Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Electrical Fundamental Practical DC Genarator

Cargado por

Ezzul Helmi0%(1)0% encontró este documento útil (1 voto)

254 vistas4 páginasDc generator is a rotating electric machine which delivers a unidirectional voltage and current. This report is to examine and test the generator condition. Student must always Wear proper workshop etire such as,safety boot, workshop jacket and proper pants.

Descripción original:

Título original

Electrical Fundamental Practical Dc Genarator

Derechos de autor

© © All Rights Reserved

Formatos disponibles

DOCX, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoDc generator is a rotating electric machine which delivers a unidirectional voltage and current. This report is to examine and test the generator condition. Student must always Wear proper workshop etire such as,safety boot, workshop jacket and proper pants.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOCX, PDF, TXT o lea en línea desde Scribd

0%(1)0% encontró este documento útil (1 voto)

254 vistas4 páginasElectrical Fundamental Practical DC Genarator

Cargado por

Ezzul HelmiDc generator is a rotating electric machine which delivers a unidirectional voltage and current. This report is to examine and test the generator condition. Student must always Wear proper workshop etire such as,safety boot, workshop jacket and proper pants.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOCX, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 4

UNIVERSITI KUALA LUMPUR

MALAYSIAN INSTITUTE OF AVIATION TECHNOLOGY

ELECTRICAL FUNDAMENTAL 2

AKD10203

DC MOTOR AND GENERATOR REPORT

PREPARED BY:

EZZUL HELMI BIN MOHD YUSOF 53106114095

ISWAN ALIFI BIN AZILAN 53106114171

2 AEM 2

SUBMISSION DATE: 2/04/2015

PREPARED FOR:

MADAM SAHZILAWATI MOHAMAD NOR

SEMESTER JULY 2014

INTRODUCTION

A rotating electric machine which delivers a unidirectional

voltage and current. An armature winding mounted on the

rotor supplies the electricpower output. One or more field

windings mounted on the stator establish the magnetic flu

x in the air gap. A voltage is induced in thearmature coils

as a result of the relative motion between the coils and th

e air gap flux. Faraday's law states that the voltage induce

d isdetermined by the time rate of change of flux linkages

with the winding. Since these induced voltages are alterna

ting, a means of rectificationis necessary to deliver direct

current at the generator terminals. Rectification is accomp

lished by a commutator mounted on the rotor shaft.Carbo

n brushes, insulated from the machine frame and secured

in brush holders, transfer the armature current from the r

otating commutatorto the external circuit.This report is to

examine and test the generator condition.

OBJECTIVE

This is report to identify some parts and the function of

the dc generator.The main part of dc generator that

student should know is the yoke,field winding,salient

poles,both the end assy,the commutators,the armature

windings and the armature core.This practical also teach

student how to inspect and method to inspect the dc

generator.This will make sure student will now the

condition of the dc generator that it is in good condition or

bad condition.

SAFETY PRECAUTION

Student must always: Wear proper workshop etire such as,safety boot,

workshop jacket and proper pants.

Must always wait and follow the instruction from the

instructor.

Do not play with all the probes.Especially with the

growler probes that generate electric.

Take care all the instrument properly.

Make sure follow the correct procedure when doing

the inspection

TOOLS AND EQUIPMENT

Set of dc generator

A multimeter to check continuity and short circuit

The growler to test armature

Hacksaw blade to check short circuit

Conclusion

The yoke is ok, field winding ok,salient poles ok,both

the end assy ok,the commutators ok,armature windings

ok and the armature core also ok.The dc generator part

that my group inspected is working in very good

condition.The dc generator is very fits and can installed

in aircraft anytime.The inspection must be done to make

sure the dc generator can work properly.

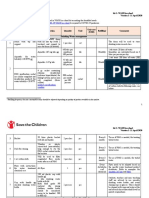

PARTS

INSPECTION/METH

ODS

RESULTS

Field Windings

Check for burn and

pitting

Virtual check on the

condition of the

winding

Virtual check and

measure the

thickness of the

carbon brush

Virtual check the

yoke.check for any

corrosion and burnt

mark

Virtual check.look for

any

damages,overheating

No burn mark.

Armature winding

Carbon brush

assembly

Yoke

The commutators

Salient poles

Both the end assy

Armature core

The winding found

to be in excellent

condition

All in normal

condition

No corrosion. No

burn mark

También podría gustarte

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDe EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesAún no hay calificaciones

- Basic Electrical Machines (Eceg132) Laboratory Manual: Department of Electrical and Computer EngineeringDocumento158 páginasBasic Electrical Machines (Eceg132) Laboratory Manual: Department of Electrical and Computer EngineeringRonan Rojas100% (1)

- Electrical Fundimental Report DC GenratorDocumento7 páginasElectrical Fundimental Report DC GenratorIpi Alifi100% (1)

- Electrical Machine Lab ManualDocumento61 páginasElectrical Machine Lab ManualPrem SharmaAún no hay calificaciones

- Electric Machines Lab Manual LatexDocumento88 páginasElectric Machines Lab Manual LatexMuhammad FarhanAún no hay calificaciones

- Basic Electrical Machines (Eceg132) Laboratory Manual: Department of Electrical and Computer EngineeringDocumento132 páginasBasic Electrical Machines (Eceg132) Laboratory Manual: Department of Electrical and Computer EngineeringRonan RojasAún no hay calificaciones

- Ee0041l-Finals (Sa) VillanuevaDocumento86 páginasEe0041l-Finals (Sa) VillanuevaKYLE LEIGHZANDER VICENTEAún no hay calificaciones

- Central Board of Secondary EducationDocumento11 páginasCentral Board of Secondary EducationManas Prasad SinghAún no hay calificaciones

- Ee0041l-Finals (Sa) KilakigaDocumento85 páginasEe0041l-Finals (Sa) KilakigaKYLE LEIGHZANDER VICENTEAún no hay calificaciones

- Fault Finding Manual 8Documento29 páginasFault Finding Manual 8Jovan KosticAún no hay calificaciones

- STANFORD Fault Finding ManualDocumento29 páginasSTANFORD Fault Finding ManualRaul E. SoliAún no hay calificaciones

- GfA Elektromaten Torsteuerung WS900 Betriebsanleitung - enDocumento23 páginasGfA Elektromaten Torsteuerung WS900 Betriebsanleitung - enRamshuAún no hay calificaciones

- Sequential SwitchingDocumento47 páginasSequential SwitchingMurali LankeAún no hay calificaciones

- 132kv SwitchyardDocumento72 páginas132kv Switchyardjogiyajee0% (1)

- Procedure Field Inspection & Testing Electrical EquipmentDocumento21 páginasProcedure Field Inspection & Testing Electrical Equipmentarifadha446100% (5)

- Power Electronics and Drives Laboratory ManualDocumento71 páginasPower Electronics and Drives Laboratory ManualSureshAún no hay calificaciones

- Report EEL Mini ProjectDocumento7 páginasReport EEL Mini Projectmohamadkhairudin3Aún no hay calificaciones

- Adu Michael Kofi - Final Year ThesisDocumento88 páginasAdu Michael Kofi - Final Year ThesisADU MICHAEL KOFIAún no hay calificaciones

- Pe Lab 10-200708Documento15 páginasPe Lab 10-200708Omar JanjuaAún no hay calificaciones

- Alternator&motors PDFDocumento24 páginasAlternator&motors PDFGargi YadavAún no hay calificaciones

- EE462 Lab ManualDocumento77 páginasEE462 Lab ManualElizabeth KellyAún no hay calificaciones

- Electrical Measurments Lab ManualDocumento45 páginasElectrical Measurments Lab ManualMohammad YunusAún no hay calificaciones

- EE Lab - 2 ManualDocumento54 páginasEE Lab - 2 Manual9v7yxyntbnAún no hay calificaciones

- 01 Measurement of The Output of Wind TurbineDocumento7 páginas01 Measurement of The Output of Wind TurbineBolWolAún no hay calificaciones

- Gre Paper 0f 2013Documento0 páginasGre Paper 0f 2013shipra51Aún no hay calificaciones

- E1 Alternator - Open Circuit CharacteristicDocumento7 páginasE1 Alternator - Open Circuit CharacteristicarjayAún no hay calificaciones

- Power Transformer Testing and Commissioning PDFDocumento6 páginasPower Transformer Testing and Commissioning PDFEric Stanton100% (1)

- Title: Practical Construction of A Solar Inverter SystemDocumento3 páginasTitle: Practical Construction of A Solar Inverter SystemhaiderAún no hay calificaciones

- Fault Finding Manual For Stamford AC Generators - July 2009 - CUMMINS Generator Technologies PDFDocumento29 páginasFault Finding Manual For Stamford AC Generators - July 2009 - CUMMINS Generator Technologies PDFpevare78% (9)

- Electrical MachineDocumento10 páginasElectrical Machinefarhan jalaludinAún no hay calificaciones

- TD - Fault Man - GB - July 2009 GBDocumento29 páginasTD - Fault Man - GB - July 2009 GB3efooAún no hay calificaciones

- 23cse083 - Eee Lab ManualDocumento97 páginas23cse083 - Eee Lab ManualChaitanya BrahmamAún no hay calificaciones

- Project Report (DC Fan Regulator)Documento19 páginasProject Report (DC Fan Regulator)tsuu0213Aún no hay calificaciones

- Lab Maunal EE462Documento77 páginasLab Maunal EE462Hussain MasoodAún no hay calificaciones

- EUE Lab - ManualDocumento65 páginasEUE Lab - Manualjabin miykael100% (1)

- Electrical Safety Guidelines - Working On Fixed Electrical InstallationsDocumento7 páginasElectrical Safety Guidelines - Working On Fixed Electrical Installationsdbarron00Aún no hay calificaciones

- ECNG1007 SinglePhaseTransformers LabDocumento15 páginasECNG1007 SinglePhaseTransformers LabLaquita Franklin100% (1)

- Electrical Fundimental Report DC GenratorDocumento7 páginasElectrical Fundimental Report DC GenratorIpi Alifi0% (1)

- Lab#6a MeggerDocumento7 páginasLab#6a MeggerRehman ButtAún no hay calificaciones

- Voltage Withstand TestDocumento4 páginasVoltage Withstand Testmshahidshaukat100% (1)

- "Dc/Ac 500 Watt Inverter Using Dual Mosfet": Polytechnic IN Electrical EngineeringDocumento26 páginas"Dc/Ac 500 Watt Inverter Using Dual Mosfet": Polytechnic IN Electrical EngineeringVasu Thakur100% (1)

- EE2302 Electrical Machines-IIDocumento25 páginasEE2302 Electrical Machines-IIkesavantAún no hay calificaciones

- 2 Workshop 2110017Documento67 páginas2 Workshop 2110017anil4shopAún no hay calificaciones

- Intership Reoort 98Documento34 páginasIntership Reoort 98Dhruvi SolankiAún no hay calificaciones

- Te Etc Pe Lab Manual 2017-18Documento36 páginasTe Etc Pe Lab Manual 2017-18wondieAún no hay calificaciones

- PG&U (EET-373) Lab ManualDocumento36 páginasPG&U (EET-373) Lab ManualAyyan MirAún no hay calificaciones

- AC Electric Machines Lab ManulDocumento98 páginasAC Electric Machines Lab Manulmuhammad_sarwar_27Aún no hay calificaciones

- Project Report of Transmission Type Eletrical SubstationDocumento44 páginasProject Report of Transmission Type Eletrical SubstationChandan_92100% (4)

- CT Saturation TestDocumento4 páginasCT Saturation TestTara P. PradhanAún no hay calificaciones

- Electrical Machines-II Lab ManualDocumento61 páginasElectrical Machines-II Lab ManualNaga Raju100% (1)

- Q5 and 6Documento15 páginasQ5 and 6AttaUrRahmanAún no hay calificaciones

- KVGCDocumento46 páginasKVGCLê Văn PhúAún no hay calificaciones

- AC Generator New Project 1Documento11 páginasAC Generator New Project 1Sakar Singhal50% (4)

- Control of Power Electronic Converters and Systems: Volume 1De EverandControl of Power Electronic Converters and Systems: Volume 1Calificación: 5 de 5 estrellas5/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlDe EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlCalificación: 5 de 5 estrellas5/5 (1)

- The IEE Wiring Regulations Explained and IllustratedDe EverandThe IEE Wiring Regulations Explained and IllustratedCalificación: 4 de 5 estrellas4/5 (14)

- Power Transformer Online Monitoring Using Electromagnetic WavesDe EverandPower Transformer Online Monitoring Using Electromagnetic WavesAún no hay calificaciones

- UHV Transmission TechnologyDe EverandUHV Transmission TechnologyChina Electric Power Research InstituteAún no hay calificaciones

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsAún no hay calificaciones

- Tecplot 360 2013 Scripting ManualDocumento306 páginasTecplot 360 2013 Scripting ManualThomas KinseyAún no hay calificaciones

- Mathematical Geophysics: Class One Amin KhalilDocumento13 páginasMathematical Geophysics: Class One Amin KhalilAmin KhalilAún no hay calificaciones

- Musings On A Rodin CoilDocumento2 páginasMusings On A Rodin CoilWFSCAO100% (1)

- Erickson Transformer DesignDocumento23 páginasErickson Transformer DesigndonscogginAún no hay calificaciones

- Ap06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónDocumento9 páginasAp06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónJenny Lozano Charry50% (2)

- 1.2 The Main Components of Computer SystemsDocumento11 páginas1.2 The Main Components of Computer SystemsAdithya ShettyAún no hay calificaciones

- How Can You Achieve Safety and Profitability ?Documento32 páginasHow Can You Achieve Safety and Profitability ?Mohamed OmarAún no hay calificaciones

- Emco - Unimat 3 - Unimat 4 LathesDocumento23 páginasEmco - Unimat 3 - Unimat 4 LathesEnrique LueraAún no hay calificaciones

- Chapter03 - How To Retrieve Data From A Single TableDocumento35 páginasChapter03 - How To Retrieve Data From A Single TableGML KillAún no hay calificaciones

- Drug Study TemplateDocumento2 páginasDrug Study TemplateKistlerzane CABALLEROAún no hay calificaciones

- Kit 2: Essential COVID-19 WASH in SchoolDocumento8 páginasKit 2: Essential COVID-19 WASH in SchooltamanimoAún no hay calificaciones

- Org ChartDocumento1 páginaOrg Chart2021-101781Aún no hay calificaciones

- Global Review Solar Tower Technology PDFDocumento43 páginasGlobal Review Solar Tower Technology PDFmohit tailorAún no hay calificaciones

- PRELEC 1 Updates in Managerial Accounting Notes PDFDocumento6 páginasPRELEC 1 Updates in Managerial Accounting Notes PDFRaichele FranciscoAún no hay calificaciones

- Immovable Sale-Purchase (Land) ContractDocumento6 páginasImmovable Sale-Purchase (Land) ContractMeta GoAún no hay calificaciones

- Province of Camarines Sur vs. CADocumento8 páginasProvince of Camarines Sur vs. CACrisDBAún no hay calificaciones

- VB 850Documento333 páginasVB 850Laura ValentinaAún no hay calificaciones

- IBMC Competition Booklet 2013Documento40 páginasIBMC Competition Booklet 2013Rollins Center at BYUAún no hay calificaciones

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Documento3 páginasEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandAún no hay calificaciones

- Cara Membuat Motivation LetterDocumento5 páginasCara Membuat Motivation LetterBayu Ade Krisna0% (1)

- Admission Notice: Weekend Masters Program (WMES)Documento4 páginasAdmission Notice: Weekend Masters Program (WMES)masud100% (1)

- Inspection and Test Plan Piling: 1. Document ReviewDocumento3 páginasInspection and Test Plan Piling: 1. Document ReviewZara BhaiAún no hay calificaciones

- Kuper ManualDocumento335 páginasKuper Manualdonkey slap100% (1)

- Strength and Microscale Properties of Bamboo FiberDocumento14 páginasStrength and Microscale Properties of Bamboo FiberDm EerzaAún no hay calificaciones

- The Voice of The Villages - December 2014Documento48 páginasThe Voice of The Villages - December 2014The Gayton Group of ParishesAún no hay calificaciones

- RWJ Corp Ch19 Dividends and Other PayoutsDocumento28 páginasRWJ Corp Ch19 Dividends and Other Payoutsmuhibbuddin noorAún no hay calificaciones

- INTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Documento7 páginasINTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Shashank DurgeAún no hay calificaciones

- Expected MCQs CompressedDocumento31 páginasExpected MCQs CompressedAdithya kesavAún no hay calificaciones

- S 101-01 - PDF - User Interface - Computer MonitorDocumento130 páginasS 101-01 - PDF - User Interface - Computer Monitormborghesi1Aún no hay calificaciones

- BBCVDocumento6 páginasBBCVSanthosh PgAún no hay calificaciones