento1 páginaCorrosion FailuresmarcalasanAún no hay calificaciones

- Filter Flow RateDocumento2 páginasFilter Flow RatemarcalasanAún no hay calificaciones

- Labyrinth Seals and Lip SealsDocumento5 páginasLabyrinth Seals and Lip SealsmarcalasanAún no hay calificaciones

- Managing The Risk of Mixing Lubricating OilsDocumento5 páginasManaging The Risk of Mixing Lubricating OilsmarcalasanAún no hay calificaciones

- 1958 - Van Hengel - Some Notes On TheDocumento11 páginas1958 - Van Hengel - Some Notes On ThemarcalasanAún no hay calificaciones

- Maintenance and Troubleshooting of Electric MotorsDocumento8 páginasMaintenance and Troubleshooting of Electric MotorsmarcalasanAún no hay calificaciones

- Proper Pump Piping Procedure - 10 StepsDocumento9 páginasProper Pump Piping Procedure - 10 StepsmarcalasanAún no hay calificaciones

- Maintenance of Mining MachineryDocumento22 páginasMaintenance of Mining Machineryjorgeluis2000100% (1)

- Pump Efficiency With Electric Motor DriverDocumento3 páginasPump Efficiency With Electric Motor DrivermarcalasanAún no hay calificaciones

- 02chapters1 2Documento44 páginas02chapters1 2marcalasanAún no hay calificaciones

- Droop Calc 0.0166 HZ DB 5pct Droop Steam UnitDocumento132 páginasDroop Calc 0.0166 HZ DB 5pct Droop Steam UnitmarcalasanAún no hay calificaciones

- Mathematical Modeling-OptimisationDocumento12 páginasMathematical Modeling-OptimisationDr Srinivasan Nenmeli -K100% (1)

- 3.2 Electric Motors - Revised (Table Format)Documento8 páginas3.2 Electric Motors - Revised (Table Format)Sumit AgrawalAún no hay calificaciones

- 3.1 Electrical System - Revised (Table Format)Documento9 páginas3.1 Electrical System - Revised (Table Format)shahidehamzaAún no hay calificaciones

- 2.2 BoilersDocumento9 páginas2.2 BoilersSalihibnuali KpAún no hay calificaciones

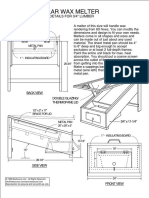

- Beehive Solar Wax MelterDocumento1 páginaBeehive Solar Wax MeltersesostrisserbiusAún no hay calificaciones

- Engineering Materials Exam GuideDocumento5 páginasEngineering Materials Exam Guidekundayi shavaAún no hay calificaciones

- HiiiiDocumento10 páginasHiiiiVenkatesan B.Aún no hay calificaciones

- Chemistry Final Exam PracticeDocumento22 páginasChemistry Final Exam PracticeRida Muhammad RazaAún no hay calificaciones

- Birla A1 Premium Cement - PST - LeafletDocumento8 páginasBirla A1 Premium Cement - PST - LeafletrishikeshAún no hay calificaciones

- Petroleum ChemistryDocumento5 páginasPetroleum ChemistryNordin SuhadatAún no hay calificaciones

- Information and Applications of BmsDocumento44 páginasInformation and Applications of Bmsapi-324119707Aún no hay calificaciones

- 2 Crucible Material Selection GuideDocumento1 página2 Crucible Material Selection GuideElder18Aún no hay calificaciones

- Properties of Low-Viscosity Nitrocellulose of Varied Nitrogen ContentDocumento5 páginasProperties of Low-Viscosity Nitrocellulose of Varied Nitrogen Contentshikaru7114Aún no hay calificaciones

- Sika Separol 10 Pds enDocumento2 páginasSika Separol 10 Pds enrony 2222Aún no hay calificaciones

- Advanced Application of Micropasma WeldingDocumento12 páginasAdvanced Application of Micropasma WeldingKonstantin MarjanuczAún no hay calificaciones

- Comparision Between CSEB and Clay BricksDocumento7 páginasComparision Between CSEB and Clay BricksShah ZaibAún no hay calificaciones

- TroyDocumento13 páginasTroyAPEX SONAún no hay calificaciones

- Literature Review On NanomaterialsDocumento5 páginasLiterature Review On Nanomaterialsafdtwtdsa100% (1)

- Corrosion Failure Analysis of Galvanized Steel Pipes in A Water Irrigation SystemDocumento6 páginasCorrosion Failure Analysis of Galvanized Steel Pipes in A Water Irrigation SystemC_rovere100% (1)

- Fiber Trade Name and Generic NameDocumento27 páginasFiber Trade Name and Generic NameGolam Sarwar100% (1)

- Chalking Rate Tester Acc. To Kempf Model 241: Din 53 159 Titangesellschaft MBH (Kronos Titan GMBH)Documento4 páginasChalking Rate Tester Acc. To Kempf Model 241: Din 53 159 Titangesellschaft MBH (Kronos Titan GMBH)Fadi MagdyAún no hay calificaciones

- BS 476: Part 7: 1997 Method For Classification of The Surface Spread of Flame of ProductsDocumento13 páginasBS 476: Part 7: 1997 Method For Classification of The Surface Spread of Flame of Productsjuli_radAún no hay calificaciones

- Is.8069.1989 HDPE WOVEN SACKS PESTICIDESDocumento12 páginasIs.8069.1989 HDPE WOVEN SACKS PESTICIDESDeepak BhanjiAún no hay calificaciones

- Petroleum Refining EngineeringDocumento24 páginasPetroleum Refining Engineeringdppriya1984100% (1)

- 1420 Turnbuckle M12 HDGDocumento2 páginas1420 Turnbuckle M12 HDGqualityAún no hay calificaciones

- Din4226 100 2002Documento18 páginasDin4226 100 2002Tecnología del Hormigón100% (1)

- Crochet Gingerbread Man Amigurumi Free PDF PatternDocumento5 páginasCrochet Gingerbread Man Amigurumi Free PDF Patternsarah.rinearAún no hay calificaciones

- 201 123 801Documento2 páginas201 123 801Jahidul Islam ShezanAún no hay calificaciones

- Explosive Management PlanDocumento28 páginasExplosive Management Planbruktawit100% (1)

- Properties of Concrete Containing Ground Granulated Blast Furnace Slag (GGBFS) at Elevated TemperaturesDocumento8 páginasProperties of Concrete Containing Ground Granulated Blast Furnace Slag (GGBFS) at Elevated Temperaturesteguh widayatAún no hay calificaciones

- Tekriwal Website ContentDocumento3 páginasTekriwal Website ContentJohn KumarAún no hay calificaciones

- TMCP Steel Plate: Structural Steel For BuildingsDocumento8 páginasTMCP Steel Plate: Structural Steel For BuildingsJOAO ELOIAún no hay calificaciones

- Final Summative Exam #2 Grade 7Documento4 páginasFinal Summative Exam #2 Grade 7Mae CudalAún no hay calificaciones

- SMA Technical NoteDocumento2 páginasSMA Technical NoteLutfi TofiqAún no hay calificaciones