Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Instrumentation Poster

Cargado por

322399mk7086Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Instrumentation Poster

Cargado por

322399mk7086Copyright:

Formatos disponibles

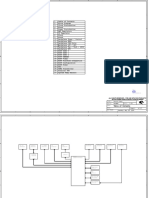

TRANSFORMER OIL TEMPERATURE MONITORING SYSTEM

Midion Kashiri

EDITH COWEN UNIVERSITY

INTRODUCTION

Power transformers heat up when they are in operation and high

temperatures reduce the operating parameters of the transformer. This

project demonstrates how a computer controlled system can monitor

the temperature of a power transformer. The temperature monitoring

system consists of a sensing device, signal conditioning circuitry, data

acquisition hardware, an actuator and the software.

DESCRIPTION

The rating of a transformer is based on the temperature rise above an

assumed maximum ambient temperature. The transformer should be capable

of continuous operation at rated power without exceeding the maximum

temperature-rise limits as specified by the manufacturer or applicable

standards.

According to ABB, a renowned transformer manufacturer, the winding must

not overheat; a temperature of about 85C is considered to be the normal

maximum working value beyond which a further rise of 10C-15C, if

sustained, will halve the insulation life of the transformer. Protection against

overload is therefore based on winding temperature, which is usually

measured by a thermal image technique. The windings are immersed in oil to

cool and insulate them. Monitoring the oil temperature gives us an awareness

of any temperature changes in the windings.

At a temperature of 85C our monitoring system should give us an alarm or

turn on some cooling fans. If the temperature continues to rise above 100C

the transformer should be disconnected from the power supply. to rise, the

transformer should be disconnected by sending a tripping signal to both the

primary and the secondary side protection breakers when the temperature

reaches 100C.

Conclusion

THE SENSOR, ACTUATOR AND DATA AQUISATION

IOur sensing device is an NTC Bosch Thermistor part number 0 280 130 026

which has a measurement range of -40 to +130C.. In practice the actuator

should be very large 3 phase AC cooling fans which are difficult to demonstrate

with in the lab because of safety and the availability of the required power

supply. Therefore to simulate our project, we will use a small lab fan and if the

temperature continues to rise above 100C we should have a voltmeter reading

of +0.285v across the transformer breaker trip circuit terminals

We used DLP-IO8 Data Acquisition Module, for this project. It is designed for

measuring voltages, controlling and monitoring processes, and acquiring

temperature data. Each of the 8 available channels can be configured for any of

the digital, analog, or temperature modes via single-byte commands. It is a 5-volt

system that derives its power from the host USB port.

.

The system runs from a set of instructions in C programming language and it

functions well. We successfully tested it by monitoring the temperature of

boiling water in the lab.

The temperature sensing device could measure the temperature and a voltage

of 0.434v appeared across the fan circuit terminals. We could not run the

actual fan due to the shortage of lab fans.

When the water temperature reached 100C a voltage of 0.285v appeared

across the circuit breaker and the circuit tripped.

RESOURCES

Oil temperature monitoring system block diagram

ABB Distribution Transformer Handbook

Bosch Data sheets

www.dlp.design.com

También podría gustarte

- Meaning of Holden Captiva Dashboard SymbolsDocumento2 páginasMeaning of Holden Captiva Dashboard Symbols322399mk708650% (2)

- Advance Laptop Chip Level Repair Engineering Training CourseDocumento15 páginasAdvance Laptop Chip Level Repair Engineering Training CourseSanjeewa Silva50% (4)

- Motherboard Vcore VRM Tier ListDocumento3 páginasMotherboard Vcore VRM Tier Listmghg100% (1)

- Centum VP 7 ENG Advanced Labs - GlobalDocumento6 páginasCentum VP 7 ENG Advanced Labs - GlobalNikhilesh Muraleedharan100% (1)

- AC DC DrivesDocumento13 páginasAC DC Drives322399mk7086Aún no hay calificaciones

- 8 Excitation Current Test (Yblood)Documento77 páginas8 Excitation Current Test (Yblood)322399mk7086Aún no hay calificaciones

- Temperature Control SystemDocumento2 páginasTemperature Control SystemNagulapati KiranAún no hay calificaciones

- Advanced Techniques in Power System Protective Relaying PDFDocumento332 páginasAdvanced Techniques in Power System Protective Relaying PDFshashikant yadavAún no hay calificaciones

- Temperature ControlDocumento9 páginasTemperature ControlMauricio López NúñezAún no hay calificaciones

- Winding Temperature IndicatorDocumento9 páginasWinding Temperature IndicatorTruong Van Quang100% (2)

- Potential TransformerDocumento27 páginasPotential TransformerVijay Pandit100% (1)

- Electronic Expansion ValveDocumento4 páginasElectronic Expansion ValvebassouadAún no hay calificaciones

- Analog Communications Lab ManualDocumento60 páginasAnalog Communications Lab ManualmailmeasddAún no hay calificaciones

- Testing of Transformer Oil and Winding Temperature IndicatorsDocumento6 páginasTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyAún no hay calificaciones

- Programmable Logic ControllerDocumento214 páginasProgrammable Logic ControllerImran Aslam67% (3)

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsDe EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsAún no hay calificaciones

- Report On Digital Switching SystemDocumento20 páginasReport On Digital Switching SystemKurban UbulAún no hay calificaciones

- Cibano 500 PTM User Manual EnuDocumento238 páginasCibano 500 PTM User Manual EnuGaurav SinghAún no hay calificaciones

- Areva - HWX VCB - Installation Operation & Maintenance ManualDocumento16 páginasAreva - HWX VCB - Installation Operation & Maintenance Manualaimiza79% (14)

- SH367309 Ev1.2aDocumento92 páginasSH367309 Ev1.2aThien Dinh86% (7)

- Advanced Temperature Measurement and Control, Second EditionDe EverandAdvanced Temperature Measurement and Control, Second EditionAún no hay calificaciones

- Auto-Transformer Maintenance and Testing TipsDocumento10 páginasAuto-Transformer Maintenance and Testing Tips322399mk7086Aún no hay calificaciones

- ManualDocumento1 páginaManualJuan Francisco BallestasAún no hay calificaciones

- Doble Test Modes ExplainedDocumento23 páginasDoble Test Modes Explained322399mk7086Aún no hay calificaciones

- Doble Test Modes ExplainedDocumento23 páginasDoble Test Modes Explained322399mk7086Aún no hay calificaciones

- Electronic Room Thermostat SRE06: Description FeaturesDocumento3 páginasElectronic Room Thermostat SRE06: Description FeaturesDaniel NogueiraAún no hay calificaciones

- 111-300 Trans Temp MonDocumento4 páginas111-300 Trans Temp MonLucian2001Aún no hay calificaciones

- HRC 800 multi-channel hot-runner control systemDocumento4 páginasHRC 800 multi-channel hot-runner control systempradeepchennai10_959Aún no hay calificaciones

- ON-OFF Temperature Control System Using MicroprocessorDocumento4 páginasON-OFF Temperature Control System Using Microprocessorsoach123Aún no hay calificaciones

- Digital ThermometerDocumento5 páginasDigital ThermometerKannan AlagumuthiahAún no hay calificaciones

- Testi NG of Transformer Oi Landwi Ndi NGT Emperature Indi CatorsDocumento7 páginasTesti NG of Transformer Oi Landwi Ndi NGT Emperature Indi CatorsENG.YONIS HUSSAINAún no hay calificaciones

- Temperature Controller Basics HandbookDocumento9 páginasTemperature Controller Basics HandbookSanctaTiffanyAún no hay calificaciones

- Biname InsulatorsDocumento8 páginasBiname InsulatorsRobAún no hay calificaciones

- AGN 027 - Winding and Bearing Temperature SensorsDocumento8 páginasAGN 027 - Winding and Bearing Temperature Sensorsmohsen_cumminsAún no hay calificaciones

- CS LabReport 8Documento10 páginasCS LabReport 8Muhammad AfzaalAún no hay calificaciones

- Pag Web Mic 1462Documento13 páginasPag Web Mic 1462rogermantilla08Aún no hay calificaciones

- AK-CC550 Návod AnglDocumento36 páginasAK-CC550 Návod AnglMatous Geront MounAún no hay calificaciones

- Unit 5Documento38 páginasUnit 5rohanrec92Aún no hay calificaciones

- Controller For Controlling One Evaporator: EKC 414A1Documento20 páginasController For Controlling One Evaporator: EKC 414A1Miteak PruteanuAún no hay calificaciones

- Danfoss EKC 201Documento16 páginasDanfoss EKC 201Georgiana DumitruAún no hay calificaciones

- AK CC 550 ServiceDocumento36 páginasAK CC 550 ServiceRobbert NovaAún no hay calificaciones

- Thermistor Based Temperature Control: Hardware RequirementsDocumento1 páginaThermistor Based Temperature Control: Hardware RequirementsFawad HassanAún no hay calificaciones

- Ss CTC AmetekDocumento8 páginasSs CTC AmetekRamses CanoAún no hay calificaciones

- EEE325 – Lab #08: Design of ON/OFF Controller for HVAC SystemDocumento7 páginasEEE325 – Lab #08: Design of ON/OFF Controller for HVAC SystemubaidAún no hay calificaciones

- Controler Danfoss RS8FS402 - AK-CC550ADocumento36 páginasControler Danfoss RS8FS402 - AK-CC550AAlexandru EnescuAún no hay calificaciones

- Temperature Calibration: Technical DataDocumento8 páginasTemperature Calibration: Technical DatalitlejhonAún no hay calificaciones

- FL 310 LG RTC enDocumento35 páginasFL 310 LG RTC enandis_aAún no hay calificaciones

- Manual Ak550Documento36 páginasManual Ak550Cristian PonceAún no hay calificaciones

- Brukermanual AK-CC450Documento36 páginasBrukermanual AK-CC450Øyvind SkulstadAún no hay calificaciones

- 100 Lab-1 SpectrophotometerDocumento16 páginas100 Lab-1 SpectrophotometerHamzah AlbrakaniAún no hay calificaciones

- THS00 Dual Temperature Humidity SensorDocumento3 páginasTHS00 Dual Temperature Humidity SensorDavid HernandezAún no hay calificaciones

- Process Control PPT 1901Documento39 páginasProcess Control PPT 1901Ashish DhimanAún no hay calificaciones

- Control and Instrumentation Summary 04-2021Documento4 páginasControl and Instrumentation Summary 04-2021kenAún no hay calificaciones

- Smart egg incubator controls temperature for various eggsDocumento9 páginasSmart egg incubator controls temperature for various eggsImran Jahan100% (1)

- Brukermanual AK-CC550ADocumento36 páginasBrukermanual AK-CC550AØyvind SkulstadAún no hay calificaciones

- Issa Bakari IssaDocumento11 páginasIssa Bakari IssaIssa BakariAún no hay calificaciones

- Development of A Temperature Control System: Hakan AYKULU 20083263 Department of Computer EngineeringDocumento23 páginasDevelopment of A Temperature Control System: Hakan AYKULU 20083263 Department of Computer EngineeringHakan AykuluAún no hay calificaciones

- CTO-20AC Data SheetDocumento3 páginasCTO-20AC Data SheetAli RizviAún no hay calificaciones

- 1815 12 PDFDocumento21 páginas1815 12 PDFUmar IftikharAún no hay calificaciones

- Fully Automated - EGG - Timer - ReportDocumento15 páginasFully Automated - EGG - Timer - ReportMalaika KhursheedAún no hay calificaciones

- TEC-25V-20A Controller ManualDocumento7 páginasTEC-25V-20A Controller Manualmitio mitioniAún no hay calificaciones

- Thermal Overload Protection 3Documento5 páginasThermal Overload Protection 3Anonymous DKv8vpAún no hay calificaciones

- Xy Wt01 Thermostat DigitalDocumento10 páginasXy Wt01 Thermostat Digitaltanee boonmalertAún no hay calificaciones

- Project ReportDocumento30 páginasProject ReportMadhuri MalhotraAún no hay calificaciones

- PTC ReissmannDocumento8 páginasPTC ReissmannAndré Carlos CorenzanAún no hay calificaciones

- Chapter 3 - Measurement Case StudiesDocumento15 páginasChapter 3 - Measurement Case StudiesfarizahAún no hay calificaciones

- ADCManualforPDs PDFDocumento20 páginasADCManualforPDs PDFahmadba70Aún no hay calificaciones

- Julabo Catalog 2012Documento182 páginasJulabo Catalog 2012sunildutttripathiAún no hay calificaciones

- Arcus-EDS Application Description SK08-T8: KNX Controller 8-Channel Temperature For PT1000Documento10 páginasArcus-EDS Application Description SK08-T8: KNX Controller 8-Channel Temperature For PT1000kardoszoltanAún no hay calificaciones

- Heartbeat and Temperatire Monitoring System NewDocumento27 páginasHeartbeat and Temperatire Monitoring System NewSonuVyasAún no hay calificaciones

- 1560369Documento8 páginas1560369KAMAL BEHLAún no hay calificaciones

- SP 24 ManualDocumento7 páginasSP 24 ManualOrlando Meza MachadoAún no hay calificaciones

- Overheat SensorDocumento2 páginasOverheat SensorPriyanshu SilAún no hay calificaciones

- Thermocouple Measurement DeviceDocumento3 páginasThermocouple Measurement DeviceylmalaverAún no hay calificaciones

- Design and Implementation of A Fully Automated Egg IncubatorDocumento7 páginasDesign and Implementation of A Fully Automated Egg IncubatorTasnim NabilahAún no hay calificaciones

- SP1 ManualDocumento13 páginasSP1 ManualAnonymous RCPxaonfvAún no hay calificaciones

- 2019.1.3 ST-E Earthing Switch Catalogue EN PDFDocumento10 páginas2019.1.3 ST-E Earthing Switch Catalogue EN PDFJosimar Llerena PintoAún no hay calificaciones

- SFRA Cables Quick ReferenceDocumento4 páginasSFRA Cables Quick ReferenceMiguel ZuñigaAún no hay calificaciones

- Electrical Testing SkillsDocumento2 páginasElectrical Testing Skills322399mk7086Aún no hay calificaciones

- SEL751 Protection Relay CommandsDocumento3 páginasSEL751 Protection Relay Commands322399mk7086Aún no hay calificaciones

- Softstarters Type PSTX30... PSTX1250: Installation and Commissioning ManualDocumento162 páginasSoftstarters Type PSTX30... PSTX1250: Installation and Commissioning Manual322399mk7086Aún no hay calificaciones

- WEG Soft Starter Manual Usass11 Brochure English PDFDocumento232 páginasWEG Soft Starter Manual Usass11 Brochure English PDFsharan87Aún no hay calificaciones

- Commissioning PSTX ManualDocumento162 páginasCommissioning PSTX Manual322399mk7086Aún no hay calificaciones

- Organisational Behaviour: Managing Change As A LeaderDocumento3 páginasOrganisational Behaviour: Managing Change As A Leader322399mk7086Aún no hay calificaciones

- WEG Soft Starter Manual Usass11 Brochure English PDFDocumento232 páginasWEG Soft Starter Manual Usass11 Brochure English PDFsharan87Aún no hay calificaciones

- PSTX ManualDocumento162 páginasPSTX Manual322399mk7086Aún no hay calificaciones

- The Functions and Features of HAT Series Air Circuit BreakersDocumento67 páginasThe Functions and Features of HAT Series Air Circuit Breakers322399mk7086Aún no hay calificaciones

- REF615 RelaysDocumento24 páginasREF615 Relays322399mk7086100% (1)

- 311l Testing ProcedureDocumento21 páginas311l Testing ProcedureJoaquim AlvesAún no hay calificaciones

- EE462L, Spring 2014 DC DC Buck ConverterDocumento37 páginasEE462L, Spring 2014 DC DC Buck ConverterprateekAún no hay calificaciones

- Power CircuitDocumento2 páginasPower Circuit322399mk7086Aún no hay calificaciones

- Lov Voltage Air Circuit BreakersDocumento29 páginasLov Voltage Air Circuit Breakers322399mk7086Aún no hay calificaciones

- The Functions and Features of HAT Series Air Circuit BreakersDocumento67 páginasThe Functions and Features of HAT Series Air Circuit Breakers322399mk7086Aún no hay calificaciones

- DIGITRIP ACBs PDFDocumento72 páginasDIGITRIP ACBs PDF322399mk7086Aún no hay calificaciones

- 3a Power Factor TheoryDocumento74 páginas3a Power Factor Theory322399mk7086Aún no hay calificaciones

- Understanding ESP ControlsDocumento74 páginasUnderstanding ESP ControlsHida CahyaniAún no hay calificaciones

- Arduino Controlled ATX Power SupplyDocumento7 páginasArduino Controlled ATX Power Supplyolaolaolaola123Aún no hay calificaciones

- EPEVER Datasheet Tracer An 50 100ADocumento3 páginasEPEVER Datasheet Tracer An 50 100AAmien Haja0% (1)

- RF and Microwave Engineering SyllabusDocumento2 páginasRF and Microwave Engineering SyllabusEng AbdiRahim Khalif AliAún no hay calificaciones

- Schematic Block Diagram1Documento60 páginasSchematic Block Diagram1Freddy ZumbaAún no hay calificaciones

- 2N3903-2N3904 MotorolaDocumento8 páginas2N3903-2N3904 MotorolaLaAngelitaOropezaAún no hay calificaciones

- Lab 1 Spring 13Documento3 páginasLab 1 Spring 13Kumaraguru RauAún no hay calificaciones

- LMR-111D Data Sheet 4921240214 UKDocumento4 páginasLMR-111D Data Sheet 4921240214 UKCristian Camilo Arias RodriguezAún no hay calificaciones

- BJ 194E 9S4 Manual Version1.1Documento27 páginasBJ 194E 9S4 Manual Version1.1osadeamos8684Aún no hay calificaciones

- Interfacing Processor To NAND Flash MemoriesDocumento11 páginasInterfacing Processor To NAND Flash Memoriesapi-3802214Aún no hay calificaciones

- Product Support Guide Ricoh Monocromatica Serie4Documento46 páginasProduct Support Guide Ricoh Monocromatica Serie4DavidEspi1990Aún no hay calificaciones

- Catálogo Do Multi LoadDocumento4 páginasCatálogo Do Multi LoadDouglas PlacedinoAún no hay calificaciones

- 12 Physics Exemplar Chapter 14Documento11 páginas12 Physics Exemplar Chapter 14Haarish KrishnamurthyAún no hay calificaciones

- Powered, Tri-Amplified Compact Line Array Module: SeriesDocumento2 páginasPowered, Tri-Amplified Compact Line Array Module: SeriesIrvanda ENVIOUSAún no hay calificaciones

- Sony Kdl-40ex645 40ex641 46ex645 50ex645 55ex645 Chassis Az3fkDocumento50 páginasSony Kdl-40ex645 40ex641 46ex645 50ex645 55ex645 Chassis Az3fkcristhianAún no hay calificaciones

- Remotek Pico ICS Repeater Introduction and Case StudyDocumento21 páginasRemotek Pico ICS Repeater Introduction and Case StudyKobby OwusuAún no hay calificaciones

- Chapter 11Documento51 páginasChapter 11vmspraneethAún no hay calificaciones

- Arctic Tern Module Schematic v1.01Documento27 páginasArctic Tern Module Schematic v1.01Foo BarAún no hay calificaciones

- Introduction to 8086/8088 Microprocessor ArchitectureDocumento39 páginasIntroduction to 8086/8088 Microprocessor ArchitectureSahilYadavAún no hay calificaciones

- Nl3224ac35 01Documento28 páginasNl3224ac35 01MantasPuskoriusAún no hay calificaciones

- Circuito PCB Control Pedal V3Documento1 páginaCircuito PCB Control Pedal V3Marcelo PereiraAún no hay calificaciones

- MIT6Documento10 páginasMIT6Ruru MartinAún no hay calificaciones

- JBL T110BT Spec Sheet English (Global)Documento2 páginasJBL T110BT Spec Sheet English (Global)Tv SerialsAún no hay calificaciones

- Specialist Switch Requirement BoQDocumento6 páginasSpecialist Switch Requirement BoQLohit YadavAún no hay calificaciones